Preparation method and application method of magnesium peroxide antibacterial agent

A technology of magnesium peroxide, application method, applied in chemical instruments and methods, biochemical treatment of peroxides/peroxyhydrates/peroxyacids/superoxides/ozone oxides, fleece protectants/moth repellants, etc. , can solve the problems of pollution, high cost, affecting the wearing performance of textiles, etc., and achieve the effect of good antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: under the temperature of 25 ℃, the magnesium chloride hexahydrate of 40.66g (0.2 mole) is added in the 30% hydrogen peroxide aqueous solution of 24.67g (0.2 mole), after magnetic sub-stirring 2 hours, add while stirring 40 g (0.4 mol) of NaOH, and stirring was continued for 20 minutes. The generated insoluble magnesium peroxide was filtered and washed 3 times with water to remove impurities. Then dry it in an oven, grind it into powder, and complete the preparation of magnesium peroxide.

[0024] Take 0.5g of the prepared powder magnesium peroxide, add 10g of acrylamide to 1L of aqueous solution to prepare the antibacterial finishing solution, immerse 40g of cotton cloth into the prepared antibacterial finishing solution, and then roll it on a paddle car, and the liquid retention rate is 90% ; After padding the finishing cotton cloth, after drying at 60° C., curing at 150° C. for 3 minutes, finally rinsing with water, and drying.

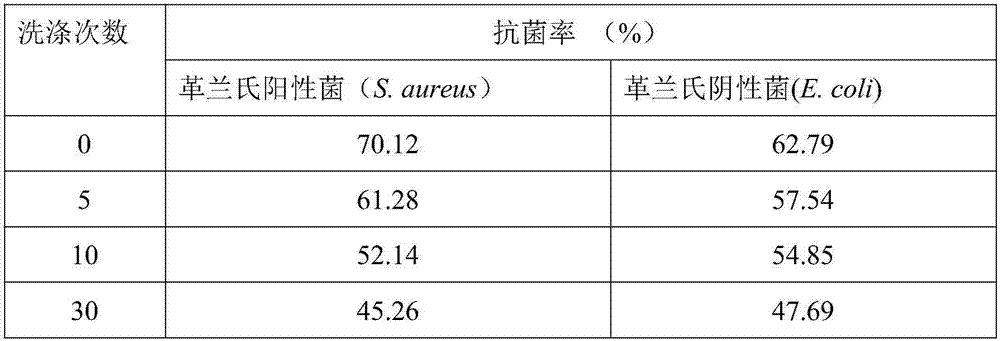

[0025] Wash the antiba...

Embodiment 2

[0029] Embodiment 2: at a temperature of 25°C, 40.66g (0.2 mole) of magnesium chloride hexahydrate was added in the 30% hydrogen peroxide solution of 45.35g (0.4 mole), and after magnetically stirred for 2 hours, it was added while stirring 40 g (0.4 mol) of NaOH, and stirring was continued for 20 minutes. The generated insoluble magnesium peroxide was filtered and washed 3 times with water to remove impurities. Then dry it in an oven, grind it into powder, and complete the preparation of magnesium peroxide.

[0030] Get 0.5g of prepared magnesium peroxide, add 10g of acrylamide into 1L aqueous solution to prepare antibacterial finishing solution, immerse 40g of cotton cloth into the prepared antibacterial finishing solution, and then roll it on a paddle car, and the liquid retention rate is 90%; The finished cotton cloth after padding is dried at 60°C, cured at 150°C for 3 minutes, rinsed with water and dried.

[0031] Wash the antibacterial cloth after processing and curin...

Embodiment 3

[0034] Embodiment 3: at a temperature of 25°C, 40.66g (0.2 mole) of magnesium chloride hexahydrate was added in the 30% hydrogen peroxide solution of 68.03g (0.6 mole), and after magnetically stirred for 2 hours, it was added while stirring 40 g (0.4 mol) of NaOH, and stirring was continued for 20 minutes. The generated insoluble magnesium peroxide was filtered and washed 3 times with water to remove impurities. Then dry in an oven to complete the preparation of magnesium peroxide.

[0035] Get 0.5g of prepared magnesium peroxide, add 10g of acrylamide into 1L aqueous solution to prepare antibacterial finishing solution, immerse 40g of cotton cloth into the prepared antibacterial finishing solution, and then roll it on a paddle car, and the liquid retention rate is 90%; The finished cotton cloth after padding is dried at 60°C, cured at 150°C for 3 minutes, rinsed with water and dried.

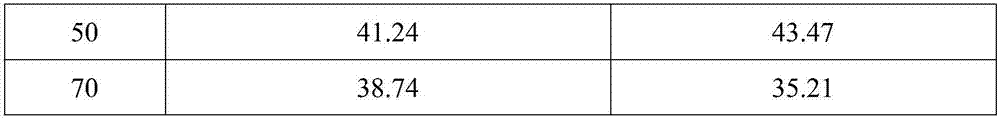

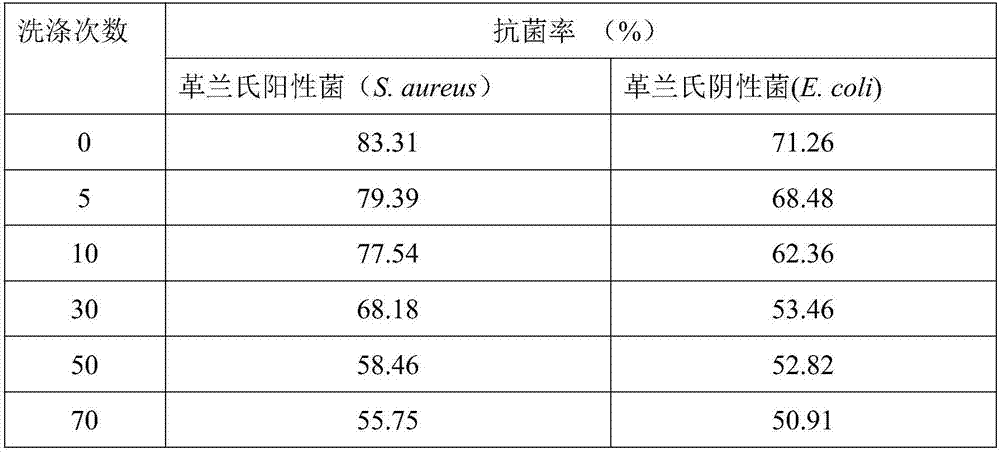

[0036] Wash the antibacterial cloth after processing and curing, and investigate the anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com