Automobile tyre valve

A technology for automobile tires and valve bodies, applied in safety valves, balance valves, valve devices, etc., which can solve the problems of tire pressure measurement deviation, inability to use single bridge pressure measurement, and inability to use automobile tire valves, etc., to achieve low manufacturing costs , good pressure-holding effect, and simple structure of the valve body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

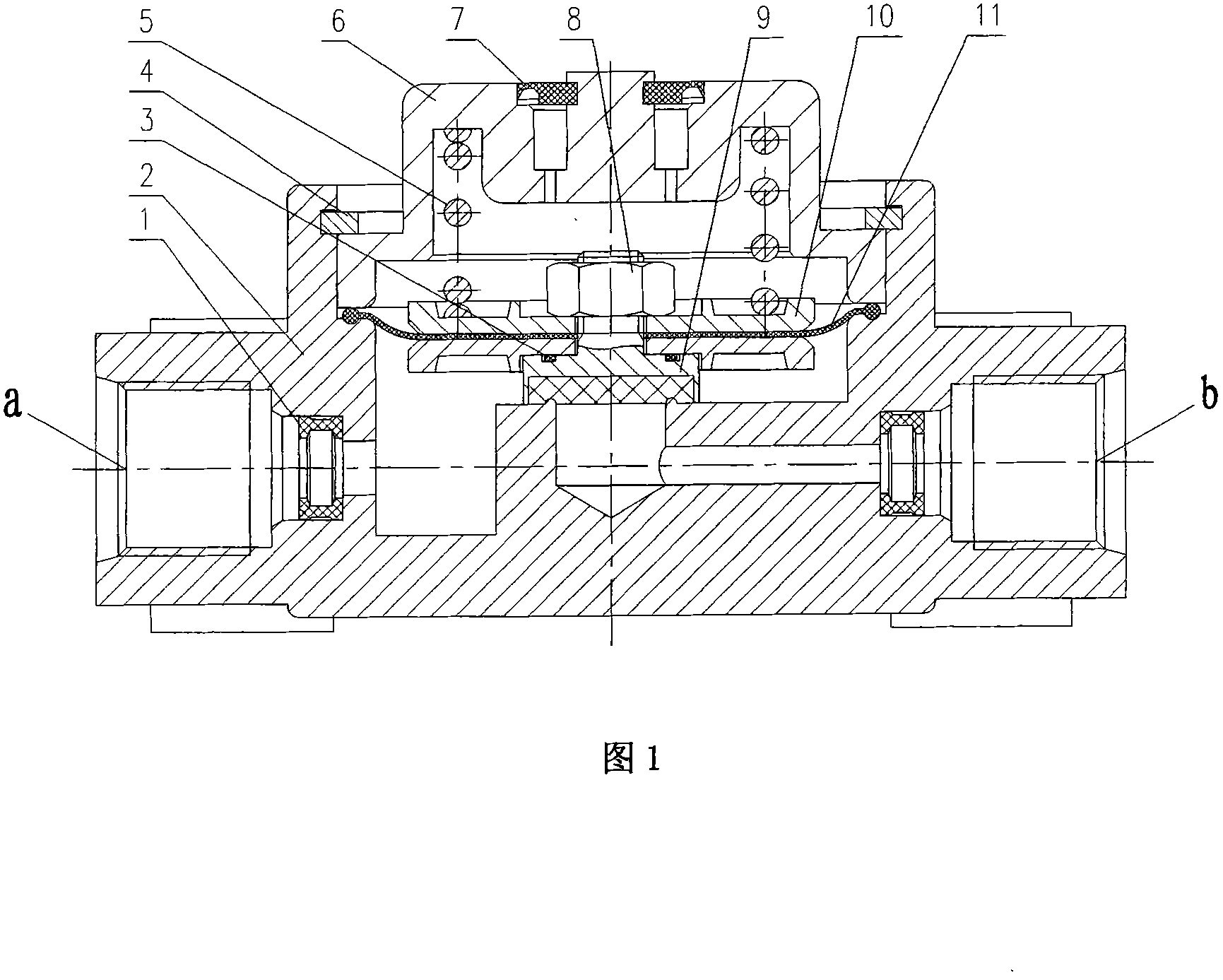

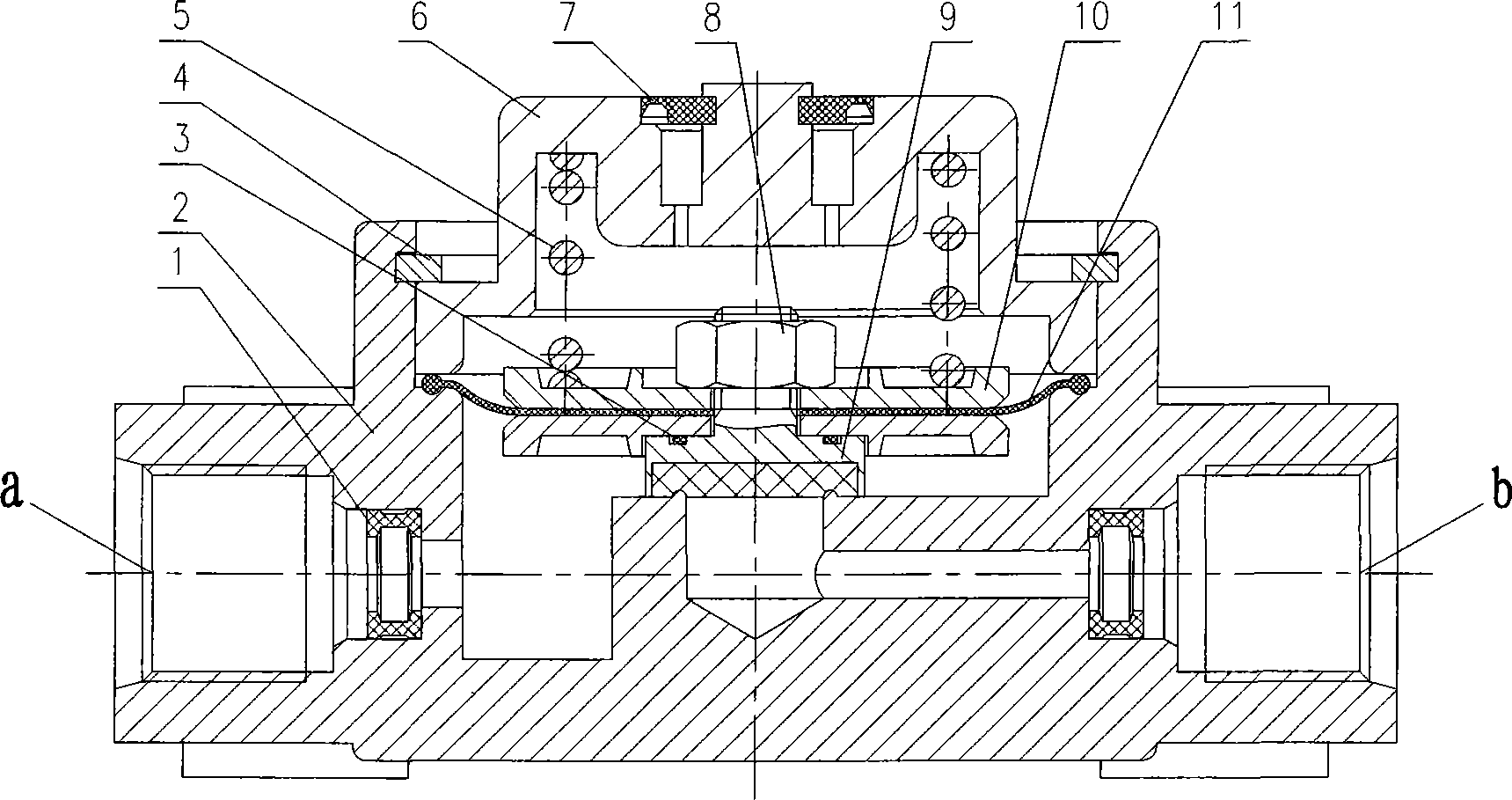

[0026] Further illustrate below in conjunction with accompanying drawing and embodiment:

[0027] aforementioned, such as figure 1 The automobile tire valve includes an I-shaped sealing ring 1, a valve body 2, an O-shaped sealing ring 3, an elastic inner card 4, a spring 5, a valve cover 6, a dust cap 7, a nut 8, a valve core 9, a diaphragm disc 10, Diaphragm 11;

[0028] The connection relationship is: from top to bottom, the dust cap 7 is installed on the top of the valve cover 6, the valve cover 6 and the valve body 2 are connected together by the elastic inner clip 4, and a diaphragm is sandwiched between the valve cover 6 and the valve body 2 11. Diaphragm 11 divides the entire valve body into upper and lower air chambers. The valve core 9 and nut 8 are screwed to fix the two diaphragm discs 10 on the upper and lower sides of the diaphragm 11. The spring 5 is located between the valve cover 6 and the diaphragm. The valve core 9 is pressed against the hole end of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com