Patents

Literature

43results about How to "Ensure full function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

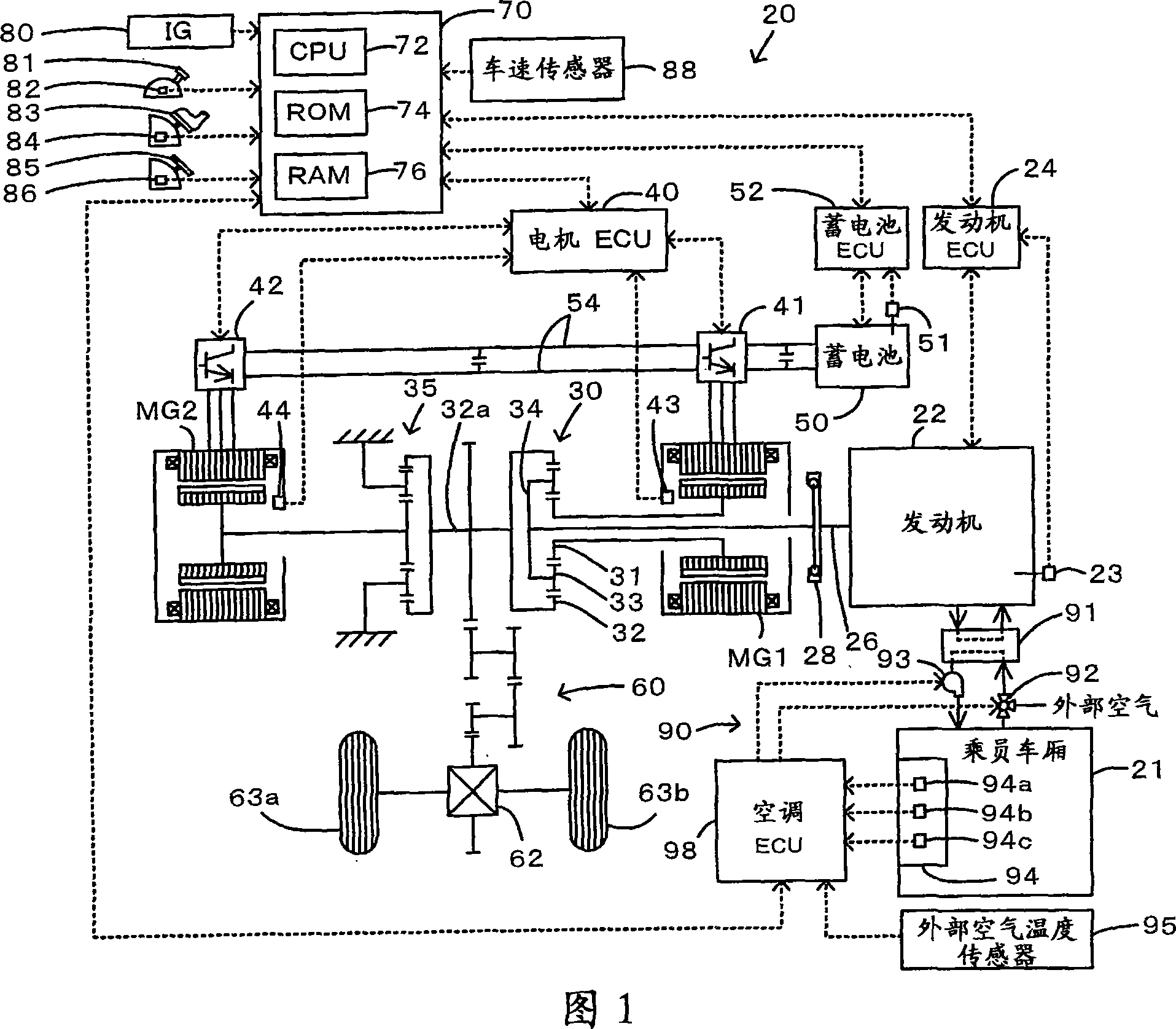

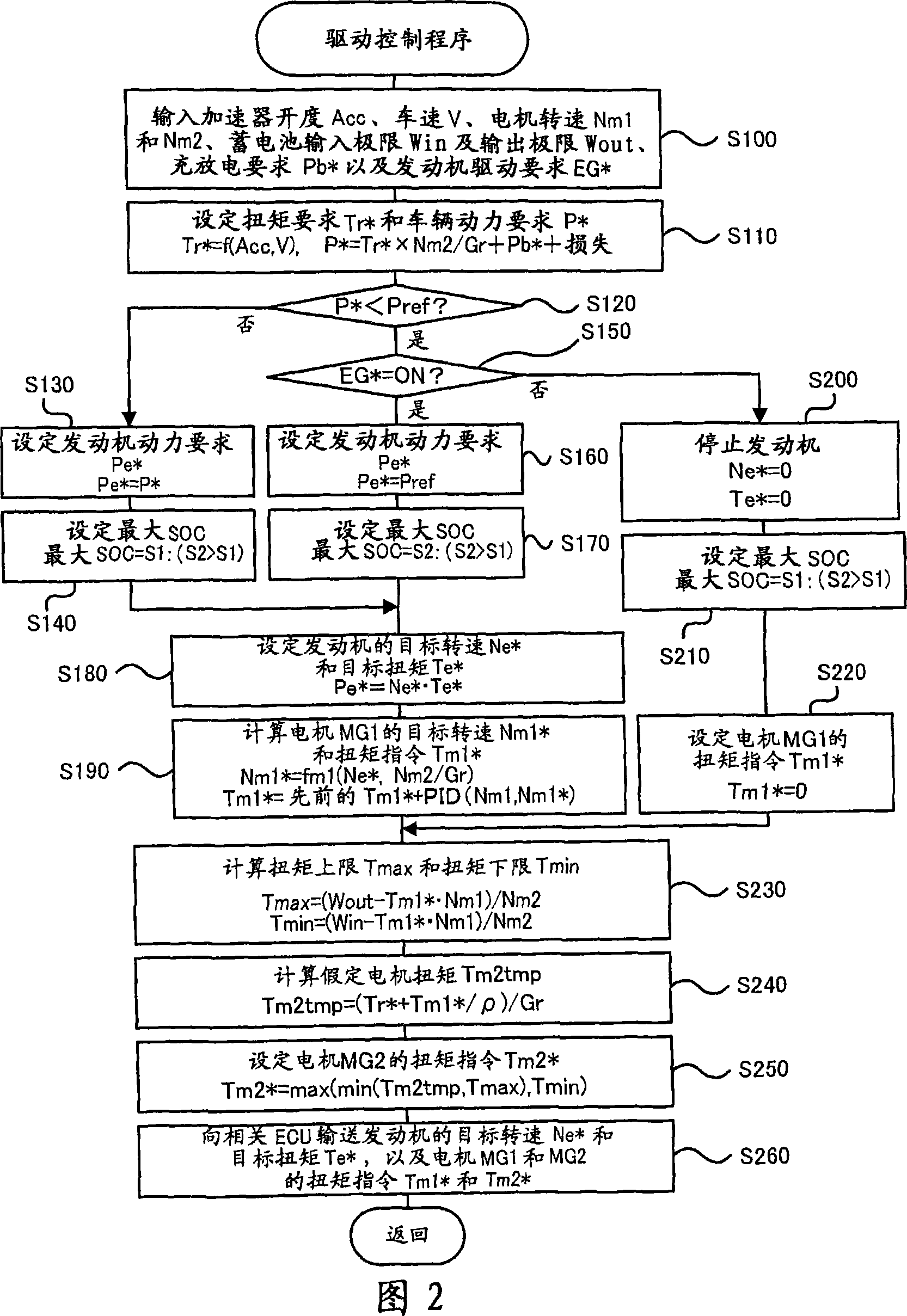

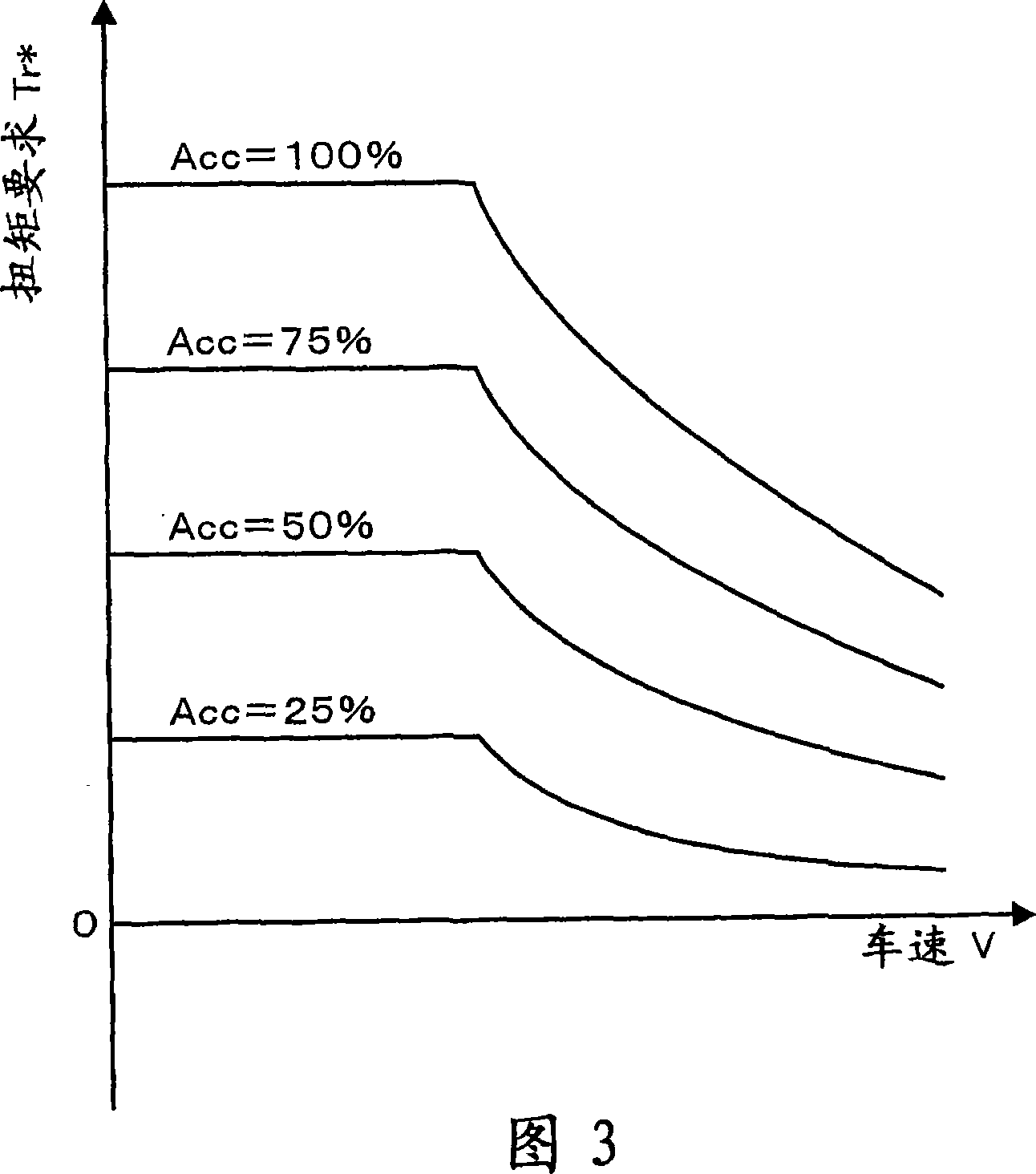

Motor vehicle and control method of motor vehicle

ActiveCN101065565AReduce consumptionIncrease temperatureHybrid vehiclesAir-treating devicesLower limitState of charge

When a vehicle power demand P* is less than a threshold value Pref, which is set to or around a lower limit of a relatively efficient drive range of an engine (step S120) and when an engine drive demand EG* is set ON because of requirement for heating by an air conditioning system (step S150), the drive control of the invention sets the threshold value Pref to an engine power demand Pe* (step S160) and sets a higher level S2 than a standard level S1 to a maximum SOC (state of charge) of a battery (step S170). This drive control starts load operation of the engine with charge of the battery. The load operation of the engine desirably improves the fuel consumption of the vehicle, compared with independent operation of the engine.

Owner:TOYOTA JIDOSHA KK

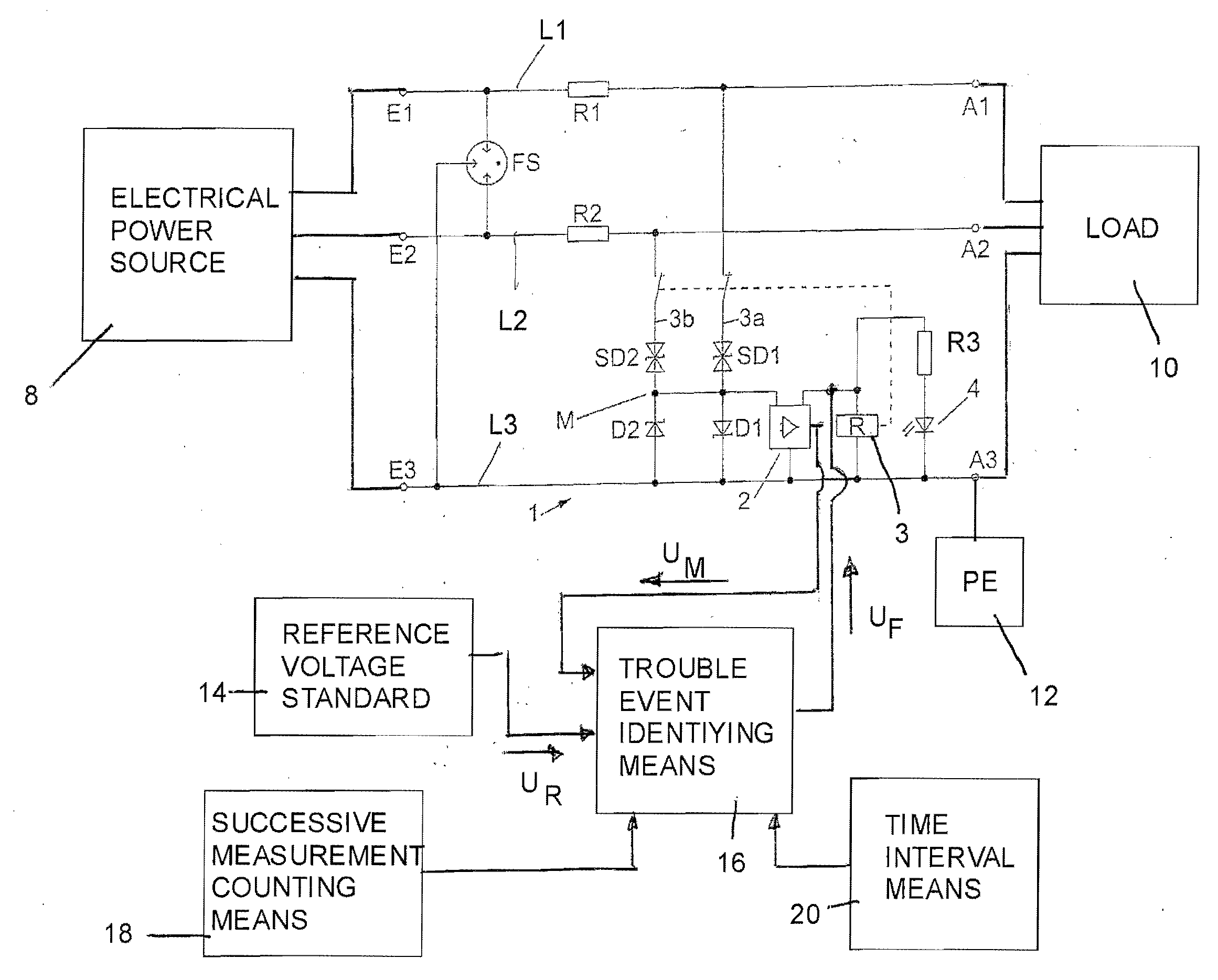

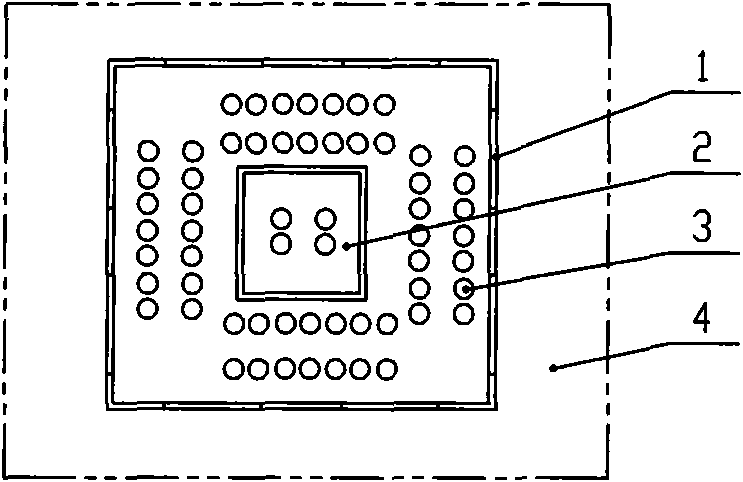

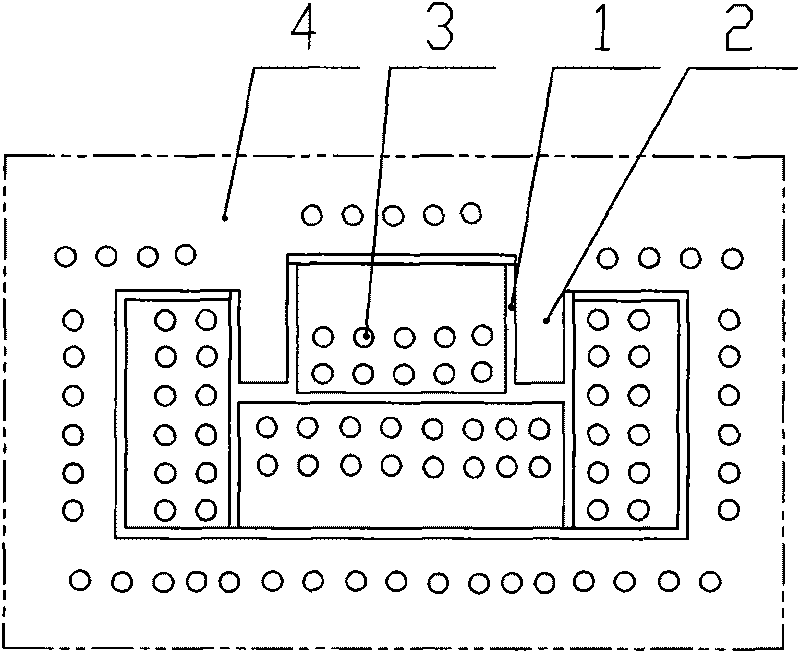

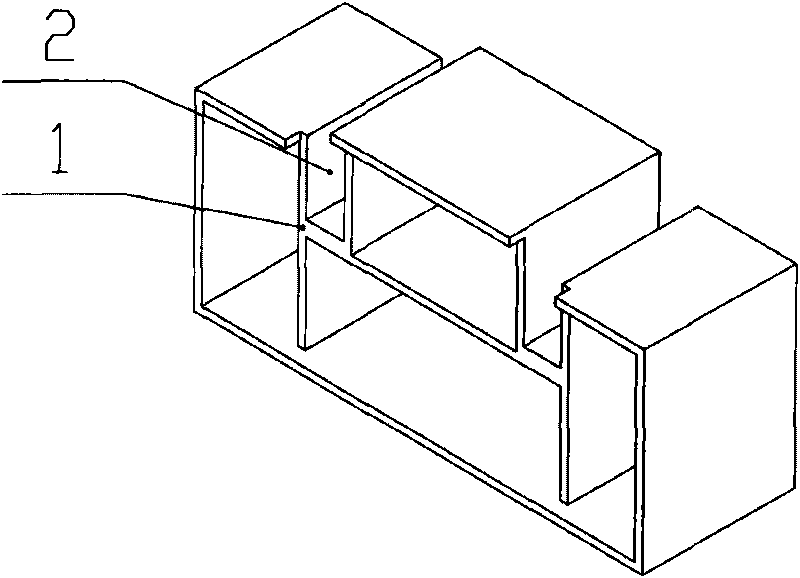

Protection Device

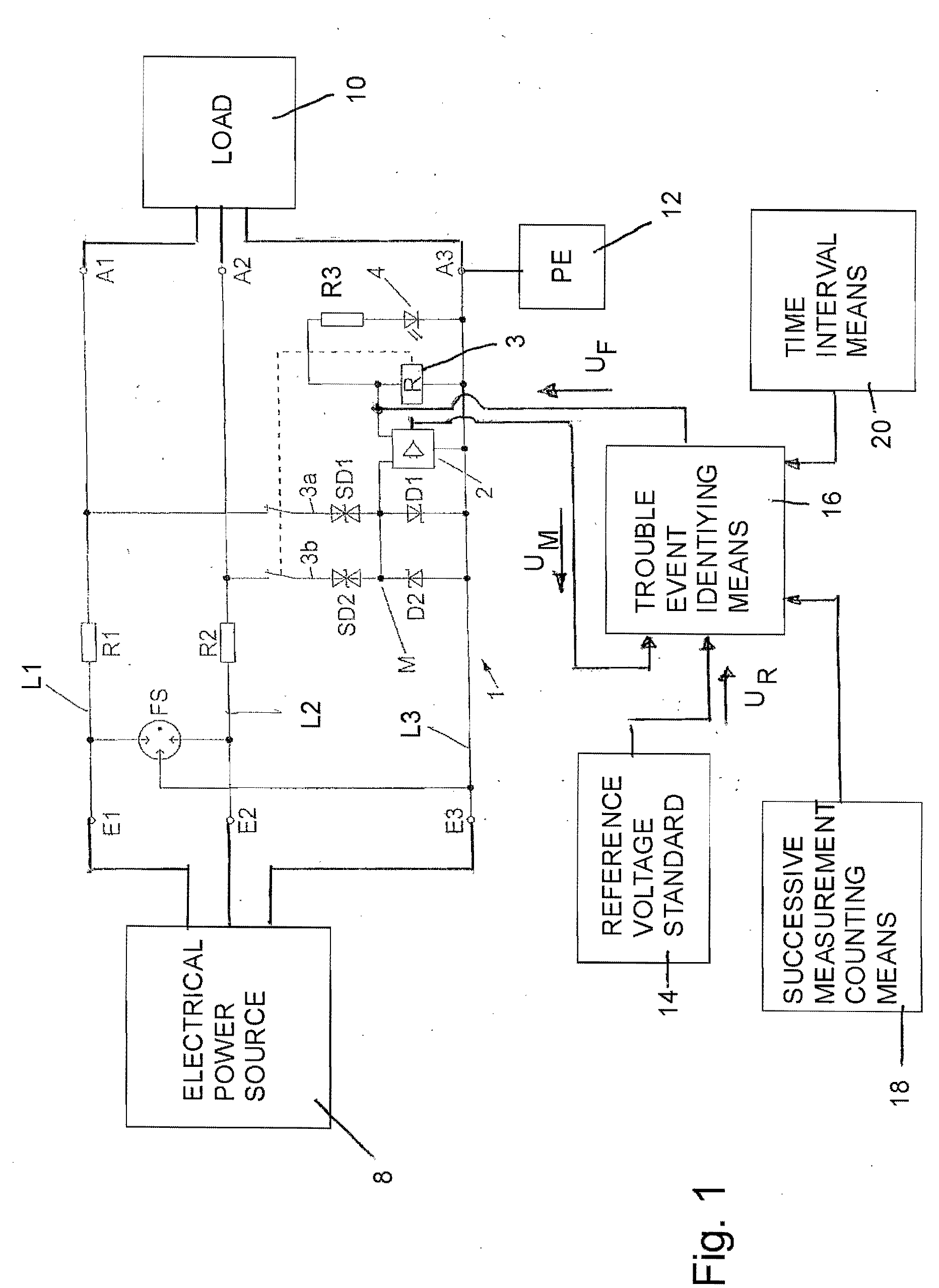

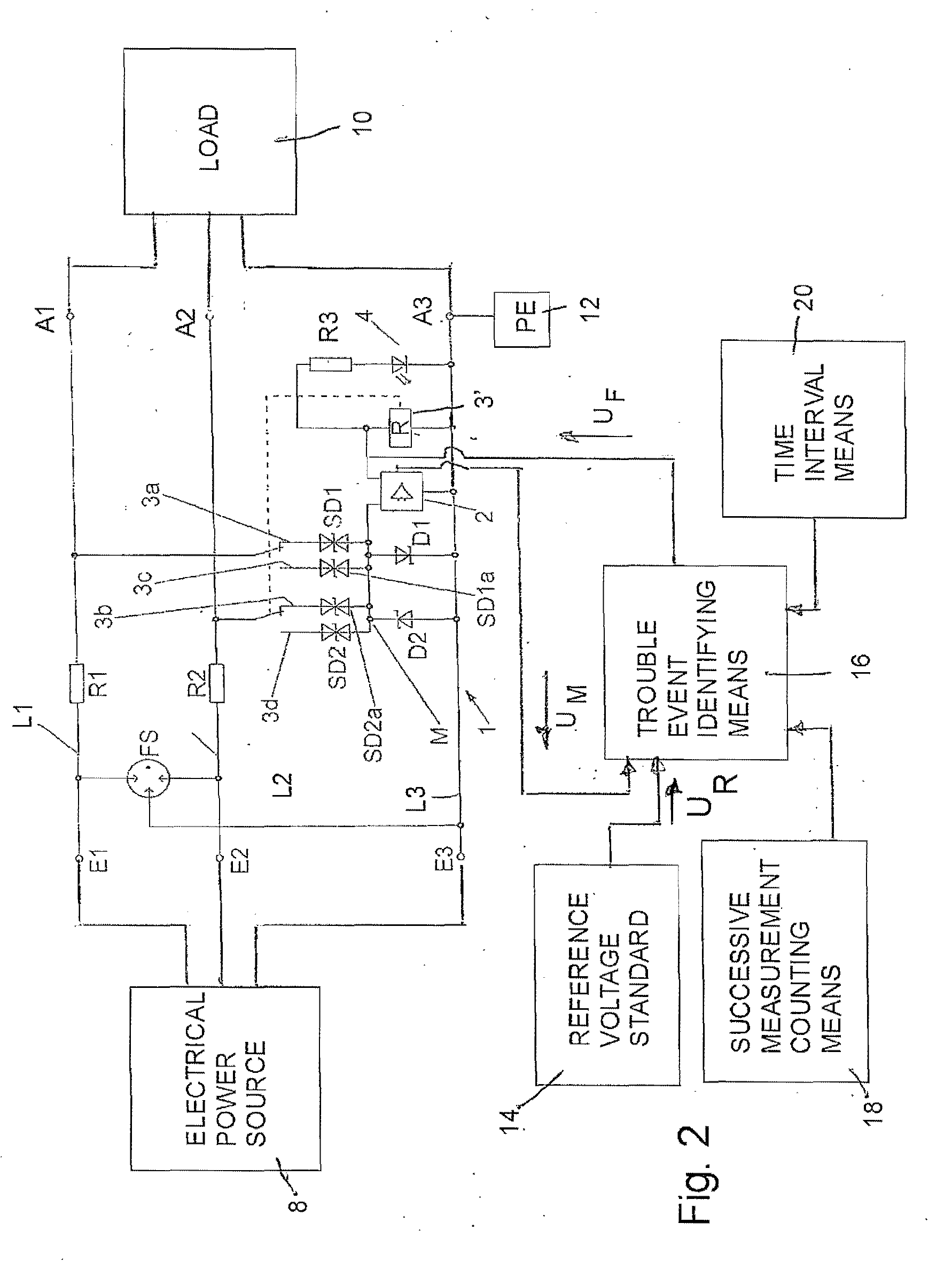

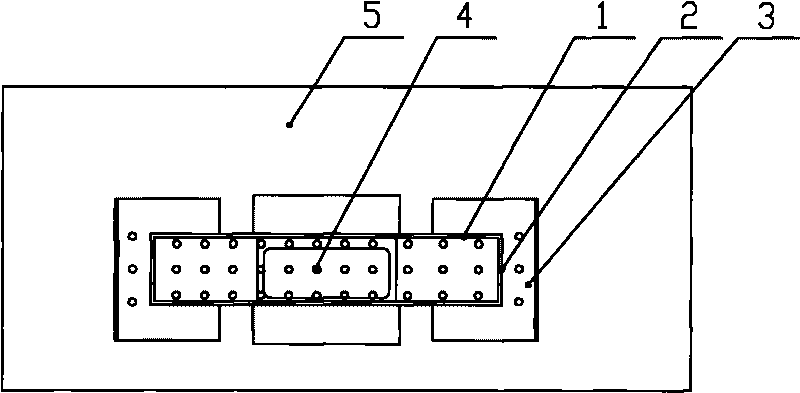

InactiveUS20110026179A1Decrease expenditureEnsure full functionEmergency protective arrangements for limiting excess voltage/currentArrangements responsive to excess voltageVoltage referenceEngineering

An overvoltage protection circuit is provided for protecting a load against overload damage, including a coarse protection device for dissipating the major portion of the energy of the trouble event, a plurality of fine protection devices for limiting the remaining portion of the trouble energy to a safe value, a diagnostic arrangement for determining the operating condition of the destructible fine protection devices, and a disconnect arrangement for disconnecting from the protection circuit at least one of the fine protection devices that has been determined to be faulty. A trouble event identifying arrangement compares with a reference voltage standard a measured voltage existing at a measuring junction between the fine protection devices, and generates a fault signal in the event of destruction of a fine protection device. A display arrangement indicates whether or not a fine protection device has been determined to be faulty.

Owner:WEIDMULLER INTERFACE GMBH & CO KG

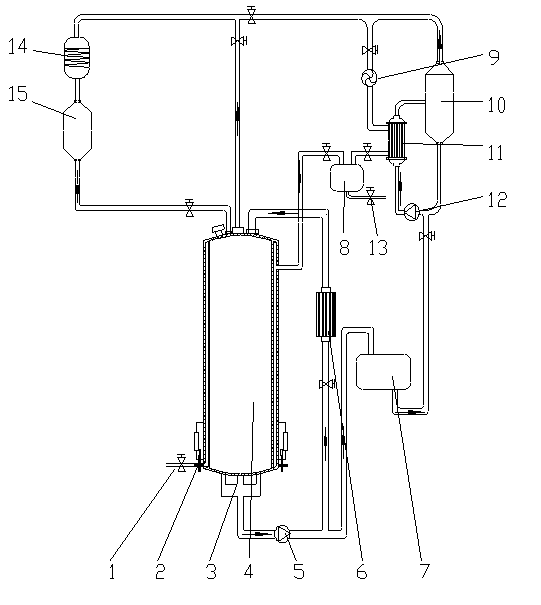

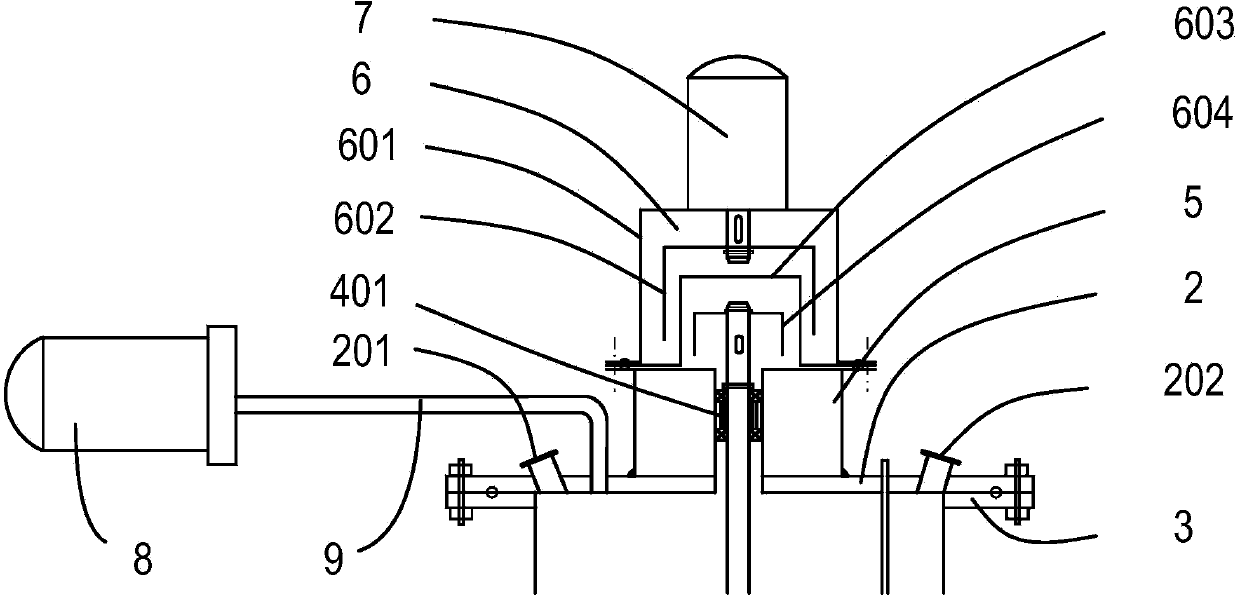

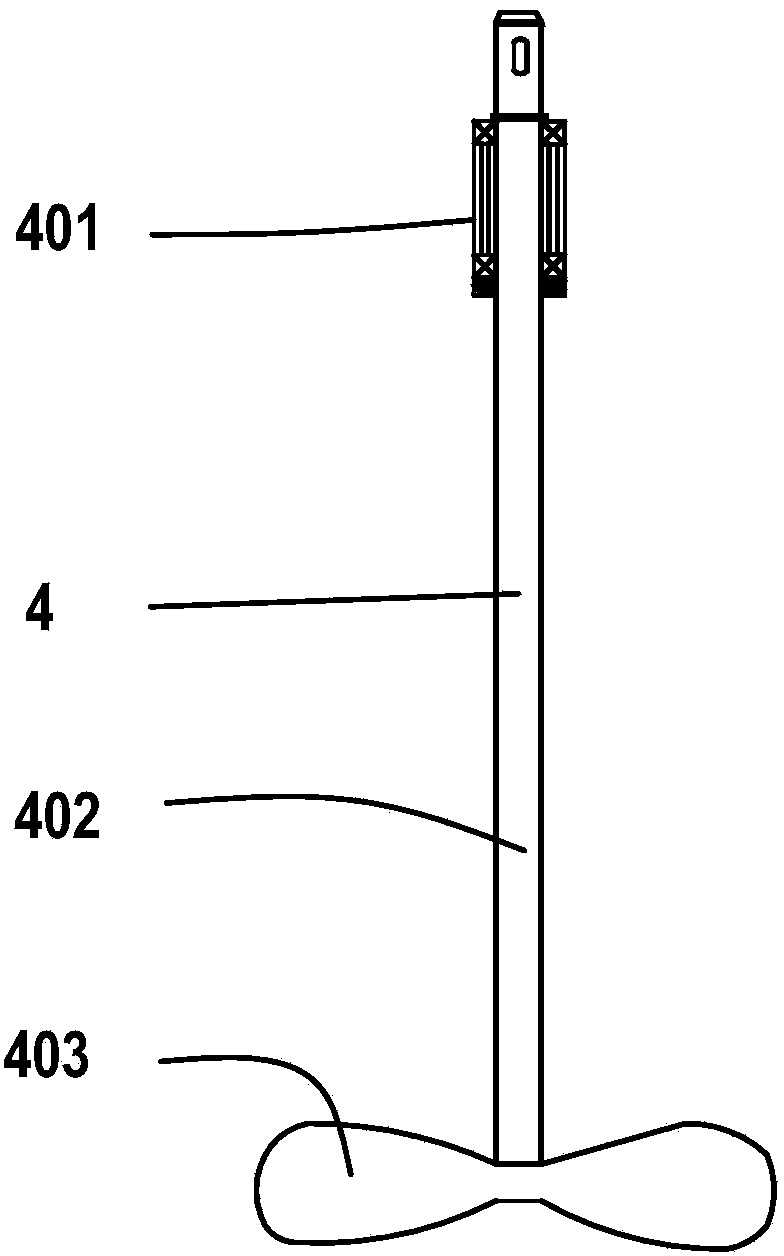

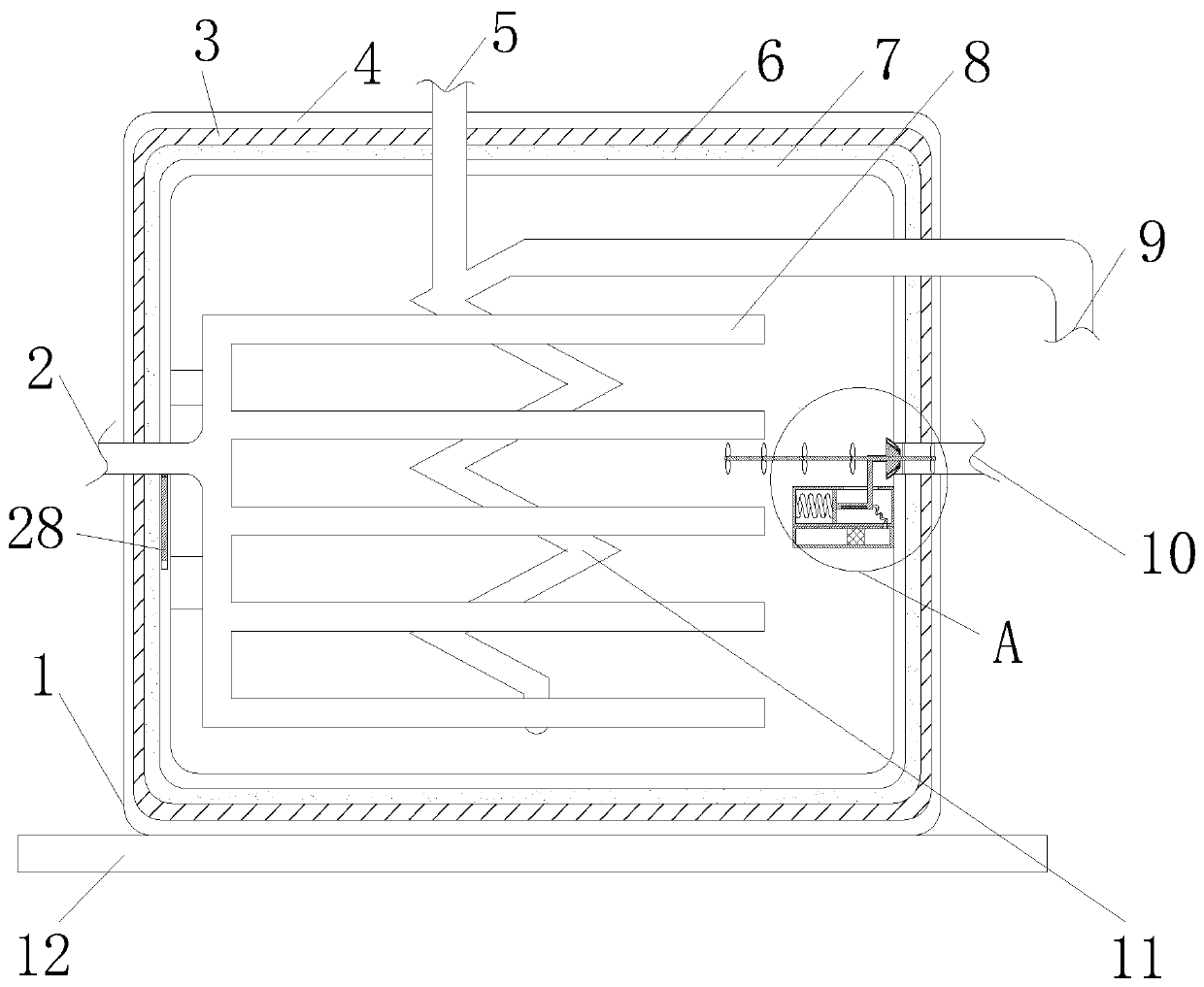

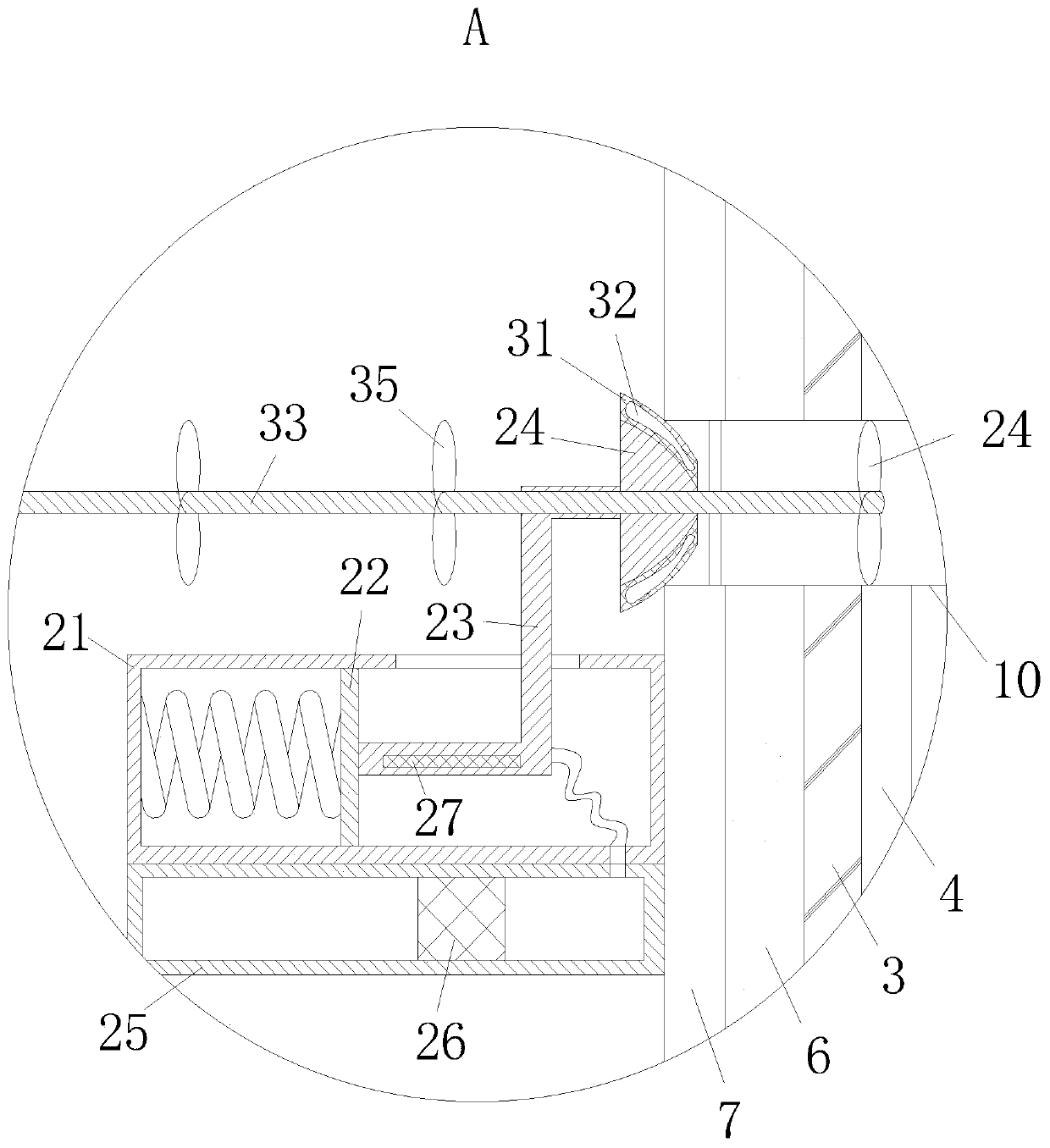

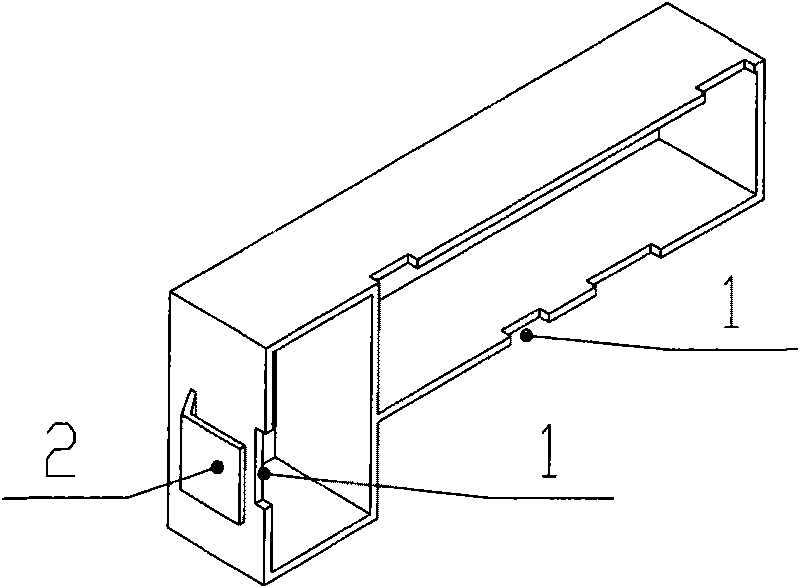

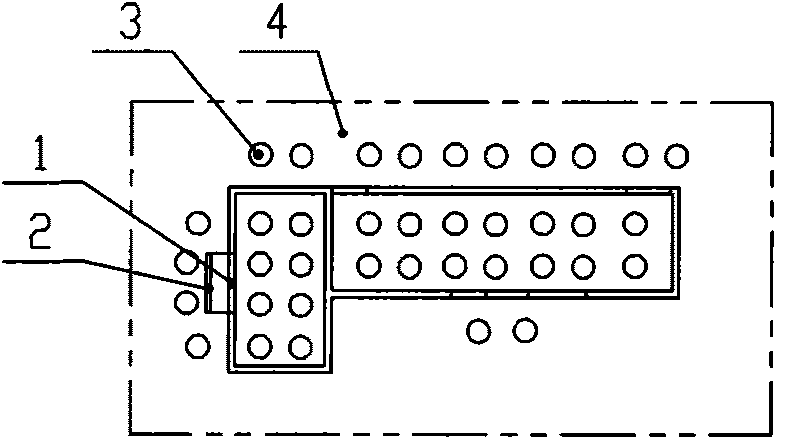

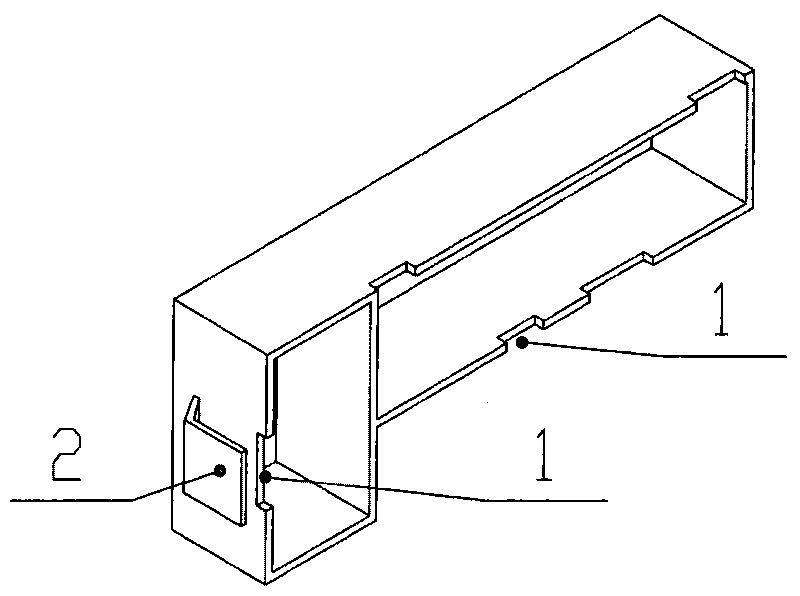

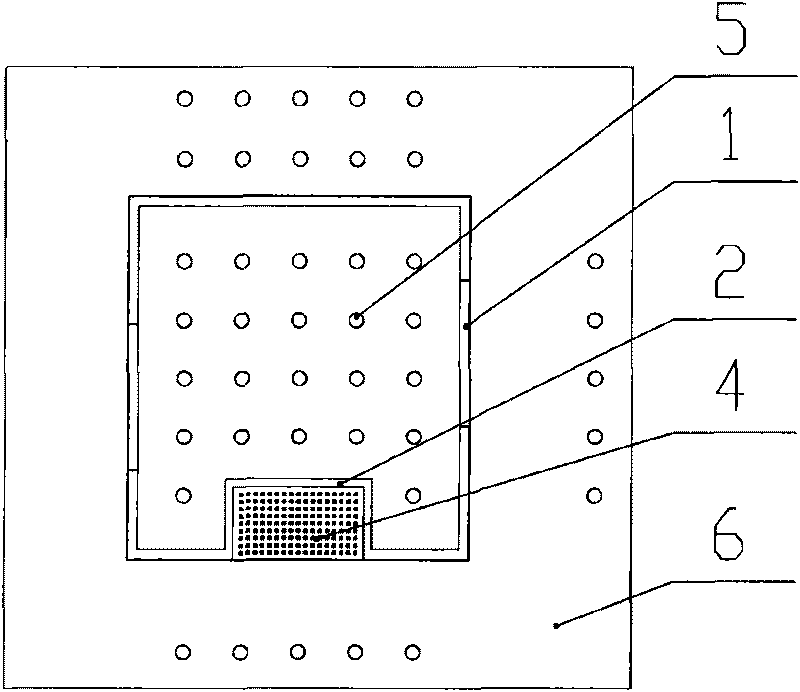

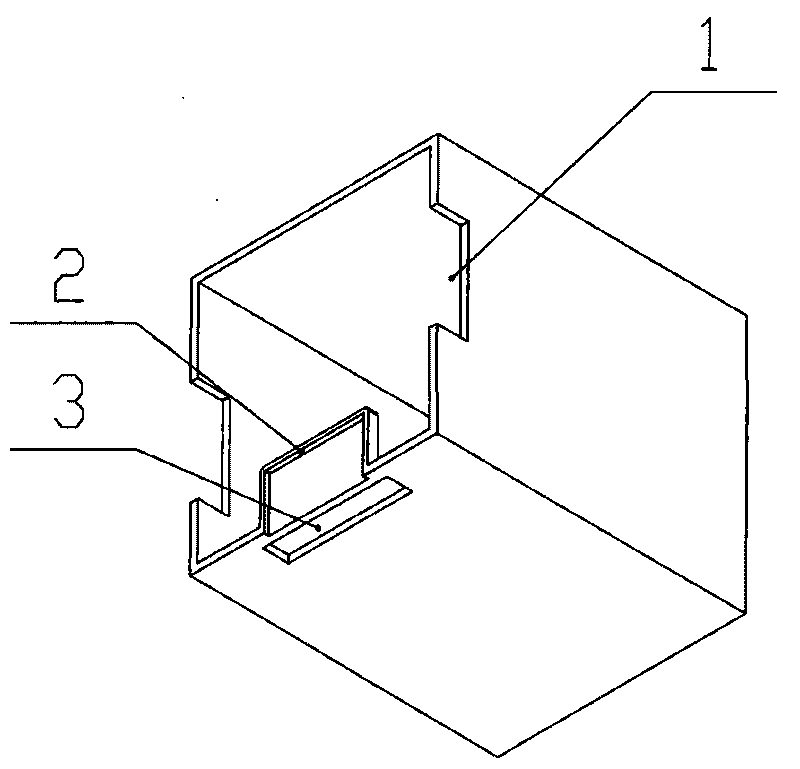

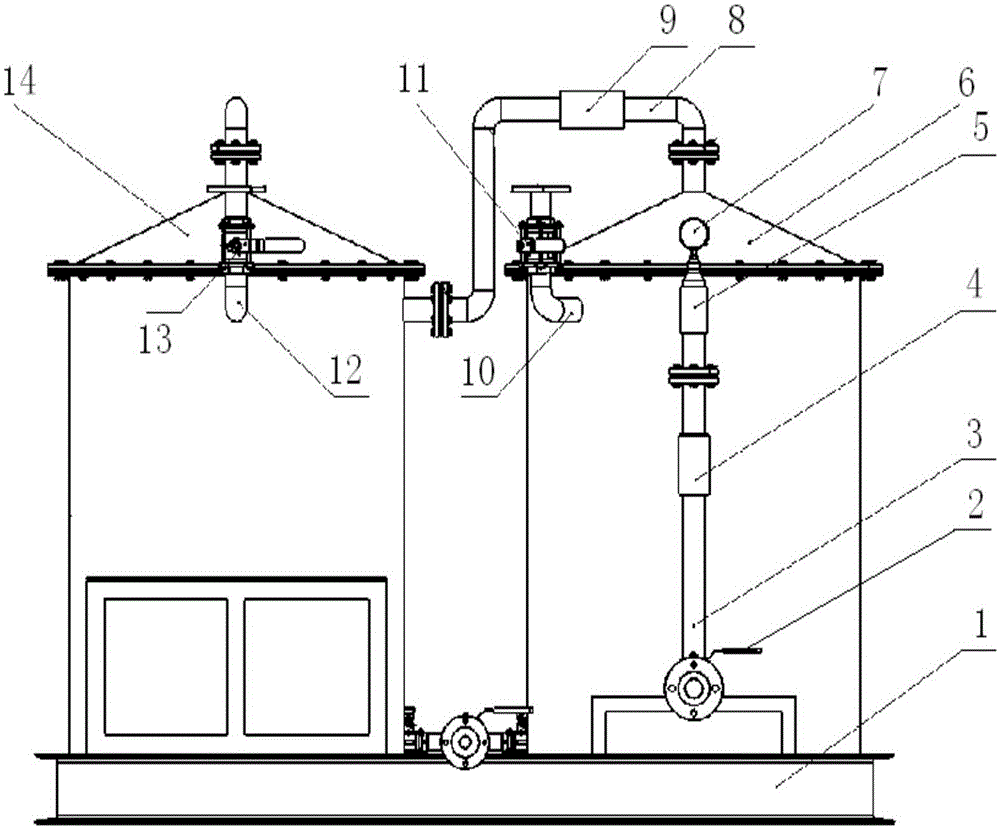

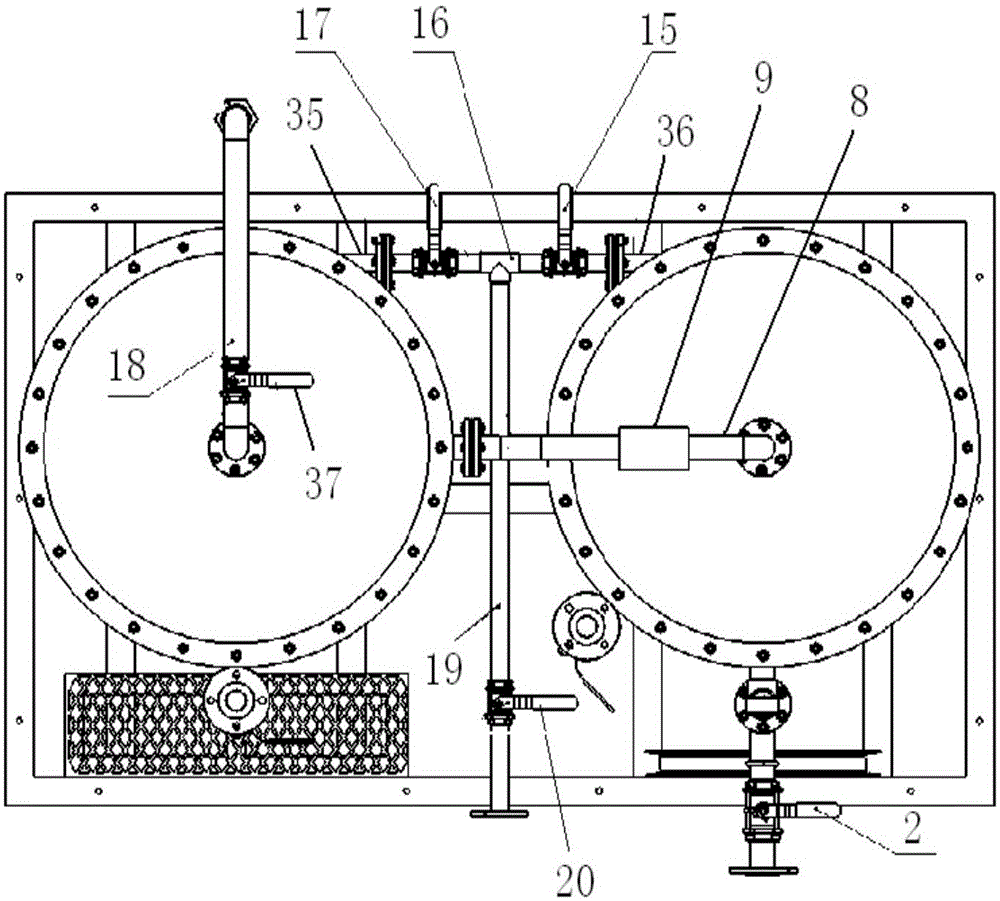

Extracting and concentrating all-in-one machine

ActiveCN103908799AEnsure full functionImprove extraction transfer rateSolid solvent extractionGas compressorLiquid storage tank

The invention relates to an extracting and concentrating all-in-one machine, belongs to the field of extracting and concentrating of traditional Chinese medicines, and particularly relates to an integrated device for dynamically extracting and concentrating traditional Chinese medicines. The extracting and concentrating all-in-one machine comprises an extraction tank, a medicine pump I, a heat exchanger, a medicine storage tank, a steam compressor, an evaporator, a heater, a medicine pump II, a condenser and a liquid storage tank I, wherein the bottom of the extraction tank is connected with the tops of the heat exchanger and the extraction tank through a medicine pipe and the medicine pump I, and the other end of the medicine pump I is connected with the evaporator through the medicine storage tank; the top of the extraction tank is connected with the condenser and the liquid storage tank I through pipelines; the bottom of the evaporator is connected with the medicine pump II and the heater through pipelines; the pipeline at the top of the heater is connected with the middle of the evaporator; the pipeline enters the evaporator in a tangential direction; the top of the evaporator is connected with the inlet of the steam compressor through a pipeline; the outlet of the steam compressor is connected with the upper part of the heater; the lower part of the heater is communicated with the upper part of the liquid storage tank II through a pipeline; a steam trap valve is arranged on the pipeline at the lower part of the liquid storage tank II; the upper part of the liquid storage tank II is connected with a jacket of the extraction tank through another pipeline.

Owner:江西赫柏康华制药设备有限公司

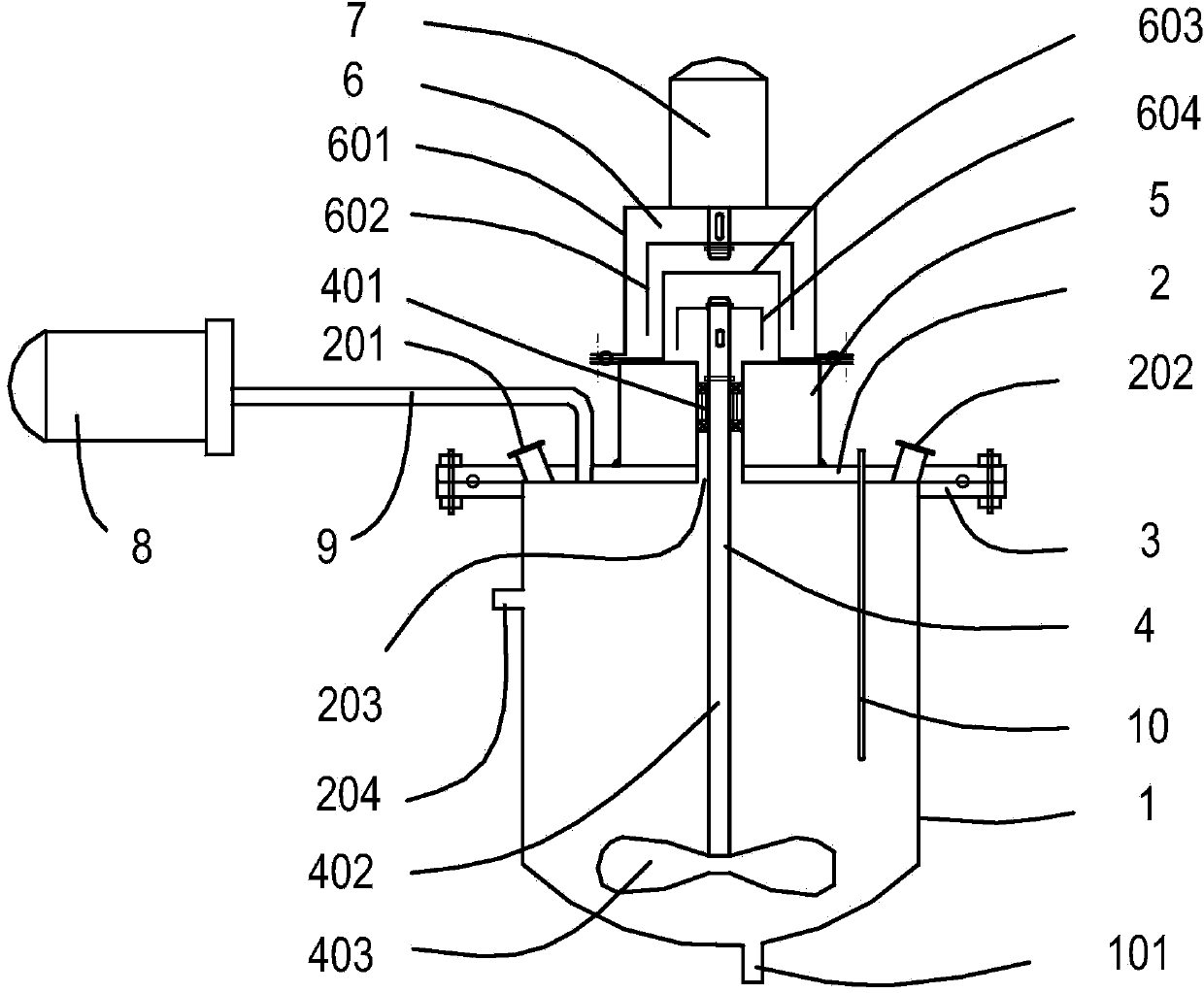

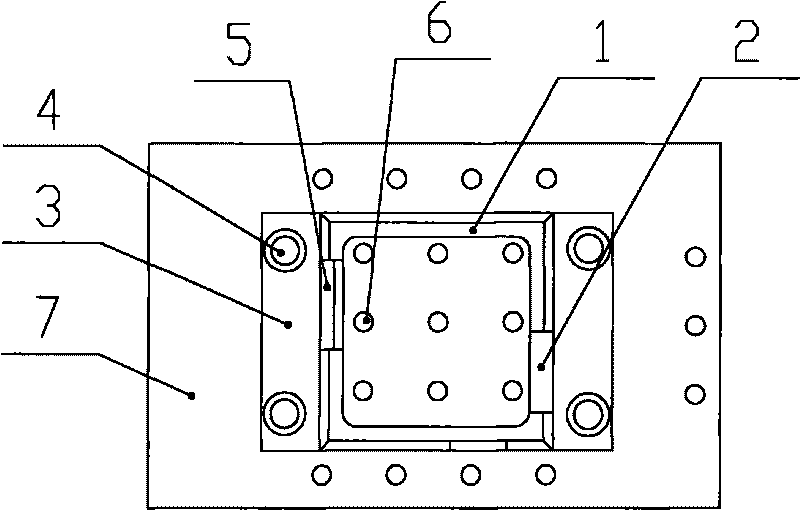

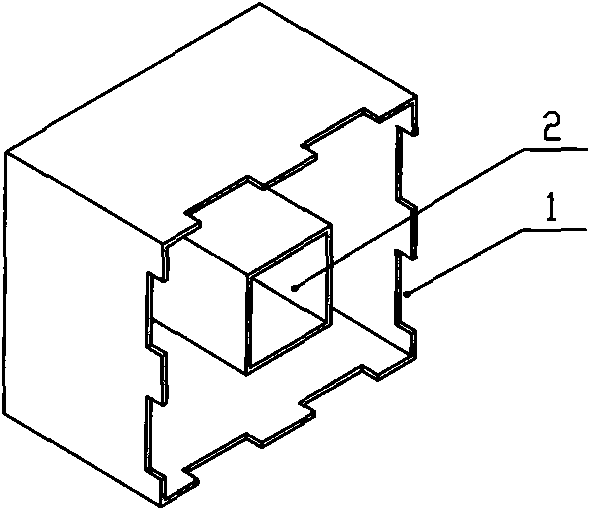

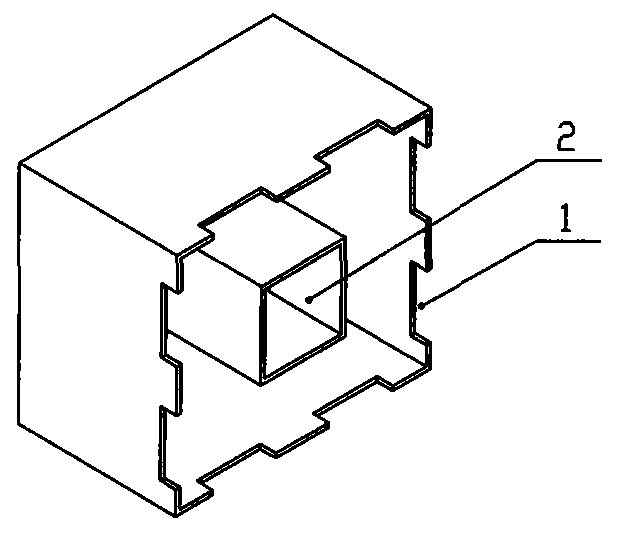

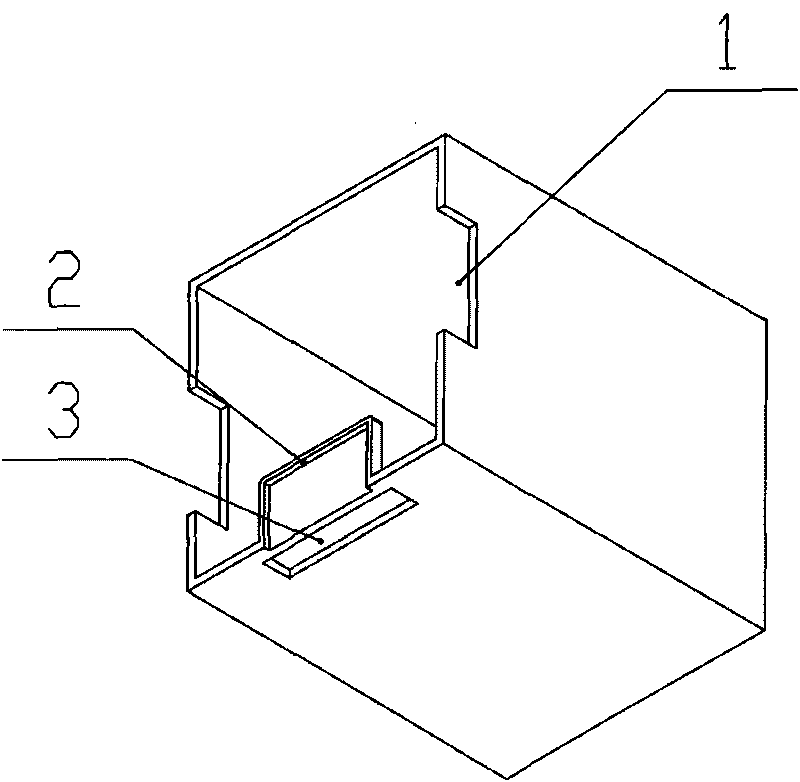

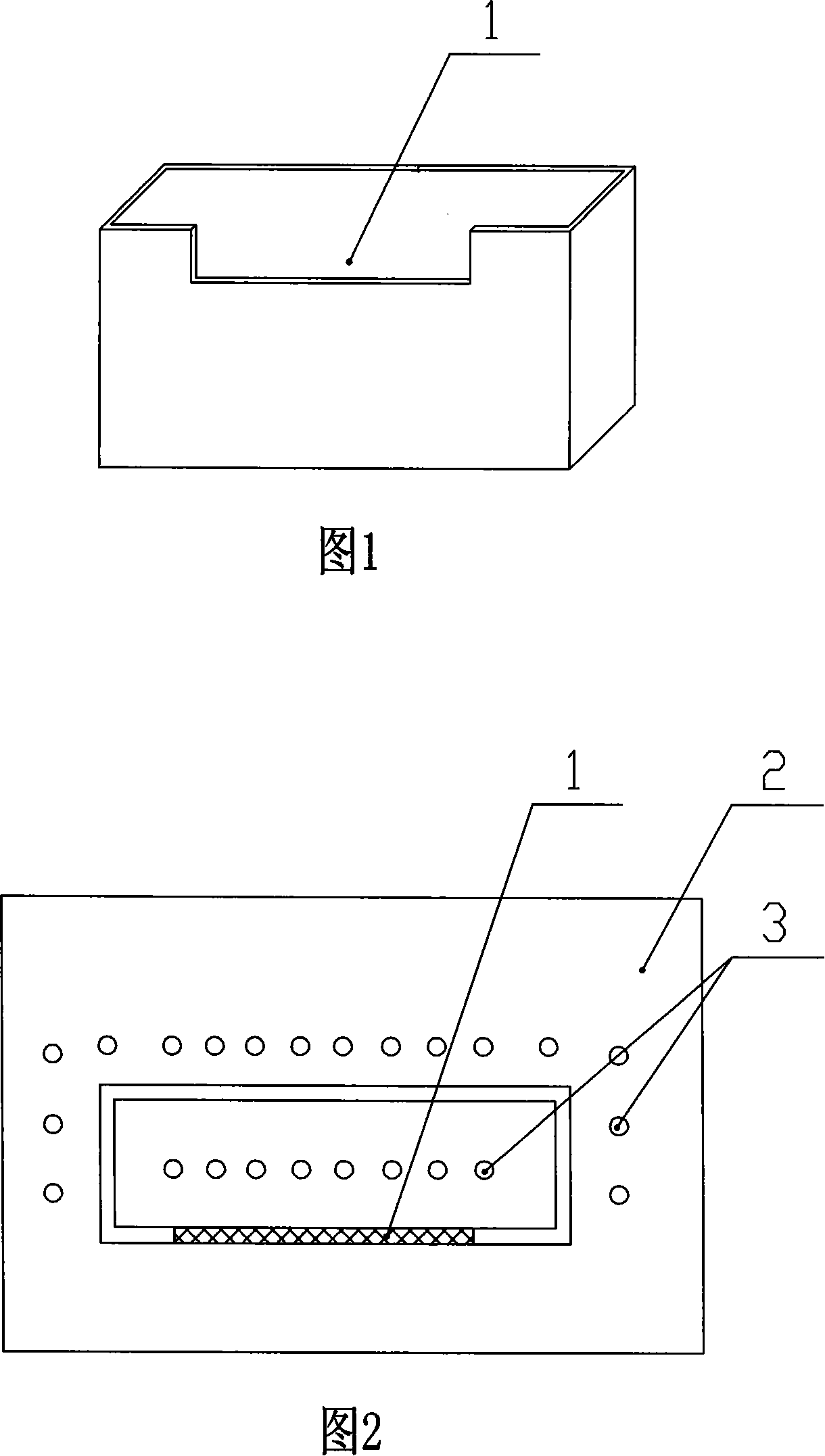

Rapid vacuum dispersion reaction kettle

InactiveCN104190323AEnhanced sealing and isolationGood consistencyPressure vessels for chemical processDrive motorEngineering

The invention discloses a rapid vacuum dispersion reaction kettle which comprises a cooling jacket layer, a reaction kettle body and a magnetic transmission device, wherein the reaction kettle body is composed of a kettle body, a kettle body flange and a kettle cover; the magnetic transmission device is composed of a base, an outer magnetic drum, an isolation bush and an inner magnetic drum; a first seal is arranged at the joint of the kettle body flange and the kettle cover; the cooling jacket layer is arranged on the kettle cover at the outer periphery of the installation opening of a stirrer; a bearing holder of the stirrer is arranged at the core part of the cooling jacket layer; a main shaft of a driving motor is connected with the outer magnetic drum; a stirring shaft is provided with stirring blades, penetrates through the bearing holder and is connected with the inner magnetic drum; the isolation bush is arranged between the inner and outer magnetic drums and is connected with the cooling jacket layer; a second seal is arranged at the joint of the isolation bush and the cooling jacket layer; the bottom of the cooling jacket layer is seamlessly connected with the kettle cover; a vacuum pipe communicated with the kettle body is arranged on the reaction kettle body. The rapid vacuum dispersion reaction kettle can provide both a vacuum reaction environment and a positive pressure protection atmosphere reaction environment; the alloy reaction is uniform and rapid; no solid grain impurities are generated and the alloy phase is uniform in dispersion.

Owner:TIANQI LITHIUM CORP

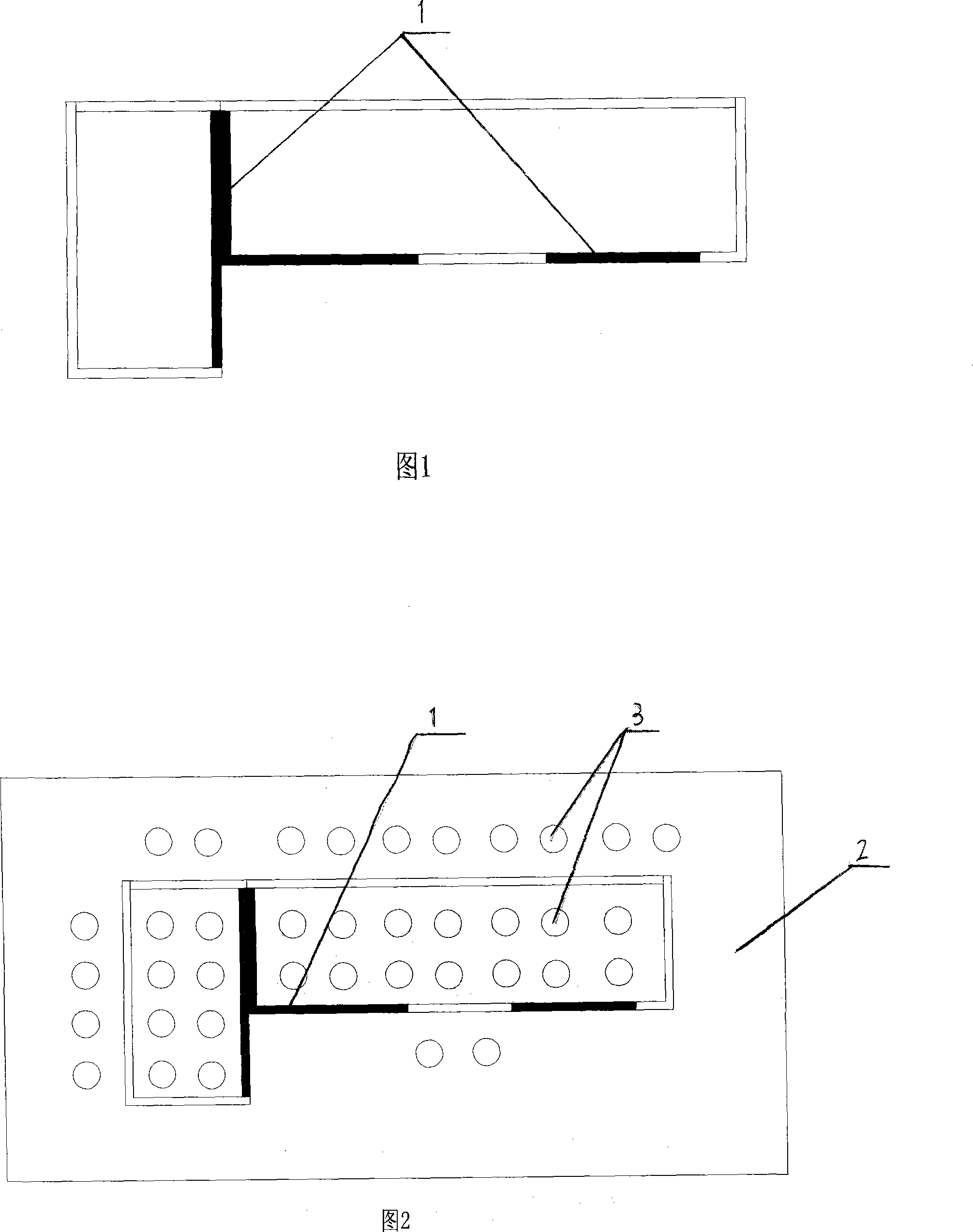

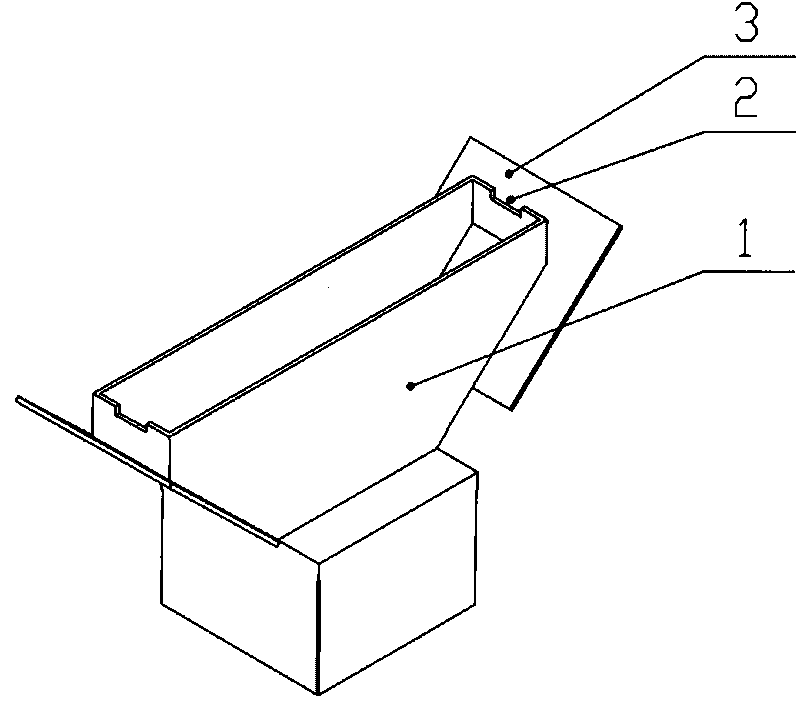

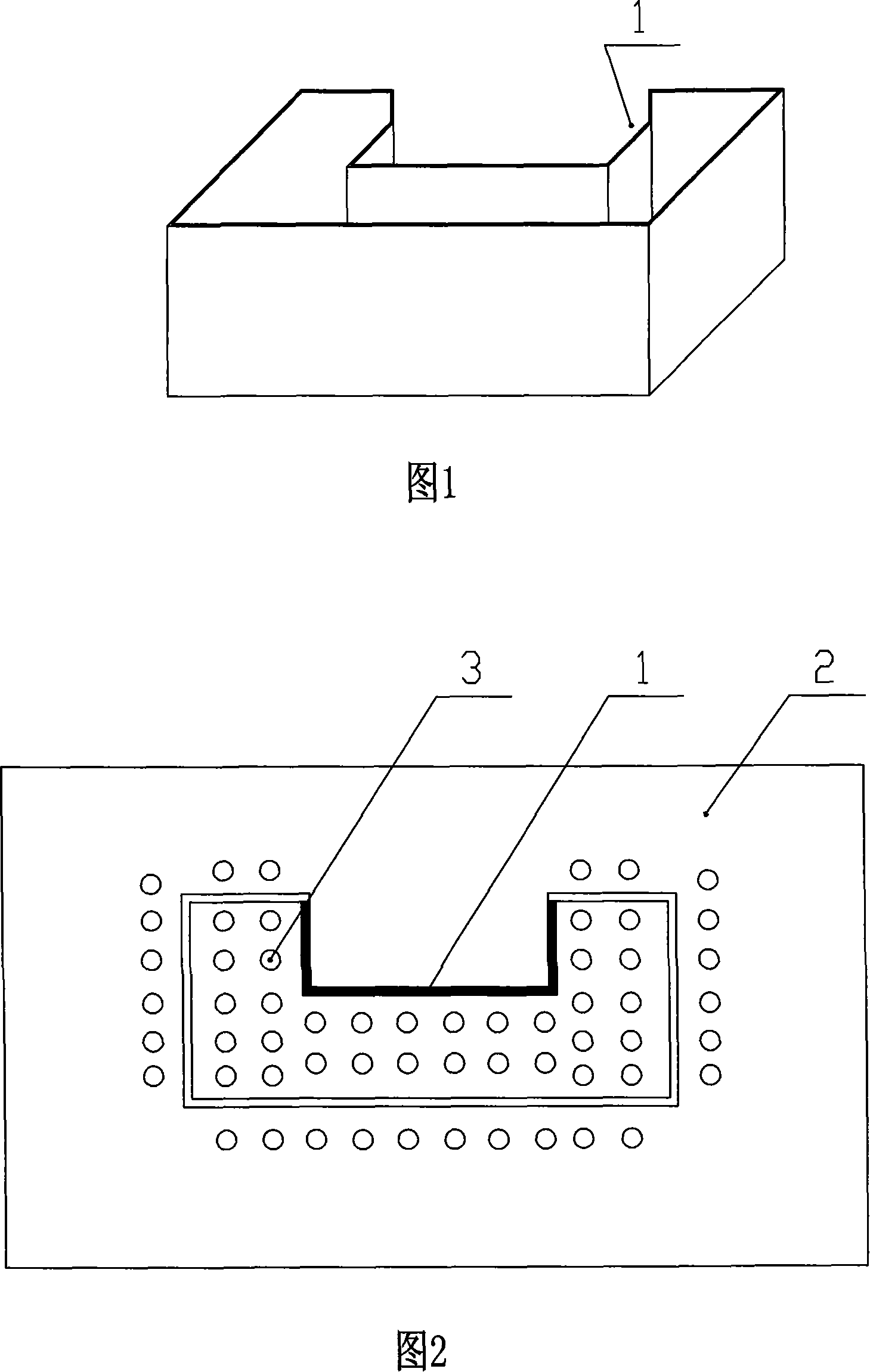

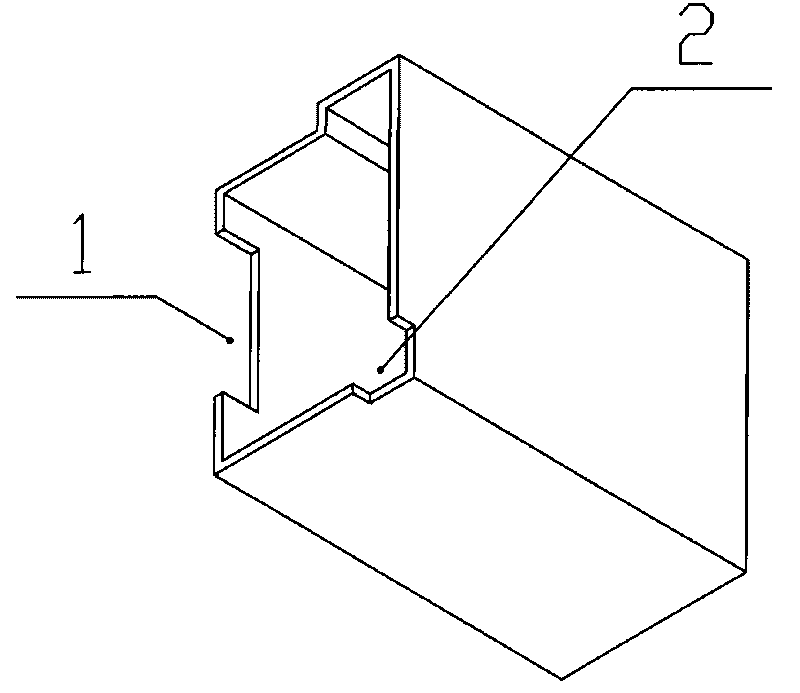

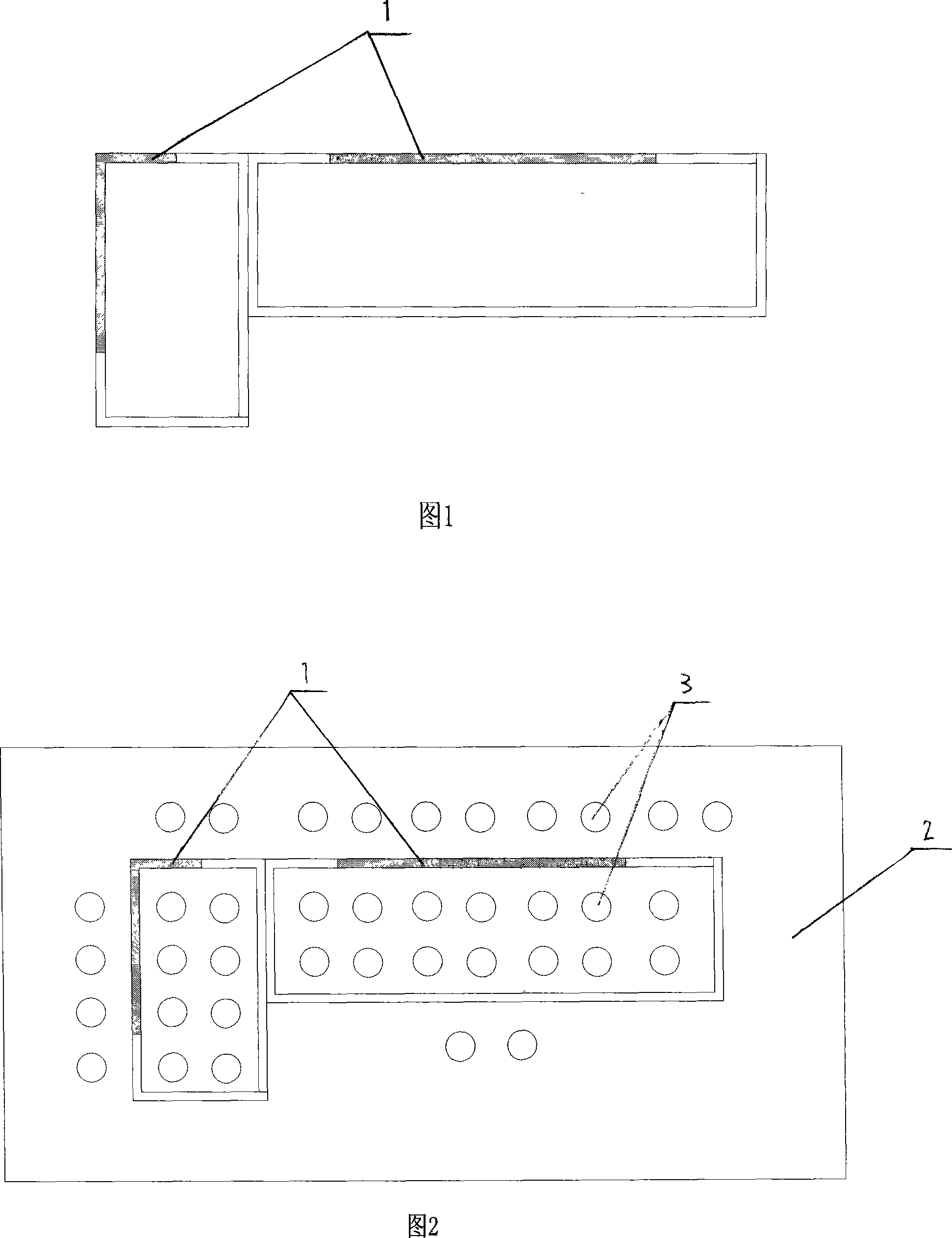

Inner opening L-shaped stannum port of spilled stannum port

InactiveCN101179908AChange directionDoes not affect soldering qualityMultilayer circuit manufactureSurface layerEngineering

The invention relates to a tin furnace part of PCBA board soldering tin, in particular a tin outlet of a tin furnace. Two rectangle ends of the tin outlet are firmly connected with each other into an L-shape. The tin outlet on the lateral side of the tin outlet in L-shape is provided with a tin spill-way which is a rectangle opening with a depth of 2mm to 8mm.The invention has a simple structure and is capable of effectively increasing soldering efficiency and is applicable for large-scale automatic production; furthermore, oxidation layer on molten tin surface layer is effectively prevented from being retained on the surface of the PCBA board, and the quality of soldering spots is ensured.

Owner:苏州明杰自动化科技有限公司

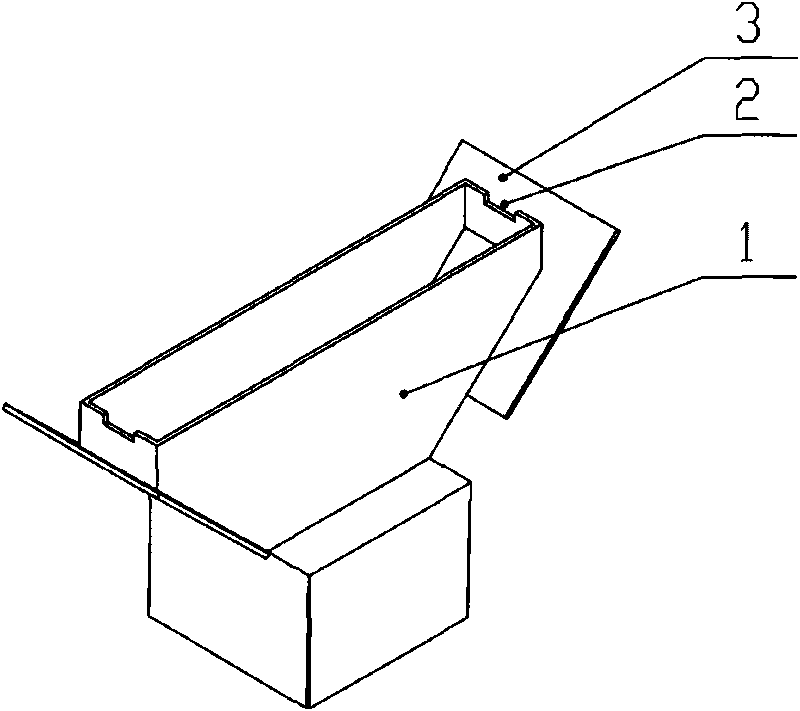

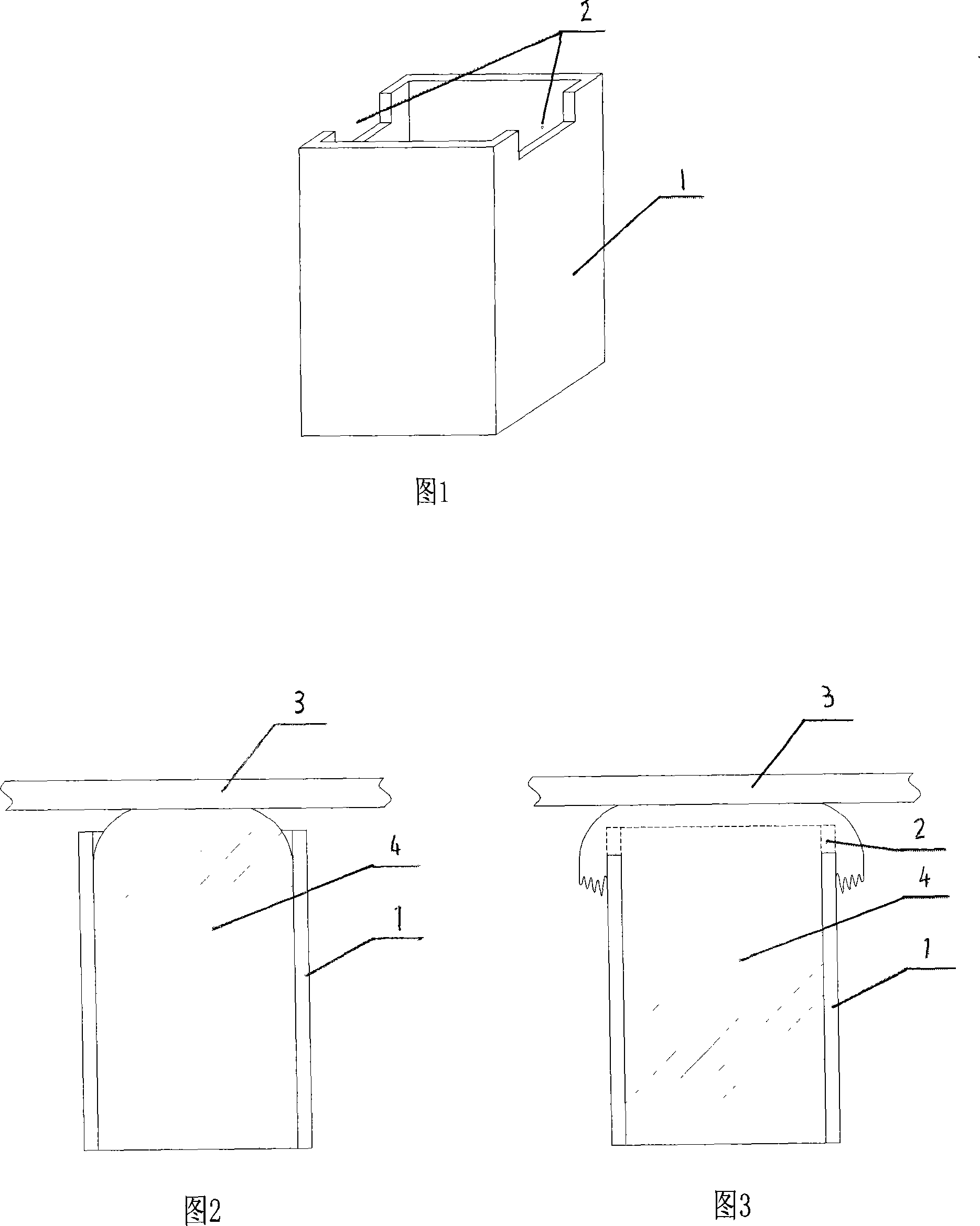

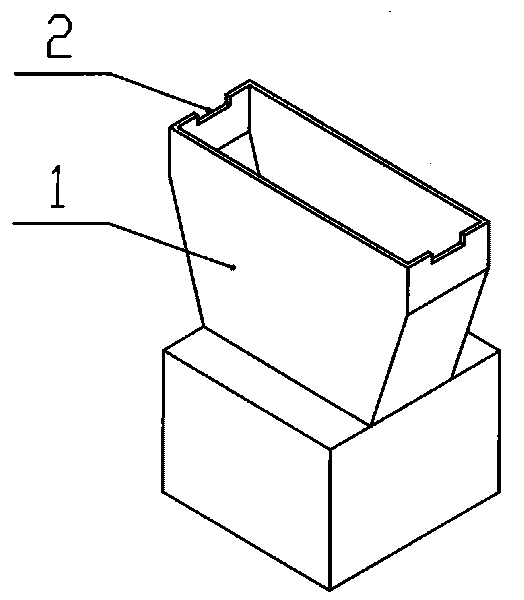

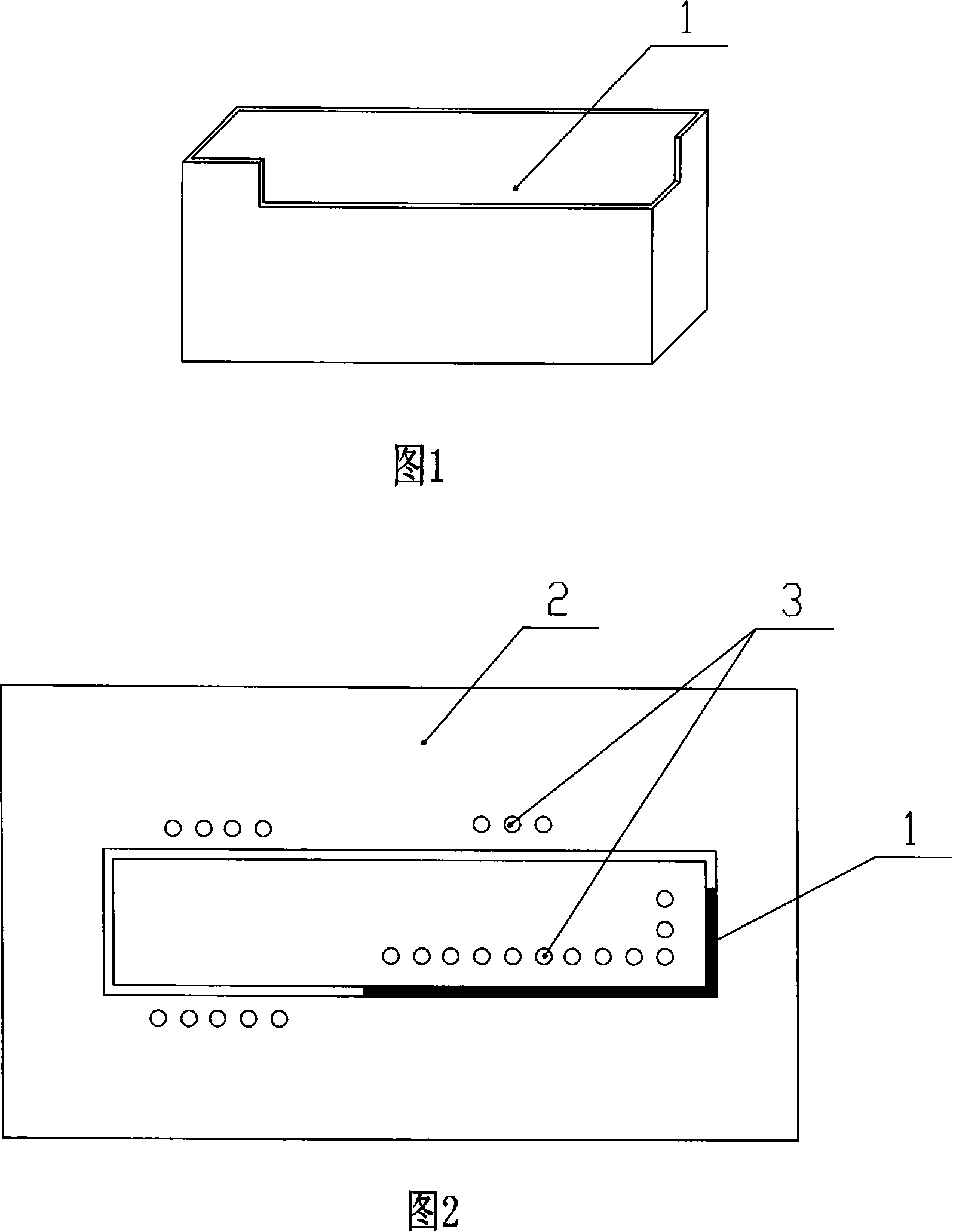

External baffle insertion type pot opening

InactiveCN101765306AChange directionDoes not affect soldering qualityPrinted circuit assemblingSurface layerEngineering

The invention relates to a tin furnace component used for PCBA board soldering tin, in particular to an insertion type tin furnace pot opening. A conical insertion opening is arranged at the opening part of the pot opening, the edge of the insertion opening is provided with at least one tin overflowing opening, the outer side of the tin overflowing opening is provided with baffle sheets, the baffle sheets are fixedly connected with the outer wall of the insertion opening, and the tin overflowing opening is a rectangular hole with the depth between 3 and 4 mm. The invention has a simple structure, can effectively improve the welding efficiency, and is suitable for large-scale automatic production, in addition, an oxide layer of the surface layer of the tin liquid is effectively prevented from being remained on the surface of a PCBA board, and the quality of welding points is ensured.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

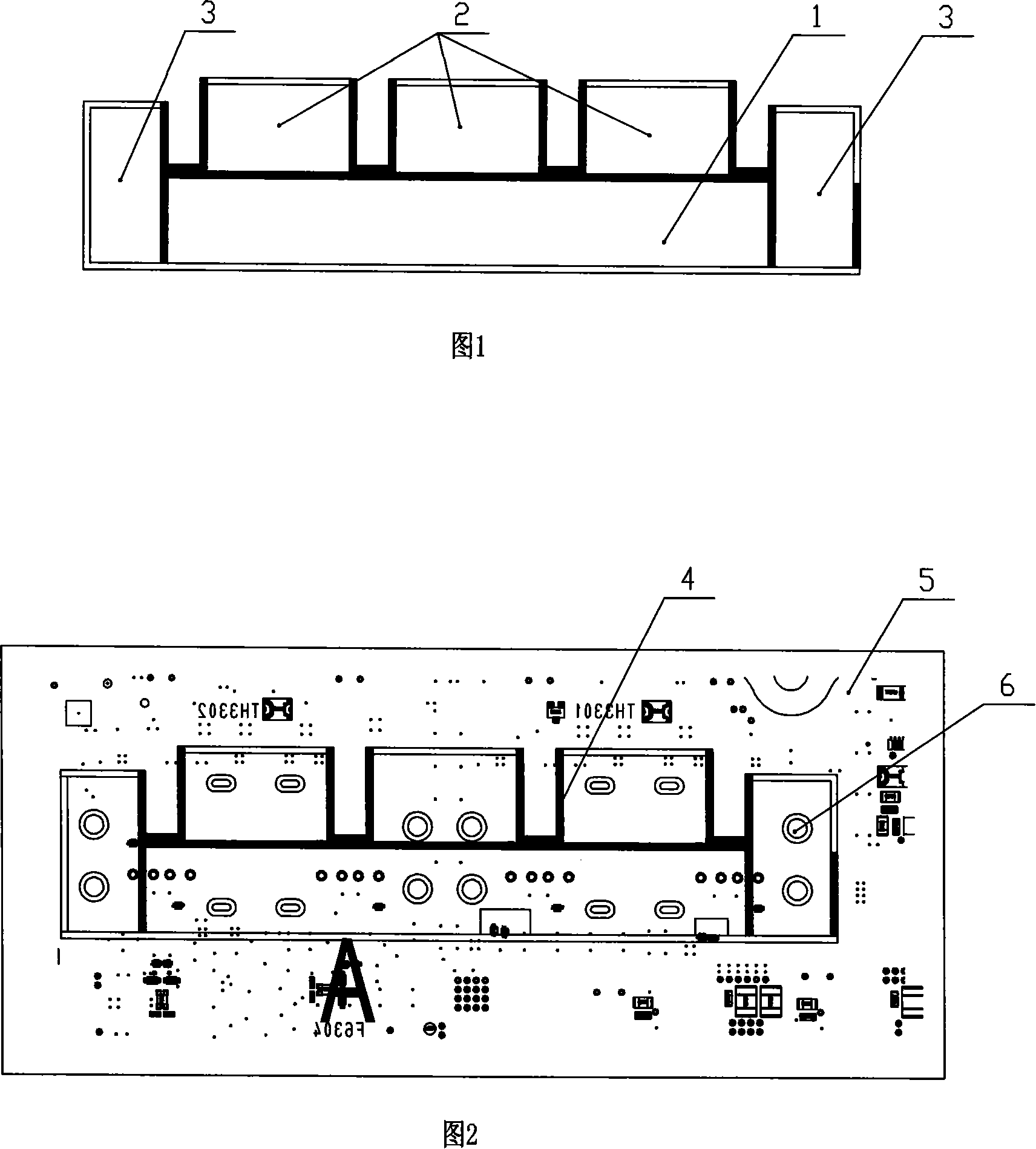

A tin furnace kettle mouth

InactiveCN101150925AChange directionDoes not affect soldering qualityPrinted circuit assemblingSolderingLiquid surfaces

The invention relates to a tin furnace component used to PCBA board soldering tin, in particular to a tin furnace kettle orifice, which is arranged above a tin groove and used for leading tin liquid to a tin outlet to generate tin wave for soldering tin, at least one tin overflow outlet is positioned around the kettle orifice tin outlet, the tin overflow outlet is a rectangular opening, the deepness is 2-8mm. The invention has a simple structure, can improve the soldering efficiency, is suitable for mass automatic production, in addition, effectively prevents an oxide layer of the tin liquid surface from remaining on the PCBA board, assures the welding joint quality.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

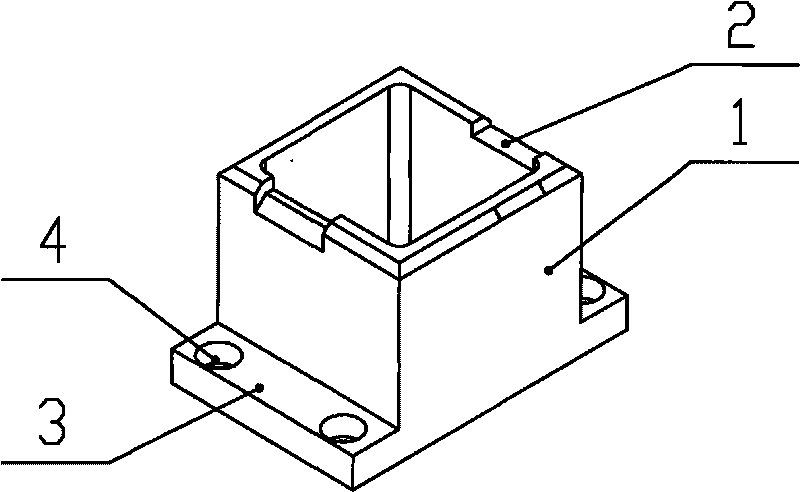

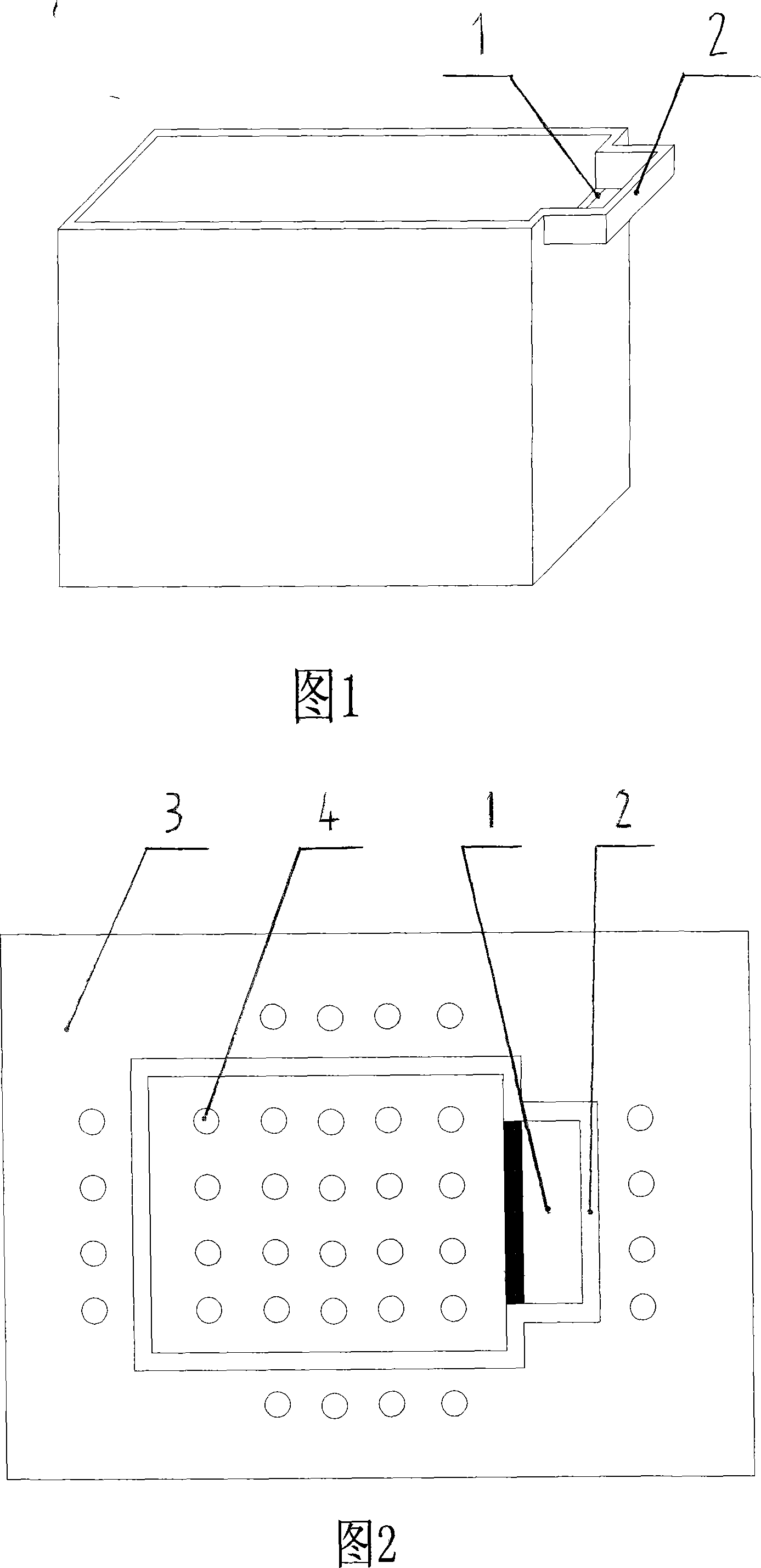

Fixed kettle mouth

InactiveCN101765321AChange directionDoes not affect soldering qualityPrinted circuit assemblingEngineeringSoldering

The invention relates to a solder stove component for soldering tin of PCBA plates, in particular to a fixed kettle mouth, which is characterized in that the mouth of the kettle mouth is provided with a cylindrical jack, and at least one tin overflowing opening is arranged on the edge of the cylindrical jack; the tin overflowing opening is of a rectangular gap, and the depth of the opening is 3 to 6mm; a tin overflowing inclined surface is arranged on the tin overflowing opening, and a base is arranged at the bottom of the cylindrical jack; and kettle mouth fixing holes are arranged on the base. The invention has simple structure, can effectively improve soldering efficiency, is suitable for large-scale automatic production, effectively prevents the oxide surface of a tin liquid surface layer from be remained on the surface of the PCBA plate, and ensures the quality of soldering contacts.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

Stannum export of stannum furnace

InactiveCN101179905AChange directionDoes not affect soldering qualityMultilayer circuit manufactureSolderingSurface layer

The invention relates to a tin furnace part of PCBA board soldering tin, in particular a tin outlet of a tin furnace. The invention is arranged above a tin bath and leads molten tin produce tin waves at the tin outlet for soldering operation. The periphery of the tin outlet has at least a tin spill-way which is a rectangle opening with a depth H of 2mm to 8mm.The invention has a simple structure and is capable of effectively increasing soldering efficiency and is applicable for large-scale automatic production; furthermore, oxidation layer on molten tin surface layer is effectively prevented from being retained on the surface of the PCBA board, and the quality of soldering spots is ensured.

Owner:苏州明杰自动化科技有限公司

Spilled stannum port with external stannum baffle type stannum export

InactiveCN101179902AChange directionFlow influenceMultilayer circuit manufactureSurface layerHeating furnace

The invention relates to a tin furnace part of PCBA board soldering tin, in particular a tin outlet of a tin furnace. The tin outlet is in a rectangle shape and is provided with at least a tin spill-way at the periphery, the two sides of which extend outward and has tin baffles of half-encircled structure. The tin spill-way is a rectangle opening with a depth of 2mm to 8mm. The invention has a simple structure and is capable of protection for soldering elements near the periphery of tin spilling effectively and realizing optional soldering for elements of the PCBA board above the tin outlet. Furthermore, oxidation layer on molten tin surface layer is effectively prevented from being retained on the surface of the PCBA board, and the quality of soldering spots is ensured.

Owner:苏州明杰自动化科技有限公司

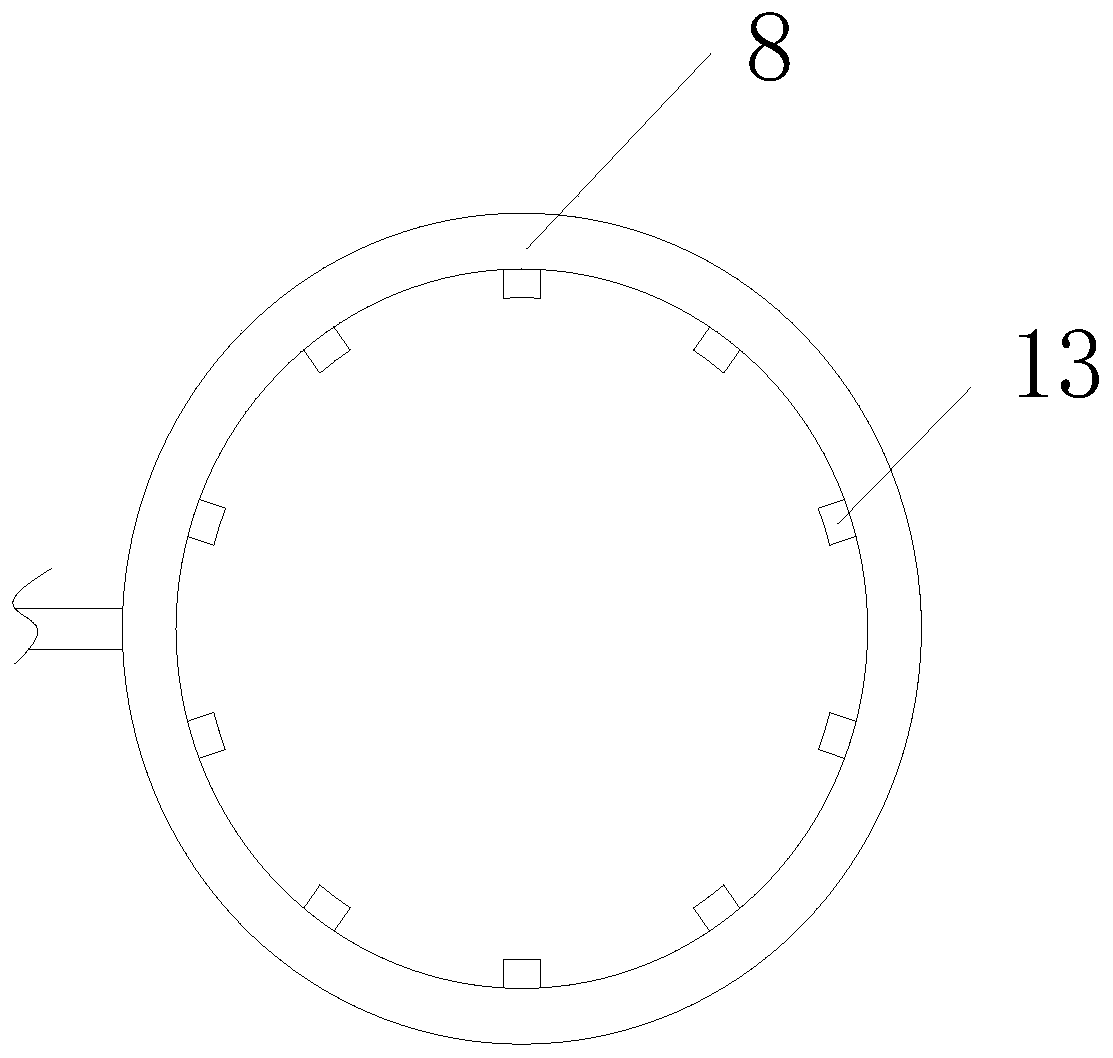

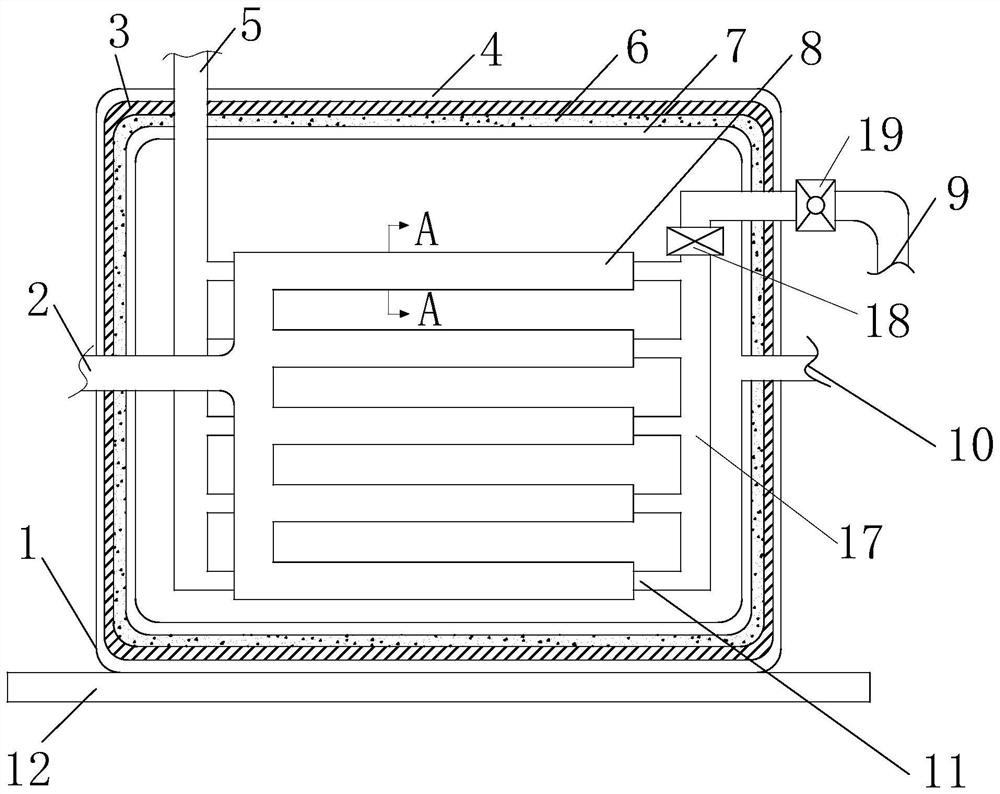

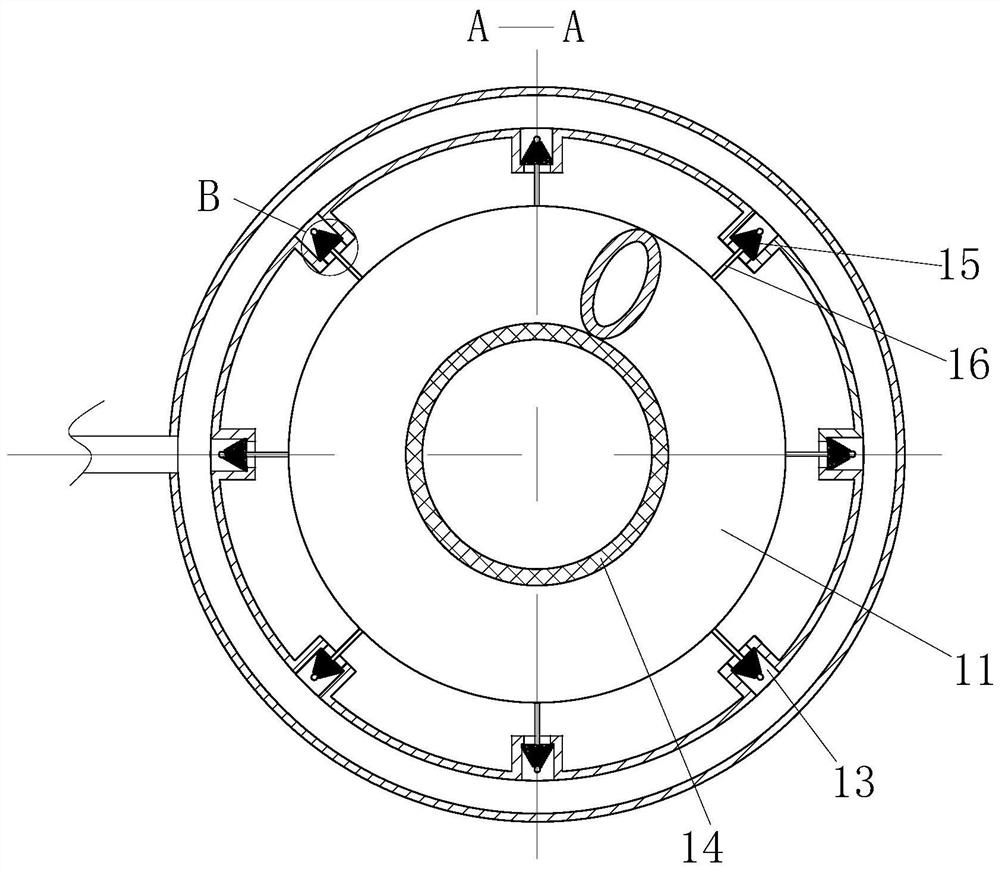

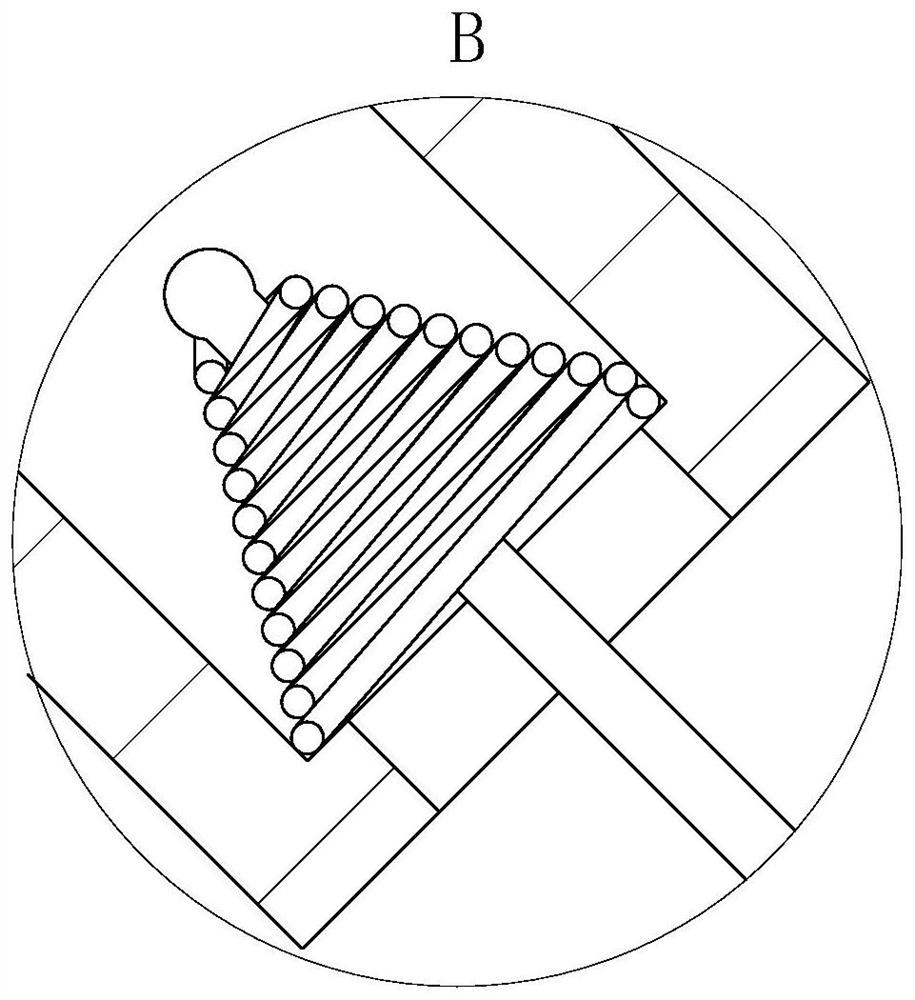

Liquid ammonia evaporator for flue gas denitration

ActiveCN111282296AImprove work efficiencyEnsure full functionEvaporation apparatusFlueLiquid ammonia

The invention belongs to the technical field of liquid ammonia evaporation devices, and in particular, relates to a liquid ammonia evaporator for flue gas denitration. The liquid ammonia evaporator comprises an evaporator box body; a supporting base is arranged at the bottom of the evaporator box body; the evaporator box body comprises a vacuum layer, a box body outer shell, a foam layer and a boxbody inner shell; the vacuum layer is arranged on the inner side of the box body outer shell; the foam layer is arranged on one side, away from the box body outer shell, of the vacuum layer; a box body inner shell is arranged on one side, far away from the vacuum layer, of the foam layer; a plurality of flue gas pipelines are arranged in the box body inner shell; a plurality of flue gas sprayingopenings are formed in an inner ring of each flue gas spraying pipeline. According to the liquid ammonia evaporator, a traditional straight pipe flue gas pipeline is arranged to be an annular flue gaspipeline, and the plurality of flue gas spraying openings are formed in the inner ring; the plurality of layers of annular flue gas pipelines are arranged, a liquid ammonia coil pipe is surrounded by360 degrees from top to bottom, the sufficiency and uniformity of heating of the liquid ammonia coil pipe are guaranteed, and the working efficiency of the liquid ammonia evaporator is greatly improved.

Owner:JINAN SHENHUA REFRIGERATION EQUIP

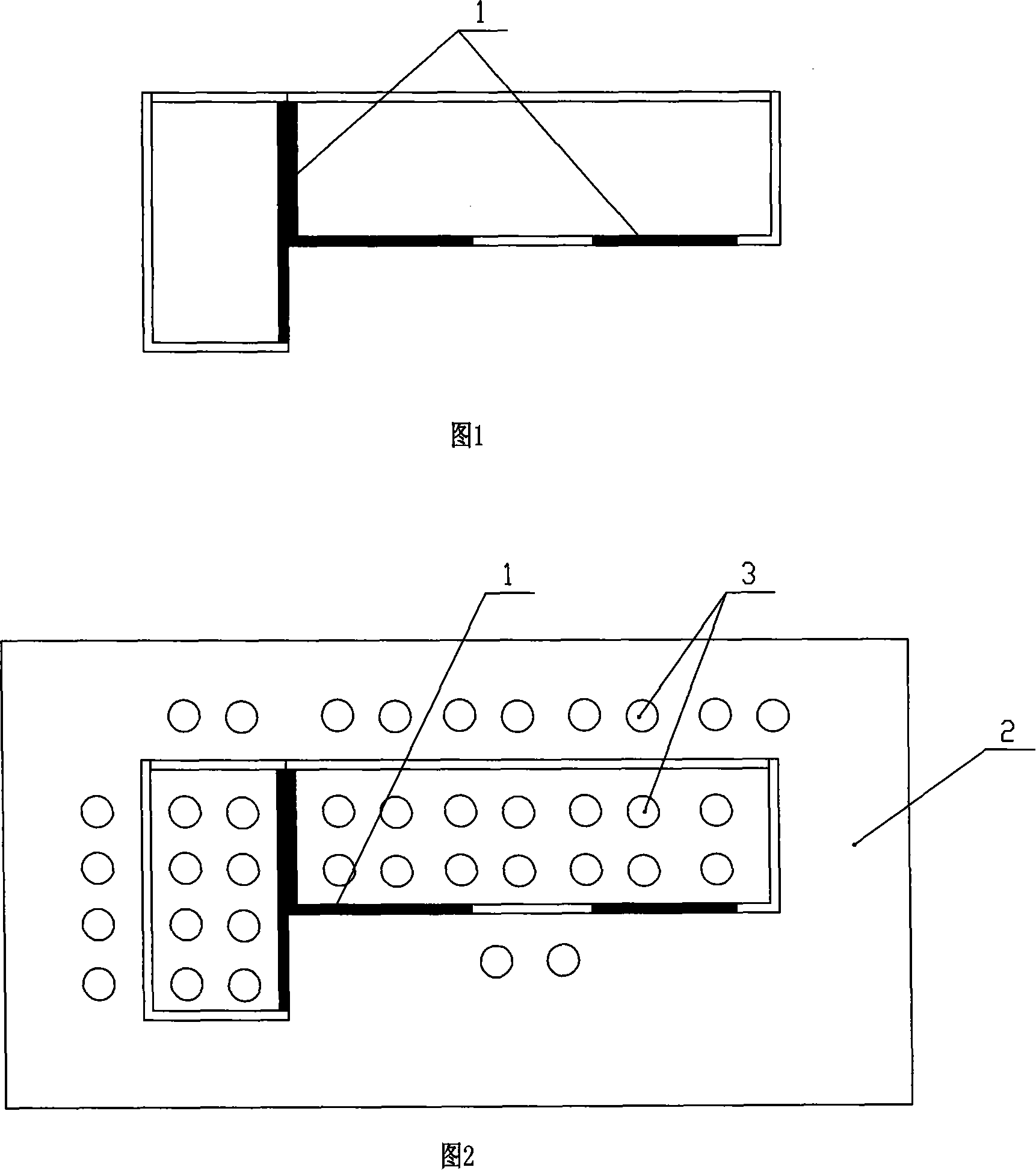

L-shaped upstream side flowing spout

InactiveCN101765322AChange directionDoes not affect soldering qualityPrinted circuit assemblingEngineeringSoldering

The present invention relates to a tin furnace component for the tin soldering of PCBA plates, in particular to an L-shaped upstream side flowing spout. Two spouts are split into an L-shaped structure. A tin overflow port is arranged at the edge port of the L-shaped upstream side flowing spout. A stopping edge is arranged at the front side of the tin overflow port, and spout side walls at the lower end of the stopping edge are fixedly connected. The tin overflow port is a rectangular breach, and the depth is three to six mm. The structure of the present invention is simple, and the welding rate can be effectively improved. The tin furnace component for the tin soldering of PCBA plates is suitable for large-scale automation production. In addition, oxide layers on tin liquid surface layers are avoided to remain on the surfaces of the PCBA plates, and the quality of welding joints is ensured.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

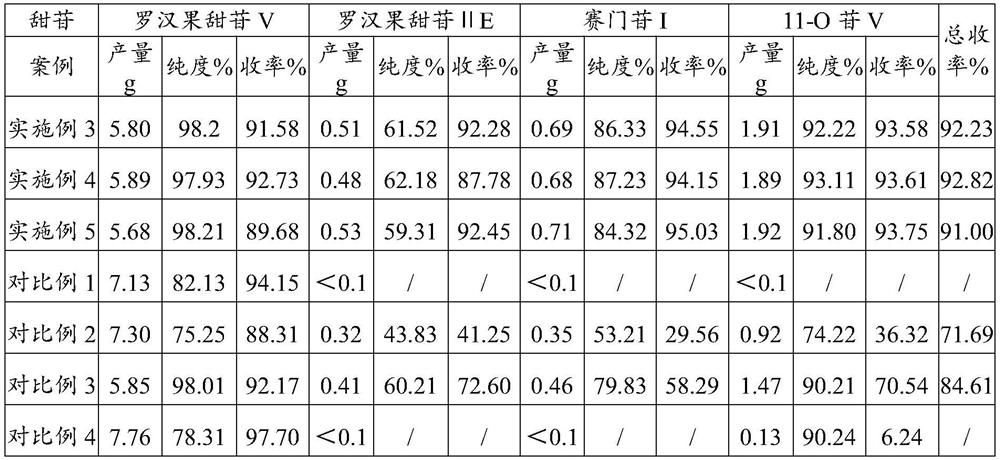

Method for separating mogroside V and rare mogroside substances

ActiveCN113461765AEffective combinationGuaranteed accuracyGlycoside steroidsAqueous ethanolMogroside V

The invention relates to the technical field of active substance separation, in particular to a method for separating mogroside V and rare mogroside substances. The method comprises the following steps: dissolving mogroside, and degassing the solution to obtain a sampling solution; loading the sampling liquid onto a multi-cascade chromatographic column formed by connecting an imprinted polymer chromatographic column and a macroporous adsorption resin chromatographic column in series, and sequentially washing the column with a degassed ethanol water solution and a degassed water washing column; releasing vacuum to normal pressure, and respectively desorbing the disconnected imprinted polymer chromatographic column with a mixed solution of acetonitrile and ethanol; respectively collecting desorption solutions containing rare mogroside substances; and desorbing the macroporous adsorption resin chromatographic column by using an ethanol aqueous solution, and collecting a desorption solution containing mogroside V. The mogroside collected by the method is high in yield and high in purity, and the chromatographic column can be recycled.

Owner:HUNAN HUACHENG BIOTECH

External flow four-opening type pot opening

InactiveCN101765332AChange directionDoes not affect soldering qualityPrinted circuit assemblingSurface layerEngineering

The invention relates to a tin furnace component used for PCBA board soldering tin, in particular to an eternal flow four-opening type pot opening. A part shielding hole is formed in the middle, a tin overflowing opening is arranged along the periphery of the opening at the outer periphery of the pot opening, and tin overflowing opening is a rectangular notch with the depth between 3 and 6 mm. The invention has a simple structure, can effectively improve the welding efficiency, and is suitable for large-scale automatic production, in addition, an oxide layer of the surface layer of the tin liquid is effectively prevented from being remained on the surface of a PCBA board, and the quality of welding points is ensured.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

Sheet type spout for avoidance of grounding block element

InactiveCN101765316AChange directionDoes not affect soldering qualityPrinted circuit assemblingEngineeringSoldering

The invention relates to a component of a soldering furnace for tin soldering of a PCBA board, in particular to a sheet type spout for avoidance of a grounding block element for welding a computer motherboard. The edge of the spout is provided with at least one tin overflow port, the tin overflow port is a rectangular opening and is 3-4mm deep; the side wall of the spout is concave inwards to form an avoidance ring for accommodating a grounding block, and the outer wall of the spout below the avoidance ring is provided with a rectangular tin overflow hole. The invention has simple structure, can effectively improve the welding efficiency, and is applicable to large-scale automated production. In addition, the invention can effectively prevent the oxide layer on the tin liquid surface from being left on the surface of the PCBA board, thereby ensuring the quality of the welding joint.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

One-side single open kettle mouth with tin overflow mouth length

InactiveCN101150926AChange directionDoes not affect soldering qualityPrinted circuit assemblingSolderingLiquid surfaces

The invention relates to a tin furnace component used to PCBA board soldering tin, in particular to a tin furnace kettle orifice. The kettle orifice has a rectangular shape, at least one tin overflow outlet is arranged on a long edge of the rectangle edges, the tin overflow outlet is a rectangular opening, the deepness is 2-8mm. The invention has a simple structure, can improve the soldering efficiency, is suitable for mass automatic production, in addition, effectively prevents an oxide layer of the tin liquid surface from remaining on the PCBA board, assures the welding joint quality.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

Fixed insertion type pot mouth

InactiveCN101765327AChange directionDoes not affect soldering qualityPrinted circuit assemblingEngineeringSoldering

The invention relates to a tin stove component used for PCBA plate soldering tin, in particular to a fixed insertion type pot mouth. The mouth part of the pot mouth is provided with a conical faucet, the edge of the conical faucet is provided with at least a tin overflowing mouth which is a rectangular gap with the depth of 3 to 6 mm, a fixed plate is arranged at the inner wall of the pot mouth, and the fixed plate is provided with a fixing hole. The invention has simple structure, can effectively increase the welding efficiency and is suitable for large-scale automatic production, and additionally, an oxide layer on the tin liquid surface is effectively prevented from being left on the surface of a PCBA plate, and the quality of welding joints is ensured.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

One-side dual open kettle mouth with tin overflow mouth length

InactiveCN101150929AChange directionDoes not affect soldering qualityPrinted circuit assemblingSolderingLiquid surfaces

The invention relates to a tin furnace component used to PCBA board soldering tin, in particular to a tin furnace kettle orifice. The kettle orifice has a rectangular shape, each long edge of the rectangle edges is provided with a tin overflow outlet respectively, the tin overflow outlet is rectangular opening, the deepness is 2-8mm. The invention has a simple structure, can improve the soldering efficiency, is suitable for mass automatic production, in addition, effectively prevents an oxide layer of the tin liquid surface from remaining on the PCBA board, assures the welding joint quality.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

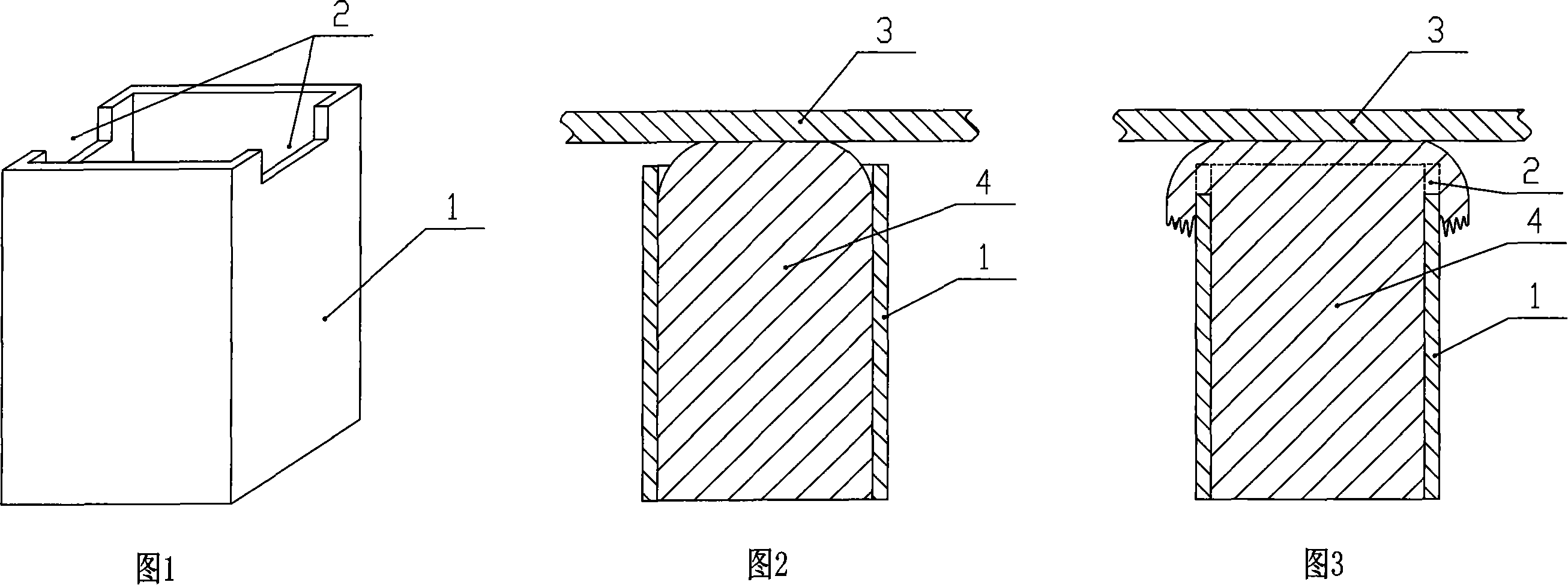

A tin overflow concave internal open kettle mouth

InactiveCN101150920AEnsure sufficiency and firmnessChange directionPrinted circuit assemblingSolderingOxide

The invention relates to a tin furnace component used to PCBA board soldering tin, in particular to a tin furnace kettle orifice. The kettle orifice has a concave shape, a tin overflow orifice is arranged at the concave tin outlet of the kettle orifice, the tin overflow orifice is a rectangular opening, the deepness is 2-8mm. The invention has a simple structure, can improve the soldering efficiency, is suitable for mass automatic production, in addition, effectively prevents an oxide layer of the tin liquid surface from remaining on the PCBA board, assures the welding joint quality.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

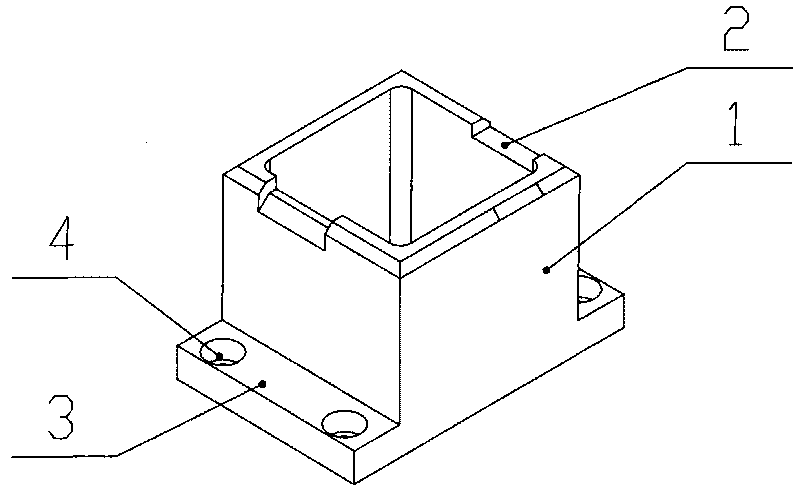

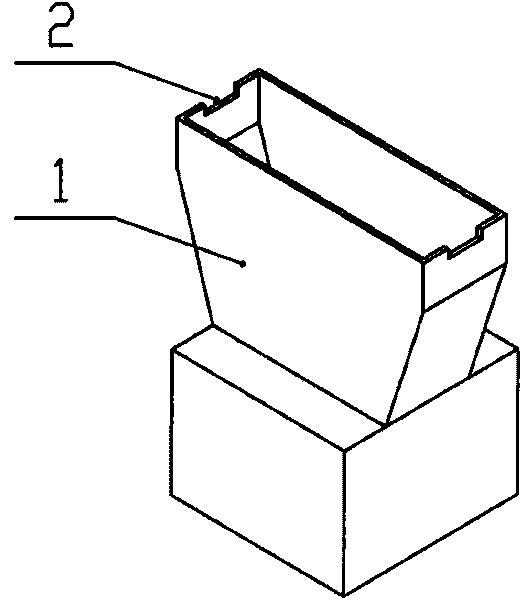

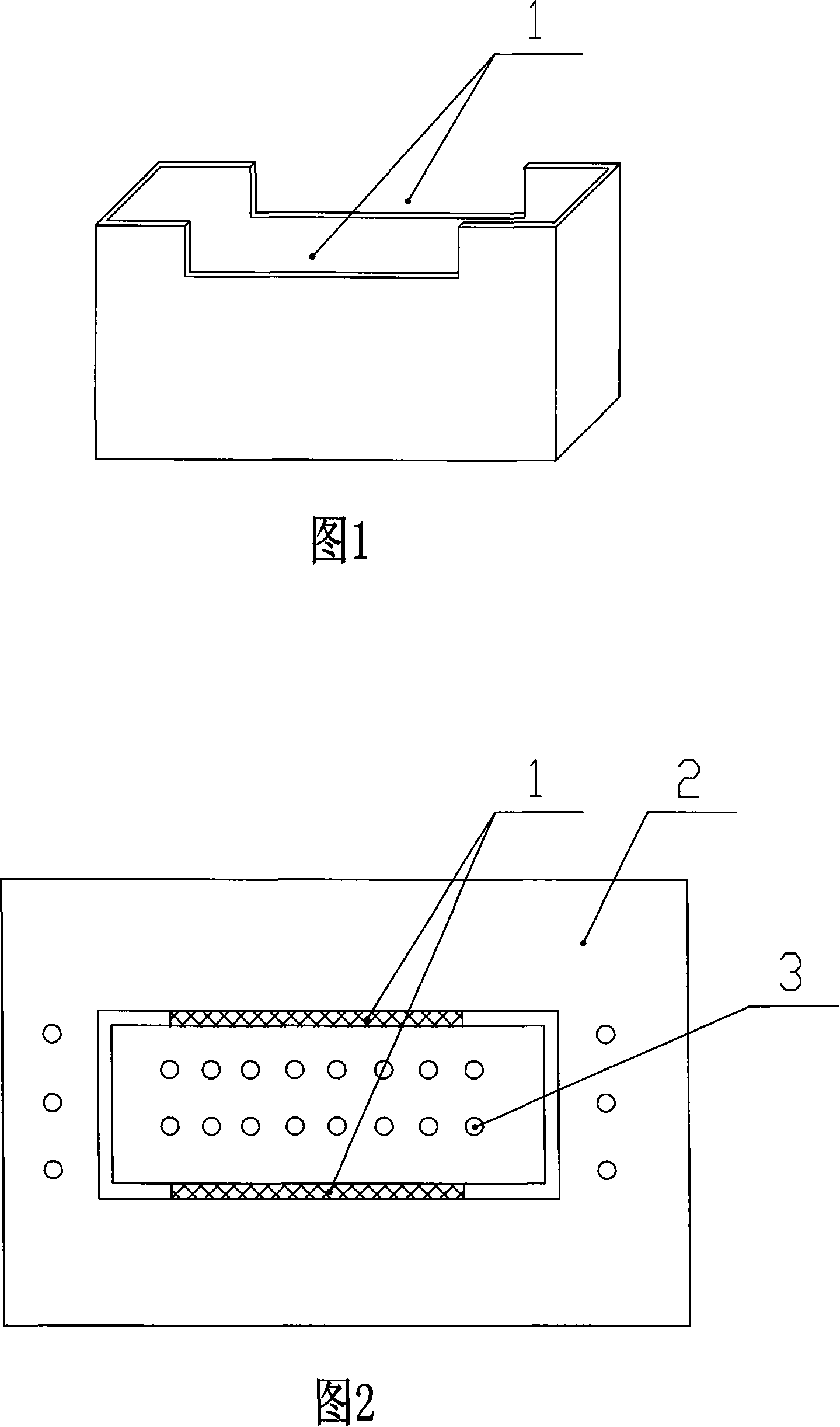

A tin overflow internal open L kettle mouth

InactiveCN101150918AEnsure sufficiency and firmnessChange directionPrinted circuit assemblingSolderingOxide

The invention relates to a tin furnace component used to PCBA board soldering tin, in particular to a tin furnace kettle orifice. Two rectangular kettle orifice ends are connected to be a 'L' shape, a tin overflow orifice is arranged at the tin outlet of the inner side of the 'L' shaped kettle orifice, the tin overflow orifice is a rectangular opening, the deepness is 2-8mm. The invention has a simple structure, can improve the soldering efficiency, is suitable for mass automatic production, in addition, effectively prevents an oxide layer of the tin liquid surface from remaining on the PCBA board, assures the welding joint quality.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

Plug-in type spout

InactiveCN101765304AChange directionDoes not affect soldering qualityPrinted circuit assemblingEngineeringSoldering

The invention relates to a tin furnace component for tin soldering of a PCBA, in particular to a plug-in type spout of a tin furnace. A tapered spigot is arranged at the opening part of the spout, and at least one tin overflow hole is arranged at the rim of the tapered spigot. The tin overflow hole is rectangular, and the depth is within 3 to 4mm. The plug-in type spout has the following characteristics: the structure is simple and the welding efficiency can be effectively increased; moreover, the plug-in type spout is suitable for automatic mass production, effectively avoids an oxidation layer of a tin liquid surface layer from being left over on the surface of the PCBA, and ensures the quality of welding points.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

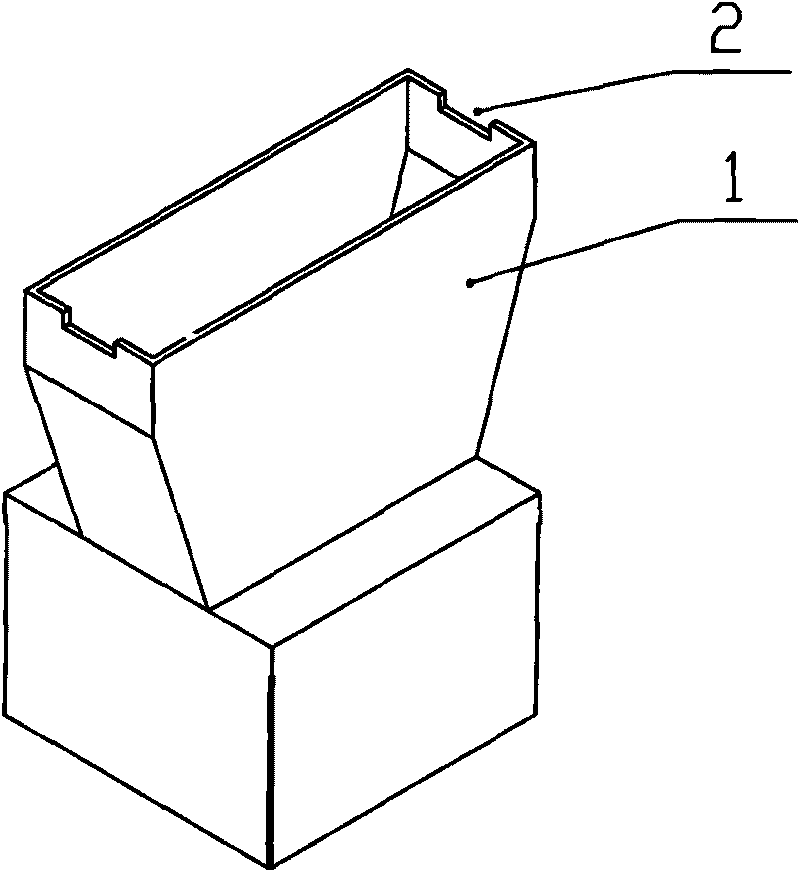

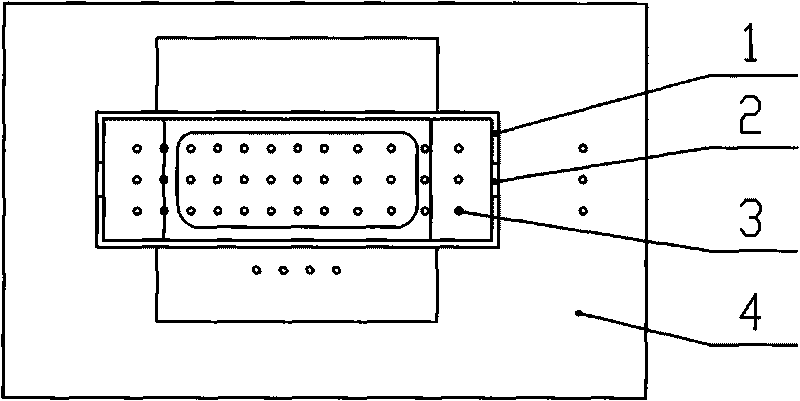

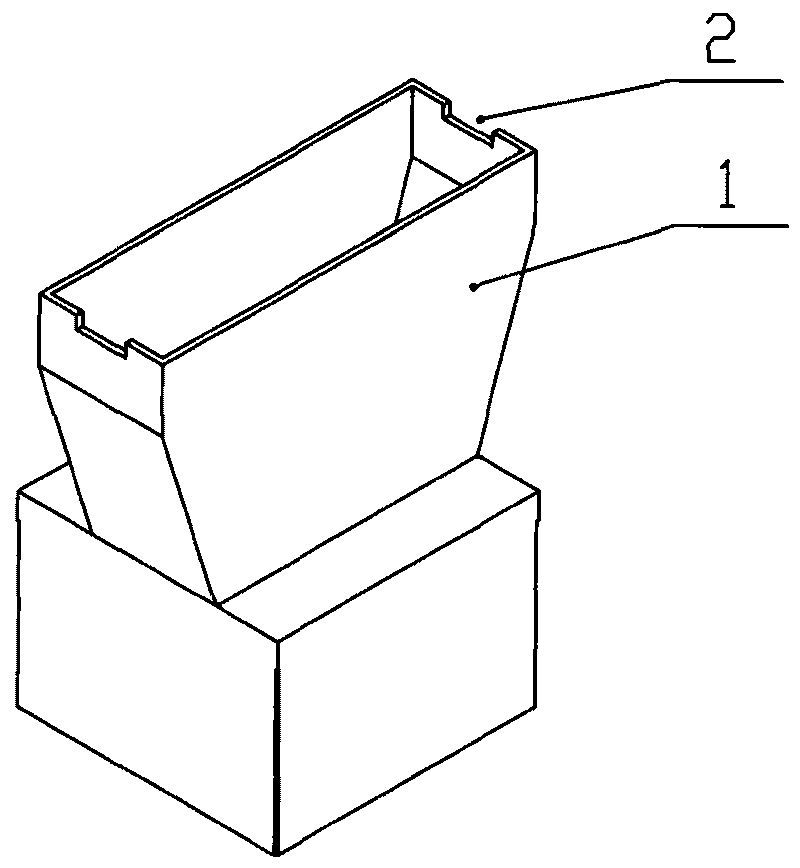

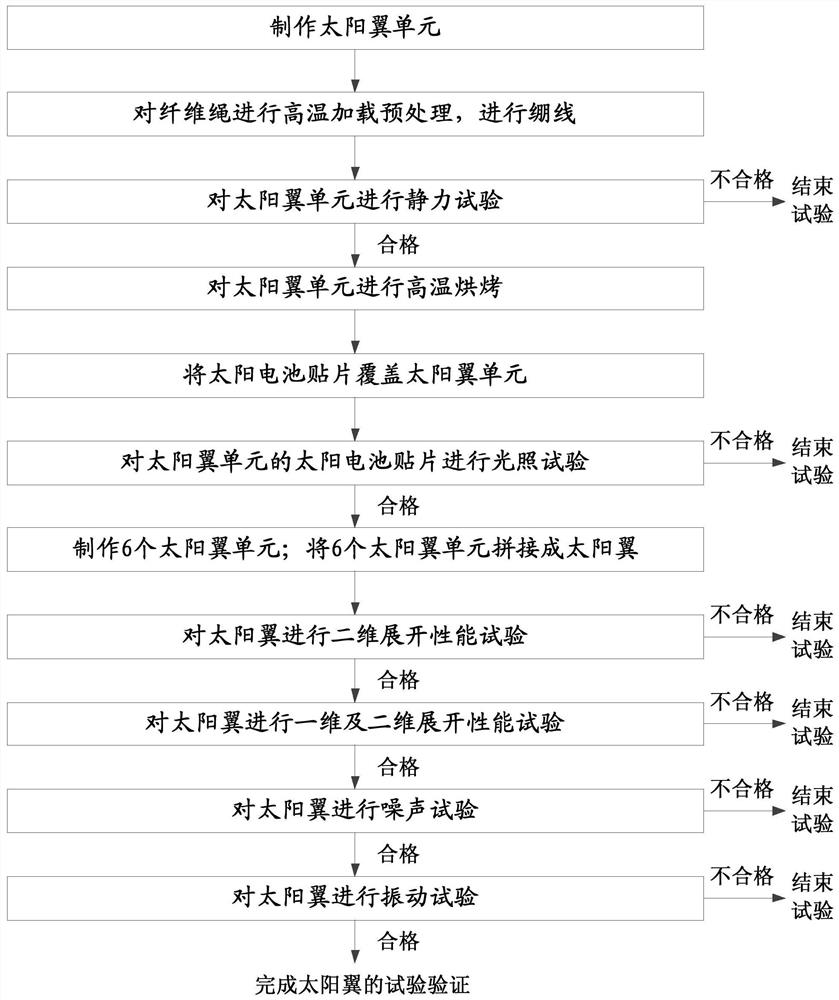

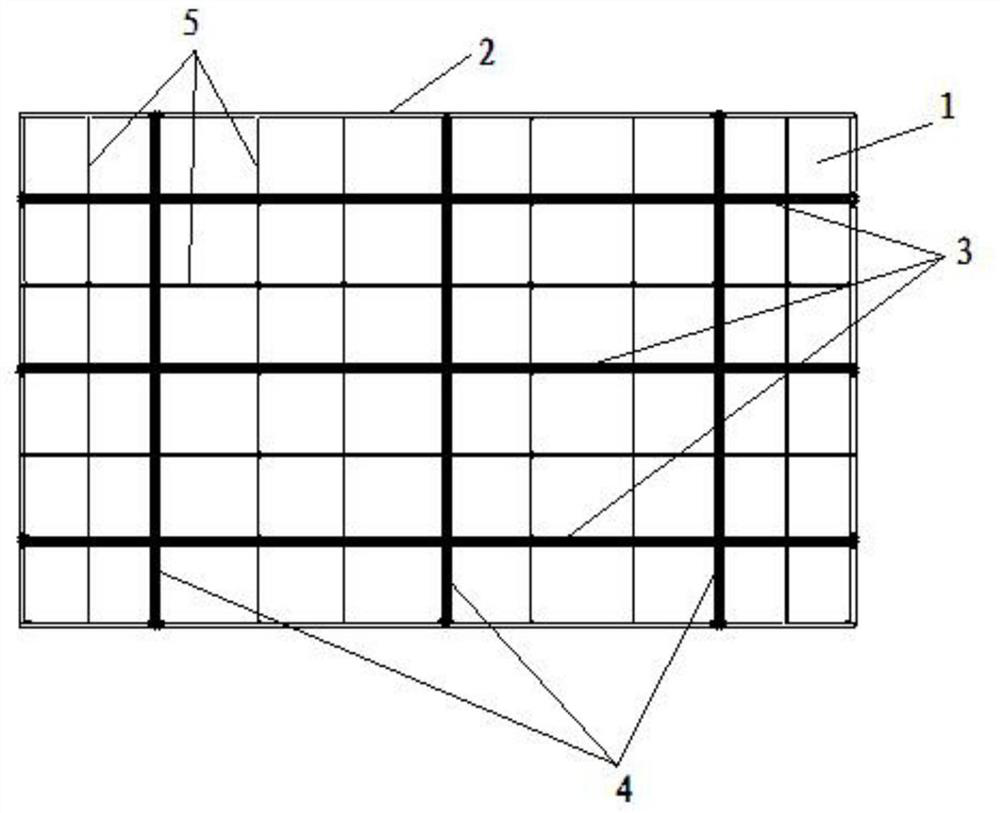

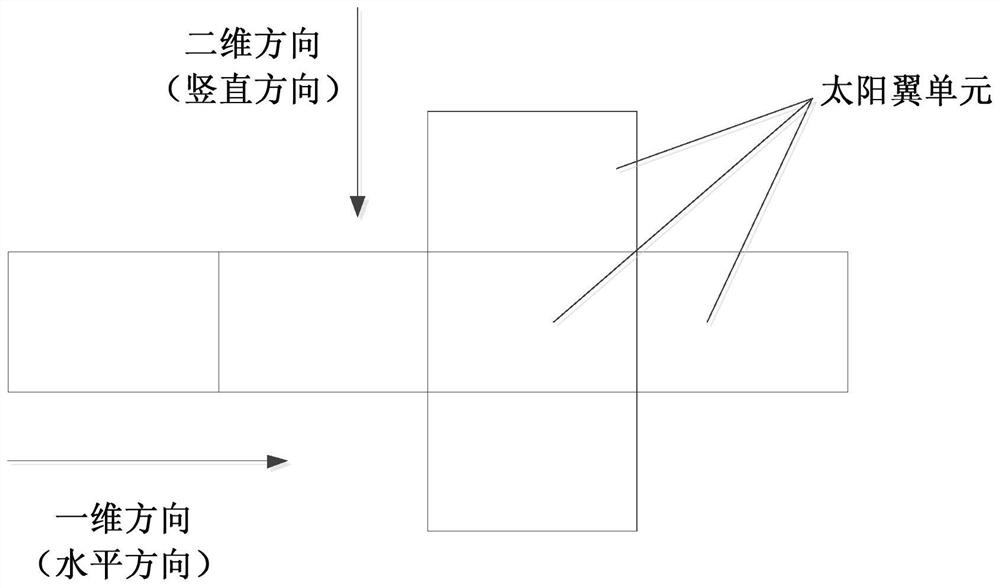

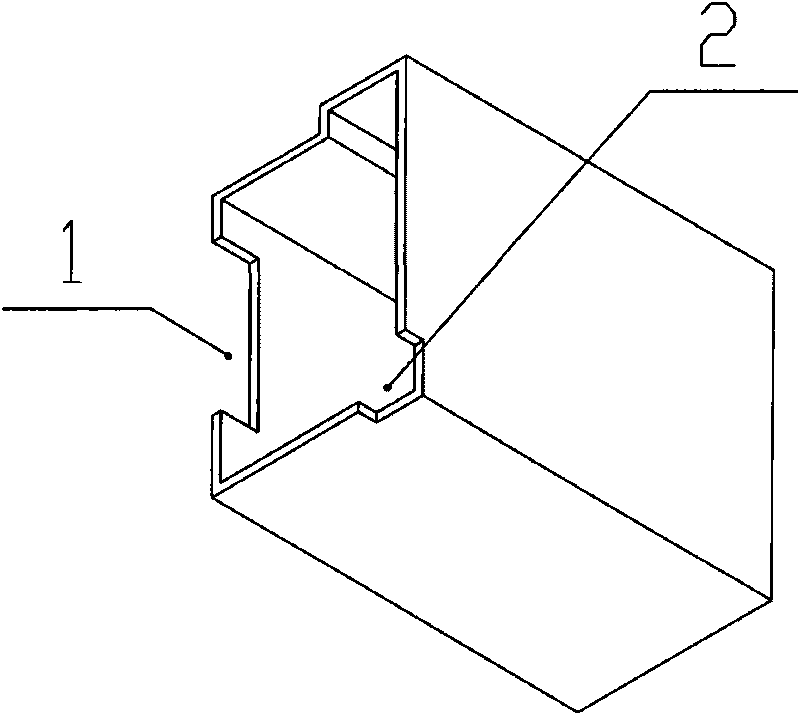

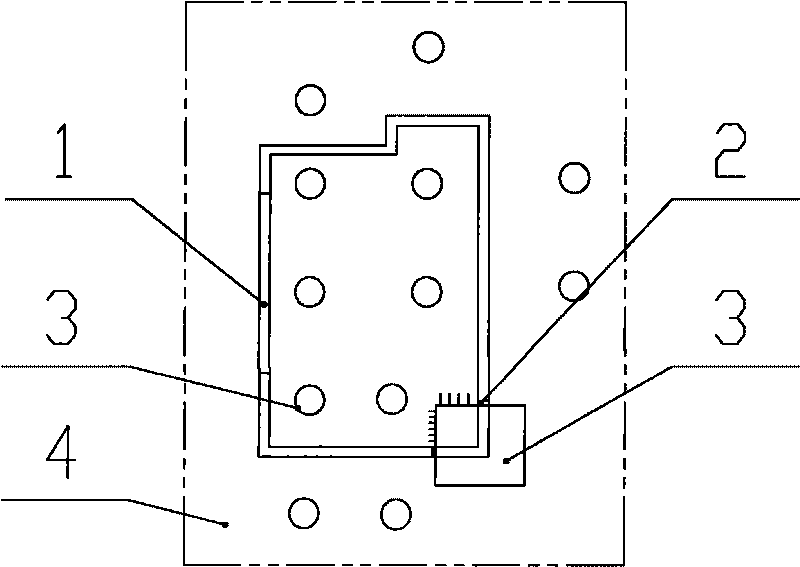

Experimental verification method for a two-dimensional quadratic semi-rigid solar wing

The invention relates to a test verification method for a two-dimensional quadratic semi-rigid solar wing, which belongs to the field of synchronous orbit long-life communication satellites; On the basis of the solar wing development process, combined with the characteristics of semi-rigid solar wings, the high-temperature loading pretreatment of fiber ropes and the high-temperature baking test before substrate patching are added, and a flow plan for the verification of distributed part assembly and deployment is proposed according to the characteristics of two-dimensional deployment to solve the problem. The problem of verification adequacy and effectiveness of the semi-rigid two-dimensional solar wing is solved; the invention not only ensures the adequacy of verification, but also improves the efficiency of product development, which is of great significance to product development.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

Two-sided straddle type and part-avoiding type spout

InactiveCN101765312AChange directionDoes not affect soldering qualityPrinted circuit assemblingSurface layerInduction motor

The invention relates to a tin furnace component for soldering tin of PCBA plates, in particular to a two-sided straddle type and part-avoiding type spout for the PCBA plates of magnetic induction motors. The spout is in a rectangular shape, wherein at least one rectangular edge is provided with a tin overflow opening; a part straddle opening is arranged on a break angle of the spout; and the tin overflow opening is a rectangular breach of which the depth is between 3 and 4 millimeters. The two-sided straddle type and part-avoiding type spout has a simple structure, can effectively improve the welding efficiency, and is suitable for large-scale automatic production; and in addition, the two-sided straddle type and part-avoiding type spout effectively prevents an oxidation layer of a surface layer of tin liquid from remaining on the surfaces of the PCBA plates, and ensures the quality of welding contacts.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

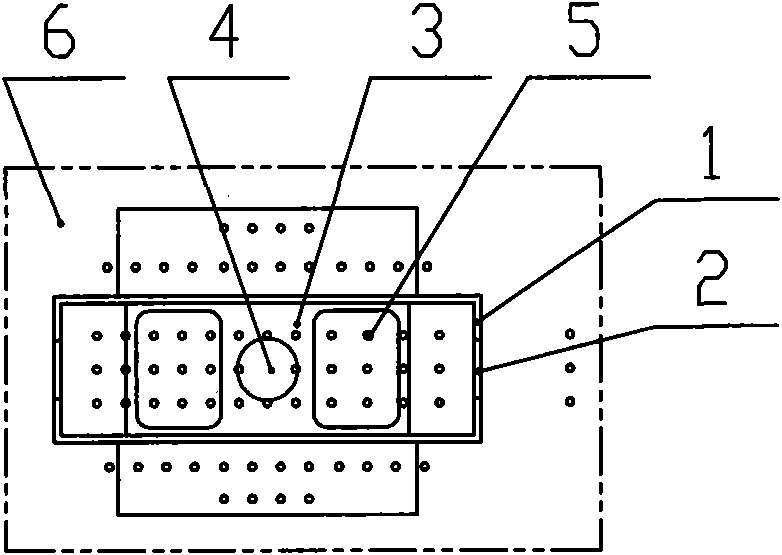

A liquid ammonia evaporator for flue gas denitrification

ActiveCN110180357BEnsure full functionImprove work efficiencyEvaporator accessoriesDispersed particle separationFlue gasHeat leak

The invention discloses a liquid ammonia evaporator for flue gas denitrification, which comprises an evaporator box, the bottom of the evaporator box is provided with a support base, and the evaporator box includes a vacuum layer, a box shell, a foam layer and a box inner shell , the inside of the box shell is provided with a vacuum layer, the side of the vacuum layer away from the box shell is provided with a foam layer, the side of the foam layer away from the vacuum layer is provided with a box inner shell, and the inside of the box inner shell is provided with at least two smoke Gas pipes, the inner wall of each flue gas pipe is spirally provided with at least eight smoke nozzles, and the inside of the flue gas pipes located in the evaporator box are spirally interspersed with liquid ammonia coils; the upper right side of the liquid ammonia coils is provided with ammonia Gas outlet, and a liquid ammonia inlet is arranged above the liquid ammonia coil, and a long straight hose is arranged at the rotation center of the spirally arranged liquid ammonia coil; the invention can avoid the need to replace the evaporator in the early stage of liquid ammonia gasification When there is flue gas in the box, the flue gas with heat leaks to cause the problem of heat loss of the flue gas.

Owner:平顶山市东鑫焦化有限责任公司

Spilled stannum port with external L-shaped stannum export

InactiveCN101179903AChange directionDoes not affect soldering qualityMultilayer circuit manufactureSurface layerSoldering

The invention relates to a tin furnace part of PCBA board soldering tin, in particular a tin outlet of a tin furnace. Two rectangle ends of the tin outlet are firmly connected with each other into an L-shape. The tin outlet on the lateral side of the tin outlet in L-shape is provided with a tin spill-way which is a rectangle opening with a depth of 2mm to 8mm.The invention has a simple structure and is capable of effectively increasing soldering efficiency and is applicable for large-scale automatic production; furthermore, oxidation layer on molten tin surface layer is effectively prevented from being retained on the surface of the PCBA board, and the quality of soldering spots is ensured.

Owner:苏州明杰自动化科技有限公司

An open kettle mouth at tin overflow corner

InactiveCN101150927AChange directionDoes not affect soldering qualityPrinted circuit assemblingSolderingLiquid surfaces

The invention relates to a tin furnace component used to PCBA board soldering tin, in particular to a tin furnace kettle orifice. The kettle orifice has a rectangular shape, a tin overflow outlet 1 is arranged at least at one corner of the kettle orifice tin outlet, the tin overflow outlet 1 is a rectangular opening, the deepness is 2-8mm. The invention has a simple structure, can improve the soldering efficiency, is suitable for mass automatic production, in addition, effectively prevents an oxide layer of the tin liquid surface from remaining on the PCBA board, assures the welding joint quality.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

A tin overflow concave external open kettle mouth

InactiveCN101150921AChange directionDoes not affect soldering qualityPrinted circuit assemblingEngineeringSoldering

The invention relates to a tin furnace component used to PCBA board soldering tin, in particular to a tin furnace kettle orifice. The kettle orifice consists of a long and narrow rectangular main kettle orifice and at least two branch kettle orifices which are arranged fixedly on sides of the main kettle orifice, end kettle orifices are arranged at both ends of the main kettle orifice, a tin overflow outlet is arranged at the concave circumference which consists of two adjacent branch kettle orifices and the main kettle orifice, and a tin overflow is arranged at the joint of the main and branch kettle orifices, and at the connected surface of the end kettle orifices and the main kettle orifice respectively, the overflow orifice is a rectangular opening, the deepness is 2-8mm. The invention has a simple structure, can improve the soldering efficiency, is suitable for mass automatic production, in addition, effectively prevents an oxide layer of the tin liquid surface from remaining on the PCBA board, assures the welding joint quality.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

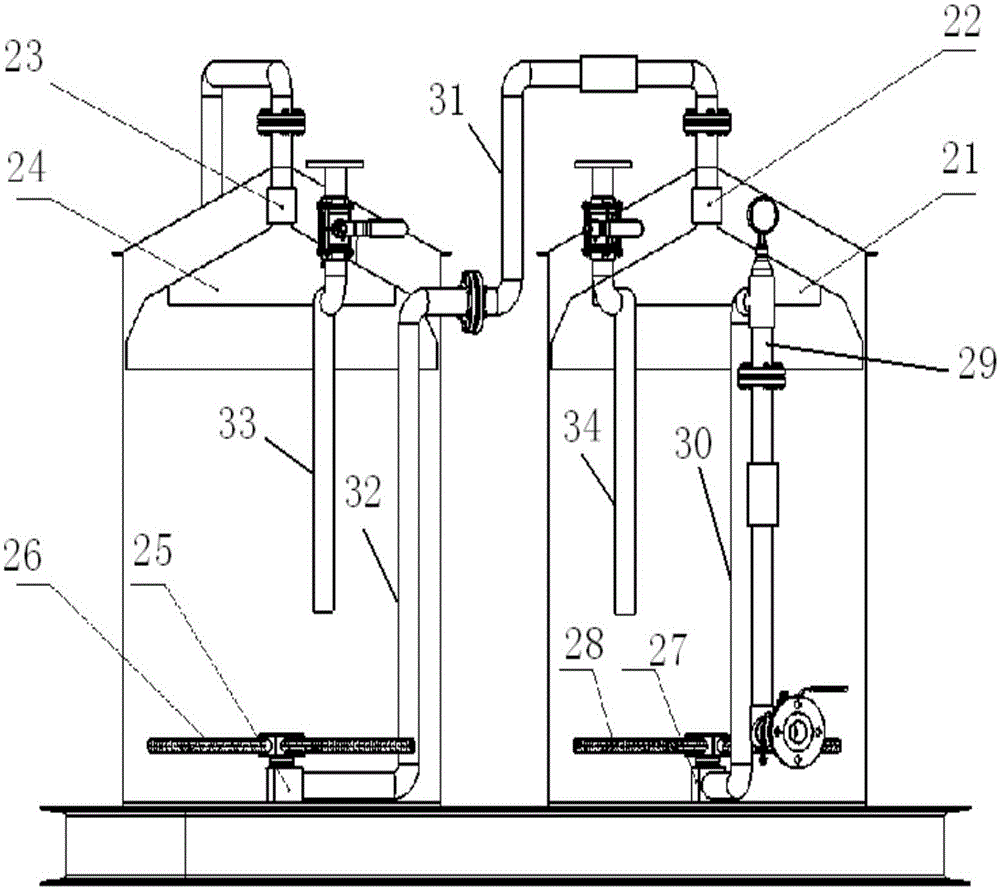

Pressure-stock-type two-stage double-agent desulfurization device and application method thereof

ActiveCN105032150AReduce corrosionAvoid harmDispersed particle separationVapor–liquid separatorProduct gas

The invention relates to the field of oil exploitation, and discloses a pressure-stock-type two-stage double-agent desulfurization device and an application method thereof. The device comprises a primary desulfurization tank and a secondary desulfurization tank. Gas pressure dividers and gas dispersers are arranged on the bottoms of the inner cavities of the primary and secondary desulfurization tanks. Gas deflection collection hoods and gas-liquid separators are arranged on the tops of the desulfurization tanks. A partial pressure control valve is arranged on a gas route before the primary desulfurization rank. A pressure-stock control valve is arranged between the primary and secondary desulfurization tanks. With the device, a hydrogen sulfide component in ground oil storage square can associated gas can be subjected to dynamic desulfurization treatment progressively with pressure, with the process flow of the device, while production is not stopped. Therefore, hydrogen sulfide content in the oil storage square cans can reach related standards, corrosion to delivery equipment can be reduced, injury caused by hydrogen sulfide is prevented, and personal safety of staffs is improved.

Owner:陕西明特石油技术有限公司

One face single open type stannum export of long spilled stannum port

InactiveCN101179904AChange directionDoes not affect soldering qualityMultilayer circuit manufactureSurface layerSoldering

The invention relates to a tin furnace part of PCBA board soldering tin, in particular a tin outlet of a tin furnace. The tin outlet is in a rectangle shape, and a long side on one side of the rectangle sides is provided with a tin spill-way which is a rectangle opening with a depth of 2mm to 8mm.The invention has a simple structure and is capable of effectively increasing soldering efficiency and is applicable for large-scale automatic production; furthermore, oxidation layer on molten tin surface layer is effectively prevented from being retained on the surface of the PCBA board, and the quality of soldering spots is ensured.

Owner:苏州明杰自动化科技有限公司

Internal opening full flow convex pot mouth

InactiveCN101765300AChange directionDoes not affect soldering qualityPrinted circuit assemblingSurface layerDip soldering

The invention relates to a solder pot component used for tin soldering of a PCBA board, in particular to an internal opening full flow convex pot mouth. Four rectangle pot mouths are spliced into an inverted m structure; the middle part is provided with a tin overflow tank, each joint of every two adjacent pot mouths and the edge of the tin overflow tank are provided with tin overflow openings; and the tin overflow openings are rectangle openings and have a depth of between 3 and 6mm. The internal opening full flow convex pot mouth has simple structure, can effectively improve the soldering efficiency, is suitable for large-scale automation production, and also effectively prevents an oxide layer on the surface layer of the tin liquor from leaving on the surface of the PCBA board to guarantee the quality of the soldering joint.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com