Flexible railway separating thrusting slip construction method and equipment thereof

A technology of flexible track and construction method, applied to roofs, building components, buildings, etc., can solve the problems of time-consuming, manpower and material resources, complex construction process, large geometric size, etc., to improve sliding efficiency and facilitate flexible and dispersed layout , the effect of reducing the stiffness requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

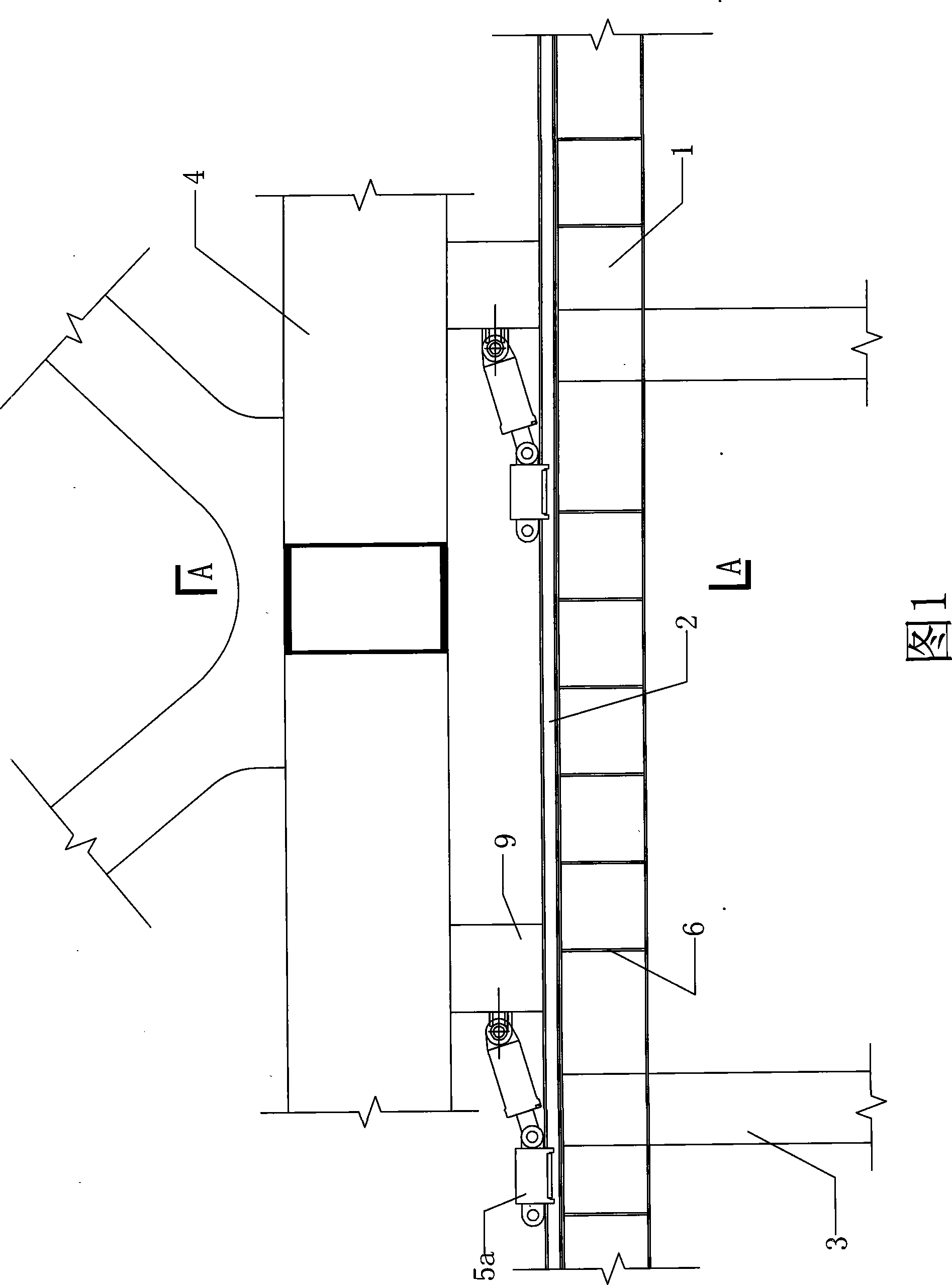

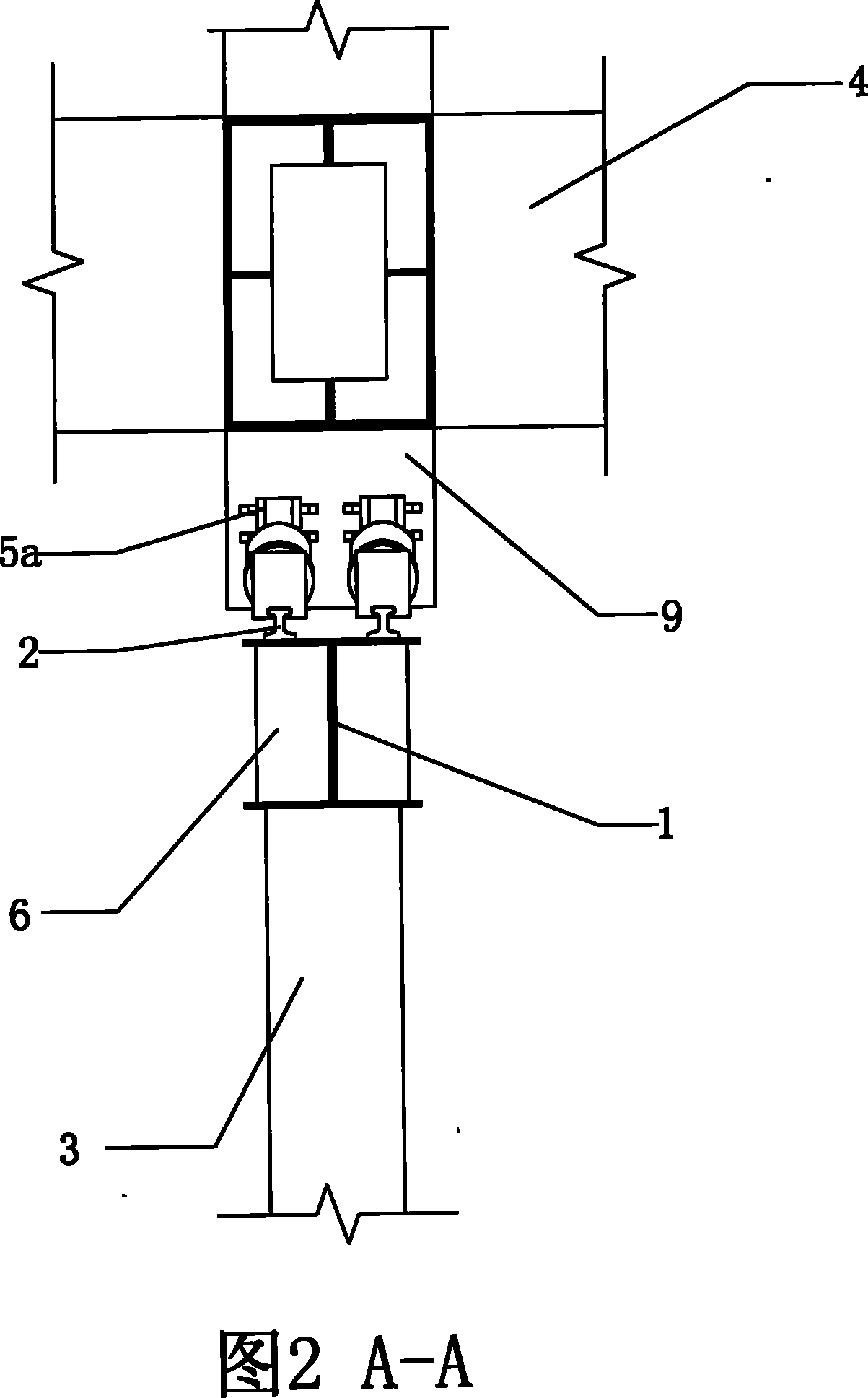

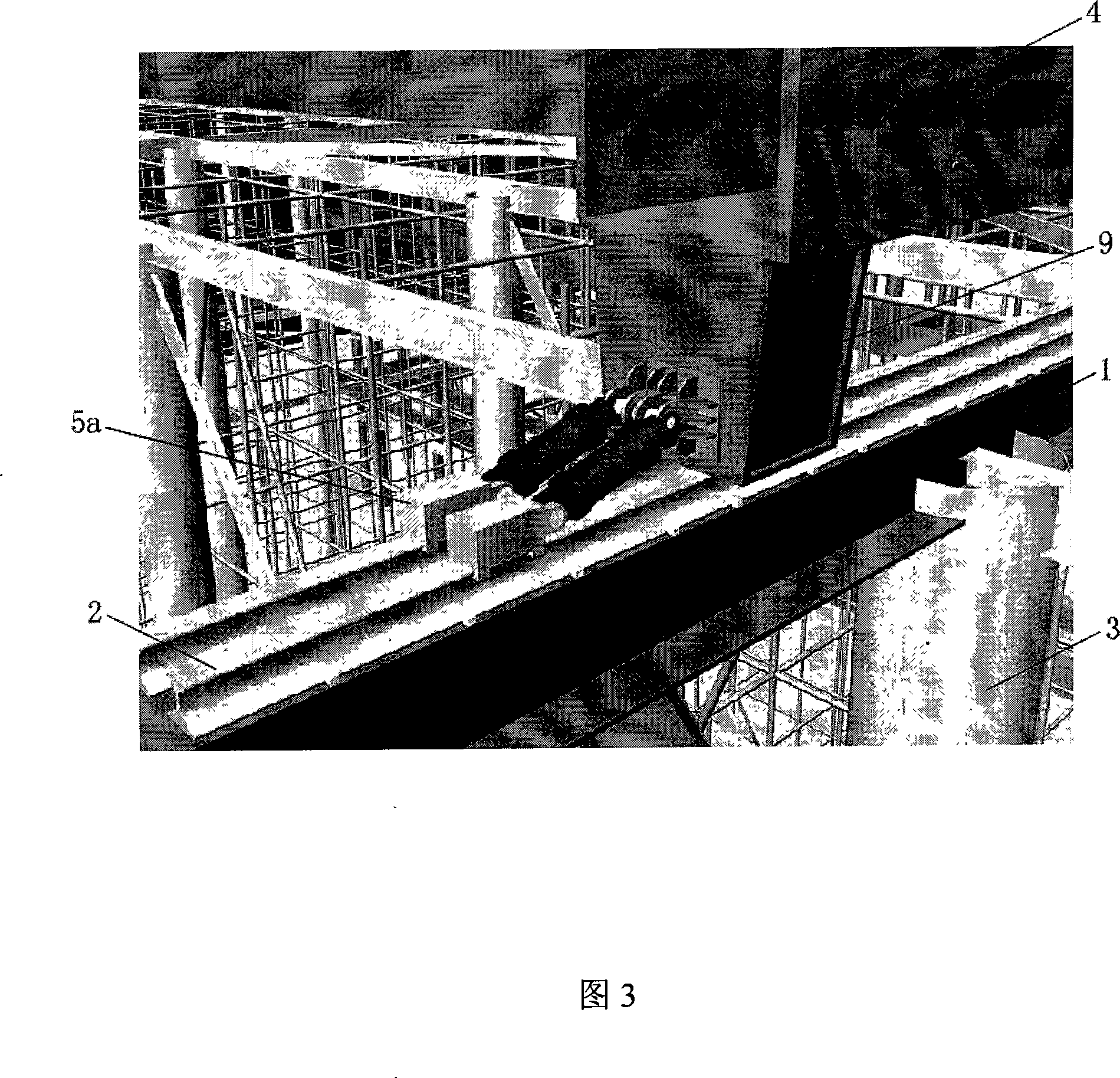

[0043] Examples of the present invention are Figure 4-13 As shown, the specific implementation is described in further detail.

[0044] like Figure 4-13 The shown flexible track separation type push-slide construction method and its equipment are one of the embodiments of the present invention, and the total construction area of the building is about 66280m2 2 , the total height of the building is 44.5m, and the structural system is a reinforced concrete shear wall-steel truss overhanging suspension structure, which adopts a combination of a large cantilevered steel truss structure at the top and a floor suspension structure. A total of 8 large-scale cantilevered steel trusses, using two-way cross plane trusses, trusses 8m high, 124m long, supported on the upper part of the shear wall, and fixed to the steel pipe concrete columns in the shear wall, the upper and lower chords of the steel trusses are respectively set with five floors and steel beams on the six floors to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com