Hydraulic locating type damping changing impact damper

A shock absorber and variable damping technology, which is applied in the direction of shock absorber, liquid shock absorber, spring/shock absorber, etc., can solve the problems of reducing the ride comfort of the car and increasing the dynamic load of the bearing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

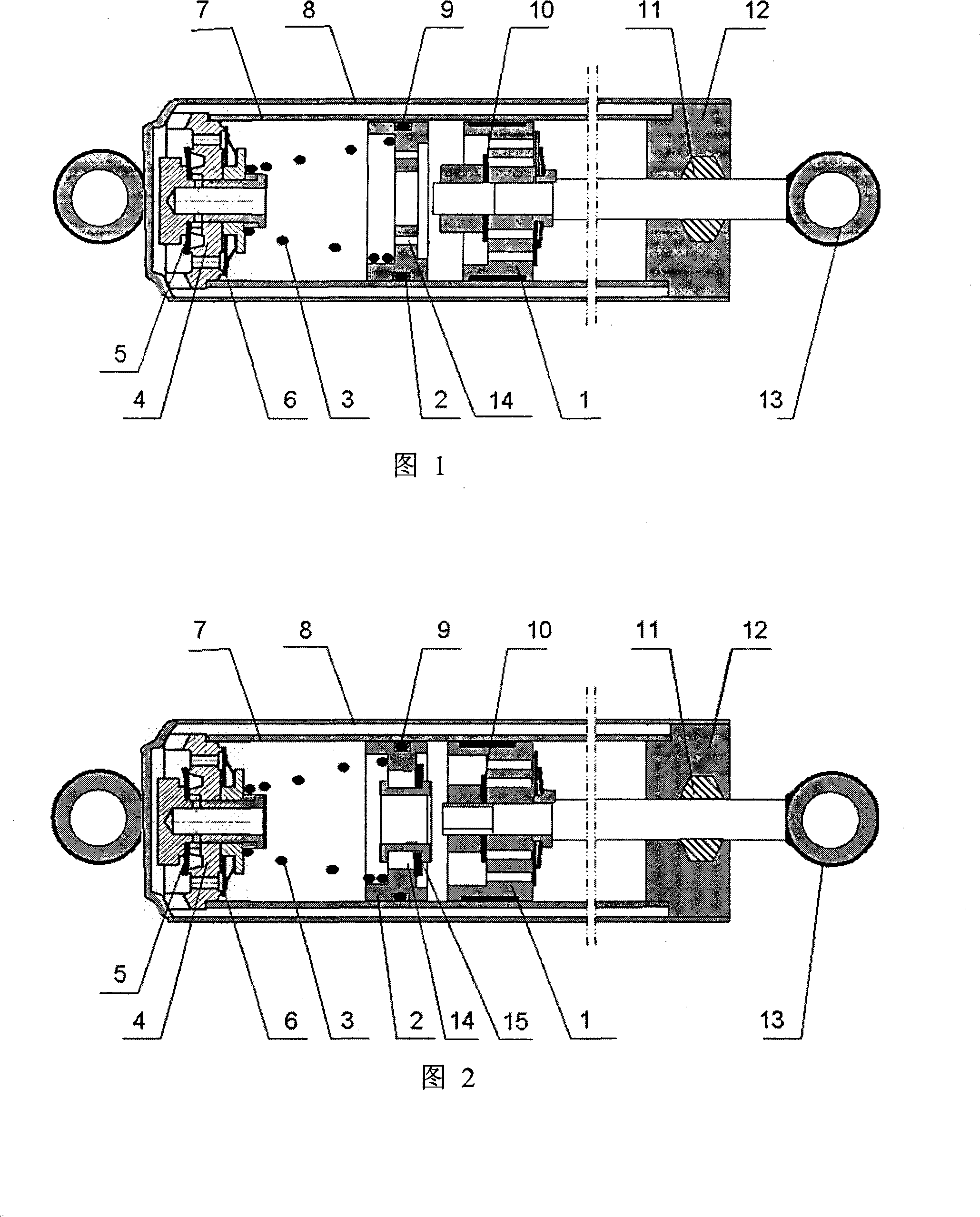

[0010] The present invention is described in further detail below in conjunction with the embodiment given with accompanying drawing.

[0011] Referring to Fig. 1, a hydraulic limit variable damping shock absorber includes a shock absorber working cylinder 7, an oil storage cylinder 8 nested outside the shock absorber working cylinder 7, and a main The piston 1, the compression unloading valve 5 and the oil inlet valve 6 arranged on the bottom valve seat 4 of the shock absorber working cylinder 7 are characterized in that a central valve is also set between the main piston 1 and the bottom valve seat 4 There is a floating piston 2 with an axially penetrating oil main channel, and a limit damping hole 14 is provided on the outer periphery of the main oil channel of the floating piston 2 ; a limit spring 3 is arranged between the bottom valve seat 4 and the floating piston 2 .

[0012] Referring to FIG. 2 , a limit unloading valve 15 is also provided on the limit damping hole 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com