Spilled stannum port with external stannum baffle type stannum export

A technology of tin outlet and overflowing tin, applied in the field of tin furnace tin outlet, can solve the problems of inability to protect components, easy to form virtual welding of contacts, low work efficiency, etc., and achieve the effect of ensuring sufficiency and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

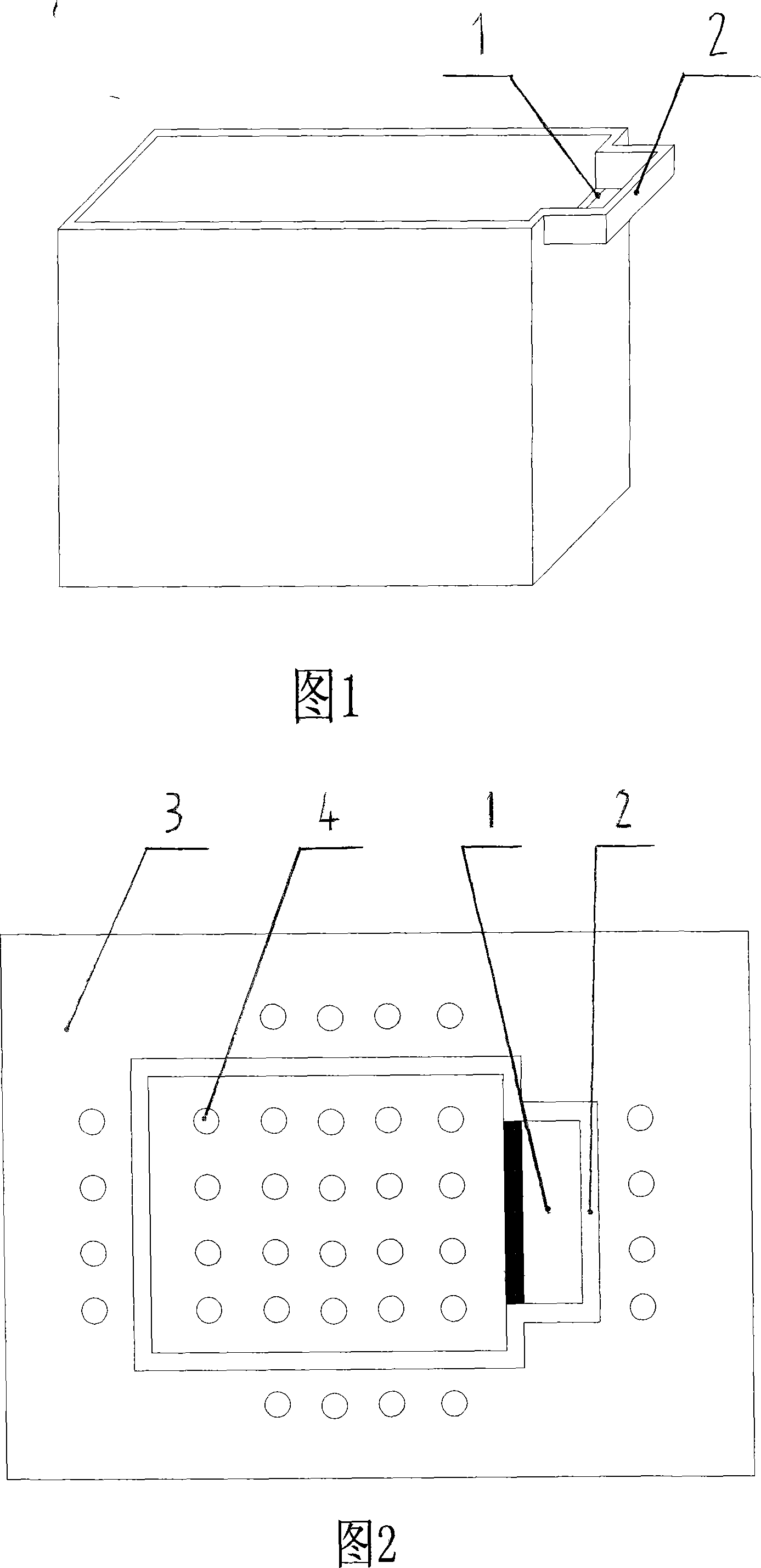

[0013] As shown in Figure 1, a kind of tin outlet with a tin baffle outside the overflow tin outlet, the shape of the tin outlet is rectangular, and at least one tin baffle 1 is arranged on the inner wall of the tin outlet of the tin outlet. At least one tin overflow opening 2 is opened around the tin outlet. The shape of the tin outlet is rectangular, and at least one tin overflow opening 1 is respectively arranged on the long side of the rectangle. The tin overflow opening 1 is a rectangular gap with a depth of 2-8mm.

[0014] As shown in FIG. 2 , the tin outlet of the present invention is mainly used in the case where there are some electronic components 4 that do not need to be soldered above the tin outlet. The tin baffle 1 installed at the tin outlet of the tin outlet blocks the tin liquid gushing out of the upper tin outlet, so that the tin liquid changes the flow direction after hitting the tin baffle 1 and diverts it from both sides of the tin baffle 1. Out of the ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com