Brushless motor

一种无刷电动机、电动机的技术,应用在电动组件、电气元件、机电装置等方向,能够解决难以确保连结强度、无法实行等问题,达到部件便宜、防止飞溅、改善便易性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

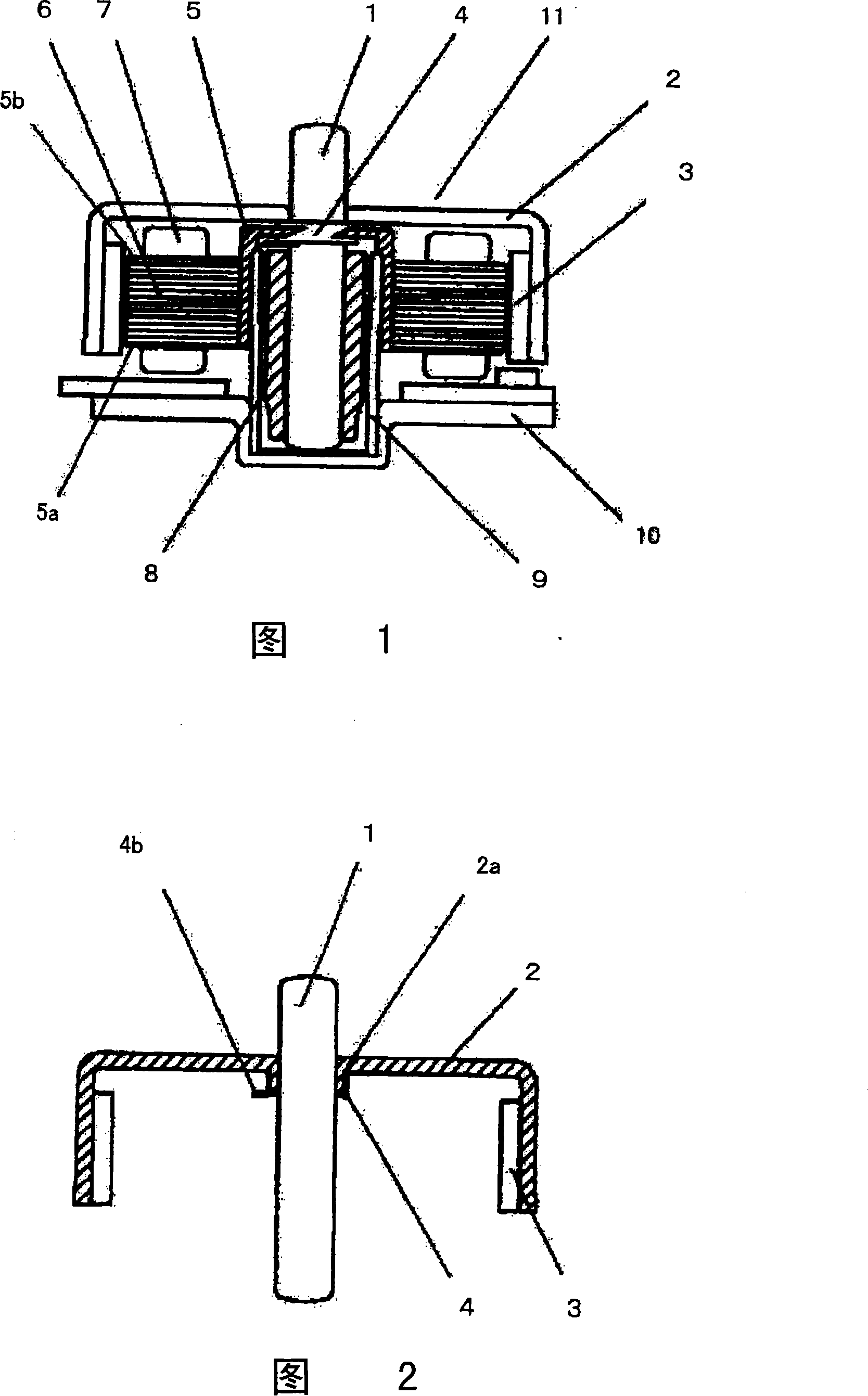

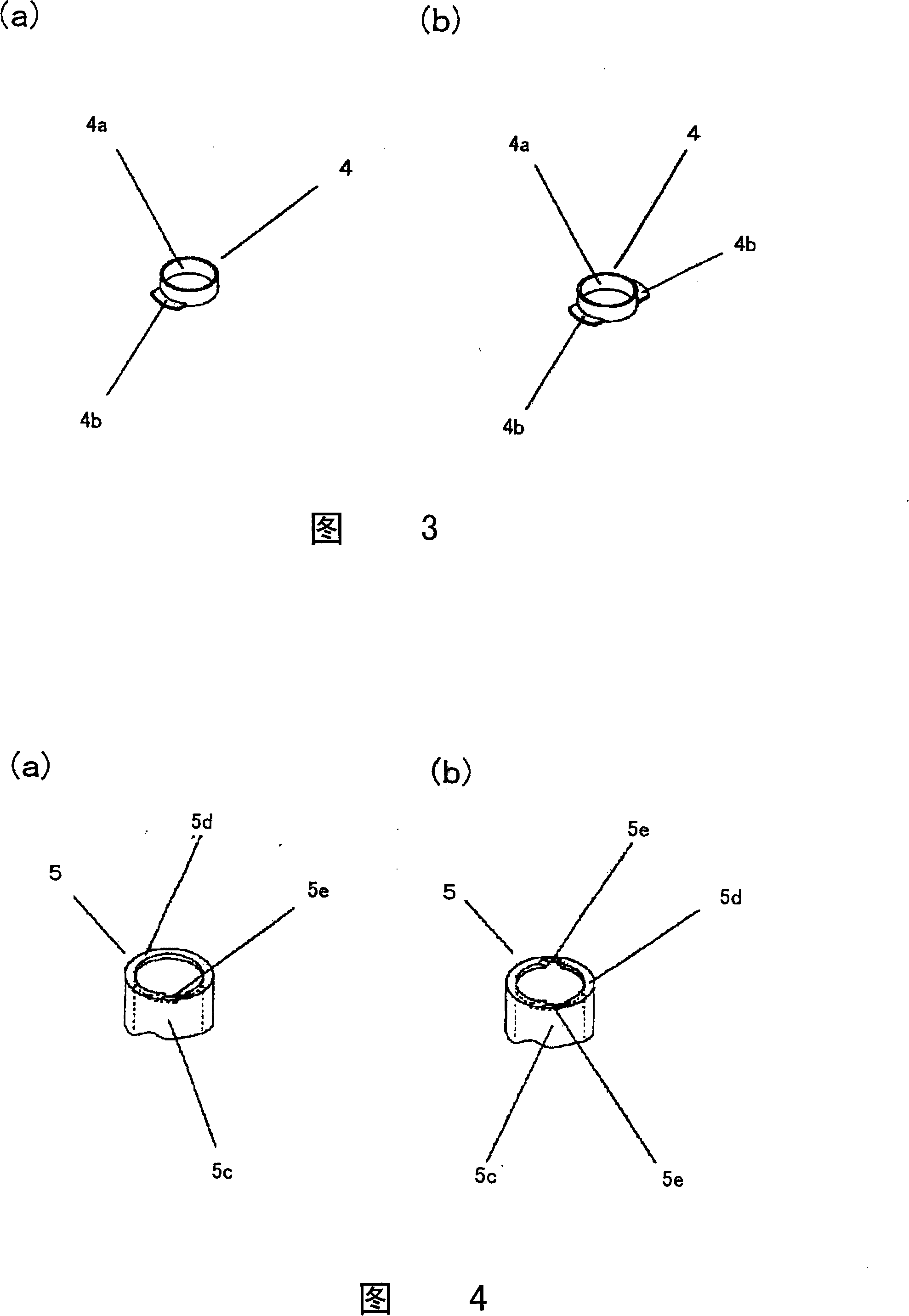

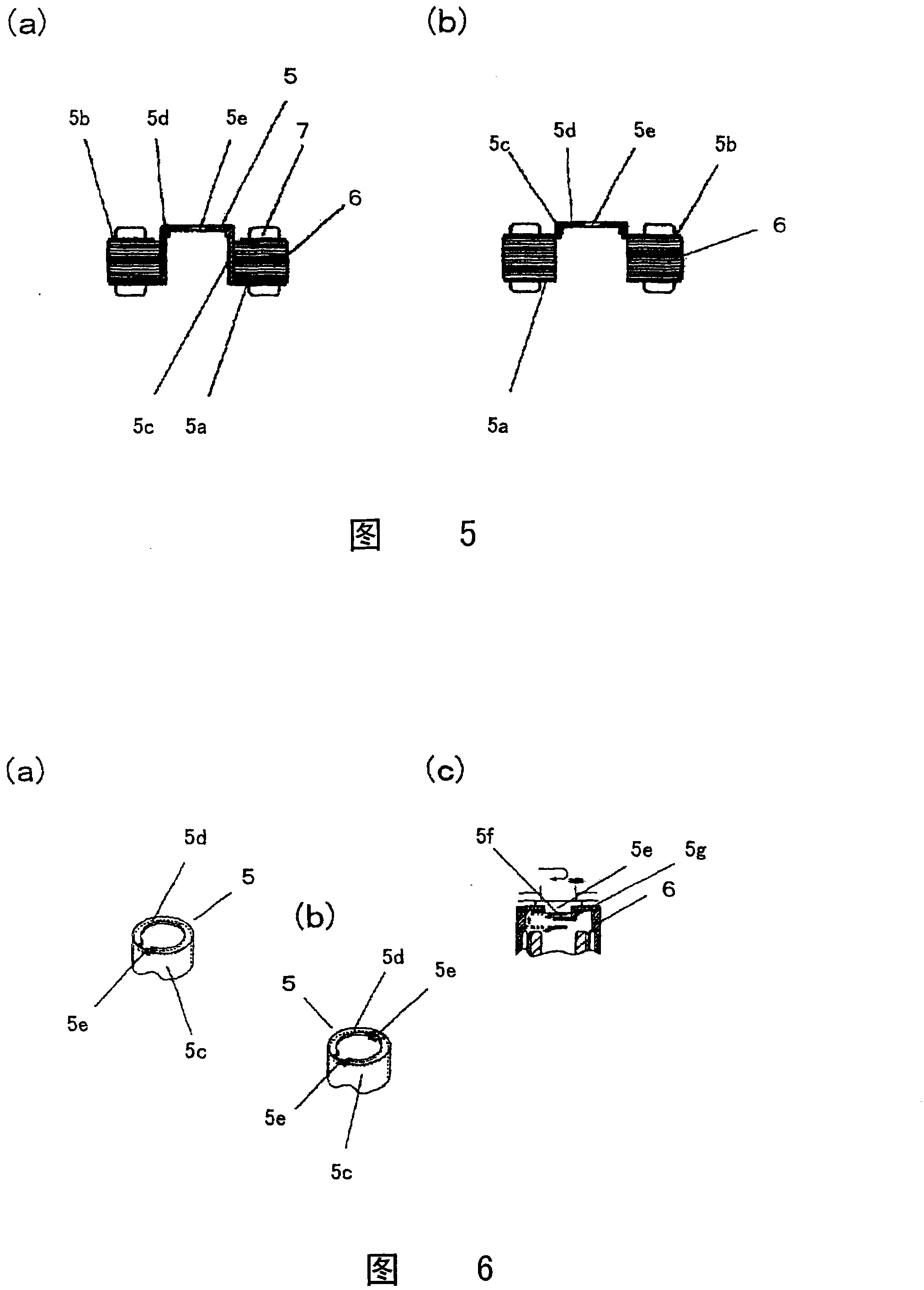

[0041] Such as figure 1 As shown, the brushless motor 11 is composed of the following rotor assembly and stator assembly. The rotor assembly consists of a rotor frame 2 with a shaft 1 fixed in the center, a rotor magnet 3 mounted on the inner peripheral side of the rotor frame 2, The engaging member 4 mounted on the fixed portion of the shaft 1 on the top surface of the rotor frame 2 is constituted; the stator assembly is composed of a bearing 8 that rotatably supports the shaft 1, and holds the bearing 8 on its inner periphery. The cylindrical bearing housing 9 on the side, the motor mounting plate 10 that fixes and holds the bearing housing 9 in the center by press-fitting, etc., the stator core 6 installed on the outer peripheral side of the bearing housing 9, and the gasket is assembled on the The insulating members 5 a and 5 b on the surface of the stator core 6 are formed by a coil 7 wound with wires and a fall-off preventing member 5 mounted on the stator core 6 .

[...

Embodiment 2

[0048] Figure 9 and Figure 10 (a), Figure 10 (b) shows the brushless motor of (Example 2) of this invention.

[0049] Such as Figure 9 As shown, the brushless motor is composed of a rotor portion 33 and a stator portion 40 .

[0050] The rotor part 33 has: a turntable part 28 for placing the disc, a rotor frame case 29, a disc alignment member 30 supporting the disc together with the turntable part 28, a rotor magnet 31 mounted on the rotor frame case 29, And the shaft 1 fixed to the center of the above-mentioned rotor frame case 29 .

[0051] The stator part 40 has: a bearing 8 supporting the above-mentioned shaft 1, a bearing housing 9 holding the bearing 8, an axial thrust stopper 36 supporting the shaft 1 in the axial direction, and a coil wound with a rotor magnet 31 opposite to the above-mentioned rotor magnet 31. 37 iron core 38, and the motor mounting plate 10 holding the above-mentioned bearing housing 9.

[0052] The bearing housing 9 is integrally formed i...

Embodiment 3

[0056] Figure 11 (a), Figure 11 (b) shows Example 3 of the present invention.

[0057] Figure 9 In this example, the bottom of the recess 10a of the motor mounting plate 10 is flat, and the base end of the bearing housing 9 fits in the recess 10a only with its outer circumference. A groove 41 into which the base end of the bearing housing 9 fits is formed at the bottom of the bearing housing 9 . Other components of brushless motors and Figure 9 same.

[0058] In detail, such as Figure 11 As shown in (a), a groove 41 is also integrally provided on the bottom surface of the recess 10 a formed in the motor mounting plate 10 . The axial thrust baffle 36 is provided on the inner side than the groove 41 .

[0059] Additionally, if Figure 11 As shown in (b), the above-mentioned groove 41 is further formed with protrusions 42 at several positions whose height is set to be lower than the inner diameter side wall surface 43 of the fitting groove. This is a projection at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com