Light source comprising led arranged in recess

A technology of light source and recess, applied in the field of light source, to achieve the effect of improving efficiency, reducing heat path and reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

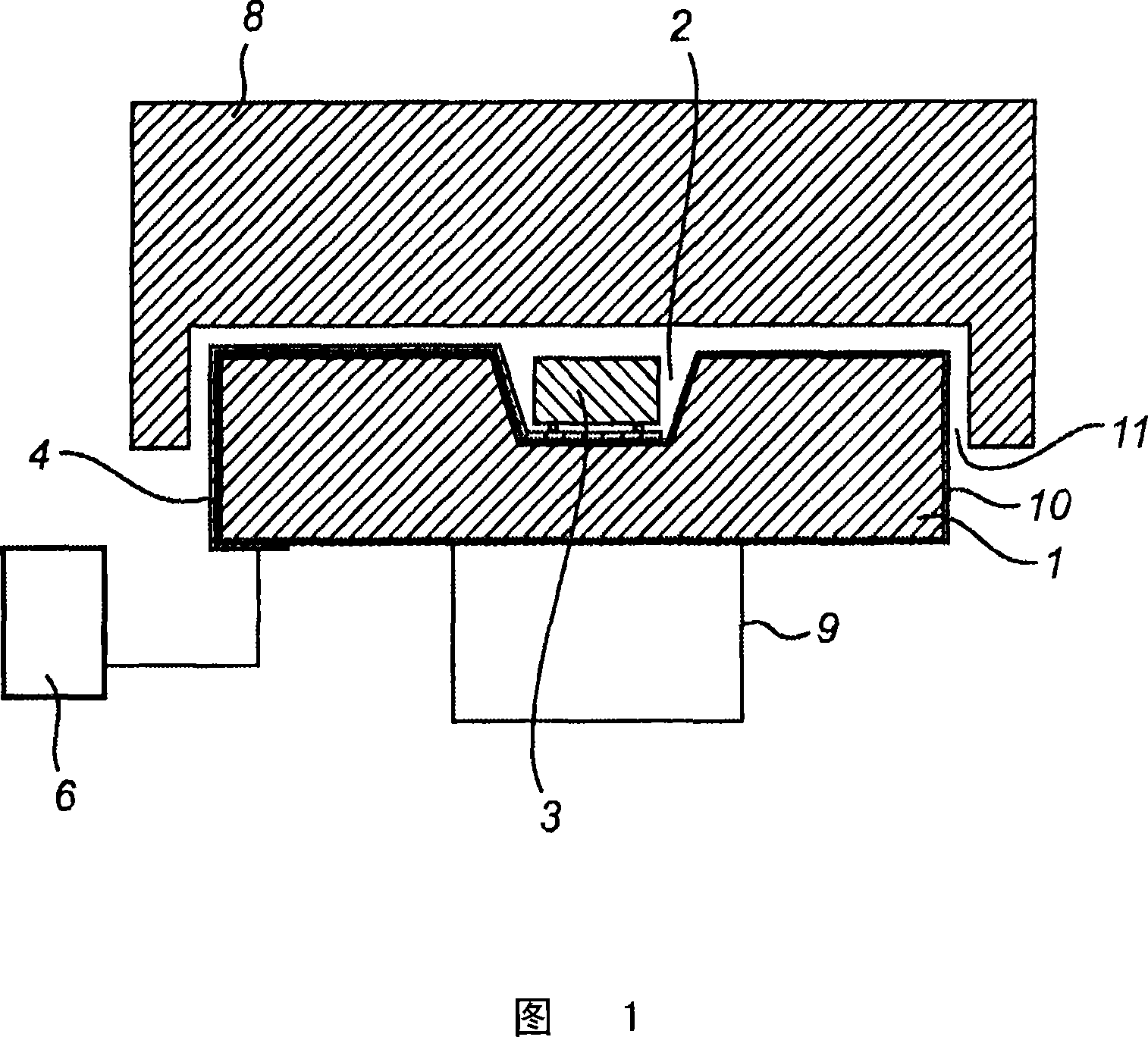

[0045] A schematic embodiment of a light source according to the invention is shown in FIG. 1 .

[0046] A silicon substrate 1 is provided, with SiO 2 The electrically insulating surface layer 10 of the substrate is provided with a recess 2 on the front side of the substrate. Light emitting diodes (LEDs) 3 are arranged in the recess 2 . The recess 2 is conical with an opening area larger than the bottom area.

[0047] The LED 3 is connected to the circuit 4 , arranged on the substrate 1 and located in the recess 2 . The connection between LED3 and circuit 4 is provided by solder bumps on the underside of the LED.

[0048]The circuit 4 passes through one side edge of the substrate and is connected to the LED driver unit 6 by contacts on the back side of the substrate 1 .

[0049] A light collimator 8 is provided so as to collimate the light emitted by the LED 3, and the light collimator includes a recess in which the substrate 1 is provided such that the collimator 8 partia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com