Tobacco shred, tablet cigarette non- inertia on-line real time tare removing quantificationally packing system

A non-inertial, sheet cigarette technology, applied in the field of quantitative boxing system, can solve the problems of large inertial error, low measurement accuracy, and poor accuracy of the measurement system, and achieve the effect of small maintenance, high measurement accuracy and improved boxing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

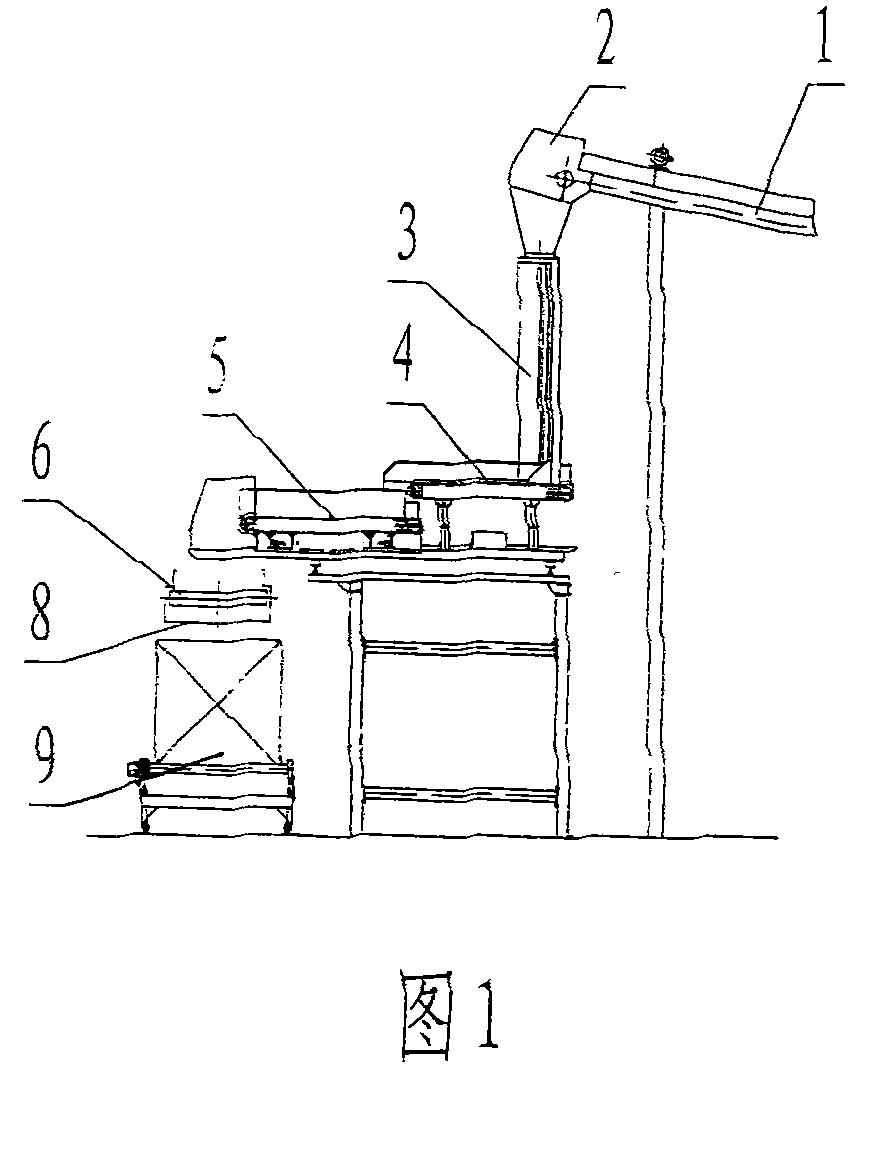

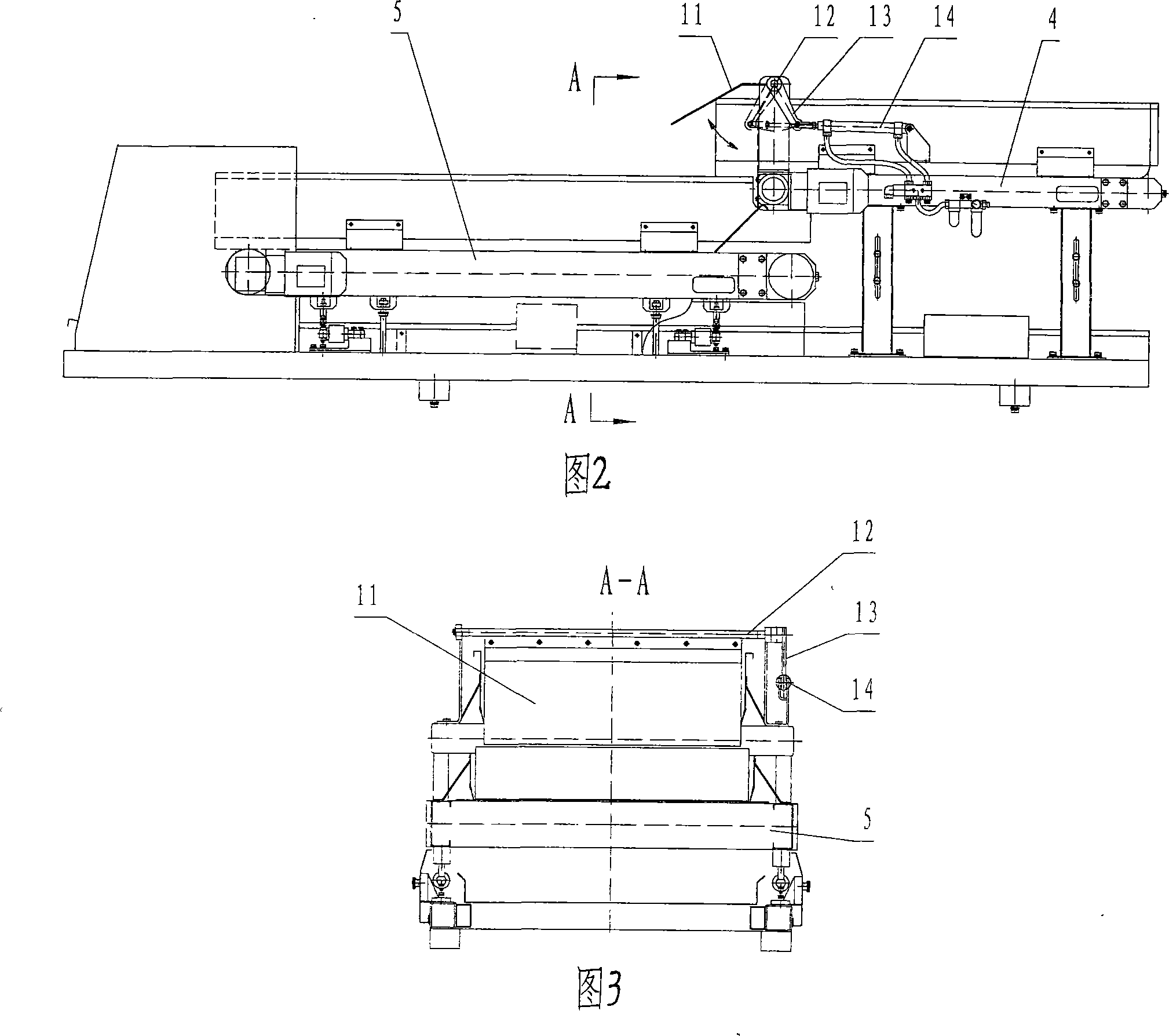

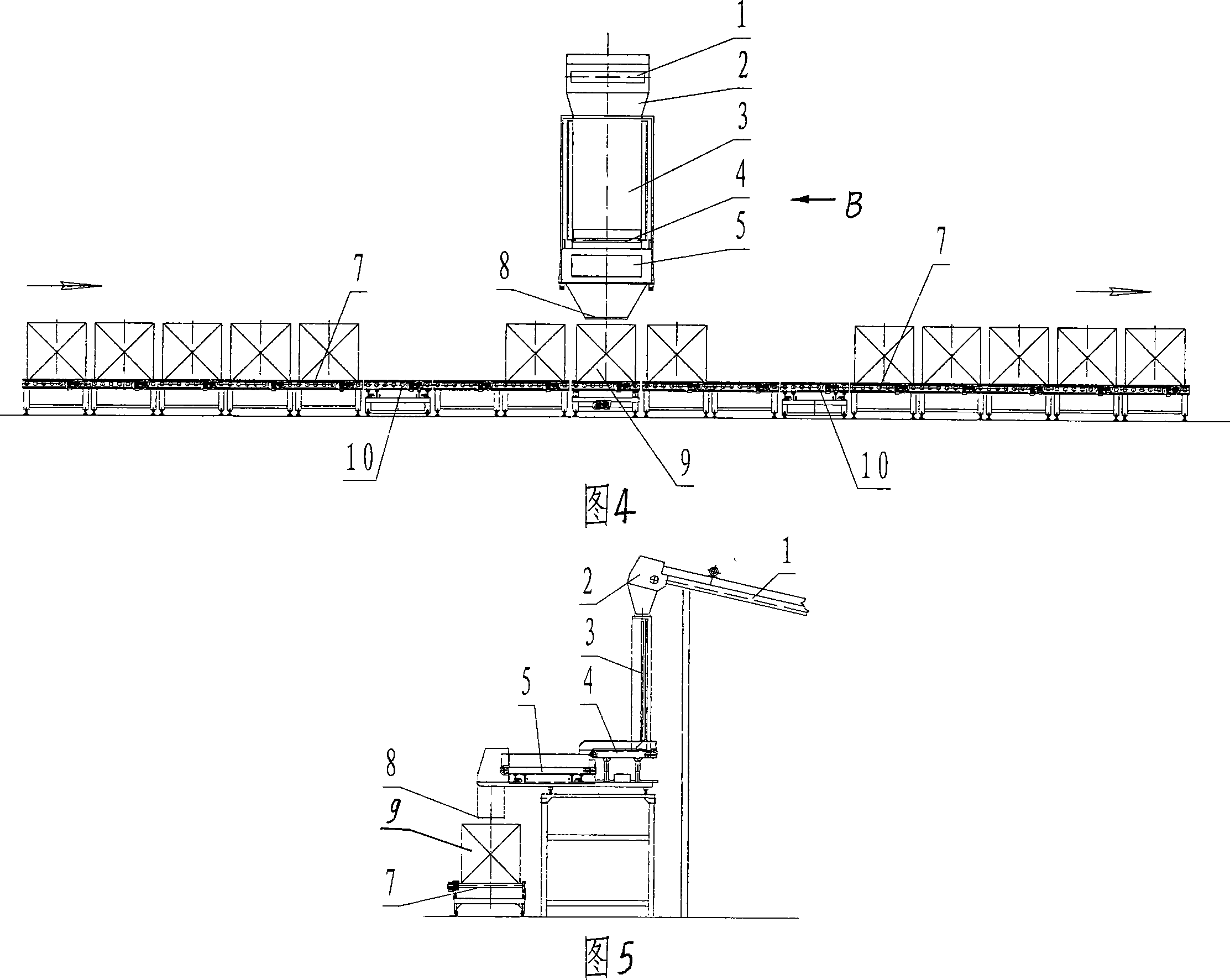

[0058] The present invention will be further described below in conjunction with the accompanying drawings, but the content of the present invention is not limited thereto.

[0059] The non-inertial on-line quantitative weighing device for shredded tobacco and sheet tobacco provided by the present invention includes a material storage pipe 3, a buffer conveyor 4 and a full-suspension electronic belt scale 5, wherein the material storage pipe 3 is a vertical pipe, and its upper end is a material inlet end , the lower end is the material outlet end, so as to send the material from above to the subsequent buffer conveyor or store it in the vertical pipe; the buffer conveyor 4 is located below the storage pipe 3, and its material input end is connected to the lower end of the storage pipe 3 The material outlet ends are connected, and the material output end is located above the input end of the belt scale 5. Through the operation and stop of the buffer conveyor, the accurate measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com