Method for oil-alkali separation of oil-containing alkali liquor

A liquid-liquid separator, lye technology, applied in separation methods, liquid separation, refining with alkaline aqueous solution, etc., to achieve the effects of low energy consumption, reduced emissions, and high separation effect

Inactive Publication Date: 2008-04-16

NINGBO ZHONGYI PETROCHEM TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The technical problem to be solved by the present invention is to provide a high-efficiency, low-energy-consumption, compact-structur

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

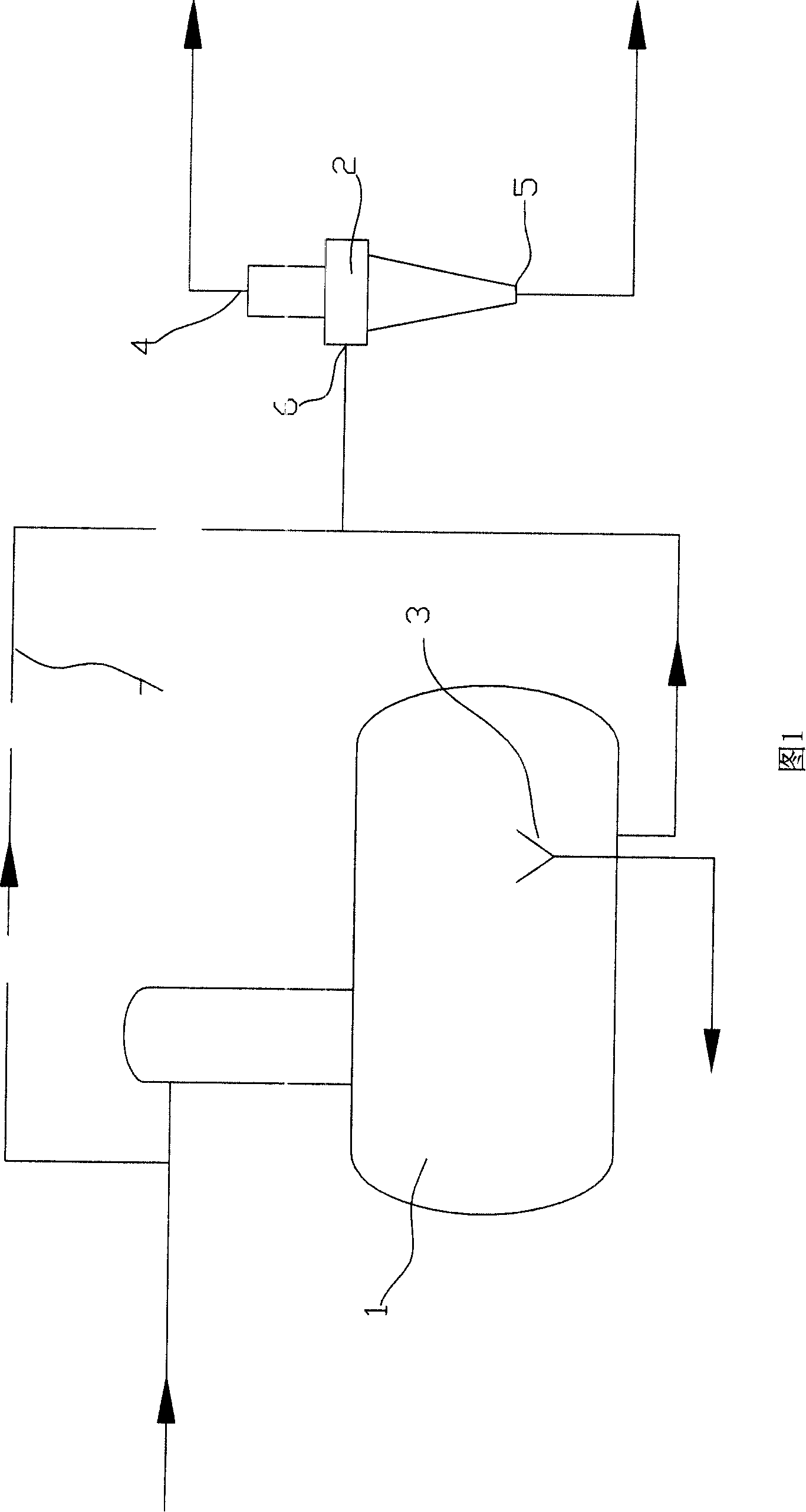

A method for oil-alkali separation of oily lye is characterized in that the method includes the following steps in turn: oily lye undergoes primary separation through a standing precipitation device and then is fed into a cyclonic-type liquid-liquid separator for oil-alkali separation; the separated oil phase is fed into a special storing tank or other appropriate treatment device, thereby realizing recycling utilization of the lye. The method which has the advantages of high efficiency, low energy consumption, compact structure, convenience for operation and low consumption is suitable for oil-alkali separation of oily lye.

Description

technical field [0001] The invention relates to a method for oil-alkali separation, in particular to an oil-alkali separation method for reuse of disulfide-containing alkali liquor produced by the oxidation of petroleum liquefied gas demercaptan alkali liquor during petroleum processing. Background technique [0002] After desulfurization of petroleum liquefied gas, the mercaptide in the lye reacts with oxygen and water to form disulfide under the action of the catalyst. The lye may still contain 500 to 30000PPM (weight ratio) of disulfides, thereby affecting the effect of circulating lye for demercaptanization of liquefied petroleum gas. At present, the commonly used measures are to discharge lye regularly or irregularly and replenish fresh lye to reduce the concentration of disulfides in the circulating lye and maintain the sweetening effect. The discharge of lye directly leads to the waste of lye and catalyst, the increase of the load of the alkali slag treatment device,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10G19/08C10G19/02B01D17/038

Inventor 聂通元徐铸德

Owner NINGBO ZHONGYI PETROCHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com