Compound material liquid storage container performance multi-dimension testing method

A liquid storage container and composite material technology, which is applied in the direction of analysis materials, instruments, measuring devices, etc., can solve the problems of lack of performance testing of composite liquid storage containers, inability to test the microscopic performance of materials, and high cost, and achieve macro performance testing results. Credible, guaranteed energy conservation, strong operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the embodiment of the inventive method is described in detail: present embodiment implements under the premise of technical solution of the present invention, has provided detailed implementation mode and process, but protection scope of the present invention is not limited to following Example.

[0022] The specific implementation steps of this embodiment are as follows:

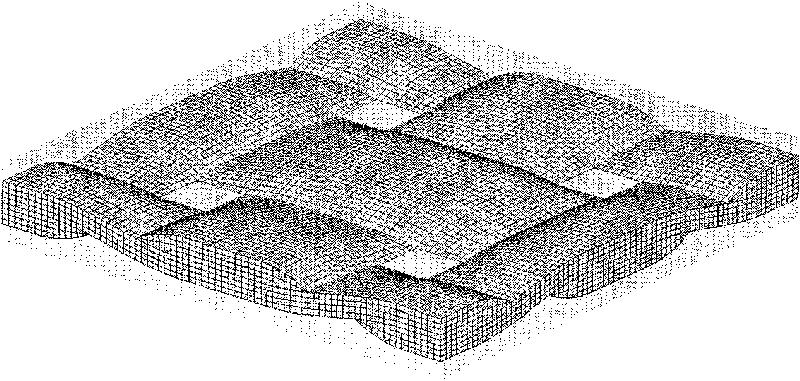

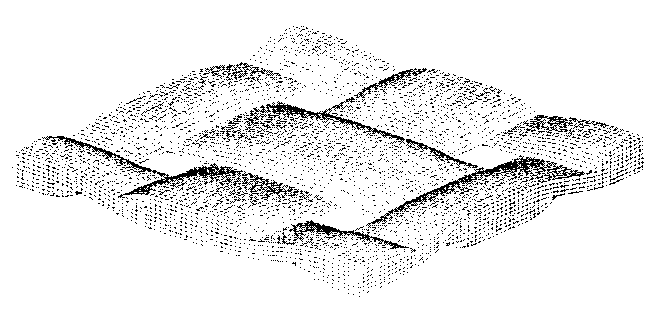

[0023] A specific example is to predict the performance of a certain type of air-dropped water tank. The air-dropped water tank (or oil tank, abbreviated below) is a special transportation equipment. The tank body is made of textile composite material, and the tank is filled with water or oil. When needed, the helicopter airdrops the water tank (without a parachute) to the designated location.

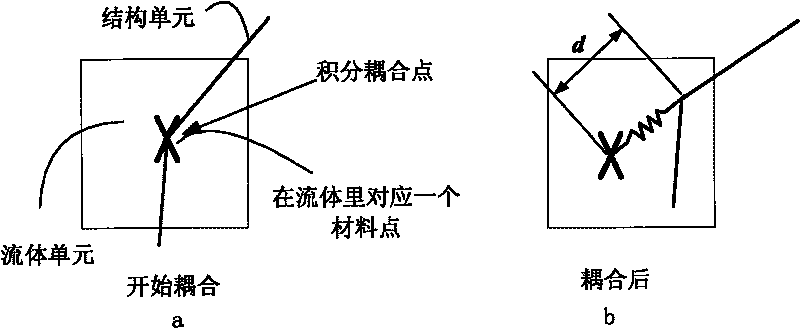

[0024] 1) Extract the mesoscopic geometric parameters of the material. The textile composite material is cut by mechanical equipment to obtain the cross sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com