Method for controlling a powder sprayer

A duster and printing machine technology, applied in the field of duster, can solve the problems of printing quality reduction, achieve high printing quality and avoid adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

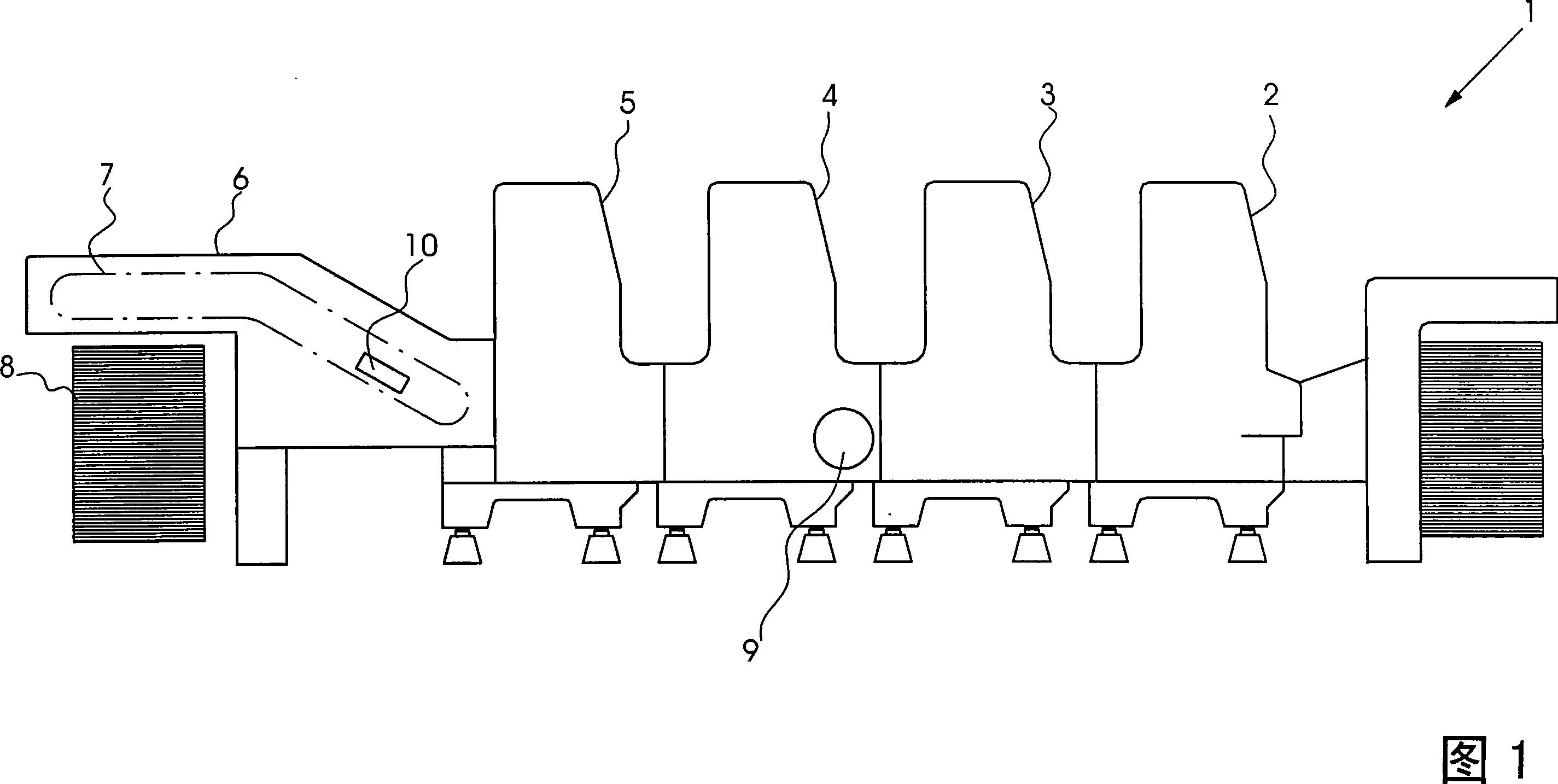

[0020] FIG. 1 shows a printing press 1 with printing units 2 to 5 and a delivery 6 . The delivery includes a chain conveyor 7 which deposits the printed sheets onto a delivery pile 8 . Furthermore, the printing press includes an inverting unit 9, which can be switched from a pure front printing mode to a perfect printing mode. In the pure front printing mode without turning over the sheets, the printed pages are printed not only in the printing units 2 and 3 arranged in front of the turning unit 9 but also in the printing units 4 and 5 arranged behind the turning unit 9 sheet for front printing. In perfecting mode, the front side of the printed sheet is printed in the upstream printing units 2 and 3 and the reverse side is printed in the downstream printing units 4 and 5 . A duster 10 is arranged in the delivery 6 , which dusts the printed sheets conveyed by the chain conveyor 7 .

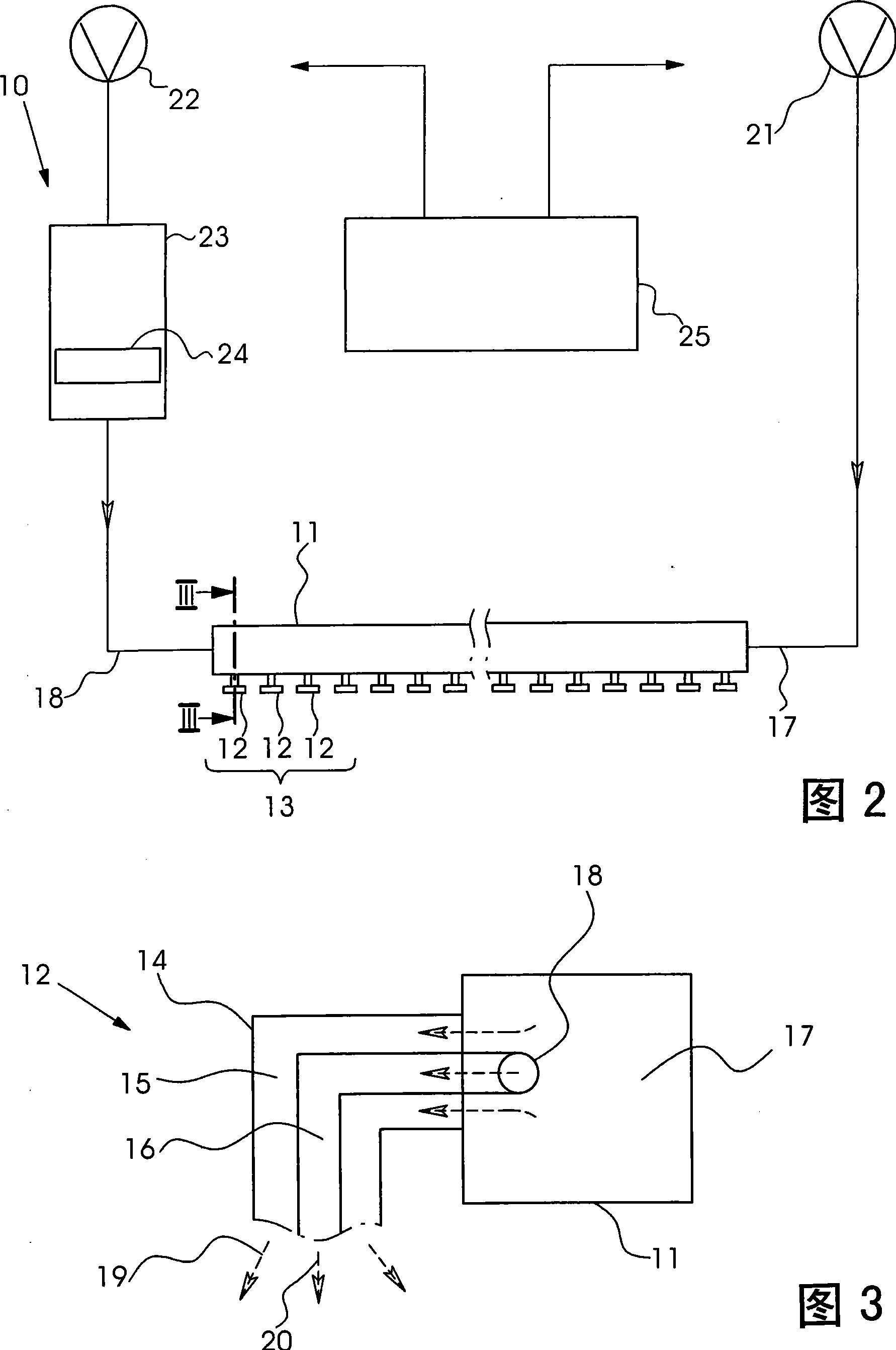

[0021] FIG. 2 shows that the duster comprises a nozzle beam 11 with shroud nozzles 12 arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com