Integrated circuit tester

A technology for detection devices and integrated circuits, which is applied in the field of detection devices and detection devices for integrated circuits, can solve problems such as inability to fine-tune, low scanning resolution, and limited range of one-time detection, so as to achieve good implementation effects and improve scanning resolution. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

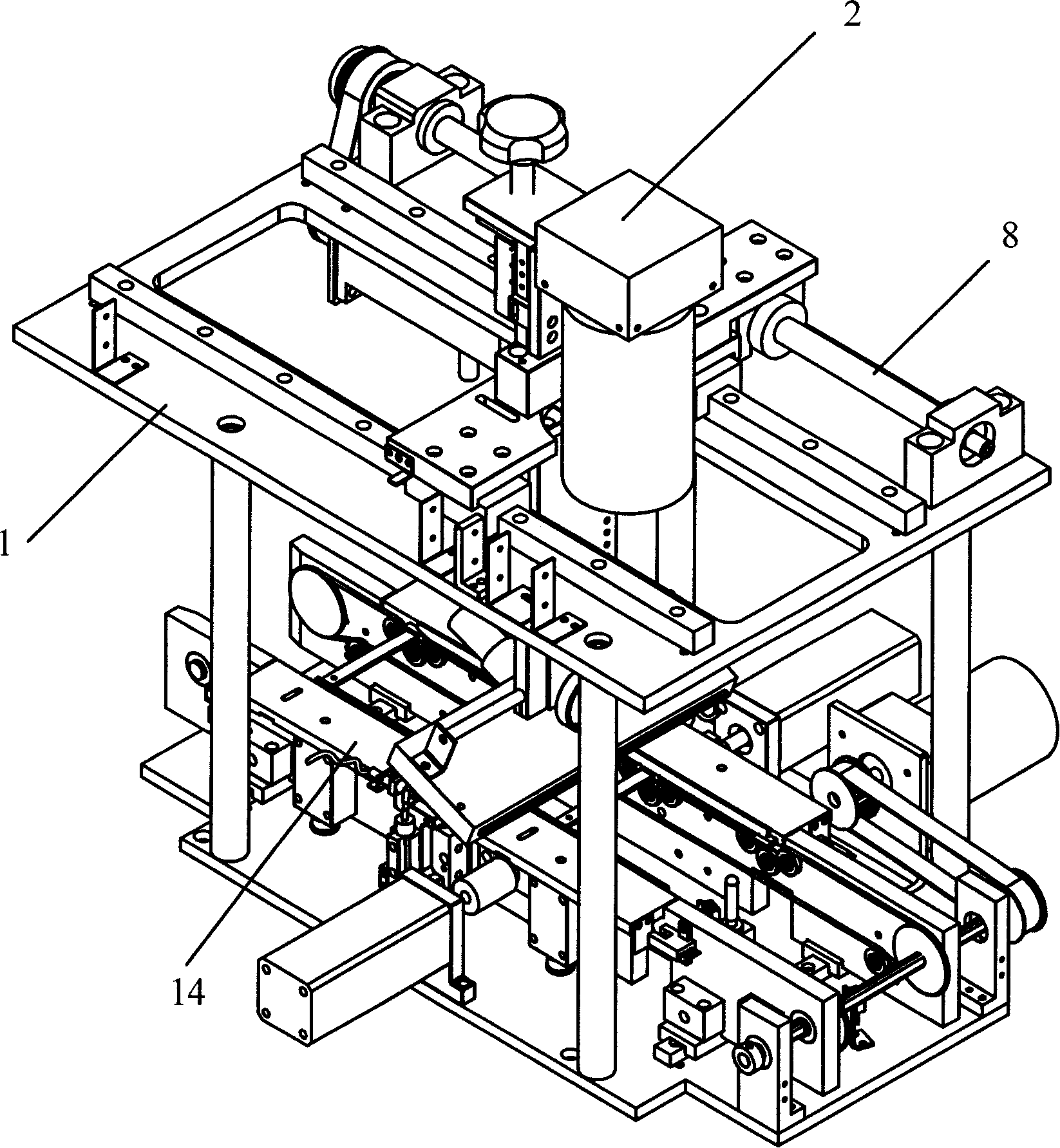

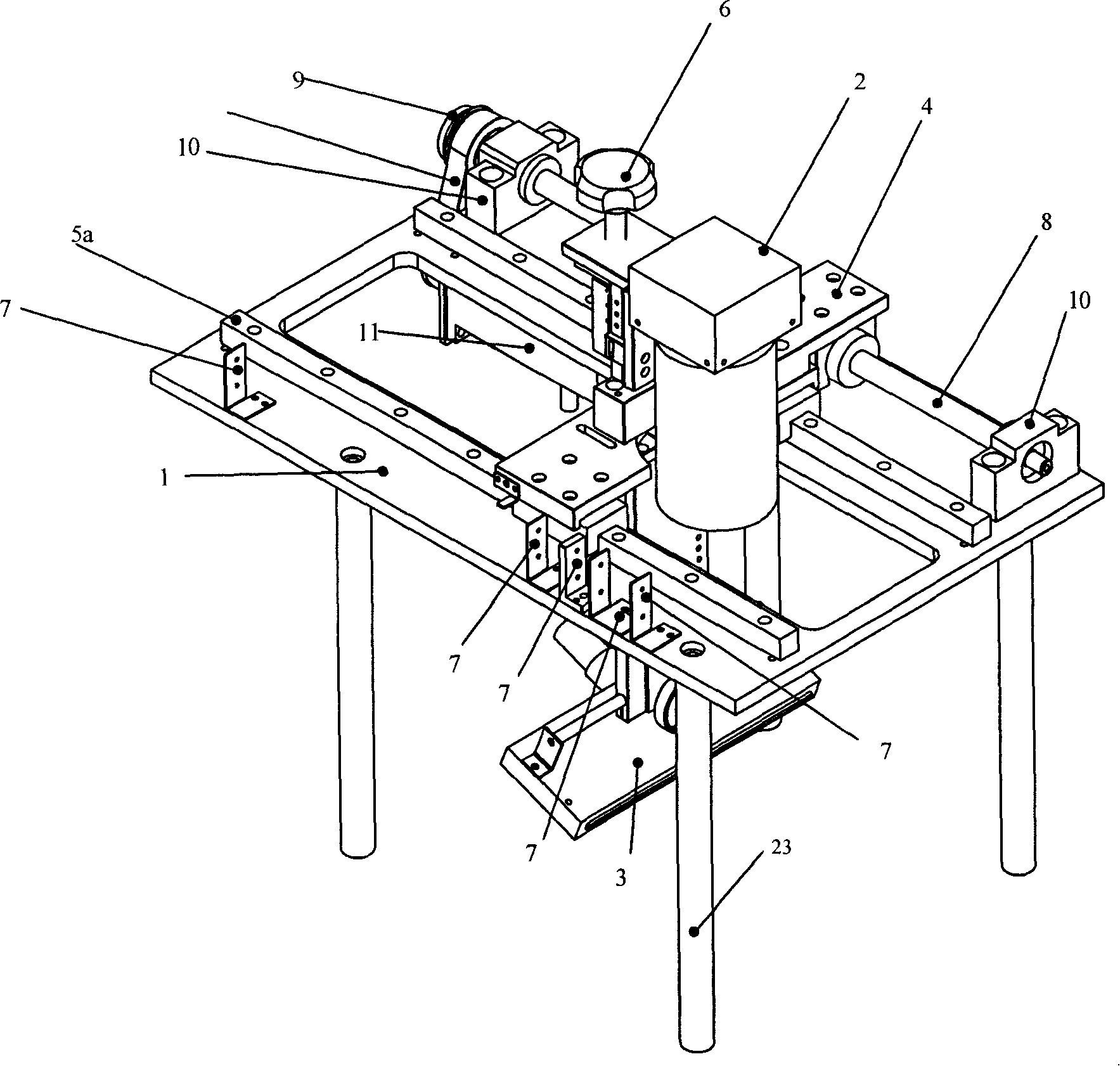

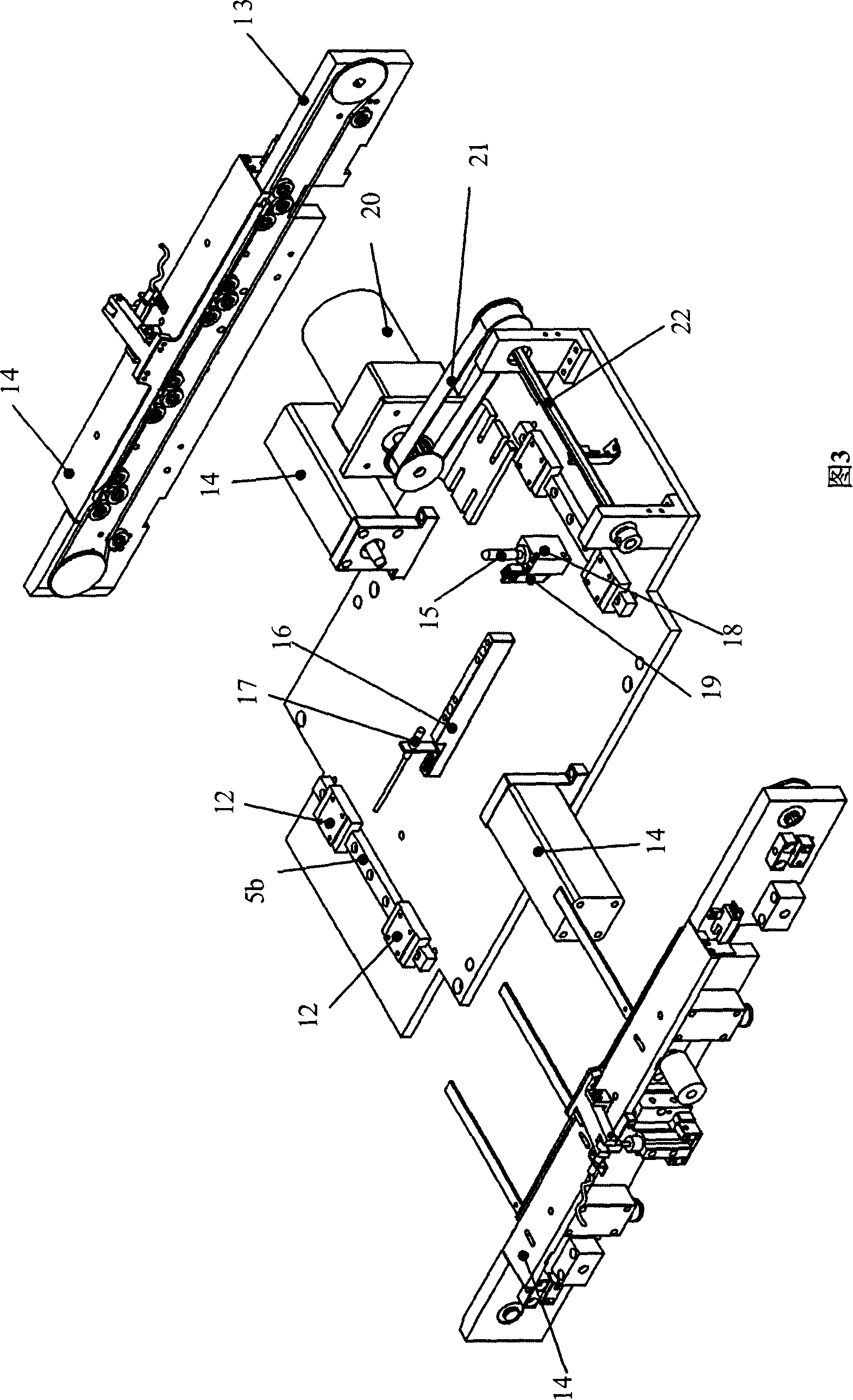

[0023] Such as Figure 1~3 The integrated circuit detection device shown includes a substrate, and is characterized in that: a sliding platform 1 and a positioning device are provided on the substrate, and a visual detection device is installed on the sliding platform 1 by connecting parts, and the positioning device includes a clamping mechanism 14, and its center width Adjustable, and can realize lifting at the same time, the visual inspection device, the sliding platform 1, and the positioning device are each driven by a driving source, so the movable detection head 2 in the visual inspection device is driven by the respective sources to move, and the clamping mechanism 14 realize opening and closing, lifting. The connecting piece is a pillar 23, which is connected with the visual inspection device through the hole of the sliding platform 1 on the base plate.

[0024] The visual detection device includes a movable detection head 2 and an ion blower 3. There is a support bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com