Ultrahigh-intensity high-toughness X120 pipe line steel and manufacturing method thereof

An X120, ultra-high-strength technology, used in temperature control, manufacturing tools, heat treatment process control, etc., can solve problems such as insufficient strength, reduce rolling mill load, improve overall performance, and reduce manufacturing costs.

Active Publication Date: 2010-09-08

BAOSHAN IRON & STEEL CO LTD

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, its strength does not meet the requirements of X120

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Login to View More

Abstract

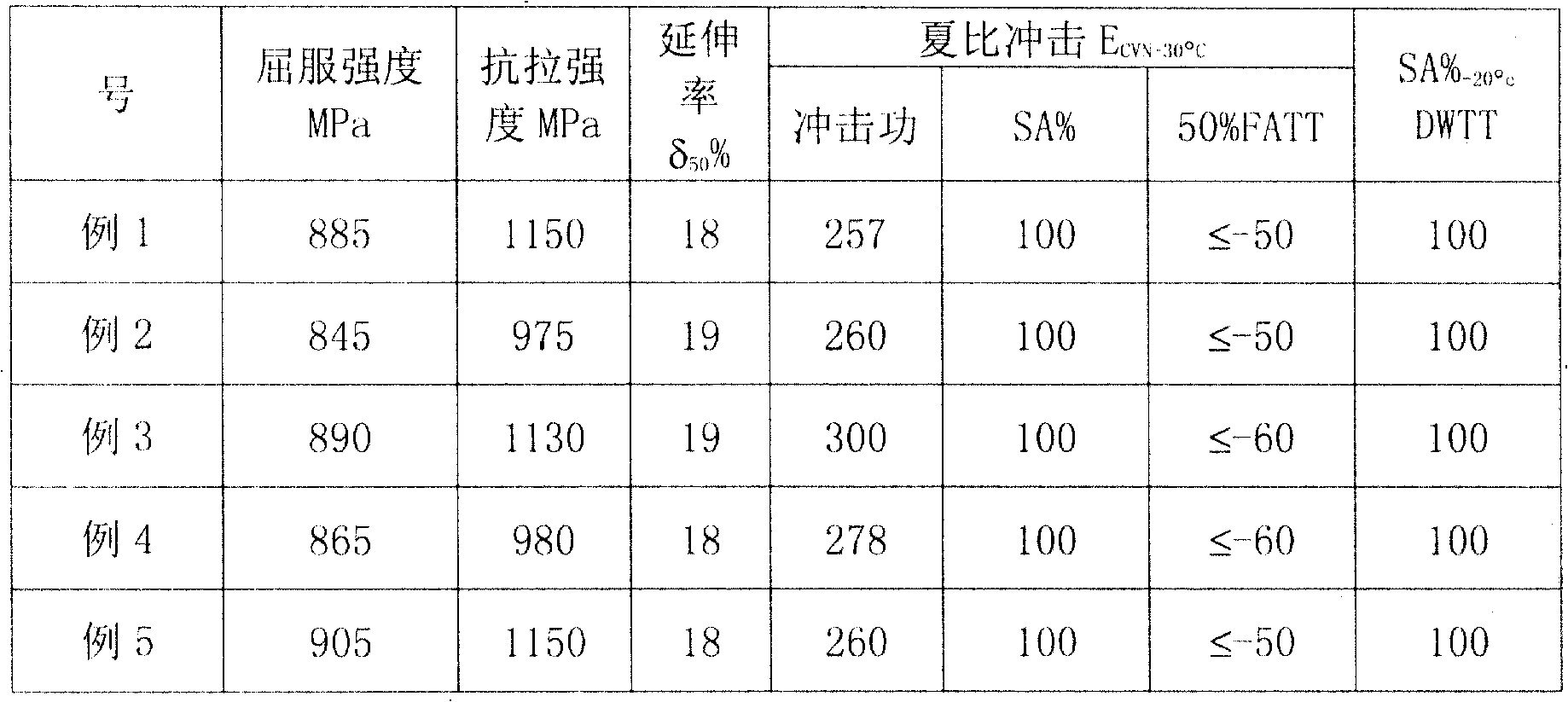

The present invention relates to one kind of high strength and high toughness X120 pipeline steel and its making process. The high strength and high toughness X120 pipeline steel consists of C 0.015-0.060 wt%, Mn 1.80-2.50 wt%, Si not more than 0.60 wt%, Ti 0.005-0.03 wt%, Al not more than 0.06 wt%, V not more than 0.15 wt%, B 0.0005-0.0030 wt%, P not more than 0.015 wt%, S not more than 0.003 wt%, Nb 0.043-0.150 wt%, N not more than 0.012 wt%, Cu not more than 0.80 wt%, Ni not more than 1.20 wt%, Cr not more than 1.20 wt%, Mo not more than 1.0 wt%, and Fe and impurity for the rest. Compared with available X80 pipeline steel, the high strength and high toughness X120 pipeline steel has 40 % higher strength and capacity of lowering pipeline constructing cost.

Description

technical field The invention relates to a pipeline steel and a manufacturing method thereof, in particular to an ultra-high-strength, high-toughness X120 pipeline steel and a manufacturing method thereof. Background technique In recent years, the changes in the energy structure and the increase in energy demand have greatly promoted the development of long-distance transmission pipelines. In order to improve transmission efficiency and reduce project investment, it has become a trend to develop steel for long-distance oil and gas transmission pipelines to high-grade steel. At present, the highest steel grade in the pipeline steel standards used by countries in the world is only X80 (yield strength greater than or equal to 555MPa). For example, CN1715434A discloses a high-strength and high-toughness X80 pipeline steel, the weight percent of its composition is: carbon 0.025-0.080%; silicon: 0.19-0.30%; manganese: 1.70-1.90%; titanium: 0.01-0.02%; : 0.015~0.040%; Vanadium: 0...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/58C21D8/00C21D8/10C21D11/00B21B37/74

Inventor 高珊郑磊吴海凤

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com