Patents

Literature

34results about How to "Does not affect soldering quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

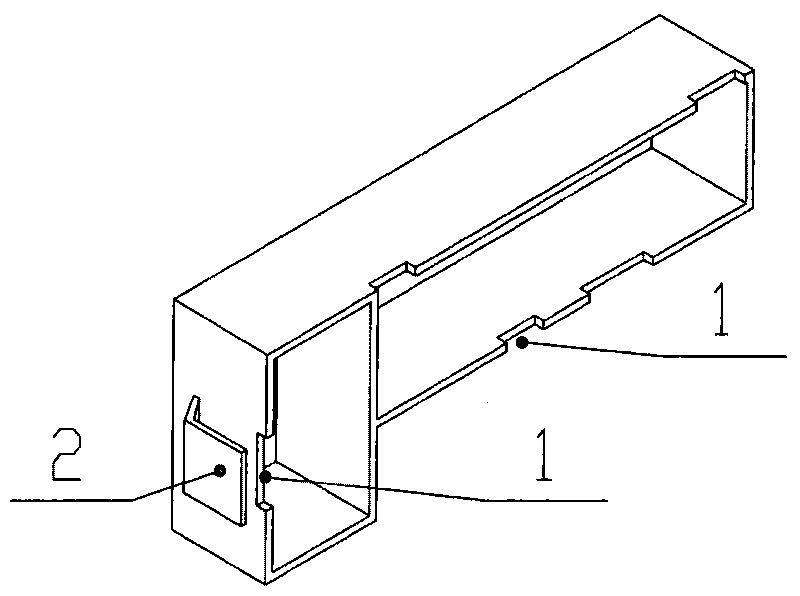

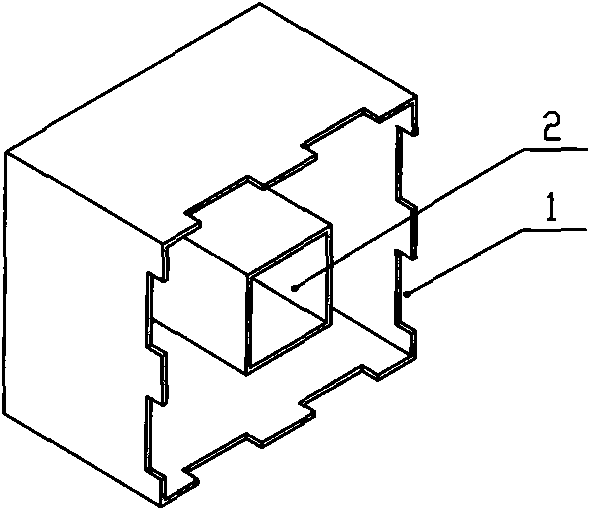

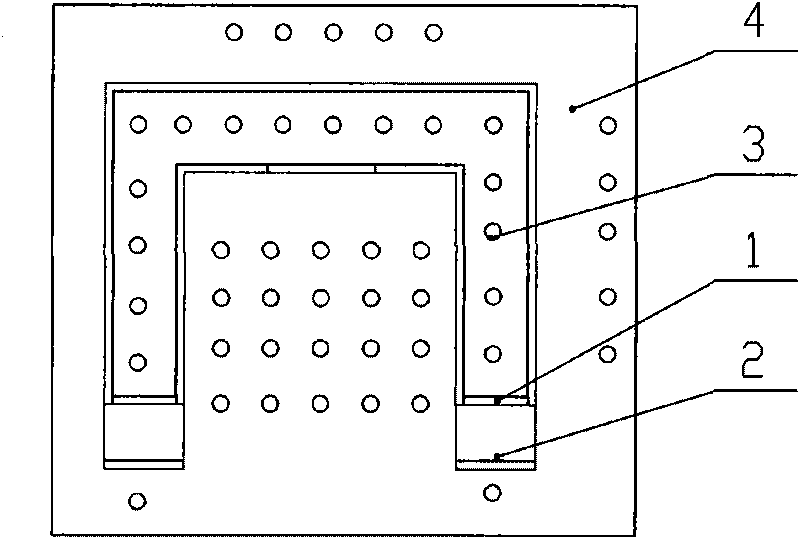

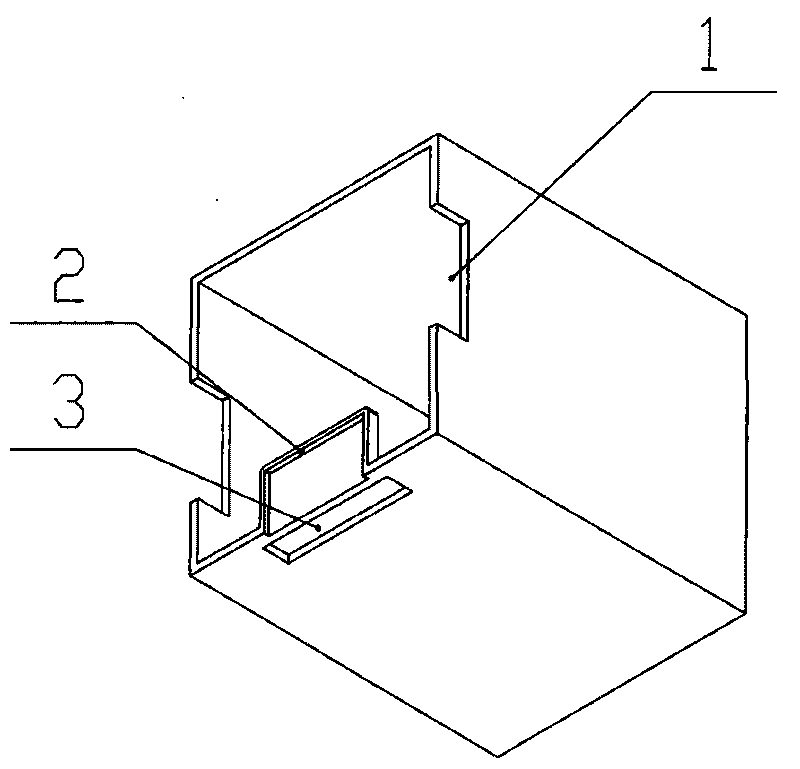

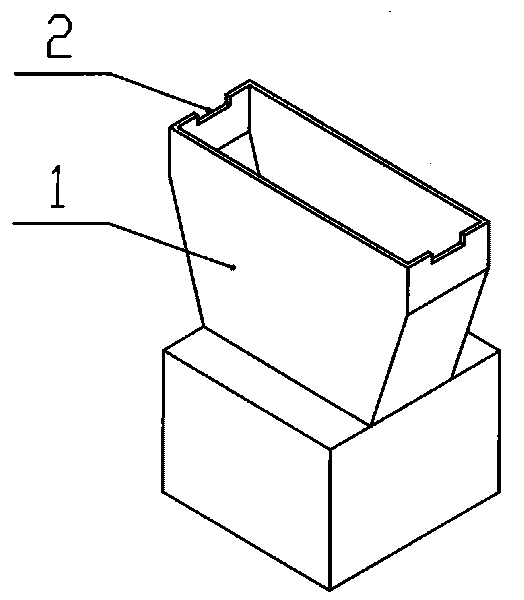

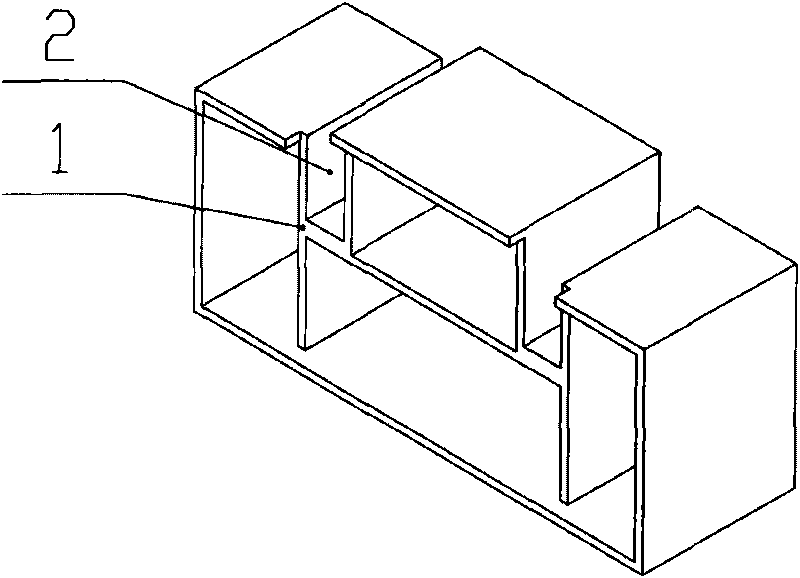

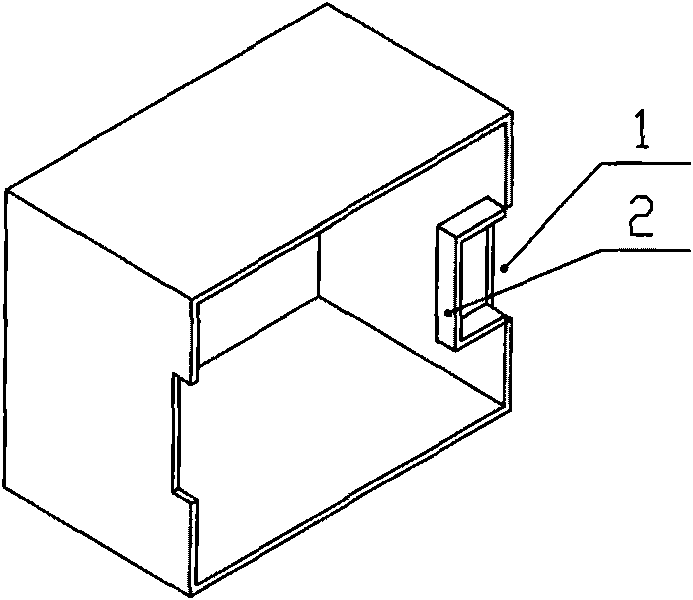

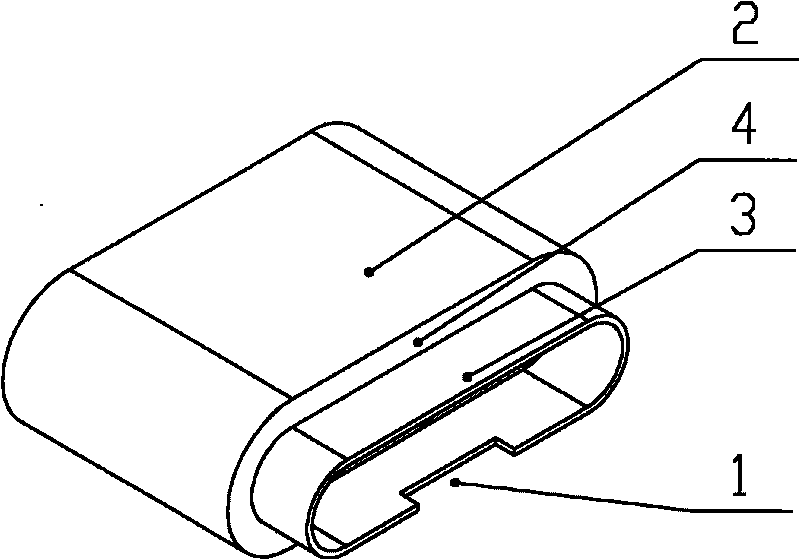

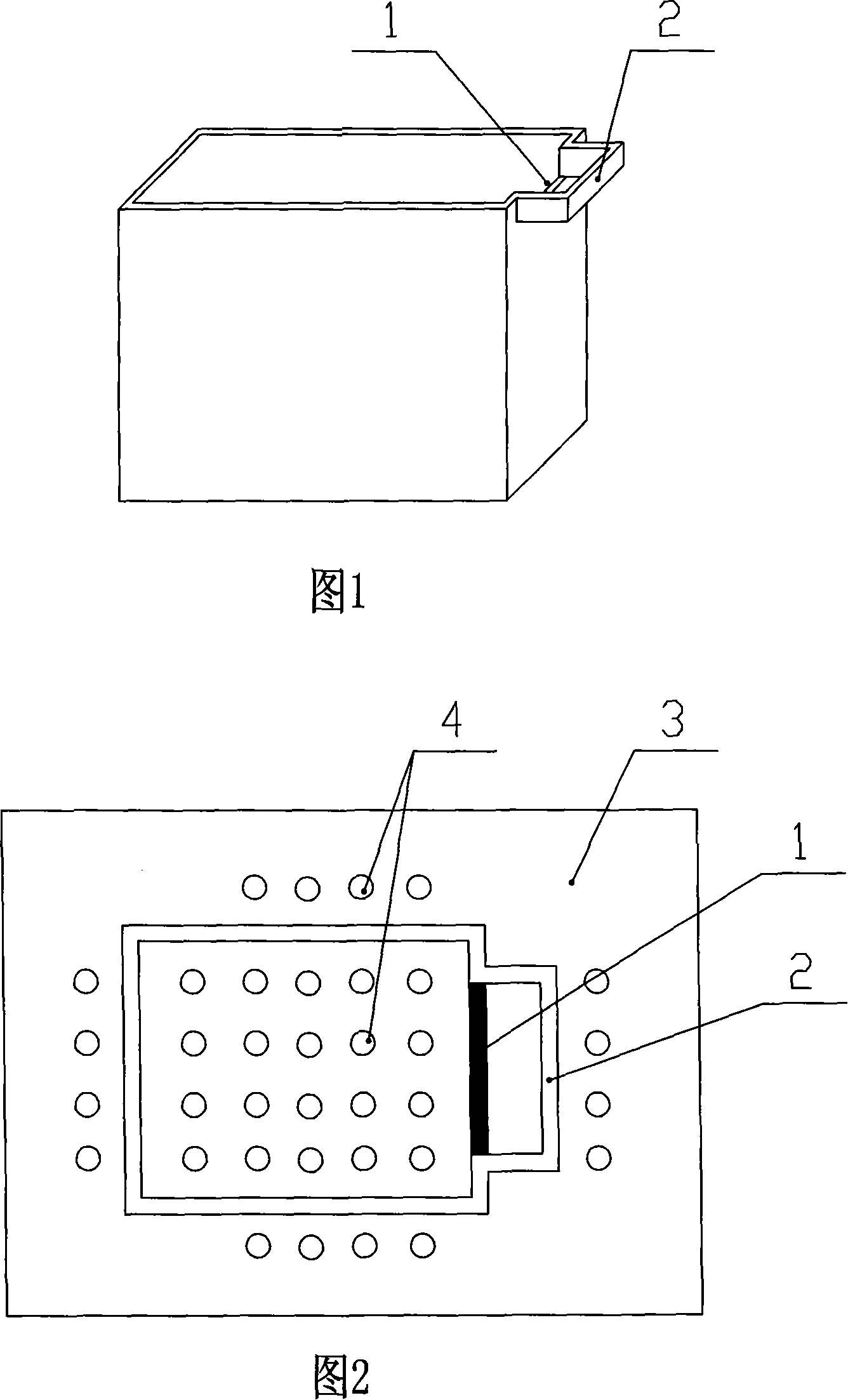

Inner opening L-shaped stannum port of spilled stannum port

InactiveCN101179908AChange directionDoes not affect soldering qualityMultilayer circuit manufactureSurface layerEngineering

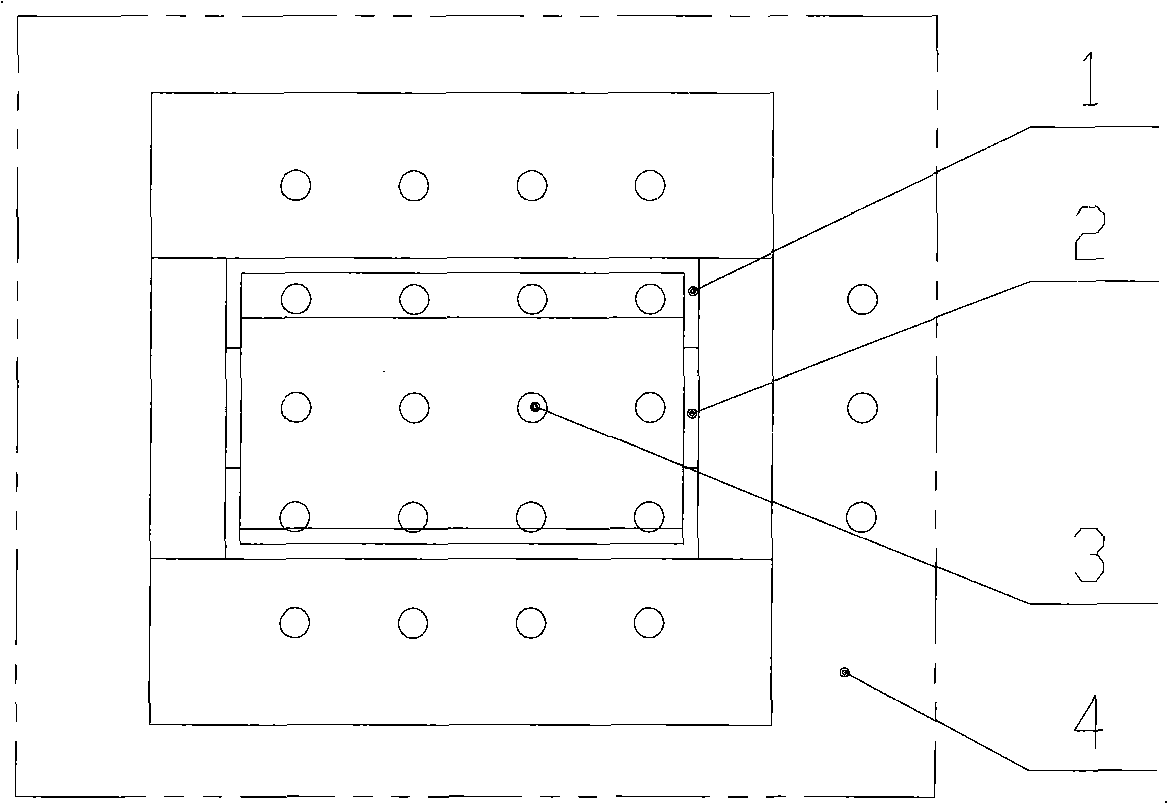

The invention relates to a tin furnace part of PCBA board soldering tin, in particular a tin outlet of a tin furnace. Two rectangle ends of the tin outlet are firmly connected with each other into an L-shape. The tin outlet on the lateral side of the tin outlet in L-shape is provided with a tin spill-way which is a rectangle opening with a depth of 2mm to 8mm.The invention has a simple structure and is capable of effectively increasing soldering efficiency and is applicable for large-scale automatic production; furthermore, oxidation layer on molten tin surface layer is effectively prevented from being retained on the surface of the PCBA board, and the quality of soldering spots is ensured.

Owner:苏州明杰自动化科技有限公司

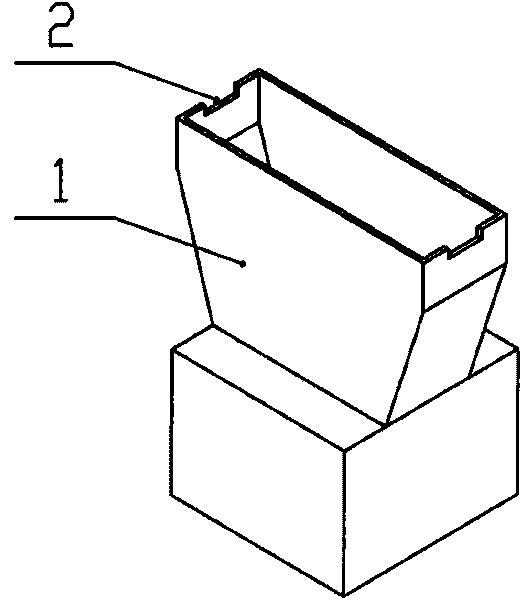

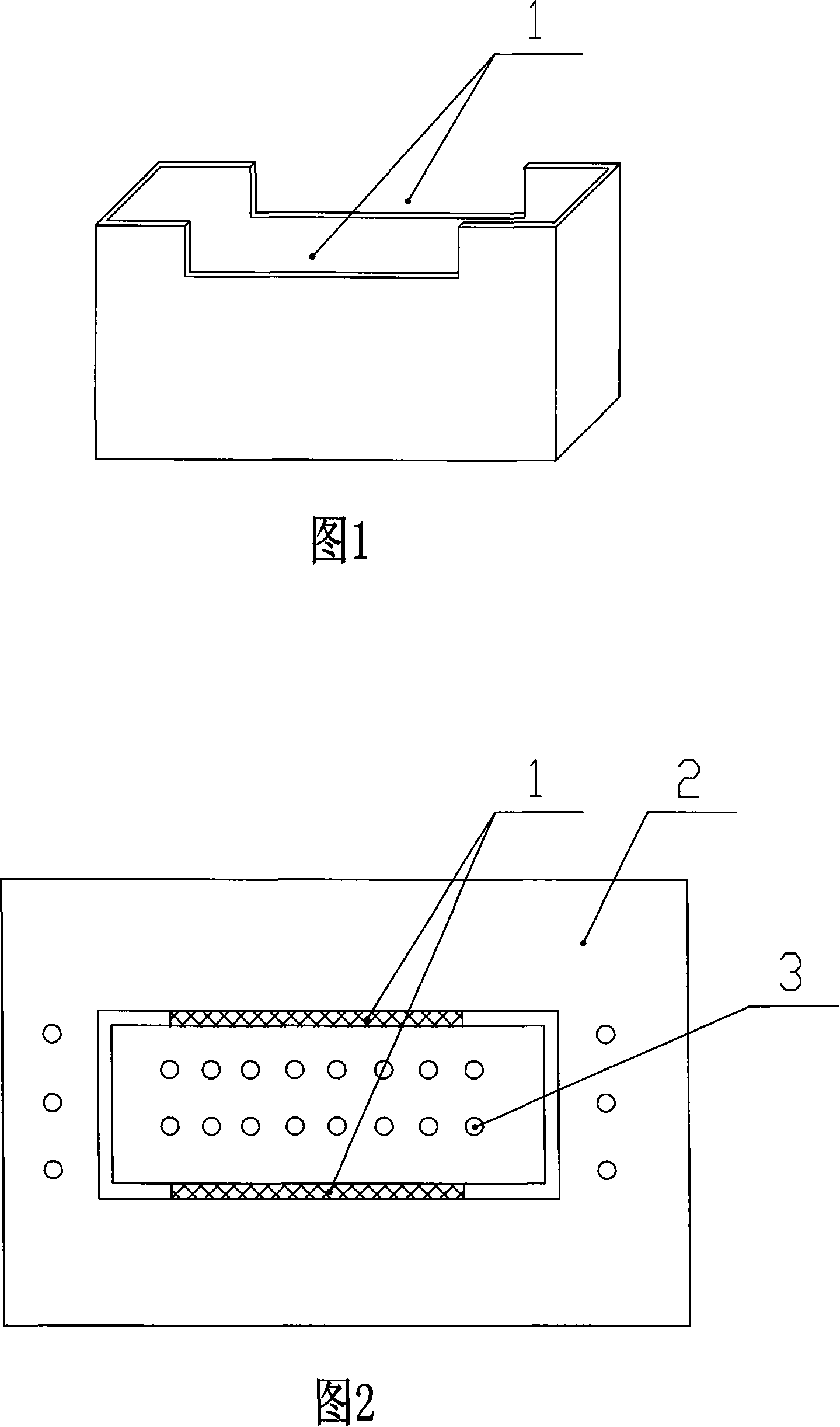

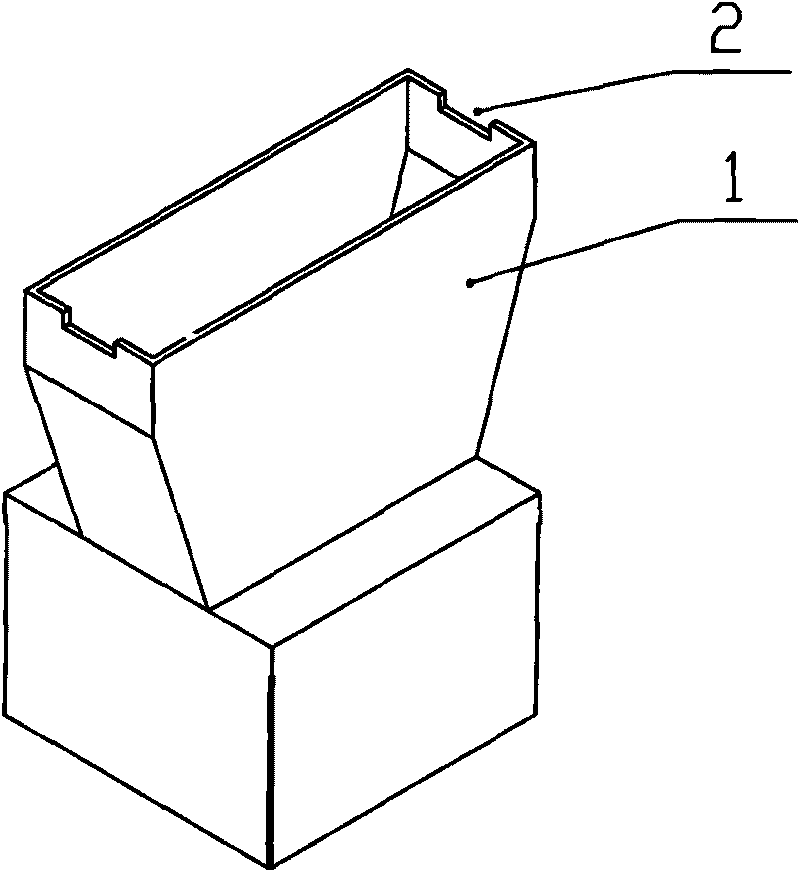

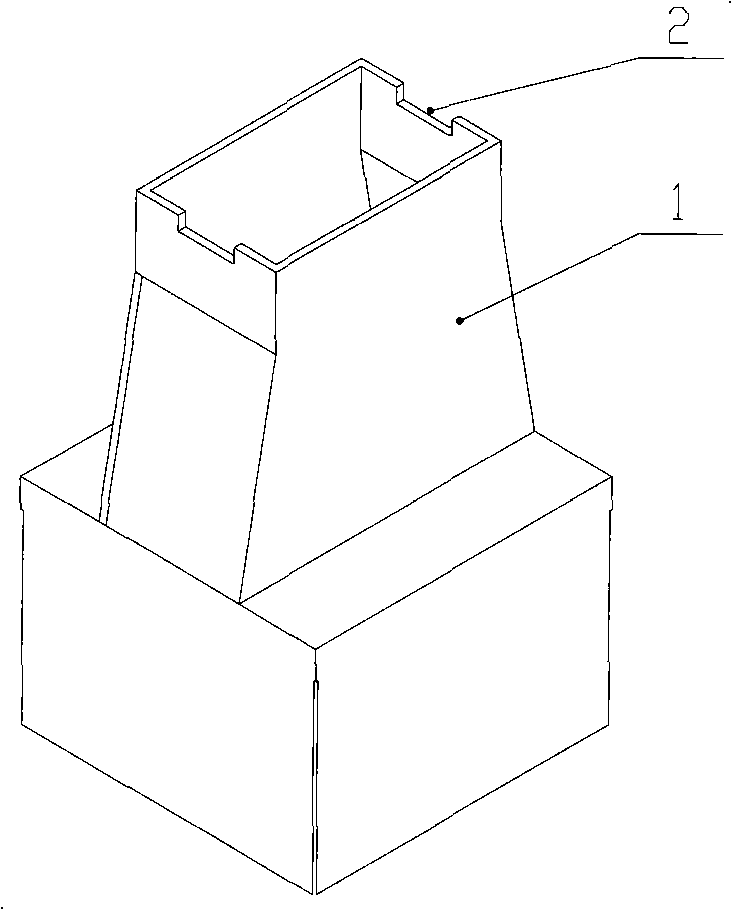

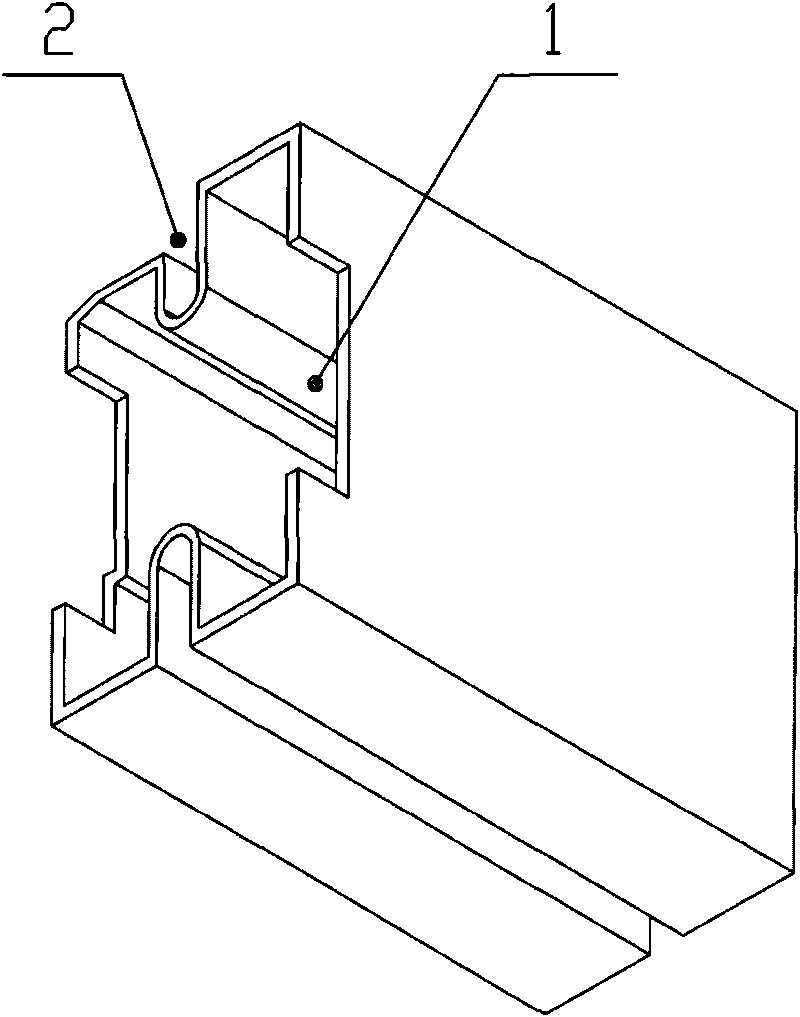

External baffle insertion type pot opening

InactiveCN101765306AChange directionDoes not affect soldering qualityPrinted circuit assemblingSurface layerEngineering

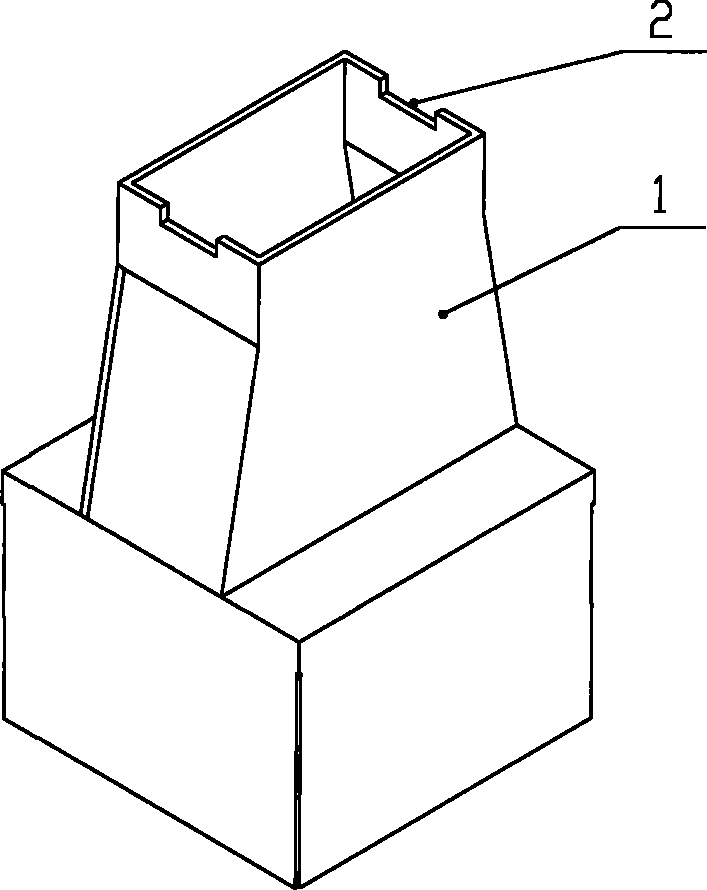

The invention relates to a tin furnace component used for PCBA board soldering tin, in particular to an insertion type tin furnace pot opening. A conical insertion opening is arranged at the opening part of the pot opening, the edge of the insertion opening is provided with at least one tin overflowing opening, the outer side of the tin overflowing opening is provided with baffle sheets, the baffle sheets are fixedly connected with the outer wall of the insertion opening, and the tin overflowing opening is a rectangular hole with the depth between 3 and 4 mm. The invention has a simple structure, can effectively improve the welding efficiency, and is suitable for large-scale automatic production, in addition, an oxide layer of the surface layer of the tin liquid is effectively prevented from being remained on the surface of a PCBA board, and the quality of welding points is ensured.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

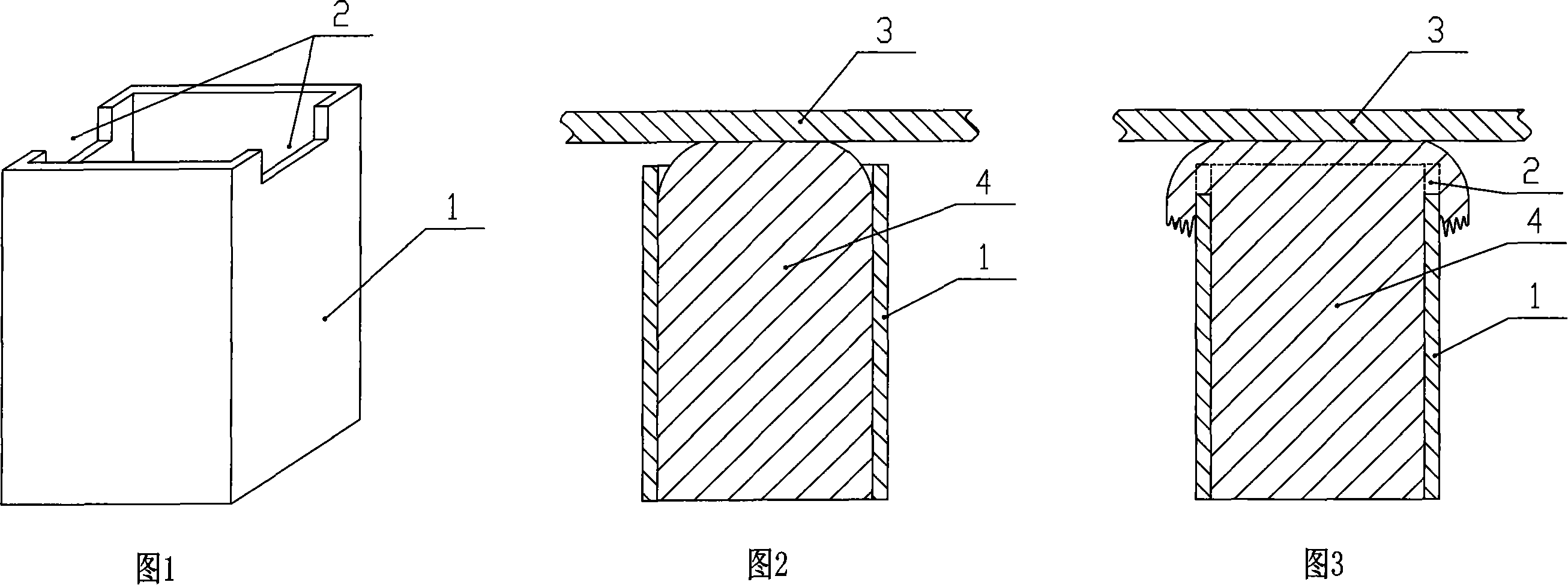

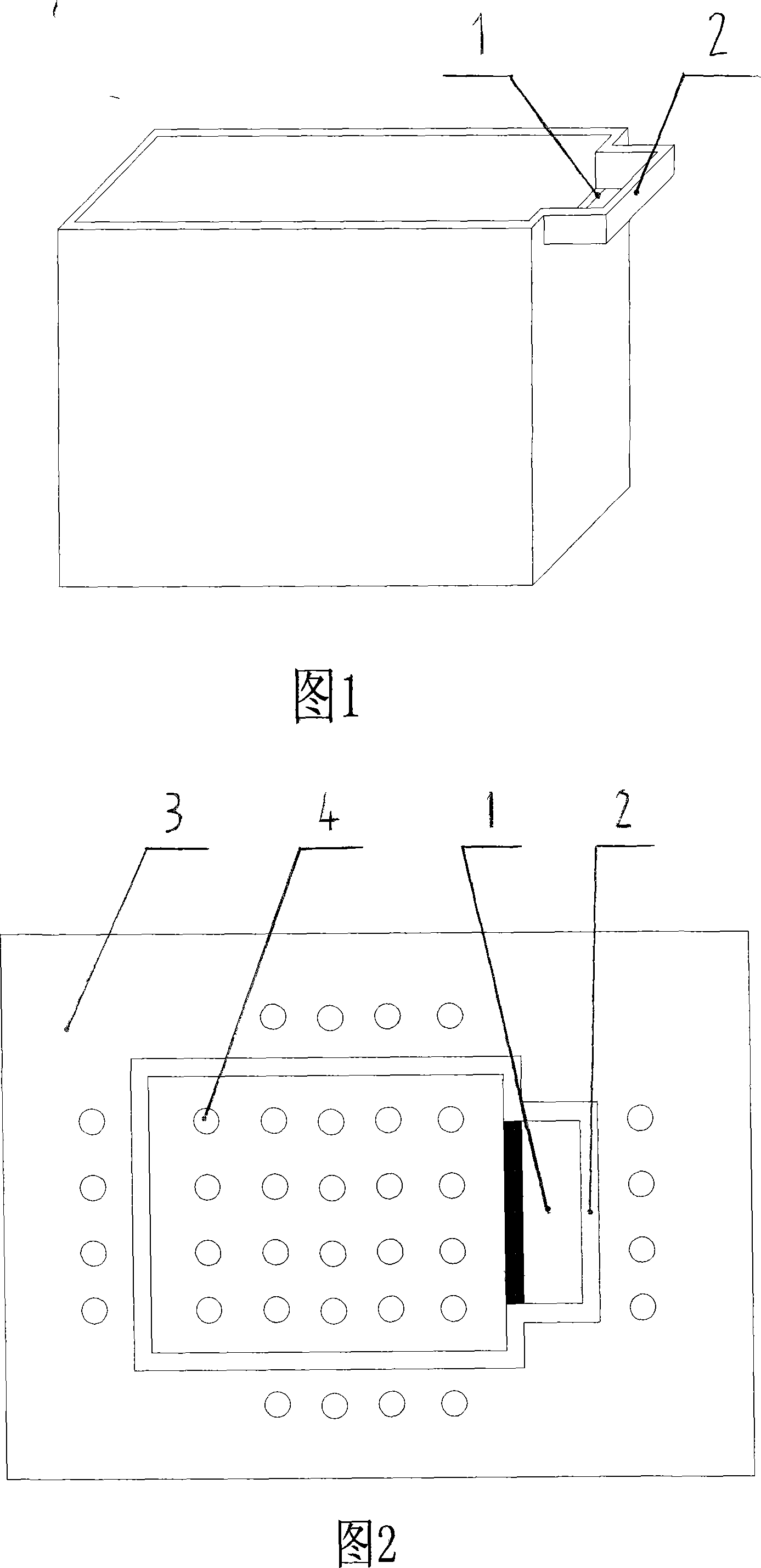

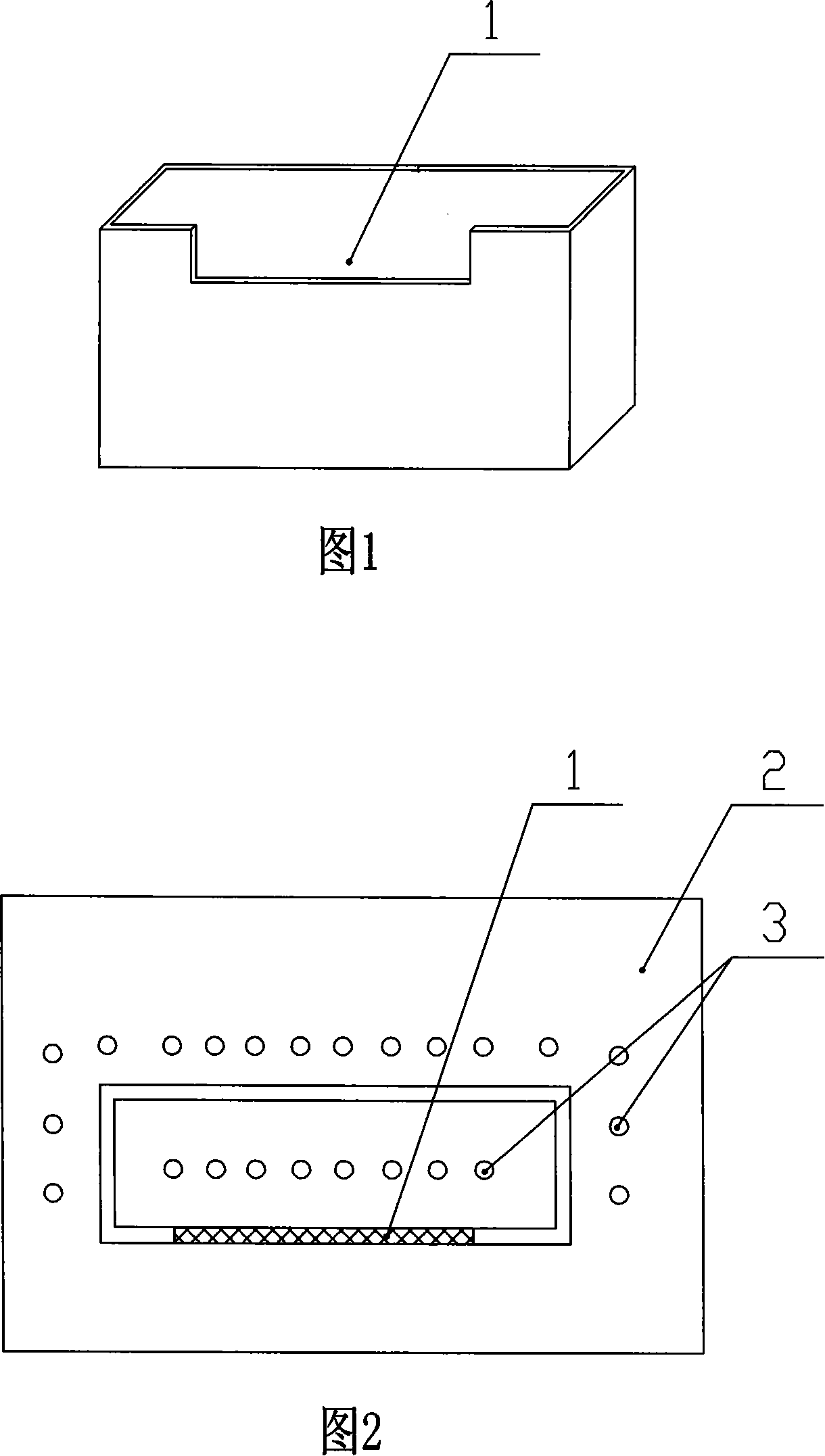

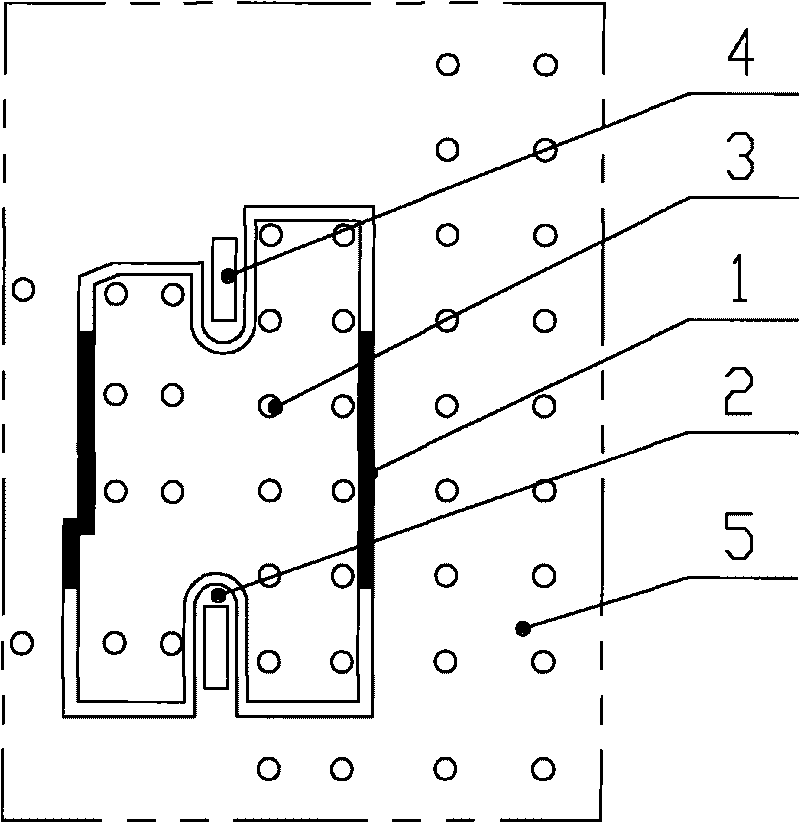

A tin furnace kettle mouth

InactiveCN101150925AChange directionDoes not affect soldering qualityPrinted circuit assemblingSolderingLiquid surfaces

The invention relates to a tin furnace component used to PCBA board soldering tin, in particular to a tin furnace kettle orifice, which is arranged above a tin groove and used for leading tin liquid to a tin outlet to generate tin wave for soldering tin, at least one tin overflow outlet is positioned around the kettle orifice tin outlet, the tin overflow outlet is a rectangular opening, the deepness is 2-8mm. The invention has a simple structure, can improve the soldering efficiency, is suitable for mass automatic production, in addition, effectively prevents an oxide layer of the tin liquid surface from remaining on the PCBA board, assures the welding joint quality.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

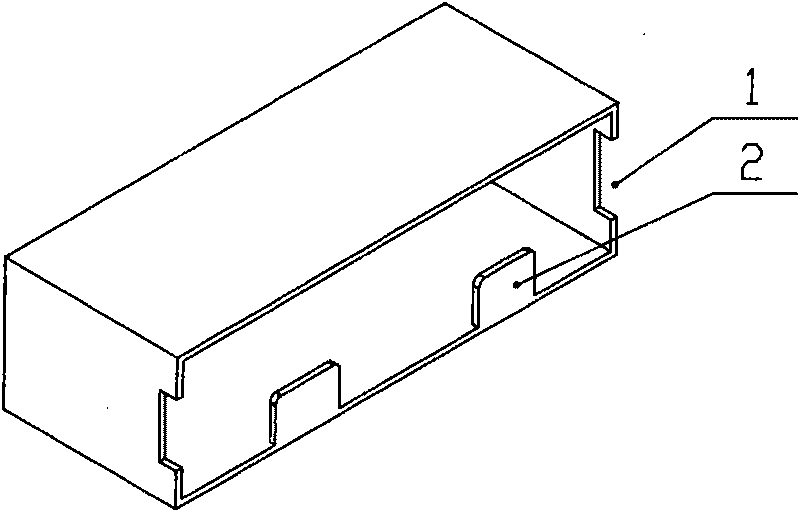

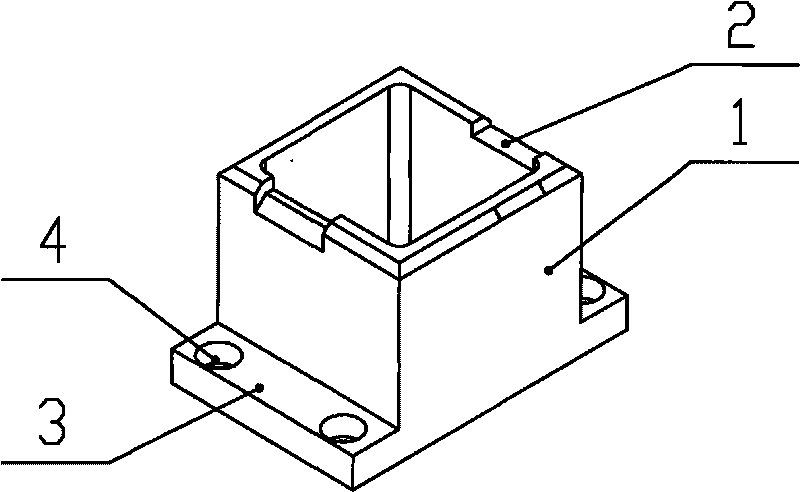

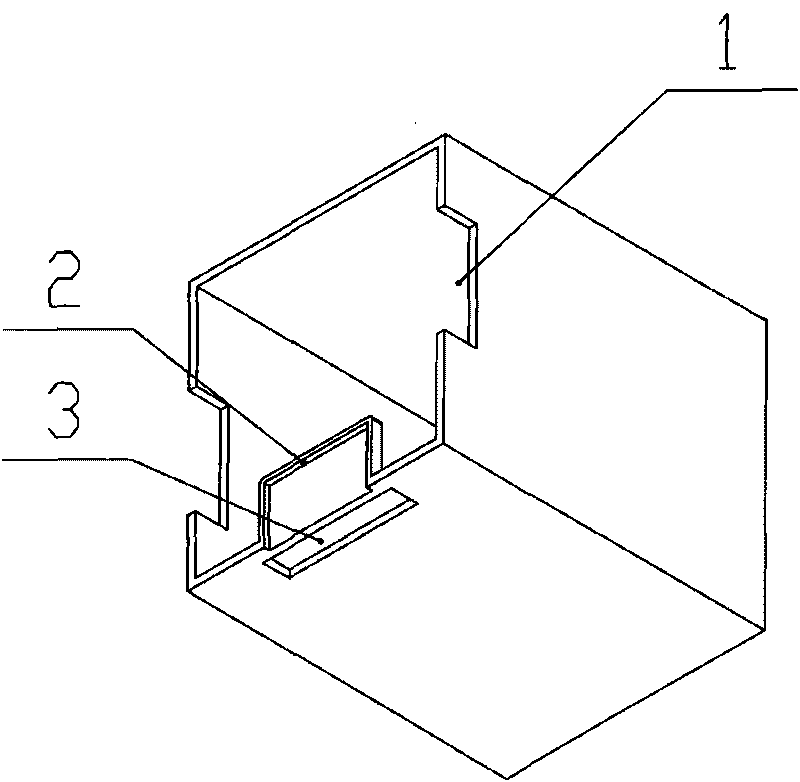

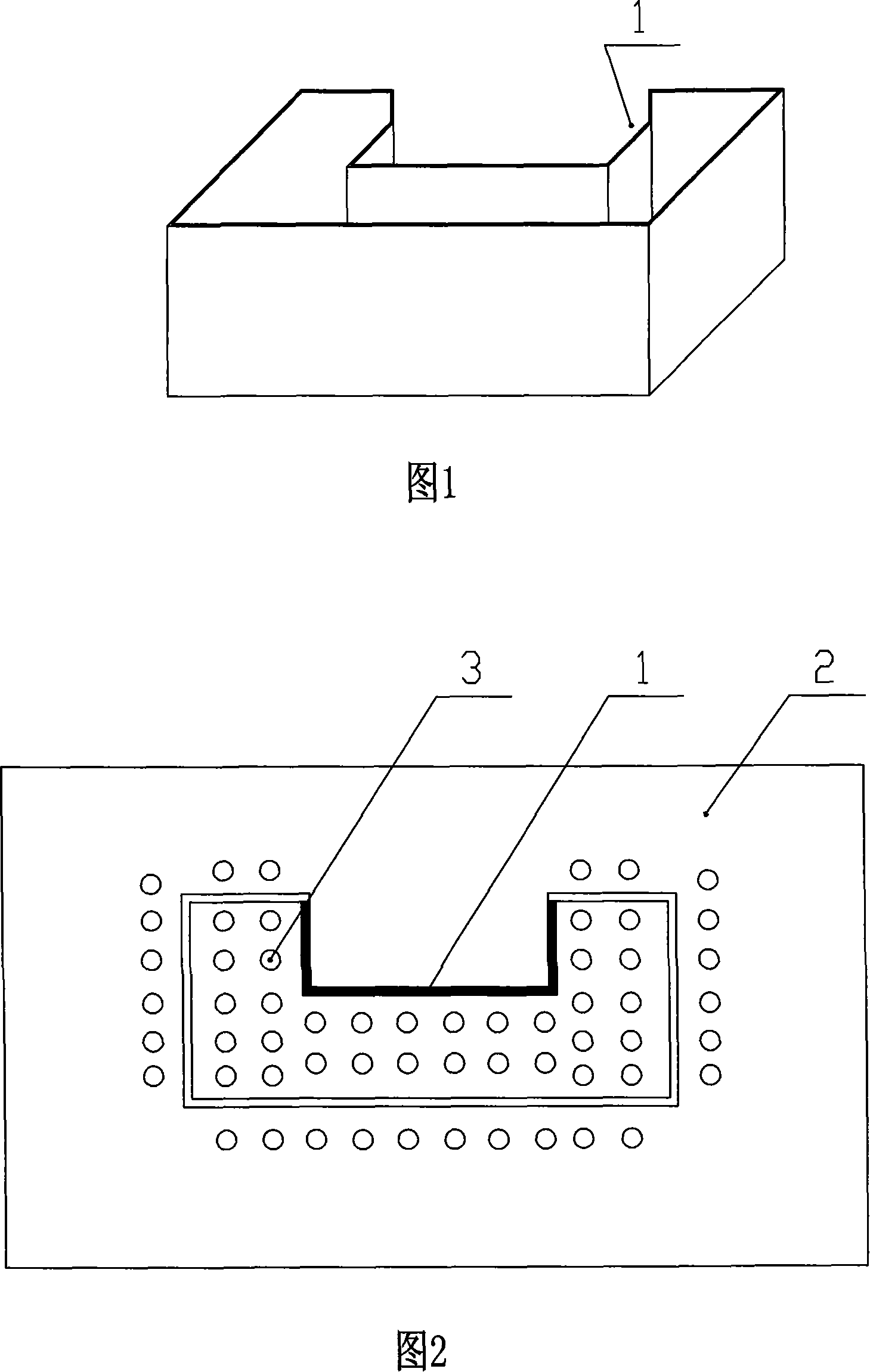

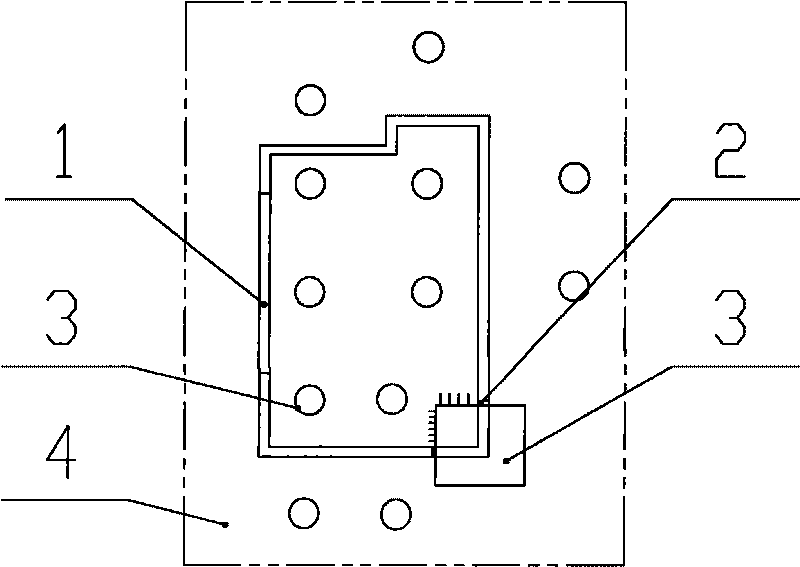

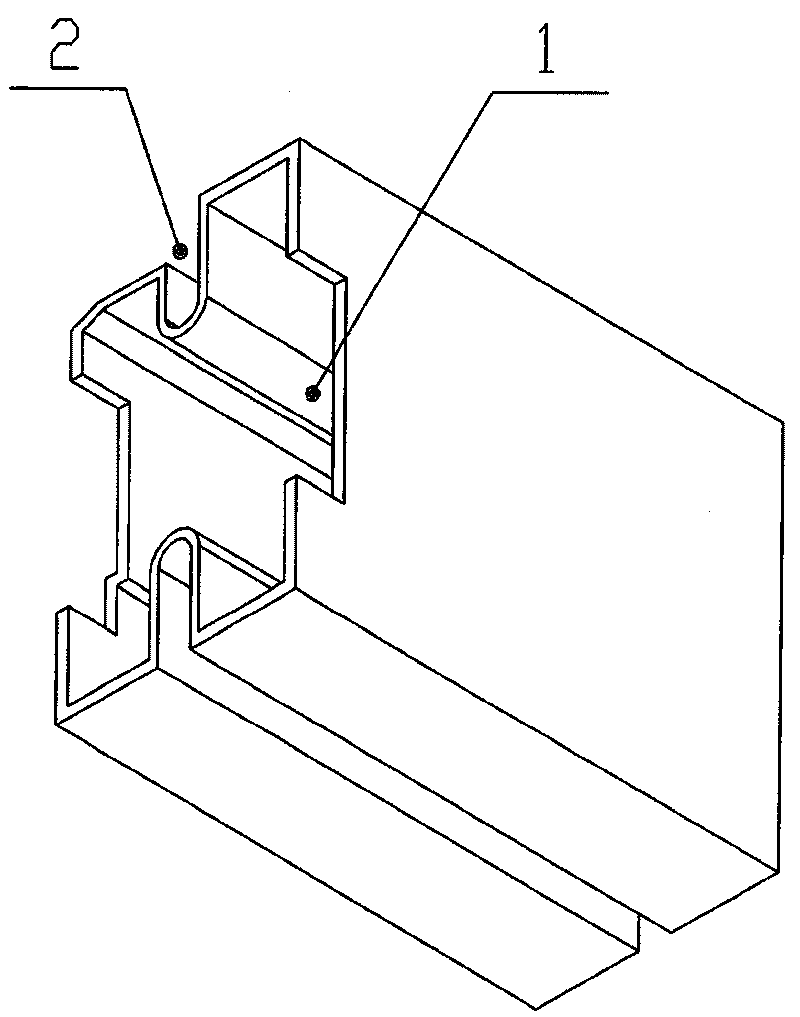

Avoidance pot mouth with tin retaining plate internally

InactiveCN101765330AChange directionDoes not affect soldering qualityPrinted circuit assemblingSolderingEngineering

The invention relates to a solder pot component used for tin soldering of a PCBA board, in particular to an avoidance pot mouth with a tin retaining plate internally. The pot mouth is of a rectangle mouth structure; the edge of the pot mouth is provided with a tin overflow opening and a tin retaining plate folded inward; and the tin overflow opening is a rectangle opening and has a depth of between 3 and 6mm. The avoidance pot mouth with the tin retaining plate internally has simple structure, can effectively improve the soldering efficiency, is suitable for large-scale automation production, and also effectively prevents an oxide layer on the surface layer of the tin liquor from leaving on the surface of the PCBA board so as to guarantee the quality of the soldering joint.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

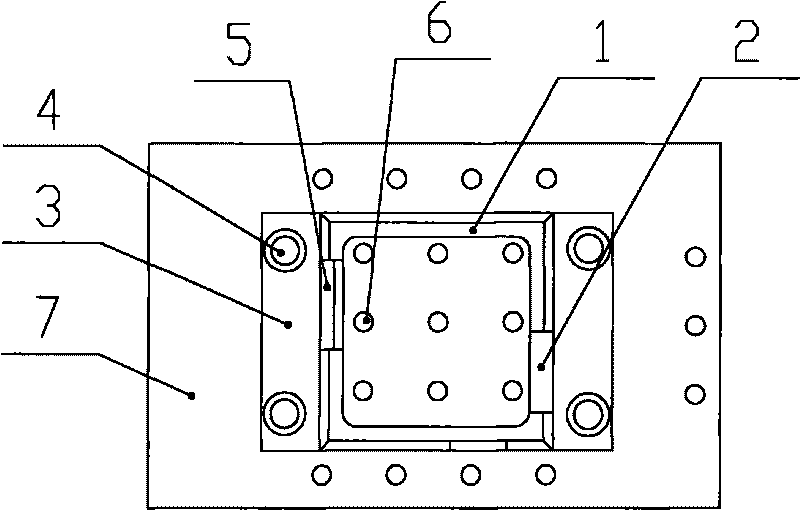

Fixed kettle mouth

InactiveCN101765321AChange directionDoes not affect soldering qualityPrinted circuit assemblingEngineeringSoldering

The invention relates to a solder stove component for soldering tin of PCBA plates, in particular to a fixed kettle mouth, which is characterized in that the mouth of the kettle mouth is provided with a cylindrical jack, and at least one tin overflowing opening is arranged on the edge of the cylindrical jack; the tin overflowing opening is of a rectangular gap, and the depth of the opening is 3 to 6mm; a tin overflowing inclined surface is arranged on the tin overflowing opening, and a base is arranged at the bottom of the cylindrical jack; and kettle mouth fixing holes are arranged on the base. The invention has simple structure, can effectively improve soldering efficiency, is suitable for large-scale automatic production, effectively prevents the oxide surface of a tin liquid surface layer from be remained on the surface of the PCBA plate, and ensures the quality of soldering contacts.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

Stannum export of stannum furnace

InactiveCN101179905AChange directionDoes not affect soldering qualityMultilayer circuit manufactureSolderingSurface layer

The invention relates to a tin furnace part of PCBA board soldering tin, in particular a tin outlet of a tin furnace. The invention is arranged above a tin bath and leads molten tin produce tin waves at the tin outlet for soldering operation. The periphery of the tin outlet has at least a tin spill-way which is a rectangle opening with a depth H of 2mm to 8mm.The invention has a simple structure and is capable of effectively increasing soldering efficiency and is applicable for large-scale automatic production; furthermore, oxidation layer on molten tin surface layer is effectively prevented from being retained on the surface of the PCBA board, and the quality of soldering spots is ensured.

Owner:苏州明杰自动化科技有限公司

Spilled stannum port with external stannum baffle type stannum export

InactiveCN101179902AChange directionFlow influenceMultilayer circuit manufactureSurface layerHeating furnace

The invention relates to a tin furnace part of PCBA board soldering tin, in particular a tin outlet of a tin furnace. The tin outlet is in a rectangle shape and is provided with at least a tin spill-way at the periphery, the two sides of which extend outward and has tin baffles of half-encircled structure. The tin spill-way is a rectangle opening with a depth of 2mm to 8mm. The invention has a simple structure and is capable of protection for soldering elements near the periphery of tin spilling effectively and realizing optional soldering for elements of the PCBA board above the tin outlet. Furthermore, oxidation layer on molten tin surface layer is effectively prevented from being retained on the surface of the PCBA board, and the quality of soldering spots is ensured.

Owner:苏州明杰自动化科技有限公司

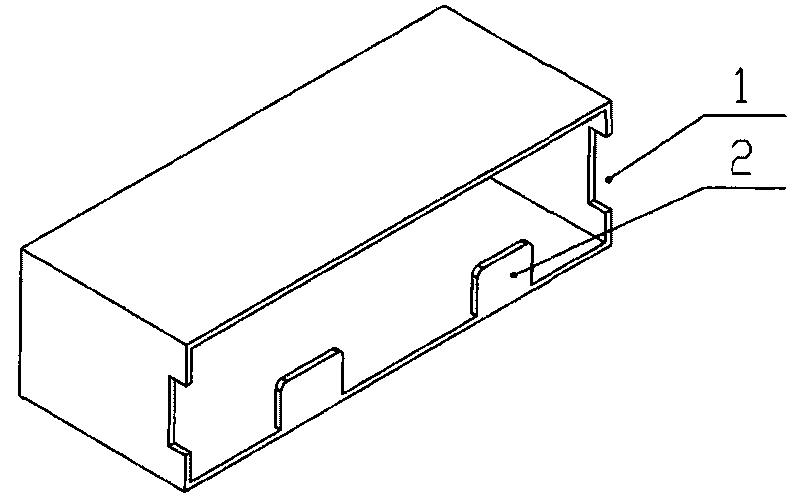

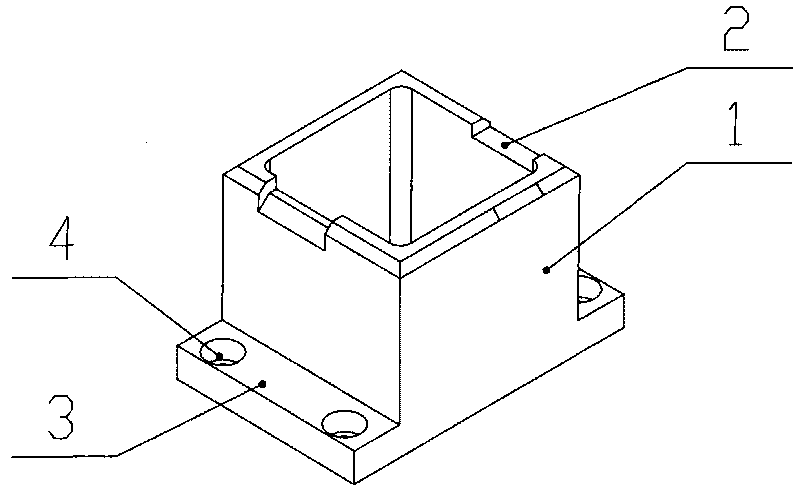

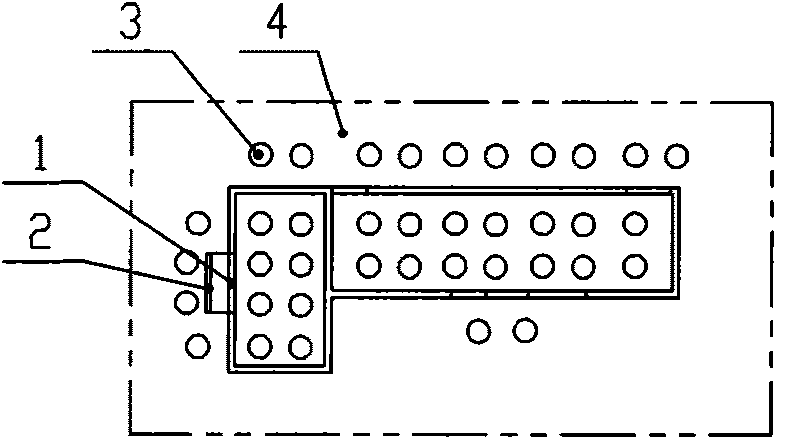

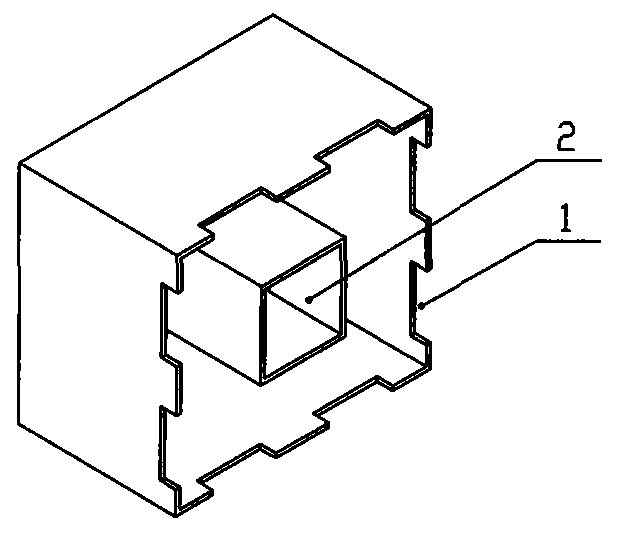

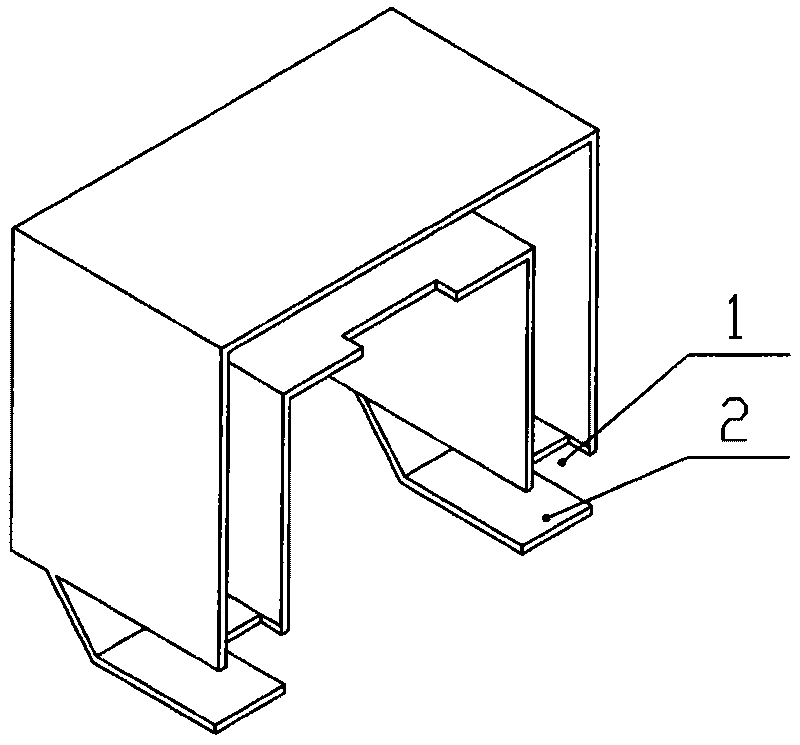

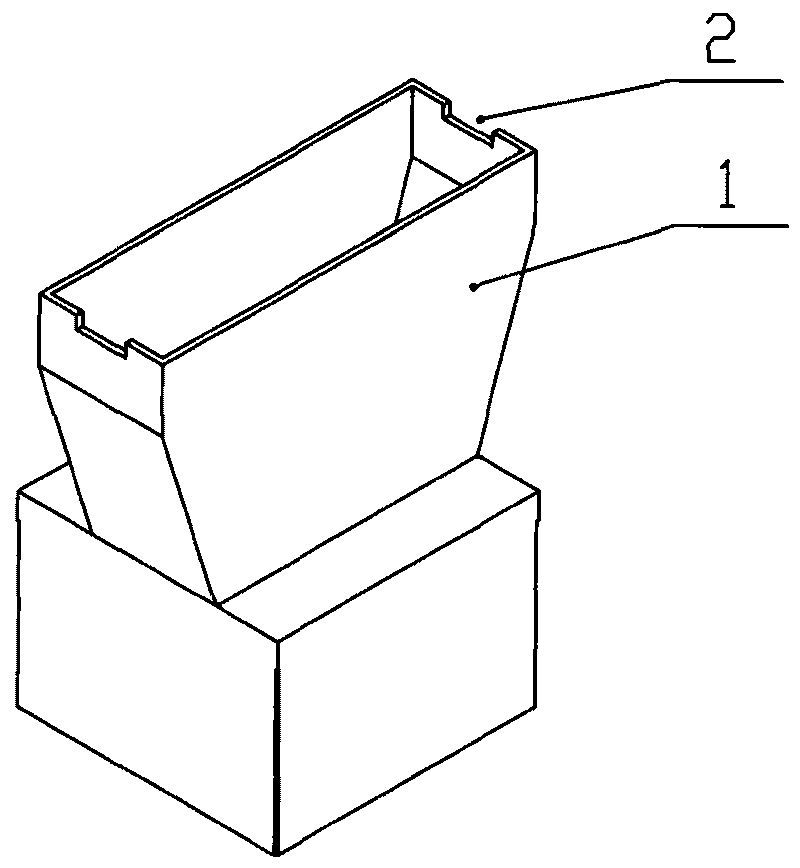

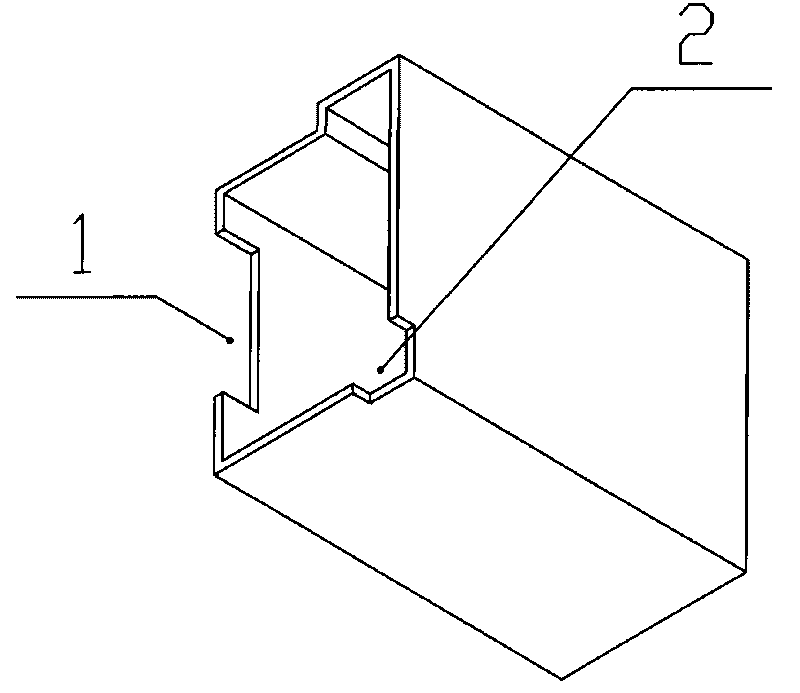

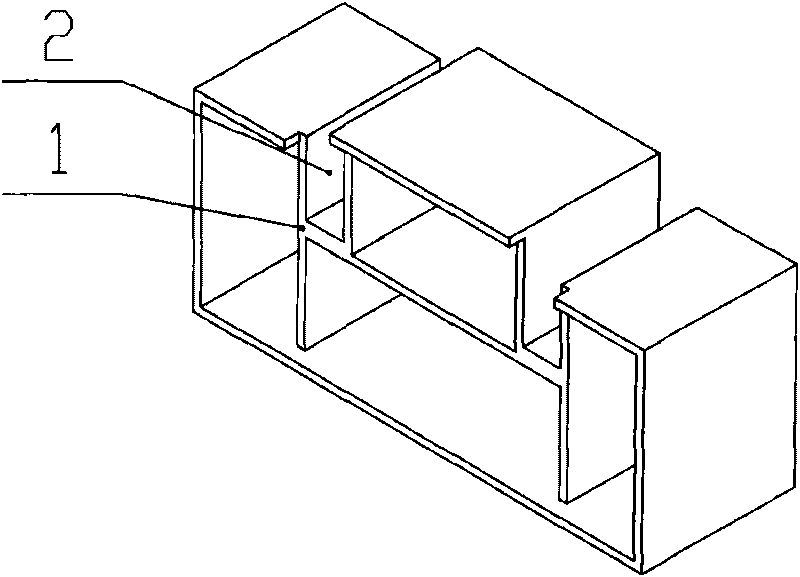

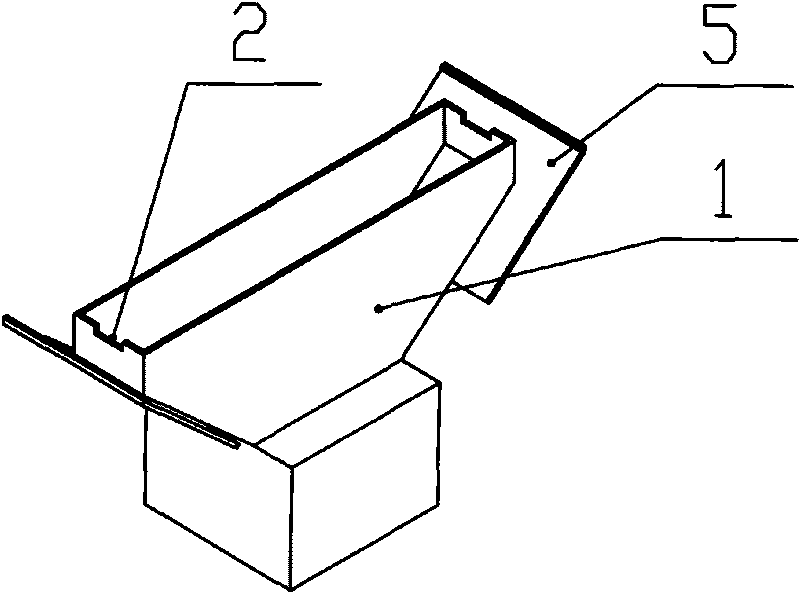

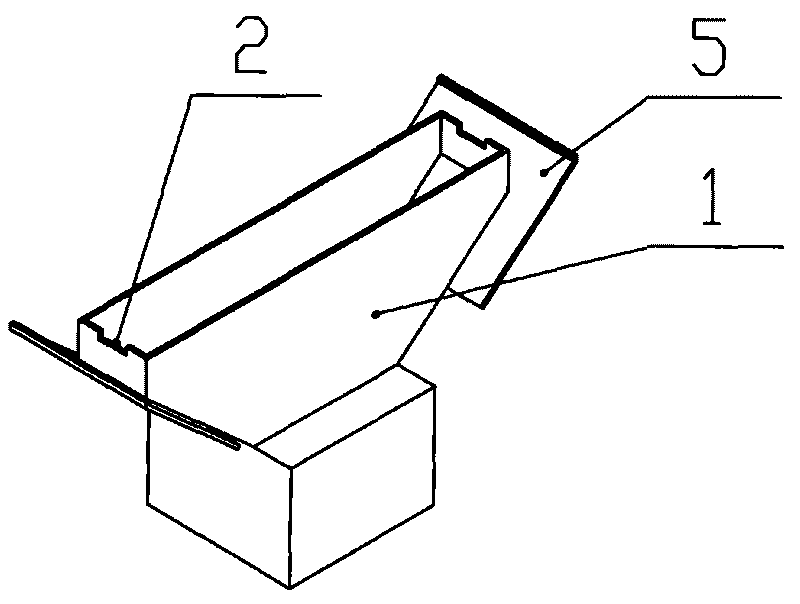

L-shaped upstream side flowing spout

InactiveCN101765322AChange directionDoes not affect soldering qualityPrinted circuit assemblingEngineeringSoldering

The present invention relates to a tin furnace component for the tin soldering of PCBA plates, in particular to an L-shaped upstream side flowing spout. Two spouts are split into an L-shaped structure. A tin overflow port is arranged at the edge port of the L-shaped upstream side flowing spout. A stopping edge is arranged at the front side of the tin overflow port, and spout side walls at the lower end of the stopping edge are fixedly connected. The tin overflow port is a rectangular breach, and the depth is three to six mm. The structure of the present invention is simple, and the welding rate can be effectively improved. The tin furnace component for the tin soldering of PCBA plates is suitable for large-scale automation production. In addition, oxide layers on tin liquid surface layers are avoided to remain on the surfaces of the PCBA plates, and the quality of welding joints is ensured.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

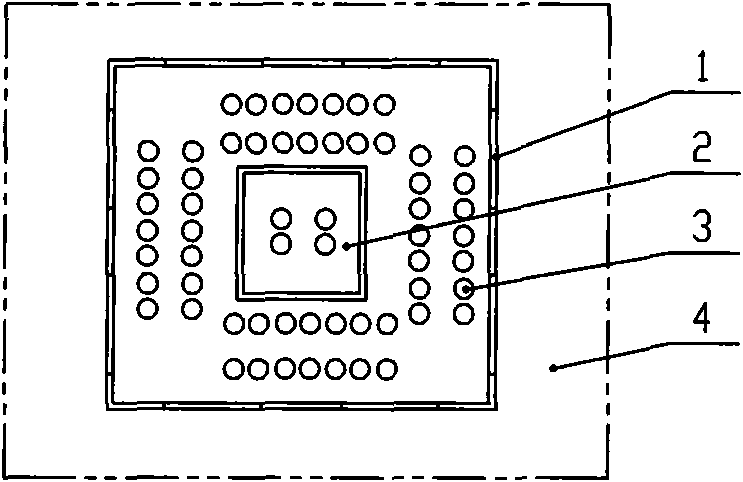

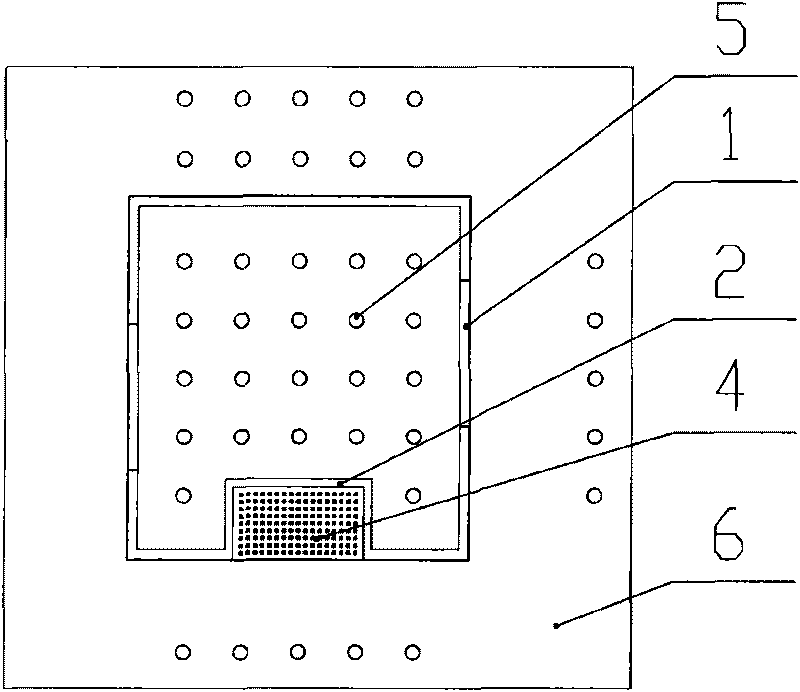

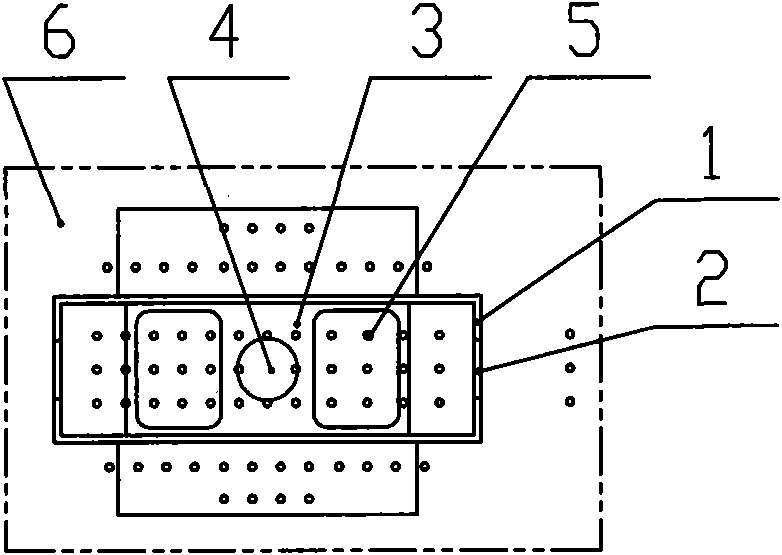

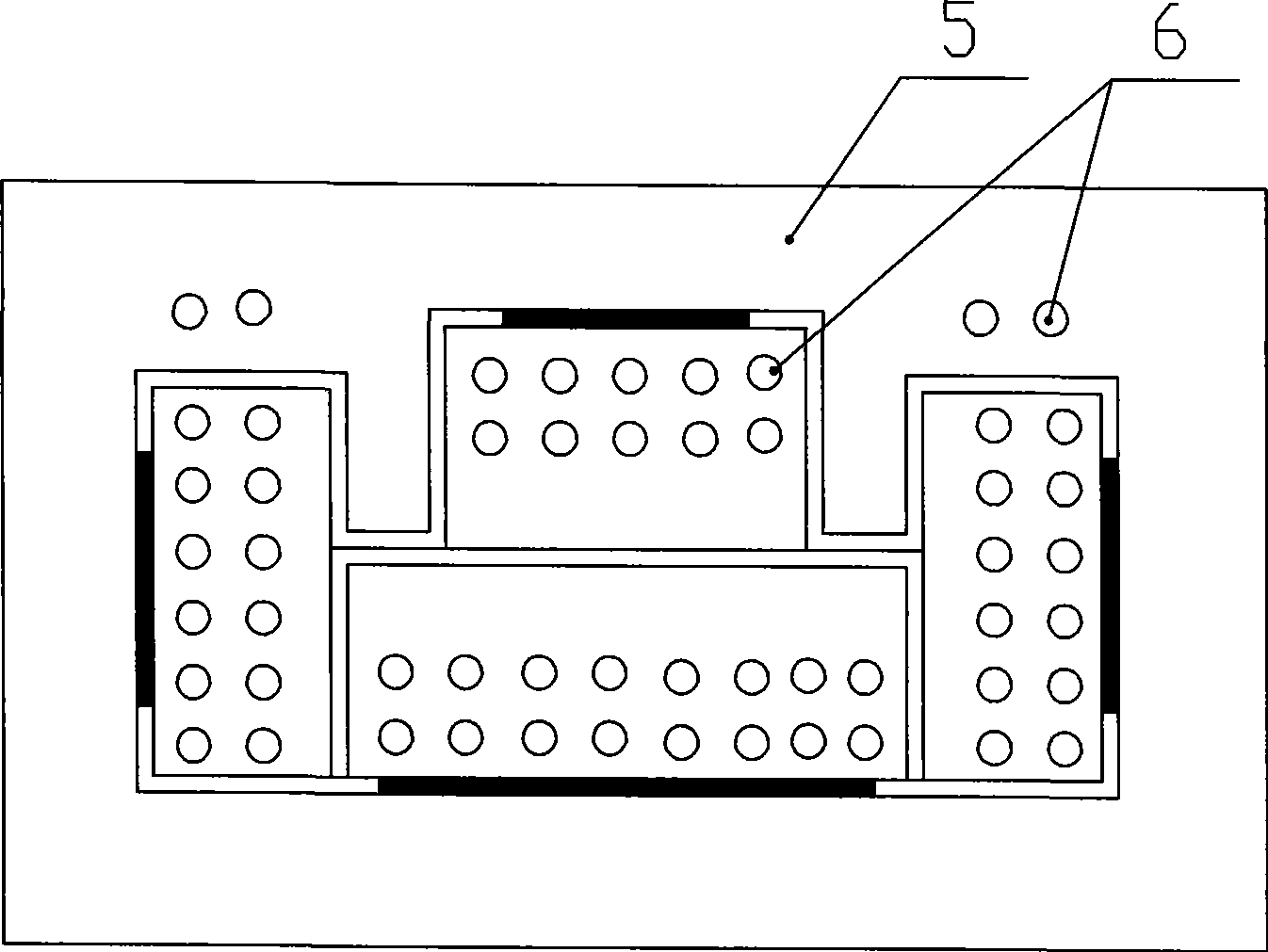

External flow four-opening type pot opening

InactiveCN101765332AChange directionDoes not affect soldering qualityPrinted circuit assemblingSurface layerEngineering

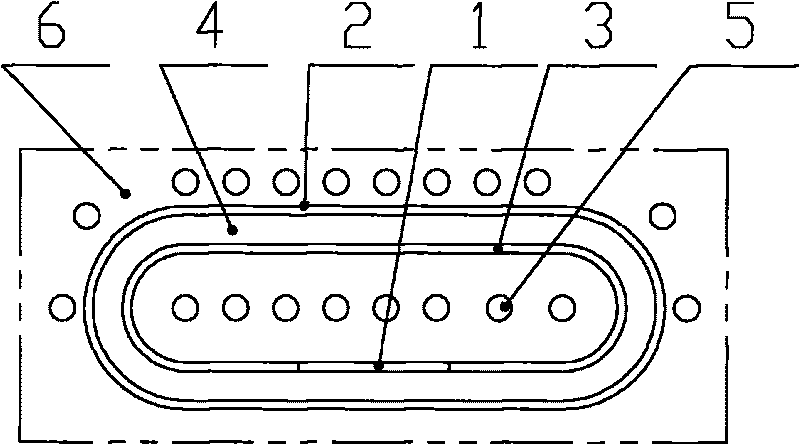

The invention relates to a tin furnace component used for PCBA board soldering tin, in particular to an eternal flow four-opening type pot opening. A part shielding hole is formed in the middle, a tin overflowing opening is arranged along the periphery of the opening at the outer periphery of the pot opening, and tin overflowing opening is a rectangular notch with the depth between 3 and 6 mm. The invention has a simple structure, can effectively improve the welding efficiency, and is suitable for large-scale automatic production, in addition, an oxide layer of the surface layer of the tin liquid is effectively prevented from being remained on the surface of a PCBA board, and the quality of welding points is ensured.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

Tin-overflowing pot having flange on side walls

InactiveCN101765323AChange directionDoes not affect soldering qualityPrinted circuit assemblingSolderingEngineering

The invention relates to a tin furnace parts used for PCBA plate soldering tin, in particular to a tin-overflowing pot having a flange on side walls. The pot has a semi-circling structure; an avoiding slot is formed on the middle part; a tin-overflowing opening is arranged on the edge of the pot; the flange is arranged in front of the tin-overflowing opening; the lower end of the flange is fixedly connected with the side wall of the pot; the tin-overflowing opening is a rectangular opening, the depth of which is ranged between 3 and 6 mm; and a tin-overflowing hole is a rectangular hole. The invention has simple structure, can efficiently promote the welding efficiency, is fit for large-scale automatic production, efficiently prevents the oxide layer on the tin liquid surface from remaining on the surface of the PCBA plate and ensures the welding quality.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

Sheet type spout for avoidance of grounding block element

InactiveCN101765316AChange directionDoes not affect soldering qualityPrinted circuit assemblingEngineeringSoldering

The invention relates to a component of a soldering furnace for tin soldering of a PCBA board, in particular to a sheet type spout for avoidance of a grounding block element for welding a computer motherboard. The edge of the spout is provided with at least one tin overflow port, the tin overflow port is a rectangular opening and is 3-4mm deep; the side wall of the spout is concave inwards to form an avoidance ring for accommodating a grounding block, and the outer wall of the spout below the avoidance ring is provided with a rectangular tin overflow hole. The invention has simple structure, can effectively improve the welding efficiency, and is applicable to large-scale automated production. In addition, the invention can effectively prevent the oxide layer on the tin liquid surface from being left on the surface of the PCBA board, thereby ensuring the quality of the welding joint.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

One-side single open kettle mouth with tin overflow mouth length

InactiveCN101150926AChange directionDoes not affect soldering qualityPrinted circuit assemblingSolderingLiquid surfaces

The invention relates to a tin furnace component used to PCBA board soldering tin, in particular to a tin furnace kettle orifice. The kettle orifice has a rectangular shape, at least one tin overflow outlet is arranged on a long edge of the rectangle edges, the tin overflow outlet is a rectangular opening, the deepness is 2-8mm. The invention has a simple structure, can improve the soldering efficiency, is suitable for mass automatic production, in addition, effectively prevents an oxide layer of the tin liquid surface from remaining on the PCBA board, assures the welding joint quality.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

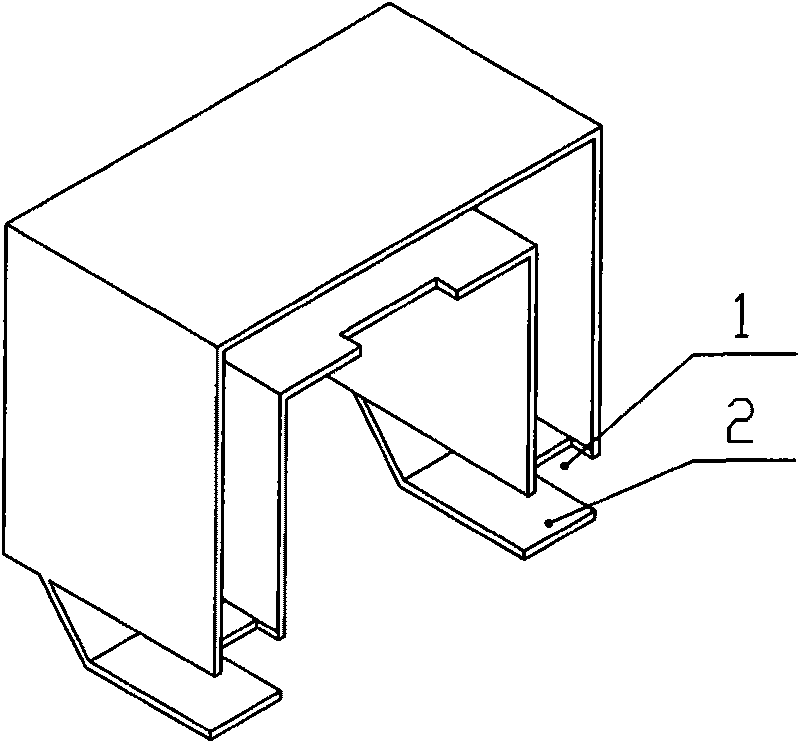

Fixed insertion type pot mouth

InactiveCN101765327AChange directionDoes not affect soldering qualityPrinted circuit assemblingEngineeringSoldering

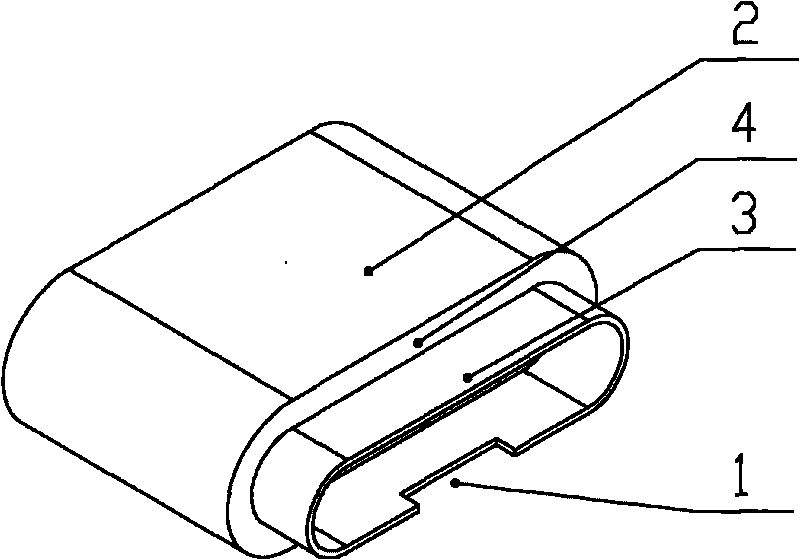

The invention relates to a tin stove component used for PCBA plate soldering tin, in particular to a fixed insertion type pot mouth. The mouth part of the pot mouth is provided with a conical faucet, the edge of the conical faucet is provided with at least a tin overflowing mouth which is a rectangular gap with the depth of 3 to 6 mm, a fixed plate is arranged at the inner wall of the pot mouth, and the fixed plate is provided with a fixing hole. The invention has simple structure, can effectively increase the welding efficiency and is suitable for large-scale automatic production, and additionally, an oxide layer on the tin liquid surface is effectively prevented from being left on the surface of a PCBA plate, and the quality of welding joints is ensured.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

One-side dual open kettle mouth with tin overflow mouth length

InactiveCN101150929AChange directionDoes not affect soldering qualityPrinted circuit assemblingSolderingLiquid surfaces

The invention relates to a tin furnace component used to PCBA board soldering tin, in particular to a tin furnace kettle orifice. The kettle orifice has a rectangular shape, each long edge of the rectangle edges is provided with a tin overflow outlet respectively, the tin overflow outlet is rectangular opening, the deepness is 2-8mm. The invention has a simple structure, can improve the soldering efficiency, is suitable for mass automatic production, in addition, effectively prevents an oxide layer of the tin liquid surface from remaining on the PCBA board, assures the welding joint quality.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

A tin overflow concave internal open kettle mouth

InactiveCN101150920AEnsure sufficiency and firmnessChange directionPrinted circuit assemblingSolderingOxide

The invention relates to a tin furnace component used to PCBA board soldering tin, in particular to a tin furnace kettle orifice. The kettle orifice has a concave shape, a tin overflow orifice is arranged at the concave tin outlet of the kettle orifice, the tin overflow orifice is a rectangular opening, the deepness is 2-8mm. The invention has a simple structure, can improve the soldering efficiency, is suitable for mass automatic production, in addition, effectively prevents an oxide layer of the tin liquid surface from remaining on the PCBA board, assures the welding joint quality.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

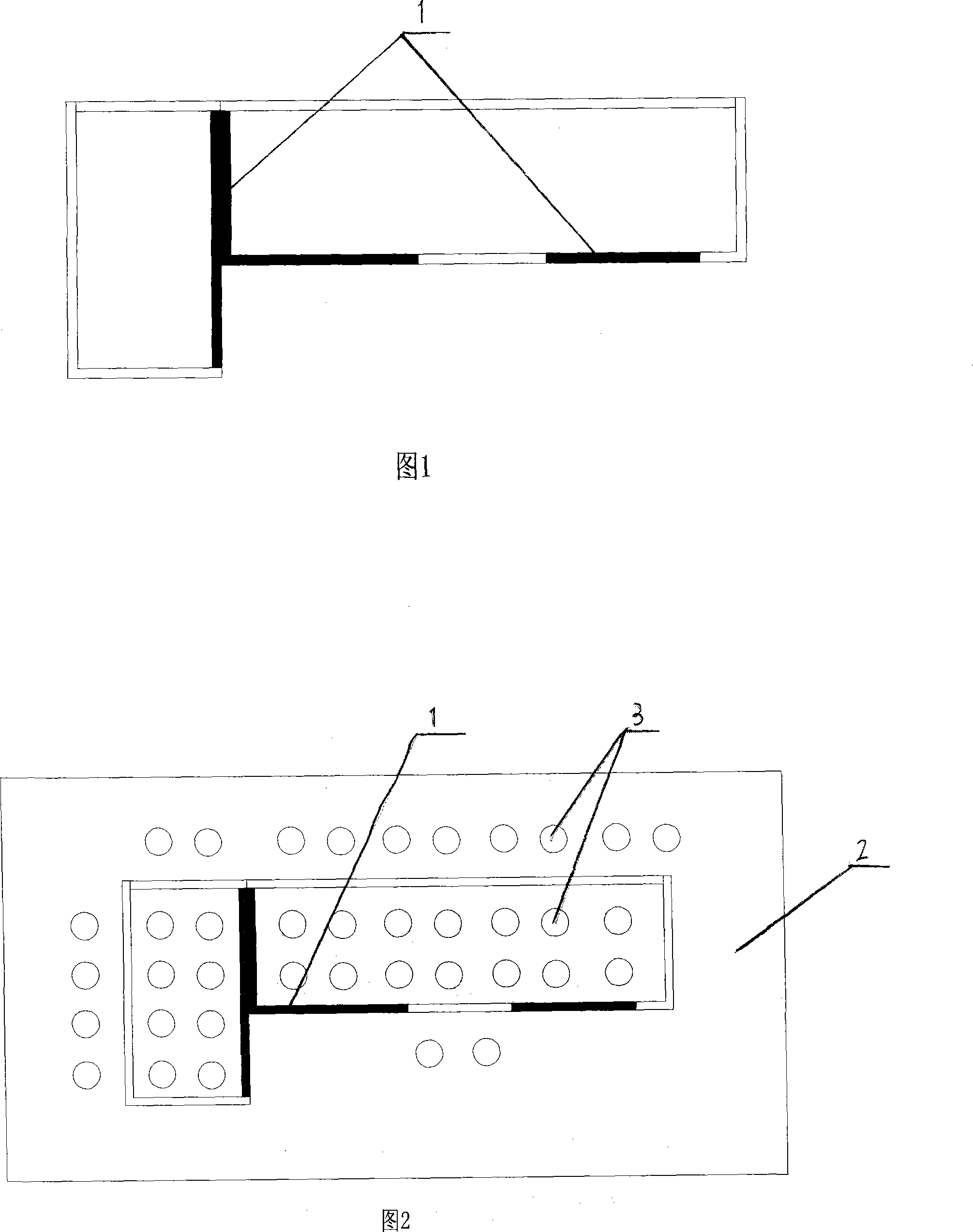

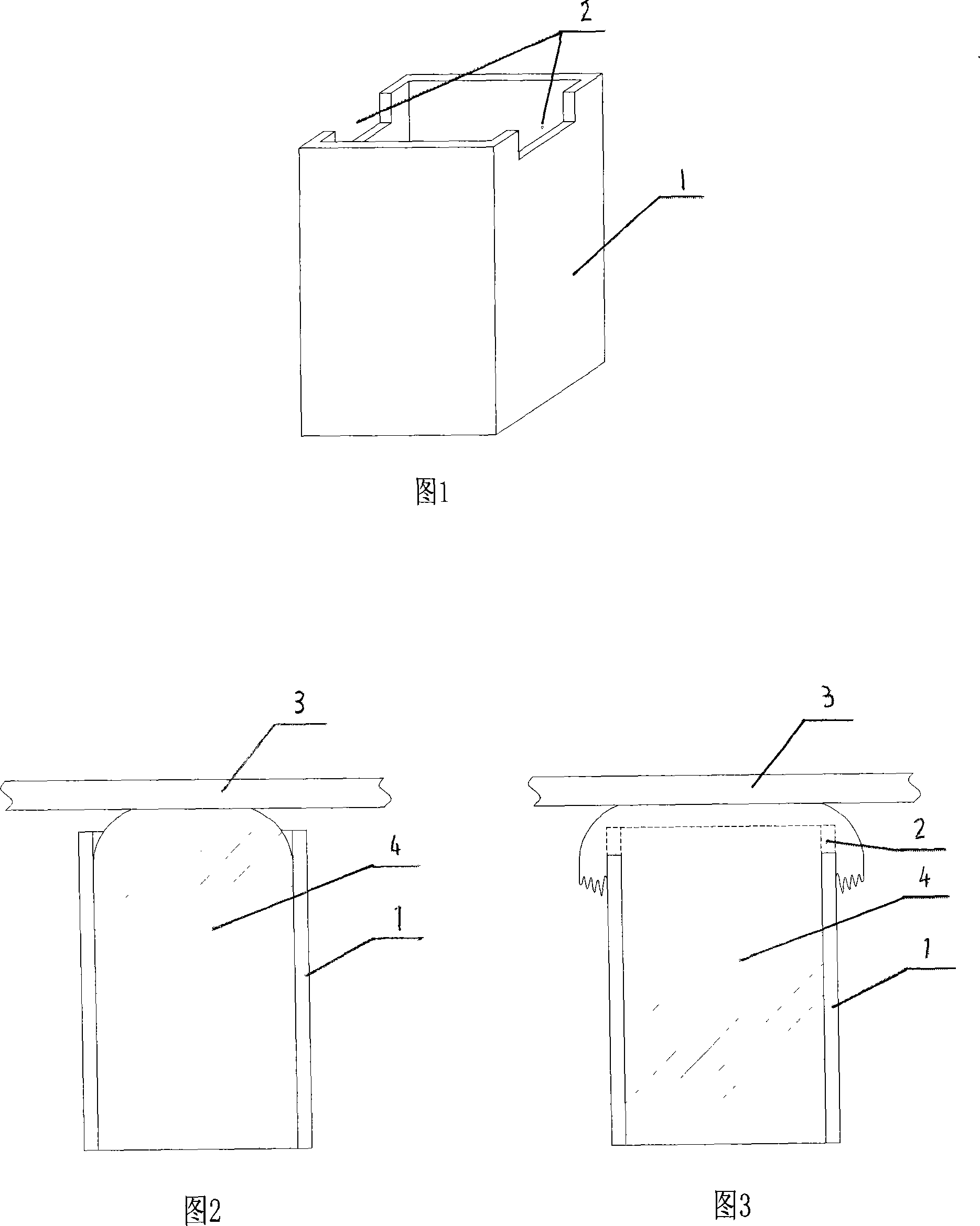

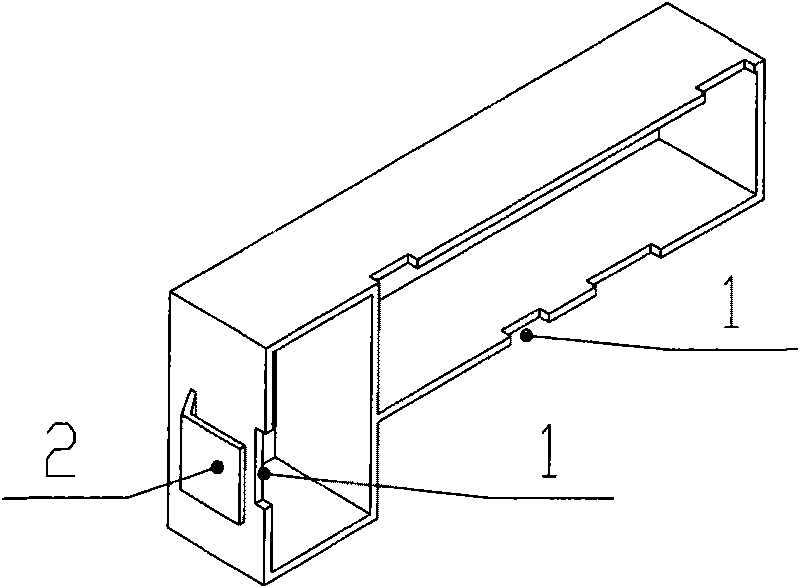

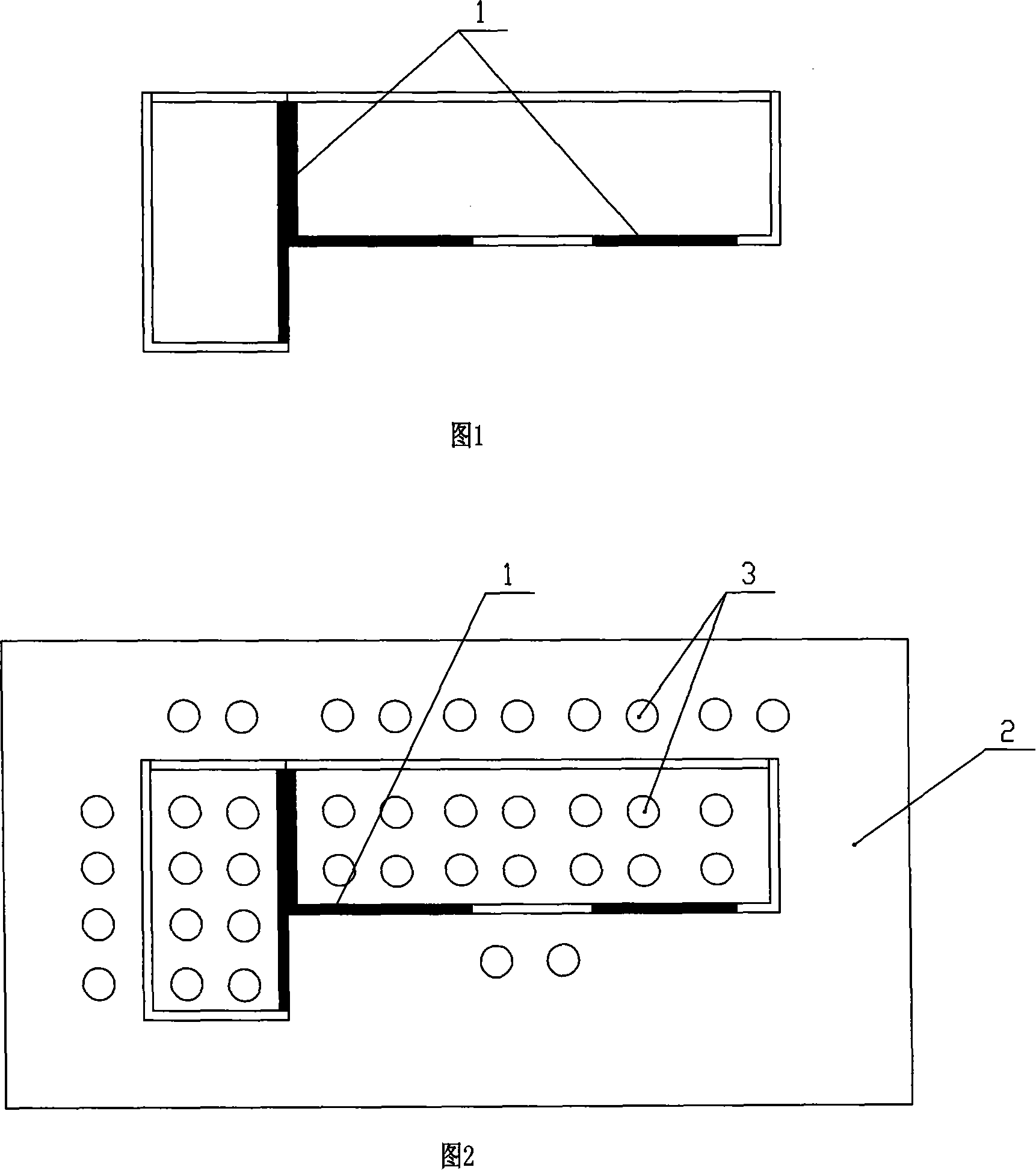

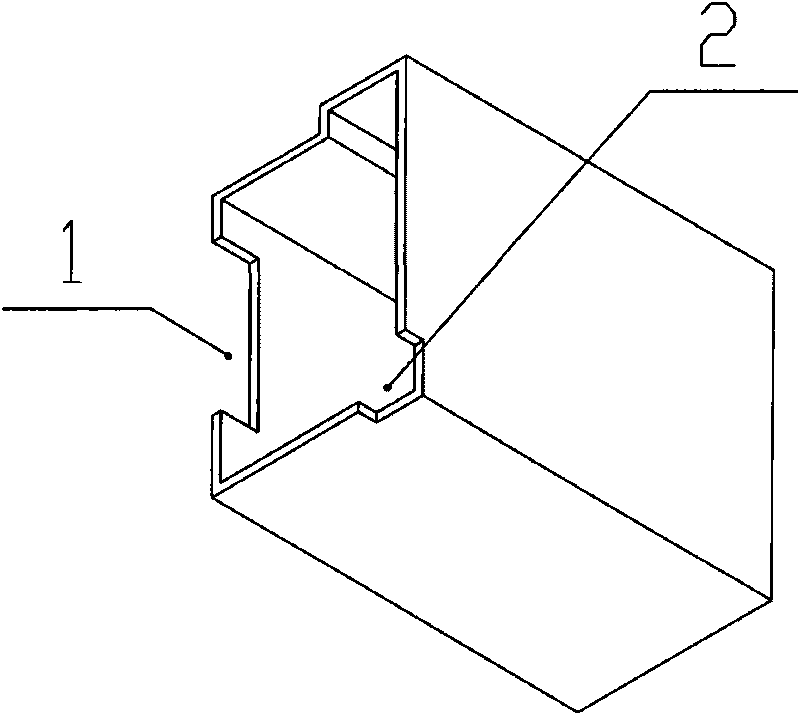

A tin overflow internal open L kettle mouth

InactiveCN101150918AEnsure sufficiency and firmnessChange directionPrinted circuit assemblingSolderingOxide

The invention relates to a tin furnace component used to PCBA board soldering tin, in particular to a tin furnace kettle orifice. Two rectangular kettle orifice ends are connected to be a 'L' shape, a tin overflow orifice is arranged at the tin outlet of the inner side of the 'L' shaped kettle orifice, the tin overflow orifice is a rectangular opening, the deepness is 2-8mm. The invention has a simple structure, can improve the soldering efficiency, is suitable for mass automatic production, in addition, effectively prevents an oxide layer of the tin liquid surface from remaining on the PCBA board, assures the welding joint quality.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

Plug-in type spout

InactiveCN101765304AChange directionDoes not affect soldering qualityPrinted circuit assemblingEngineeringSoldering

The invention relates to a tin furnace component for tin soldering of a PCBA, in particular to a plug-in type spout of a tin furnace. A tapered spigot is arranged at the opening part of the spout, and at least one tin overflow hole is arranged at the rim of the tapered spigot. The tin overflow hole is rectangular, and the depth is within 3 to 4mm. The plug-in type spout has the following characteristics: the structure is simple and the welding efficiency can be effectively increased; moreover, the plug-in type spout is suitable for automatic mass production, effectively avoids an oxidation layer of a tin liquid surface layer from being left over on the surface of the PCBA, and ensures the quality of welding points.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

Two-sided straddle type and part-avoiding type spout

InactiveCN101765312AChange directionDoes not affect soldering qualityPrinted circuit assemblingSurface layerInduction motor

The invention relates to a tin furnace component for soldering tin of PCBA plates, in particular to a two-sided straddle type and part-avoiding type spout for the PCBA plates of magnetic induction motors. The spout is in a rectangular shape, wherein at least one rectangular edge is provided with a tin overflow opening; a part straddle opening is arranged on a break angle of the spout; and the tin overflow opening is a rectangular breach of which the depth is between 3 and 4 millimeters. The two-sided straddle type and part-avoiding type spout has a simple structure, can effectively improve the welding efficiency, and is suitable for large-scale automatic production; and in addition, the two-sided straddle type and part-avoiding type spout effectively prevents an oxidation layer of a surface layer of tin liquid from remaining on the surfaces of the PCBA plates, and ensures the quality of welding contacts.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

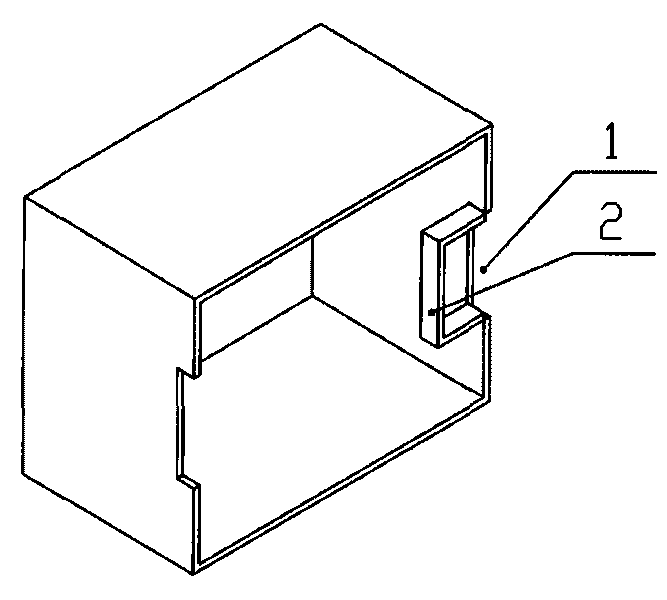

Spilled stannum port with external L-shaped stannum export

InactiveCN101179903AChange directionDoes not affect soldering qualityMultilayer circuit manufactureSurface layerSoldering

The invention relates to a tin furnace part of PCBA board soldering tin, in particular a tin outlet of a tin furnace. Two rectangle ends of the tin outlet are firmly connected with each other into an L-shape. The tin outlet on the lateral side of the tin outlet in L-shape is provided with a tin spill-way which is a rectangle opening with a depth of 2mm to 8mm.The invention has a simple structure and is capable of effectively increasing soldering efficiency and is applicable for large-scale automatic production; furthermore, oxidation layer on molten tin surface layer is effectively prevented from being retained on the surface of the PCBA board, and the quality of soldering spots is ensured.

Owner:苏州明杰自动化科技有限公司

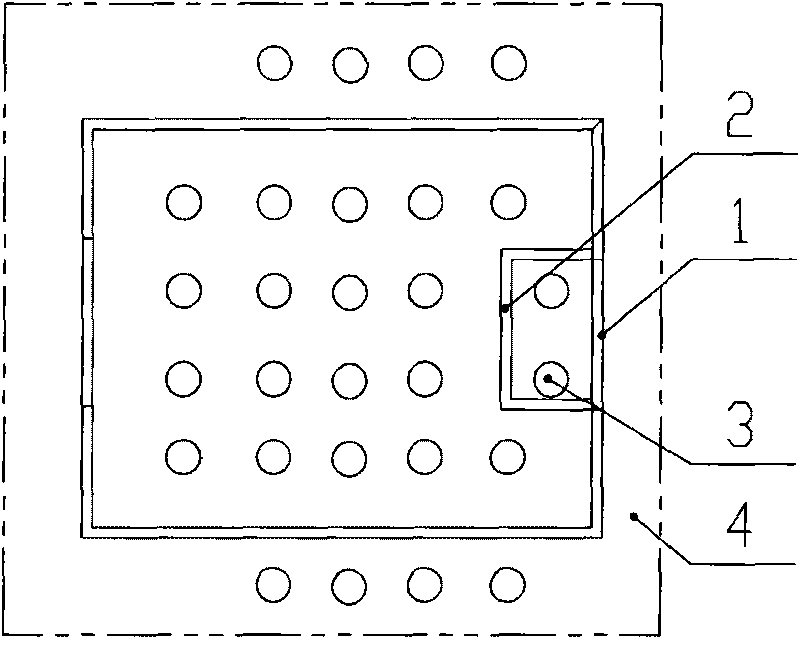

An open kettle mouth at tin overflow corner

InactiveCN101150927AChange directionDoes not affect soldering qualityPrinted circuit assemblingSolderingLiquid surfaces

The invention relates to a tin furnace component used to PCBA board soldering tin, in particular to a tin furnace kettle orifice. The kettle orifice has a rectangular shape, a tin overflow outlet 1 is arranged at least at one corner of the kettle orifice tin outlet, the tin overflow outlet 1 is a rectangular opening, the deepness is 2-8mm. The invention has a simple structure, can improve the soldering efficiency, is suitable for mass automatic production, in addition, effectively prevents an oxide layer of the tin liquid surface from remaining on the PCBA board, assures the welding joint quality.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

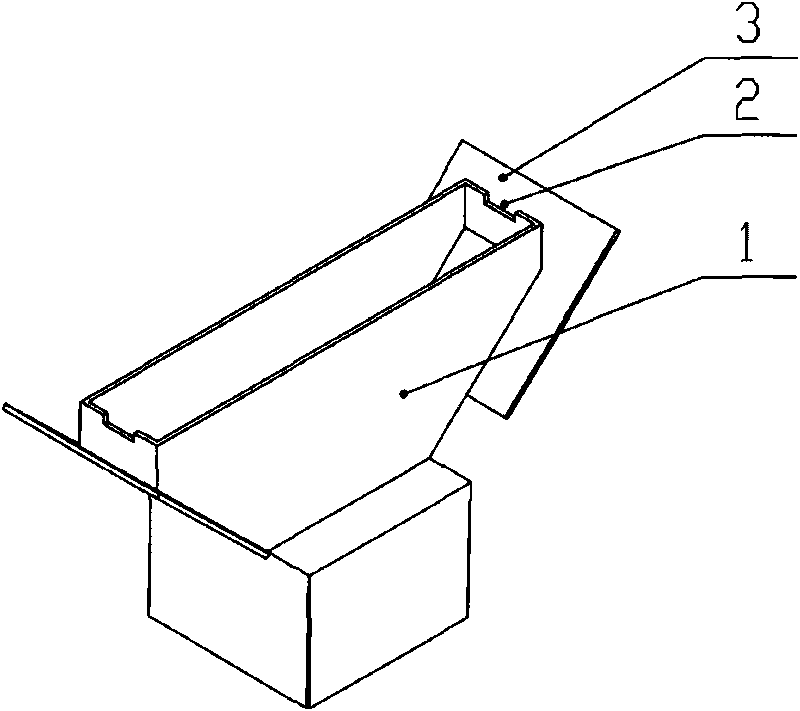

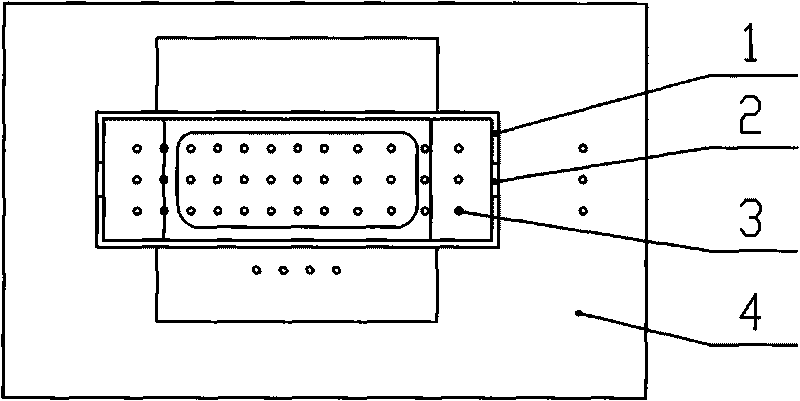

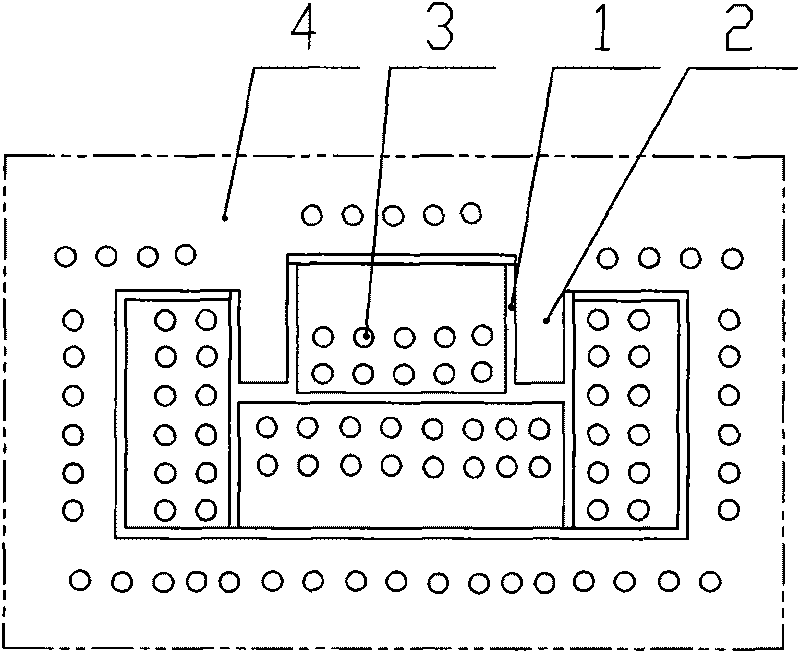

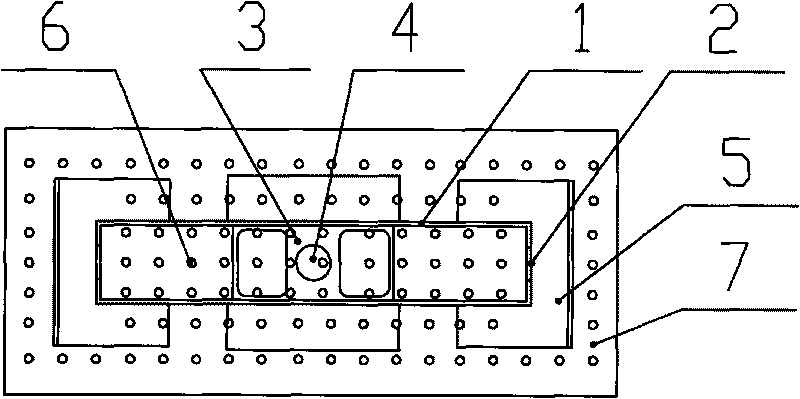

A tin overflow concave external open kettle mouth

InactiveCN101150921AChange directionDoes not affect soldering qualityPrinted circuit assemblingEngineeringSoldering

The invention relates to a tin furnace component used to PCBA board soldering tin, in particular to a tin furnace kettle orifice. The kettle orifice consists of a long and narrow rectangular main kettle orifice and at least two branch kettle orifices which are arranged fixedly on sides of the main kettle orifice, end kettle orifices are arranged at both ends of the main kettle orifice, a tin overflow outlet is arranged at the concave circumference which consists of two adjacent branch kettle orifices and the main kettle orifice, and a tin overflow is arranged at the joint of the main and branch kettle orifices, and at the connected surface of the end kettle orifices and the main kettle orifice respectively, the overflow orifice is a rectangular opening, the deepness is 2-8mm. The invention has a simple structure, can improve the soldering efficiency, is suitable for mass automatic production, in addition, effectively prevents an oxide layer of the tin liquid surface from remaining on the PCBA board, assures the welding joint quality.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

One face single open type stannum export of long spilled stannum port

InactiveCN101179904AChange directionDoes not affect soldering qualityMultilayer circuit manufactureSurface layerSoldering

The invention relates to a tin furnace part of PCBA board soldering tin, in particular a tin outlet of a tin furnace. The tin outlet is in a rectangle shape, and a long side on one side of the rectangle sides is provided with a tin spill-way which is a rectangle opening with a depth of 2mm to 8mm.The invention has a simple structure and is capable of effectively increasing soldering efficiency and is applicable for large-scale automatic production; furthermore, oxidation layer on molten tin surface layer is effectively prevented from being retained on the surface of the PCBA board, and the quality of soldering spots is ensured.

Owner:苏州明杰自动化科技有限公司

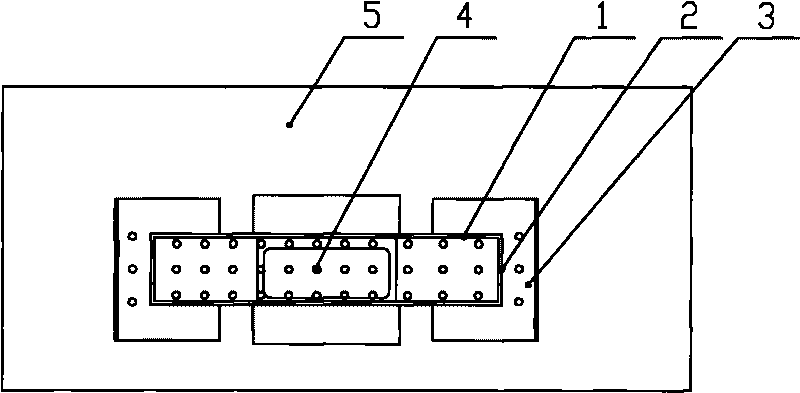

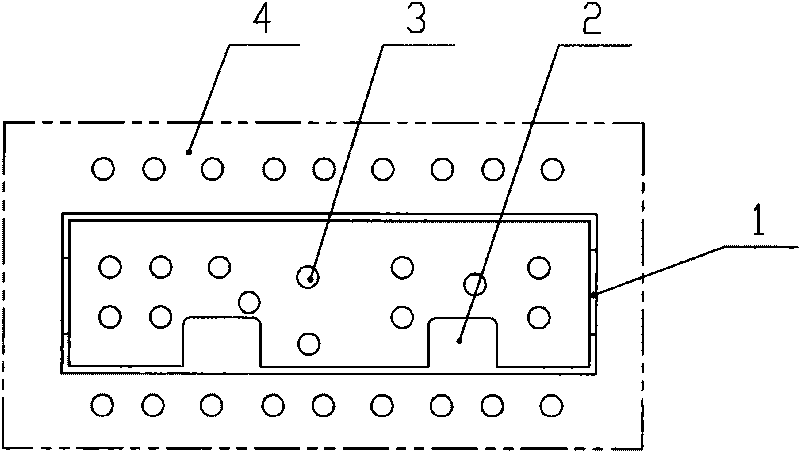

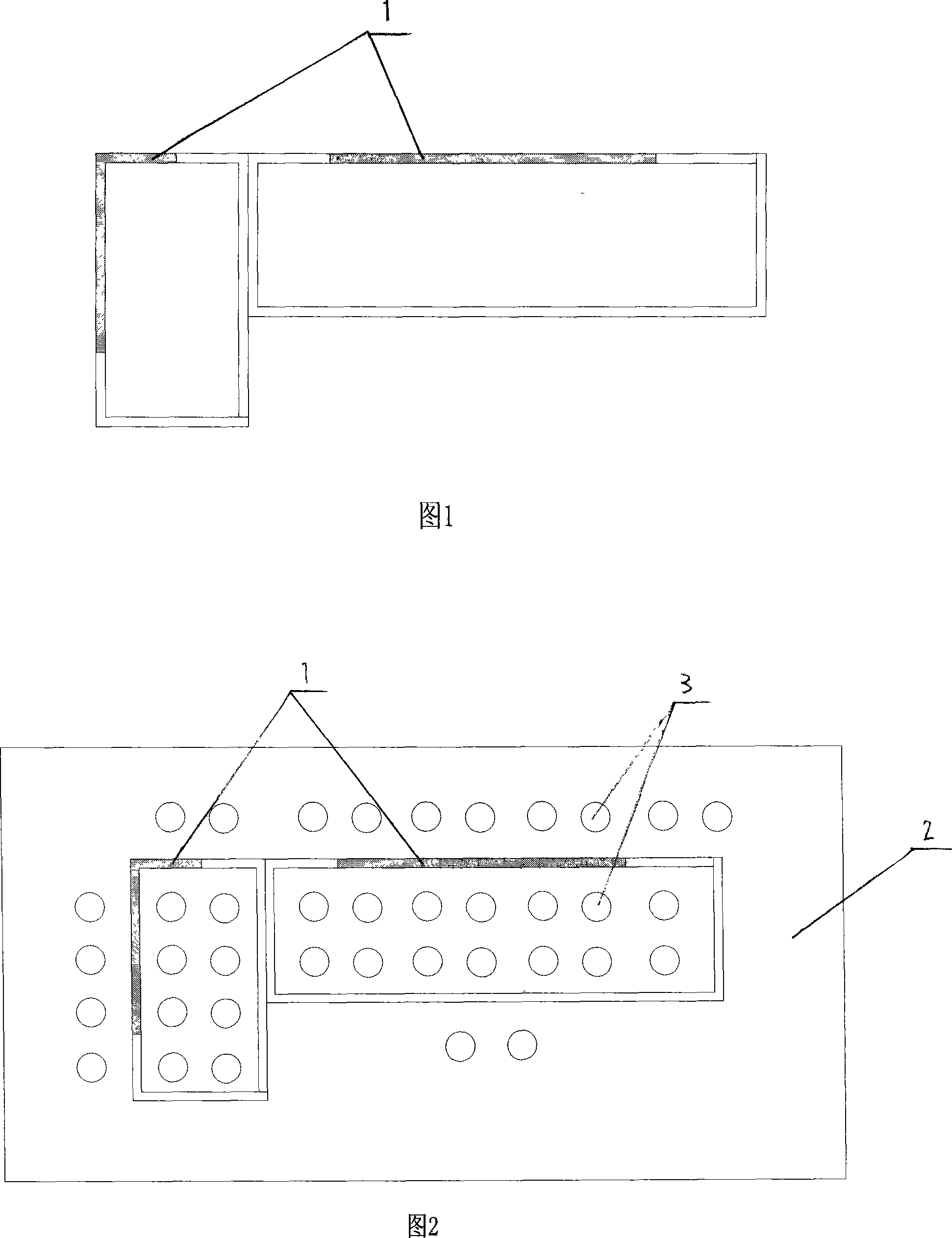

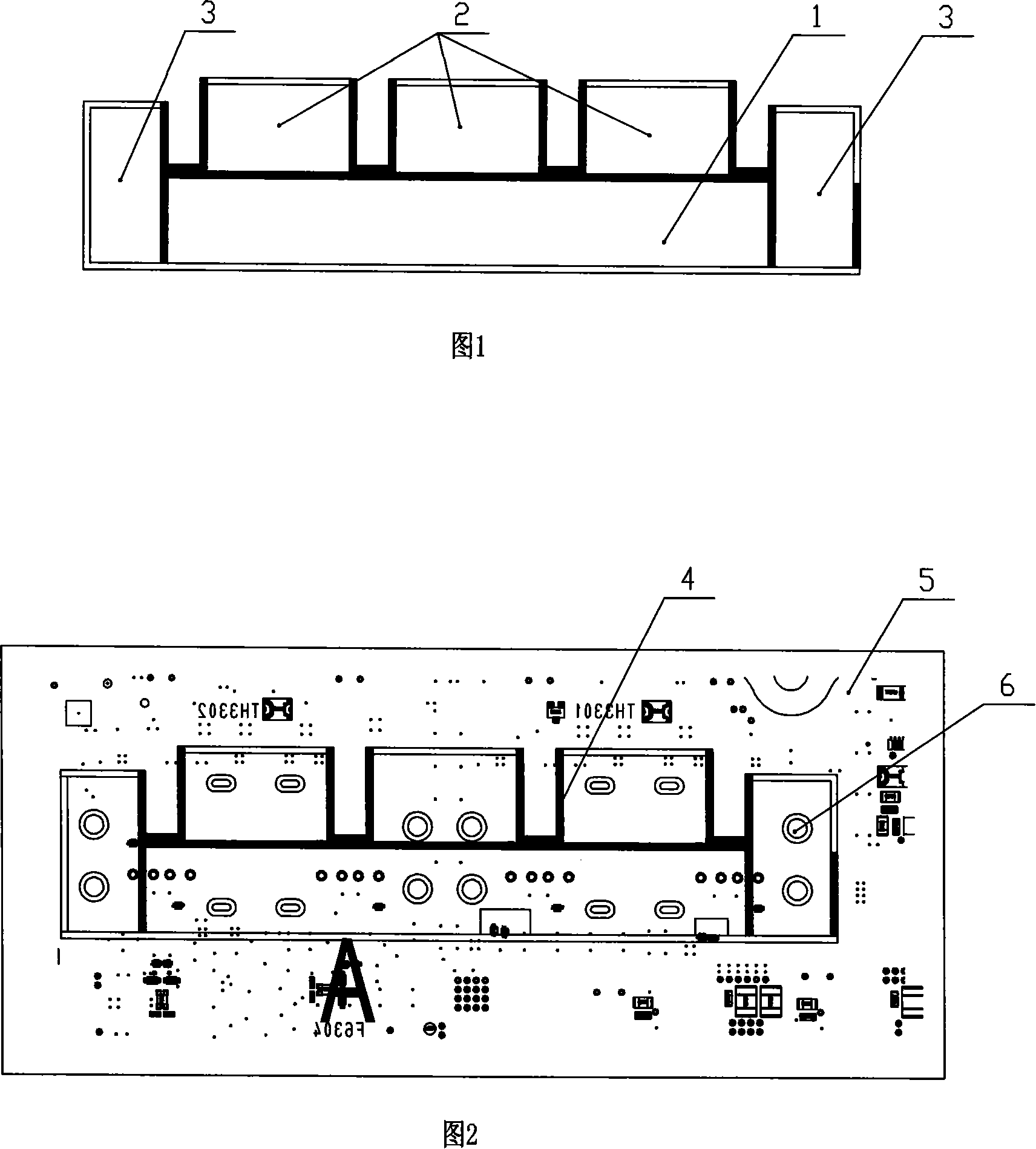

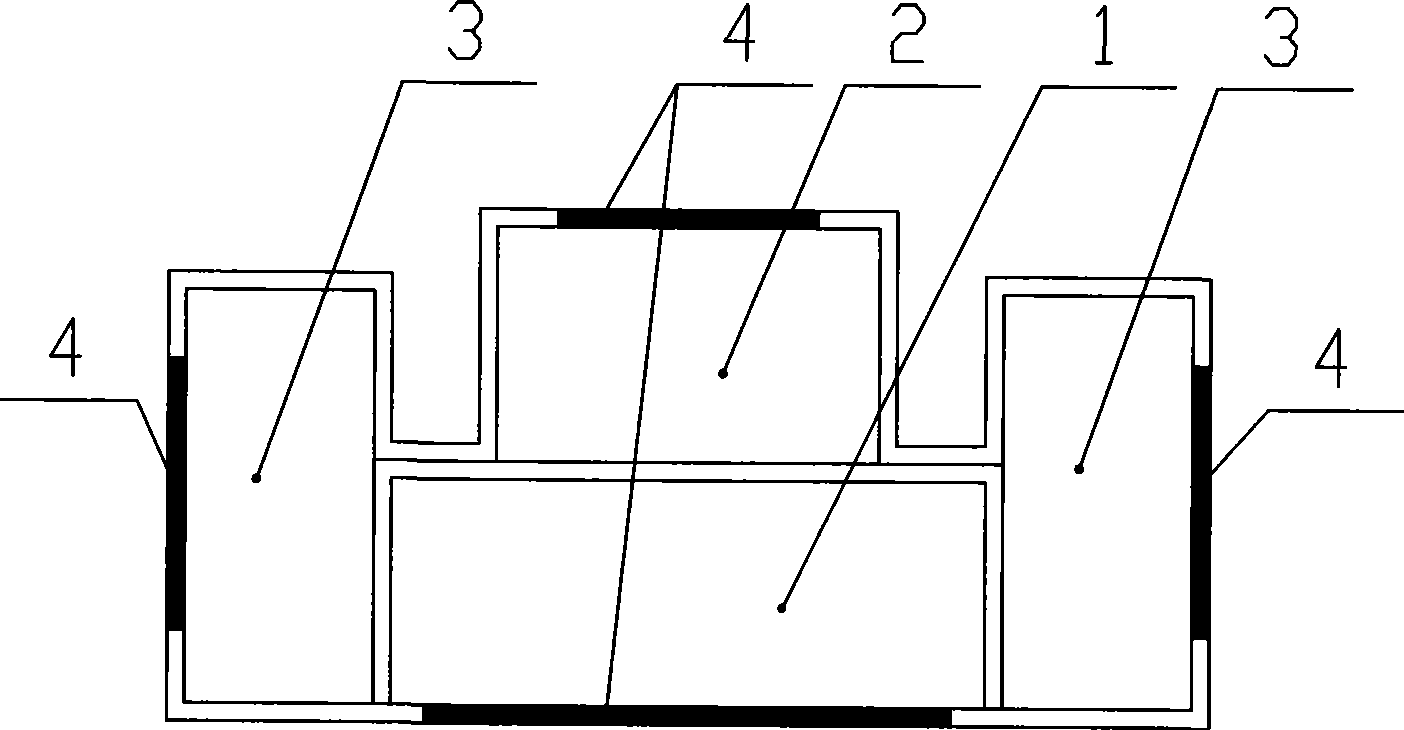

Internal opening full flow convex pot mouth

InactiveCN101765300AChange directionDoes not affect soldering qualityPrinted circuit assemblingSurface layerDip soldering

The invention relates to a solder pot component used for tin soldering of a PCBA board, in particular to an internal opening full flow convex pot mouth. Four rectangle pot mouths are spliced into an inverted m structure; the middle part is provided with a tin overflow tank, each joint of every two adjacent pot mouths and the edge of the tin overflow tank are provided with tin overflow openings; and the tin overflow openings are rectangle openings and have a depth of between 3 and 6mm. The internal opening full flow convex pot mouth has simple structure, can effectively improve the soldering efficiency, is suitable for large-scale automation production, and also effectively prevents an oxide layer on the surface layer of the tin liquor from leaving on the surface of the PCBA board to guarantee the quality of the soldering joint.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

Fixed plug-in pot opening with outer block

InactiveCN101765318AChange directionDoes not affect soldering qualityPrinted circuit assemblingEngineeringSoldering

The invention relates to a tin furnace part used for PCBA board soldering tin, in particular to a fixed plug-in pot opening with an outer block. The mouth of the pot opening is provided with a cone-shaped socket, the edge of the cone-shaped socket is provided with at least one tin-overflowing port, the inner wall of the pot opening is provided with a fixed plate with a fixed hole, and the outer side of the tin-overflowing port is provided with a block sheet. The invention with simple structure is suitable for large-scale automated production; furthermore, the invention not only can effectively increase the welding efficiency and effectively avoid the remaining of oxidizing layer of tin liquid surface on the surface of the PCBA board, but also can ensure the quality of the welding joints.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

Internally concave double-edge open type pot mouth with tin retaining plates

InactiveCN101765326AChange directionDoes not affect soldering qualityPrinted circuit assemblingSolderingOxide

The invention relates to a solder pot component used for tin soldering of a PCBA board, in particular to an internally concave double-edge open type pot mouth with tin retaining plates. The pot mouth is of a rectangle mouth structure; the opposite sides of the edges of pot mouth are respectively provided with tin overflow openings; the circular tin retaining plates are respectively arranged in the pot mouth of the tin overflow openings; and the tin overflow openings are rectangle openings and have a depth of between 3 and 6mm. The internally concave double-edge open type pot mouth with the tin retaining plates has simple structure, can effectively improve the soldering efficiency, is suitable for large-scale automation production, and also effectively prevents an oxide layer on the surface layer of the tin liquor from leaving on the surface of the PCBA board so as to guarantee the quality of the soldering joint.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

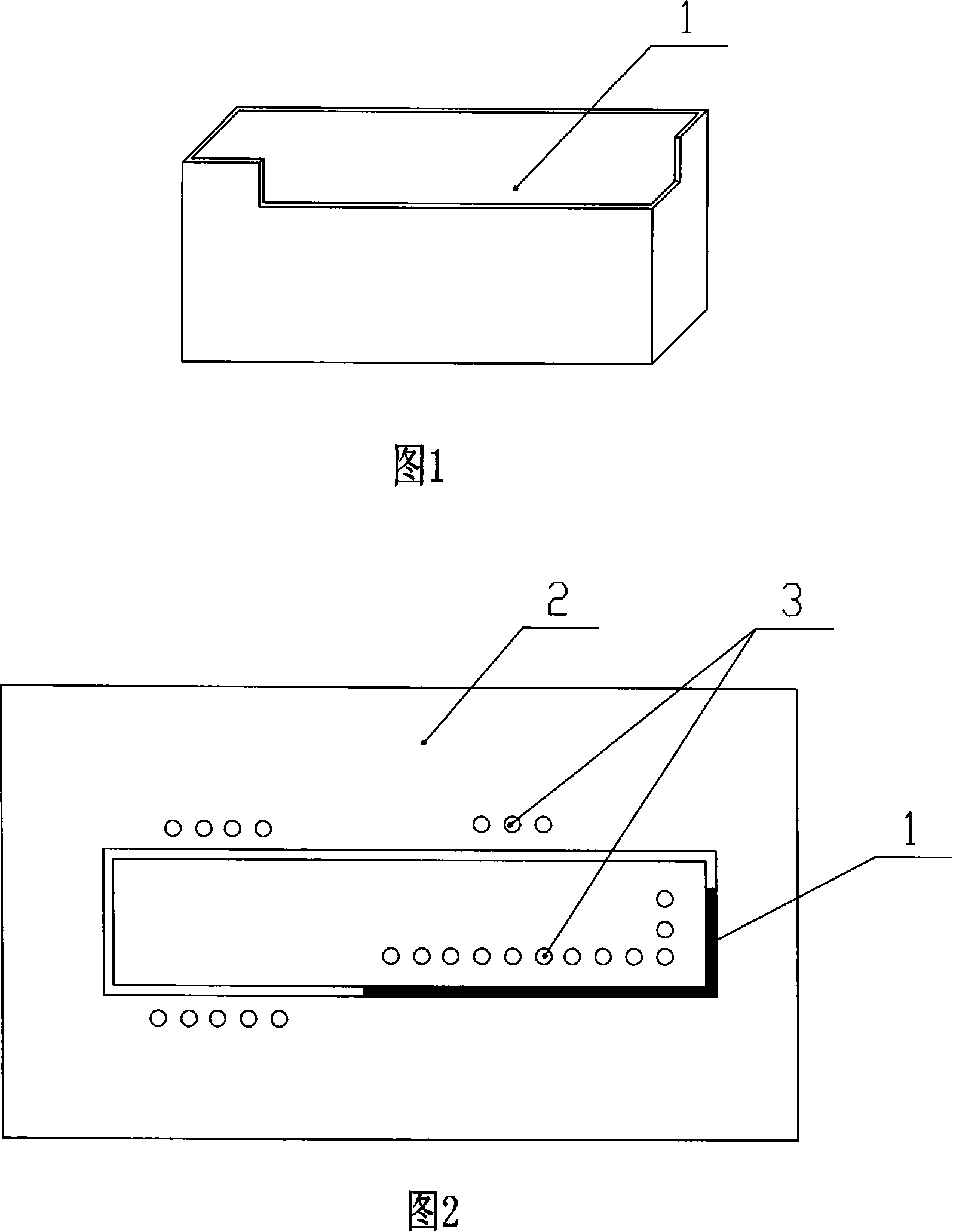

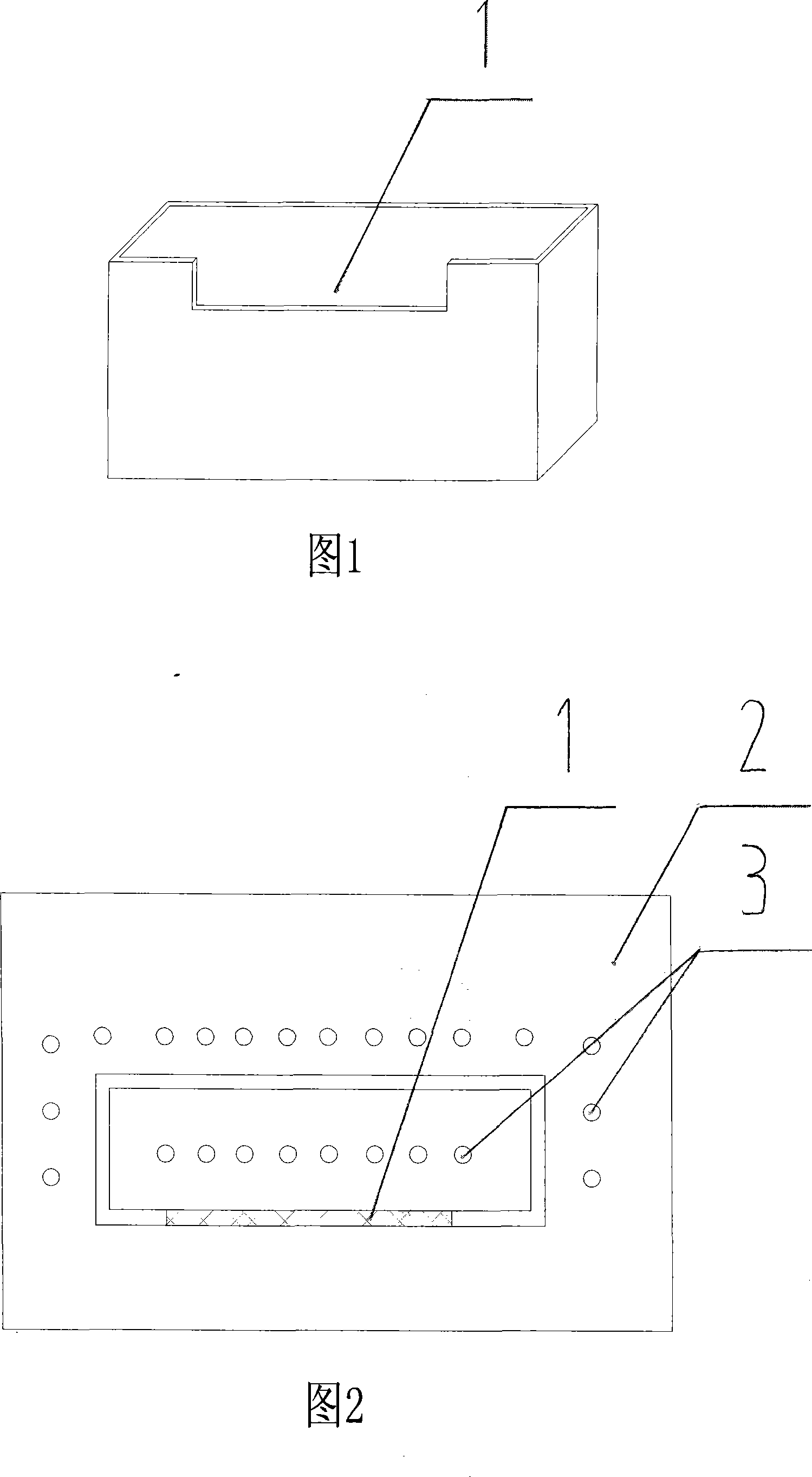

Plug-in short kettle opening

InactiveCN101801158AChange directionDoes not affect soldering qualityPrinted circuit assemblingEngineeringLiquid surfaces

The invention relates to a tin furnace component for welding tin on PCBA plates, in particular to a plug-in kettle opening of a tin furnace. The mouth of the kettle opening is provided with a conical necking socket; and at least one tin spilling opening is formed on the edge of the socket. The plug-in short kettle opening with a simple structure can effectively improve welding efficiency and is applicable to large-scale automatic production. Besides, the plug-in short kettle opening can effectively prevent an oxide layer on a tin liquid surface layer from remaining on the surfaces of the PCBA plates, thereby guaranteeing the quality of welding spots.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

Lug boss top opening type tin overflowing pot opening

InactiveCN101765299AChange directionDoes not affect soldering qualityPrinted circuit assemblingEngineeringSoldering

The invention relates to a tin furnace component used for PCBA board soldering tin, in particular to a lug boss top opening type tin overflowing pot opening, which consists of a base body and an insertion hole, wherein a step is formed between the base body and the insertion hole, a tin overflowing hole is arranged at an edge opening of the insertion opening, and the tin overflowing opening is a rectangular notch with the depth between 3 and 6 mm. The invention has a simple structure, can effectively improve the welding efficiency, and is suitable for large-scale automatic production. In addition, the invention effectively avoids the oxide layer of the tin liquid surface layer remaining on the surface of a PCBA board, and ensures the quality of welding points.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

Double-opening spout for dodging chip element

InactiveCN101765307AChange directionDoes not affect soldering qualityPrinted circuit assemblingEngineeringTin

The present invention discloses a double-opening spout for dodging chip elements, which is a tin furnace component for welding tin on PCBA plates, in particular to a spout of a tin furnace for welding chip elements on a computer main board. The spout is rectangular, wherein the side edge of one rectangular edge is provided with a tin spilling opening while the other side of the rectangular edge is provided with an inner groove. The double-opening spout with simple structure is capable of effectively improving welding efficiency and is adaptable to large-scale automatic production. Besides, the double-opening spout can effectively prevent an oxide layer on tin liquor surface from remaining on the surface of a PCBA plate, thereby guaranteeing the quality of welding spots.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

A kettle mouth with tin apron at tin overflow mouth

InactiveCN101150924AEnsure sufficiency and firmnessChange directionPrinted circuit assemblingSolderingOxide

The invention relates to a tin furnace component used to PCBA board soldering tin, in particular to a tin furnace kettle orifice. The kettle orifice has a rectangular shape, at least one tin overflow outlet is positioned around the kettle orifice tin outlet, a half-surrounded tin-shield board is extended outward at both sides of the tin overflow outlet, the tin overflow outlet is a rectangular opening, the deepness is 2-8mm. The invention has a simple structure, can protect elements around outside of the overflow tin effectively through arranging the tin-shield board, realizes selective protection for elements on the PCBA board above the kettle orifice, in addition, effectively prevents an oxide layer of the tin liquid surface from remaining on the PCBA board, assures the welding joint quality.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

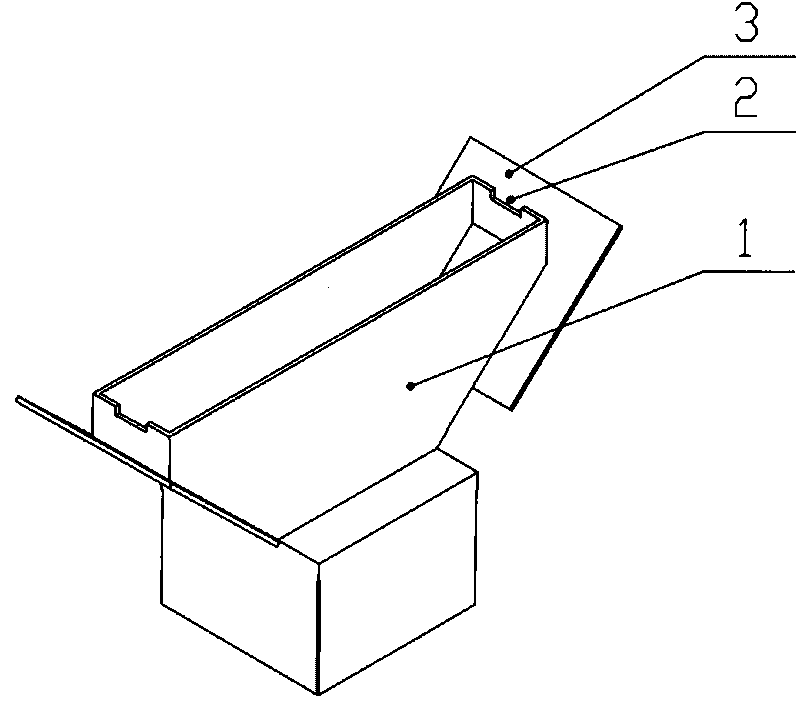

Gibbosity type kettle mouth with external-open tin-overflowing mouth

InactiveCN101415298AChange directionDoes not affect soldering qualityPrinted circuit assemblingEngineeringPrinted circuit board

The invention relates to a solder pot component applicable for PCBA (Printed Circuit Board Assembly) tin solder, in particular to a solder pot spout. The solder pot spout comprises a rectangular main spout. An auxiliary spout is arranged on the long edge of the main spout; the short edges on the two sides of the main spout are respectively provided with a side spout. A half-encircled area is enclosed by the main spout, the auxiliary spout and the side spouts. Tin leaking mouths are arranged on the walls of the interconnected face-to-face tin discharging mouth. The solder pot spout has simple structure so that the solder pot spout can effectively improve welding efficiency. Therefore, the solder pot spout applies to mass automatic production. Furthermore, the solder pot spout can effectively avoid oxide layer on the surface of the tin liquor from remaining on the surface of the PCBA, thereby ensuring the quality of the welded connection point.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com