Inner concealed oil cell of two-wheel motorcycle preventing ventilation hole from spilling oil

A two-wheeled motorcycle, built-in technology, applied in the direction of gasoline barrels, bicycle accessories, transportation and packaging, etc., can solve the problems of destructive performance, small cover, no purification treatment device, etc., and achieve the effect of reducing emission pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

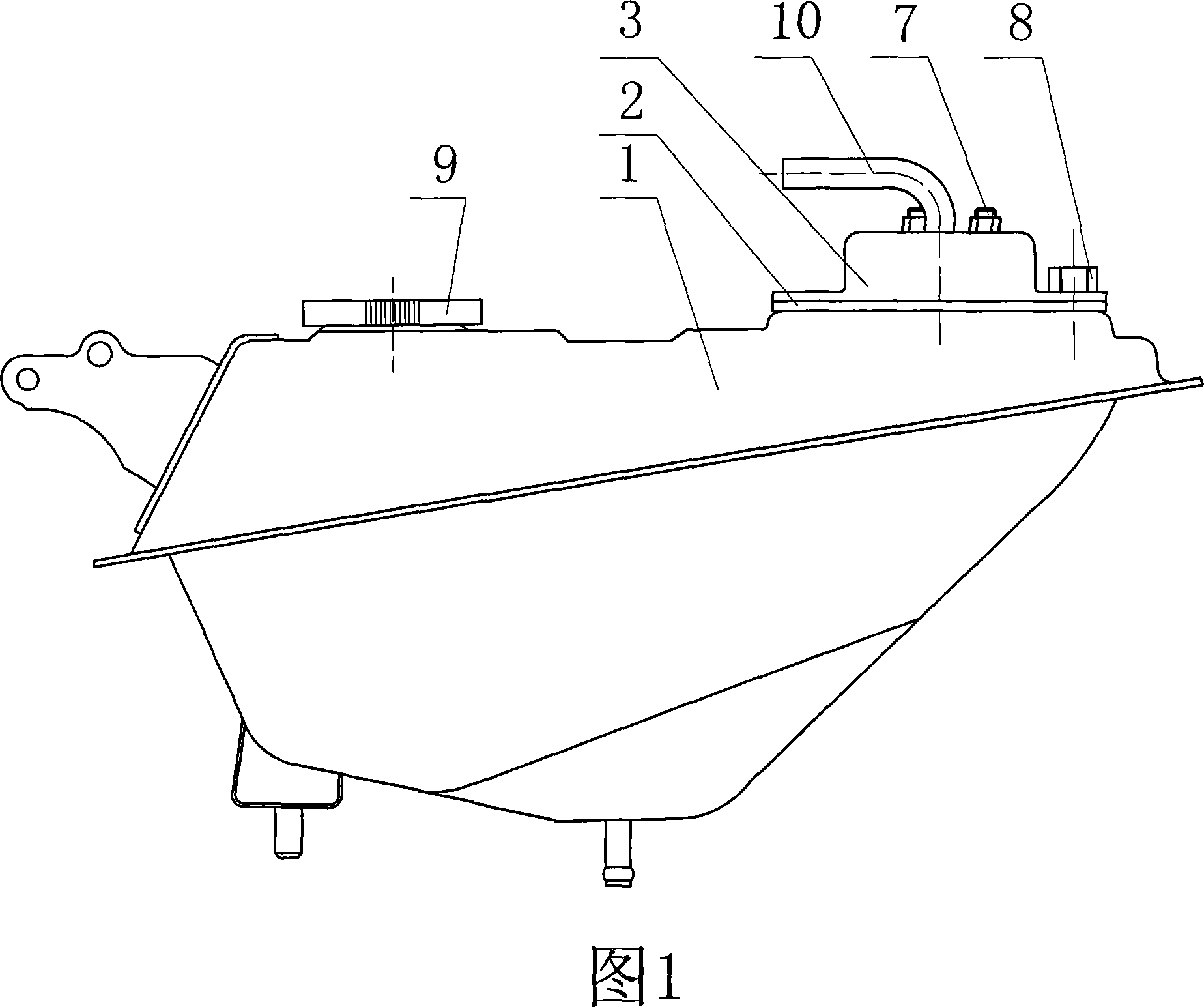

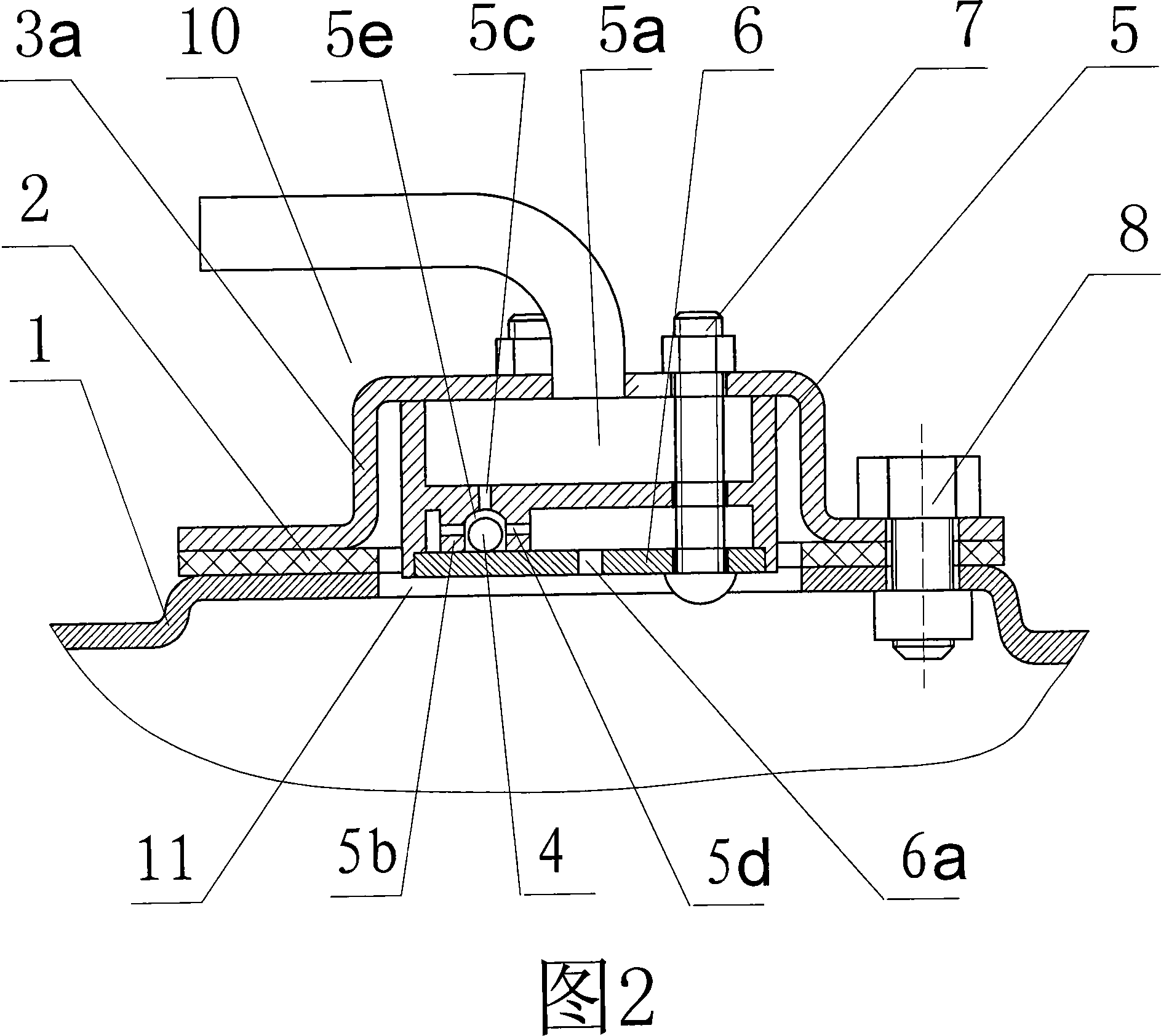

[0010] Referring to Fig. 1 and Fig. 2, a fuel tank cover 9 is provided on the oil filler port of the built-in fuel tank of the motorcycle, and a through hole 11 is additionally set on the top surface of the tank body 1 of the fuel tank, and the through hole 11 is located at the top of the tank body 1 The highest position, so that it is always higher than the liquid level of gasoline in the tank. A device 3 for ventilation and capable of automatic opening and closing is located at the upper end of the through hole 12 and is fixedly connected to the box body 1 . The device 3 for ventilation and automatic opening and closing includes a valve body 5 and a cover body 3a, the valve body 5 is fixedly connected under the cover body, the upper part of the valve body 5 is provided with an airflow buffer chamber 5a, and the lower part of the valve body is provided with a cavity Downward valve seat 5b, a vent hole 5c is located at the top of the valve cavity of the valve seat 5b, connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com