A tin overflow concave external open kettle mouth

A pot mouth and concave technology, which is applied in the field of tin furnace parts, can solve the problems that it is not suitable for large-scale batch processing, low work efficiency, and easy to form joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

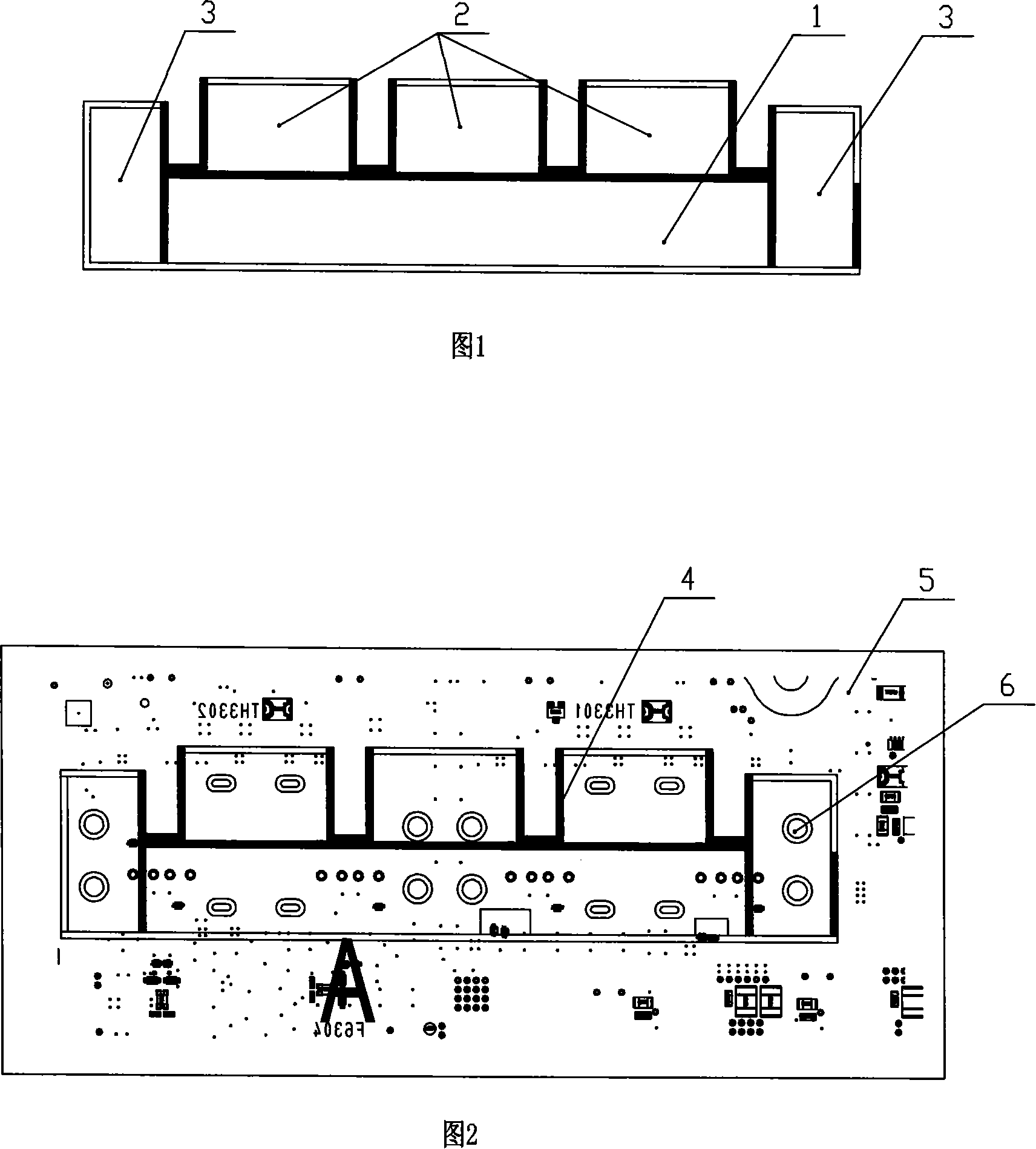

[0015] As shown in Figure 1, a tin-spill concave-shaped outwardly opening spout, the spout is composed of a long and narrow rectangular main spout 1 and at least two branch spouts 2 fixedly arranged on the side of the main spout 1, End spouts 3 are arranged at both ends of the main spout 1 . There is an overflow tin mouth 4 on the concave periphery formed by the branch spout 2 and the main spout 1 on both sides, and the end spout connected to the main spout 1 at the junction of the main spout 1 and the branch spout 2 3 A tin overflow port 4 is provided on the connection surface. The tin overflow hole 4 is a rectangular gap, and the depth of the tin overflow hole 1 is 2-8mm.

[0016] As shown in Figure 2, the spout of the present invention is mainly applied to the electronic components 6 to be welded on the PCBA board 5, which are mainly distributed in the main spout 1 area, and other electronic components that need to be welded are scattered outside it. Components 6, in this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com