L-shaped upstream side flowing spout

A spout and L-shaped technology, which is applied in the field of L-shaped spout with ribs, can solve the problems of low work efficiency, unsuitable for large-scale batch processing, easy to form false welding of joints, etc., so as to ensure the sufficiency and firmness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

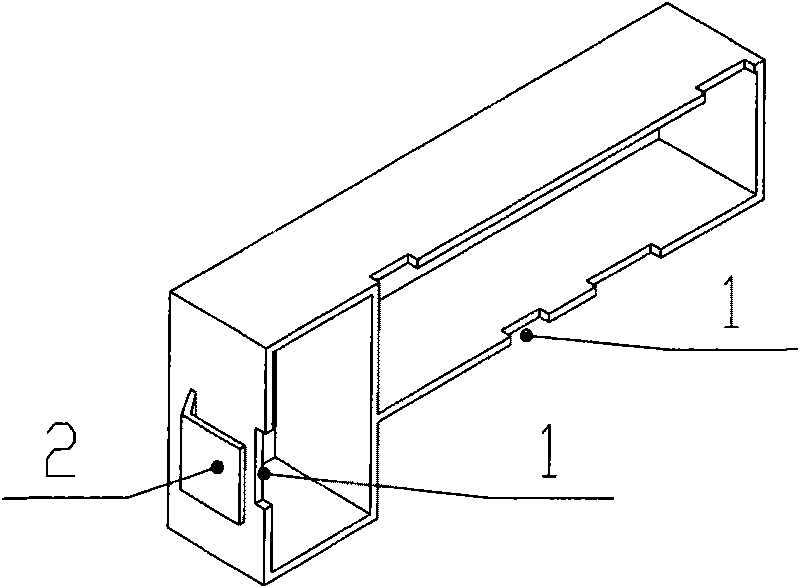

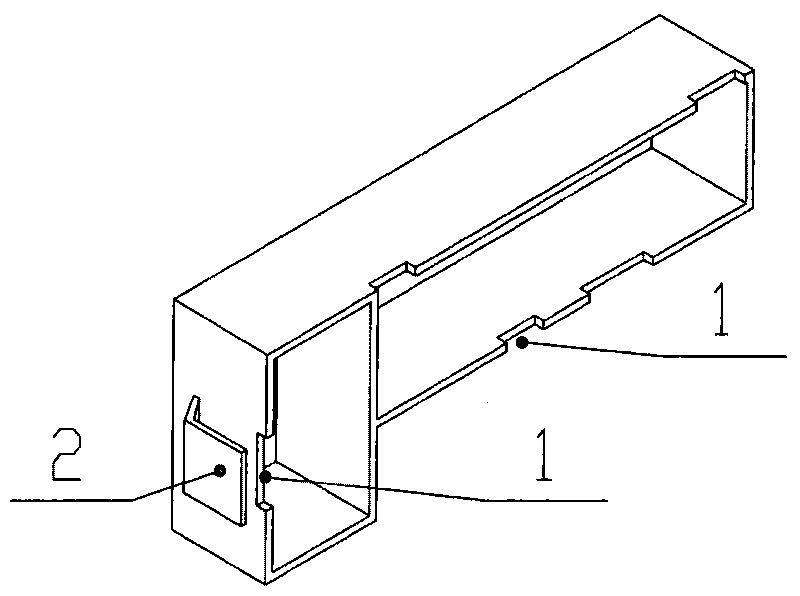

[0012] like figure 1 An L-shaped upstream spout with ribs is shown, which is composed of two spouts to form an L-shaped structure. A tin overflow port 1 is provided on the edge of the spout, and a rib is provided in front of the overflow spout 1. 2. The side wall of the spout at the lower end of the rib 2 is fixedly connected. The tin overflow opening 1 is a rectangular opening with a depth of 3-6 mm.

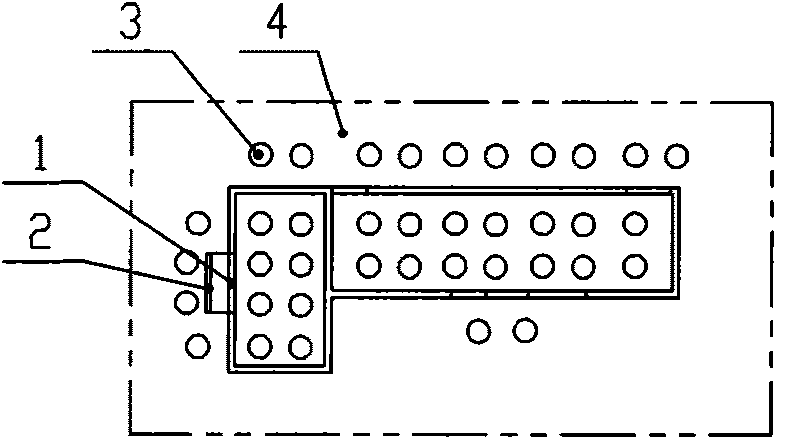

[0013] like figure 2 As shown, on the PCBA board 4 around the spout, electronic components 3 are distributed, and the edge of the spout where the electronic components on the periphery of the spout are selected to be relatively far away from the spout position is provided with a tin overflow port 1, and the spout 1 is made. The peripheral electronic components 3 are located outside the rib 2. When the tin liquid overflows from the tin overflow port 1, the rib 2 is used to limit the outward diffusion path of the tin liquid, and the peripheral electronic components 3 are solde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com