Silk quilt and preparation method thereof

A technology of silk quilt and silk floss, applied in coatings, bed sheets, blankets, etc., can solve the problems of silk not fastness to sunlight, affecting wearing performance, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

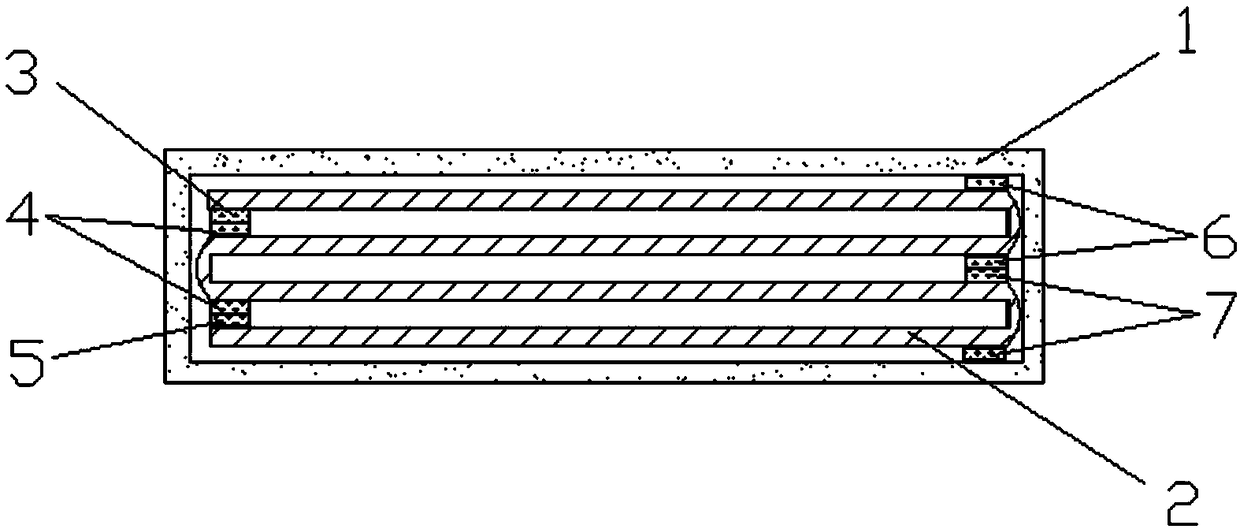

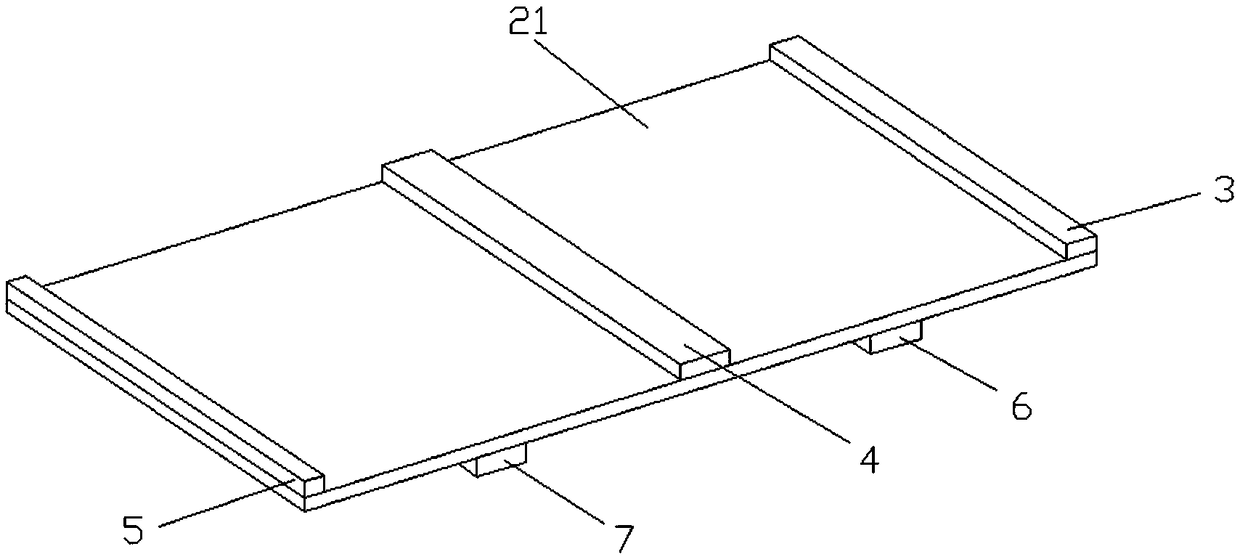

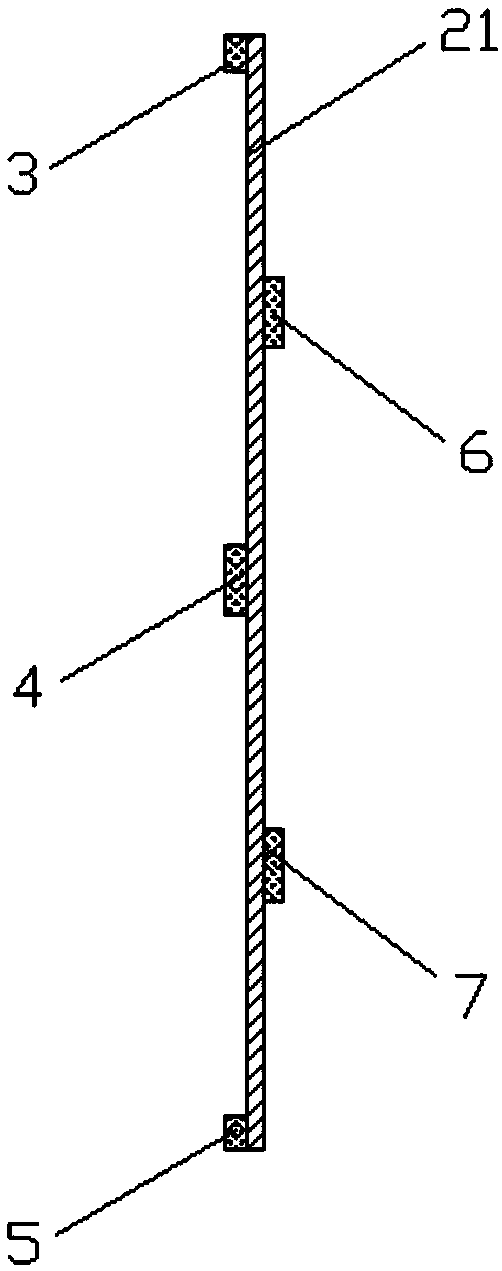

[0024] Such as Figure 1 to Figure 3 As shown, a silk quilt includes a quilt cover 1 and a quilt core 2. The quilt core 2 is set in the quilt cover 1. The quilt core 2 is folded from a whole piece of silk floss 21. The two sides of the silk floss 21 are provided with a plurality of anti-slip belts. It is a polyester flocking cloth, and its side away from the silk flock 21 has a flocking surface, and the folded silk flock 21 is bonded to each other through the contact between the flocking surfaces, so as to prevent the flocking between the silk flocks 21 and between the quilt core 2 and the quilt cover 1. There is a relative displacement between them.

[0025] The polyester flocking fabric has a relatively large frictional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com