Liquid ammonia evaporator for flue gas denitration

A liquid ammonia evaporator and evaporator box technology, applied in the direction of evaporating devices, chemical instruments and methods, boiling devices, etc., can solve the problems of no heat preservation measures, waste of resources, small direct contact area, etc., to ensure sufficient and Uniformity, enhanced work efficiency, enhanced thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

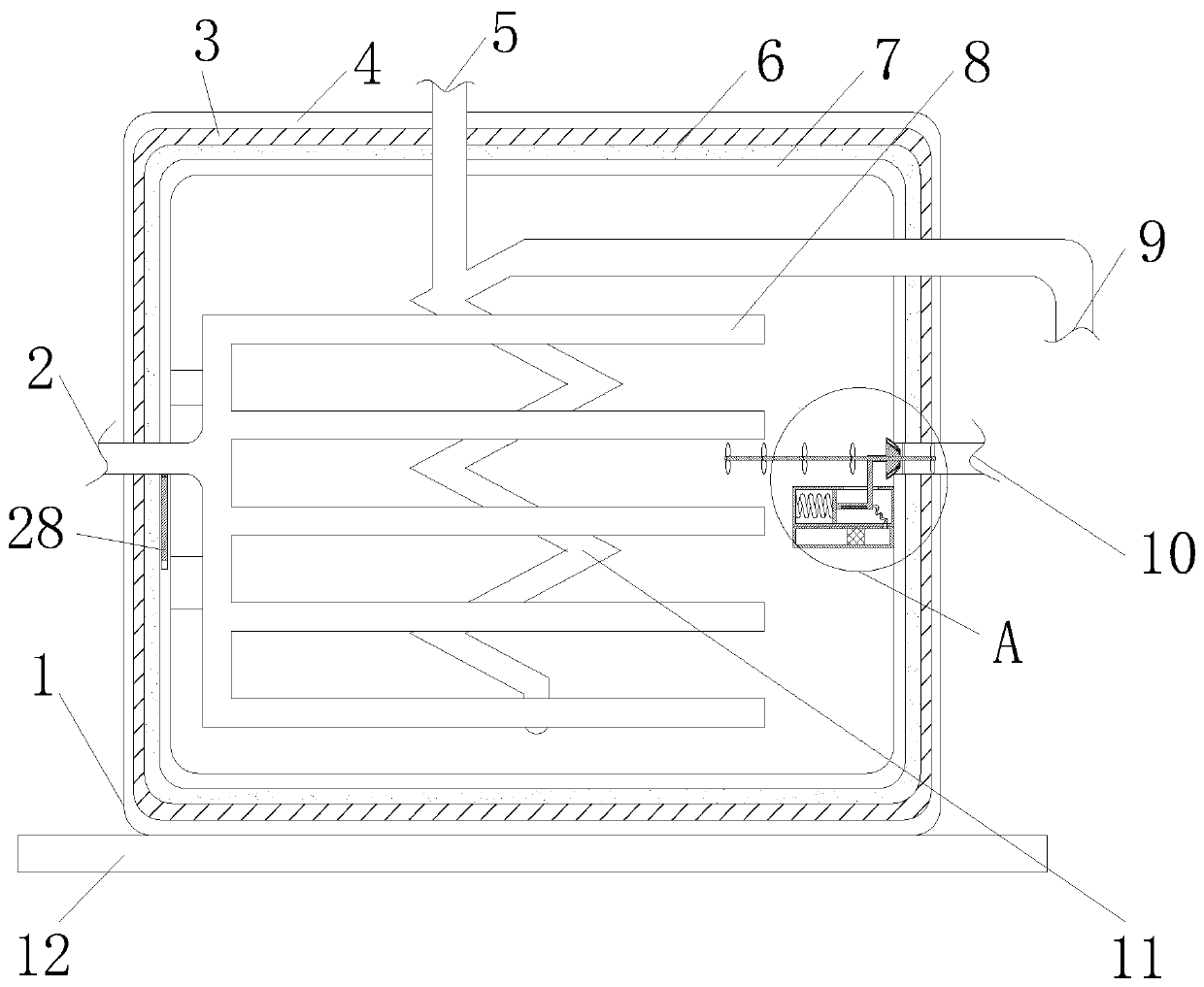

[0025] As an embodiment of the present invention, the evaporator box 1 includes a vacuum layer 3, a box shell 4, a foam layer 6 and a box inner shell 7, wherein the inside of the box shell 4 is provided with a vacuum layer 3, The vacuum layer 3 is provided with a foam layer 6 away from the side of the box shell 4, and the side of the foam layer 6 away from the vacuum layer 3 is provided with a box inner shell 7; Composed of shell 7, foam layer 6, vacuum layer 3 and box shell 4, the thermal insulation performance is very good, and the heat of the flue gas will not be lost.

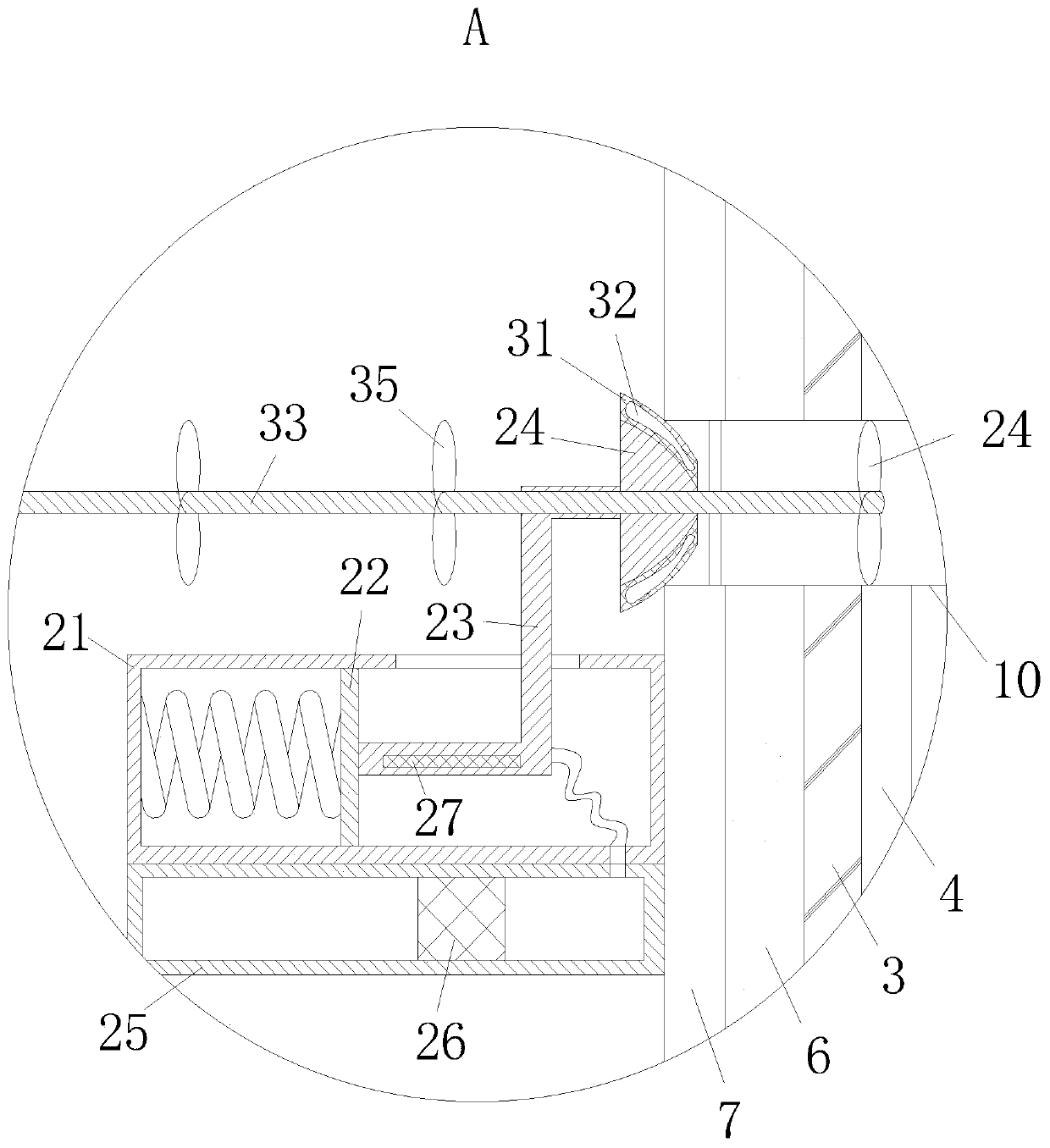

[0026] As an embodiment of the present invention, a first control box 21 is fixedly connected to the inner wall of the box inner shell 7 below the flue gas outlet 10; a sliding plate 22 is slidably connected to the first control box 21; A spring is fixedly connected between the inner wall of a control box 21 away from the smoke outlet 10; and the spring is submerged in mercury; the side surface of the slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com