Internal opening full flow convex pot mouth

A spout and flow technology, which is applied in the field of full-flow convex spout with internal opening, can solve the problems of low work efficiency, unsuitable for large-scale batch processing, and easy formation of virtual welding of joints, so as to ensure adequacy and safety. The effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

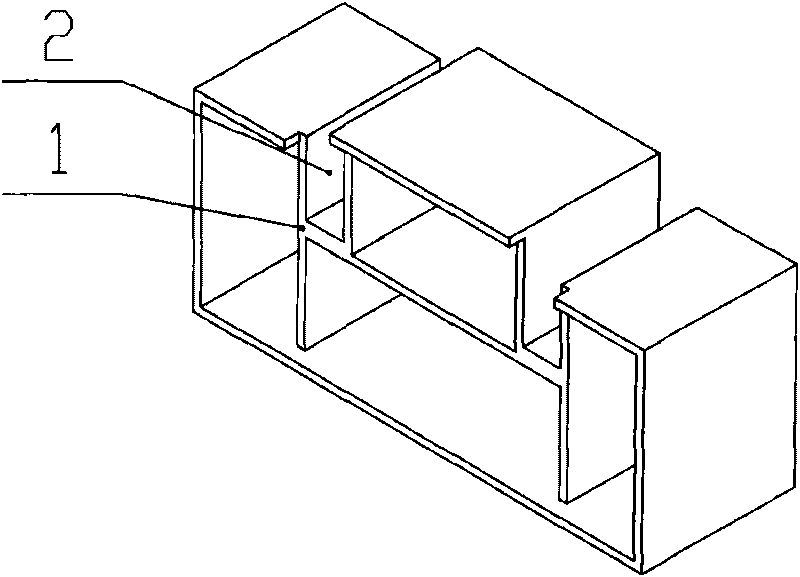

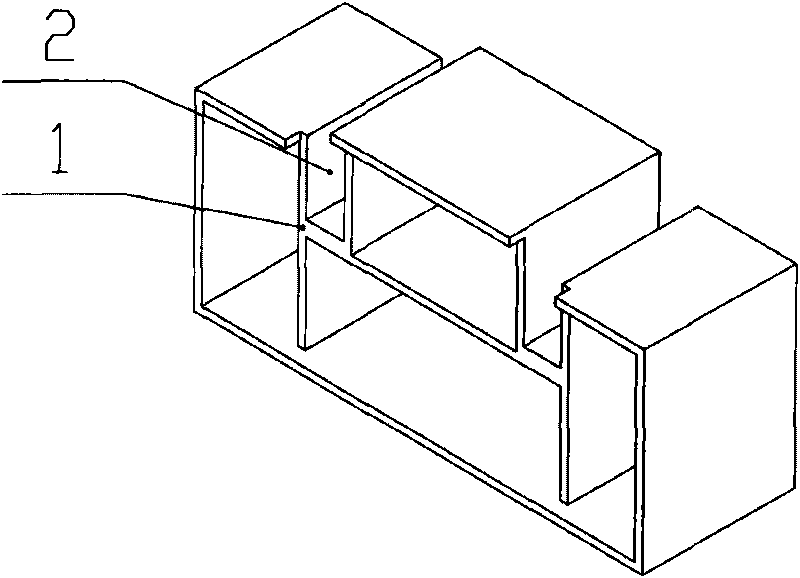

[0012] Such as figure 1 The one shown is a full-flow convex spout with inner opening, which is composed of four rectangular spouts to form a "mountain" character structure, and a tin overflow groove 2 is opened in the middle. The edge of the slot 2 is provided with a tin overflow port 1 . The tin overflow opening 1 is a rectangular opening with a depth of 3-6 mm.

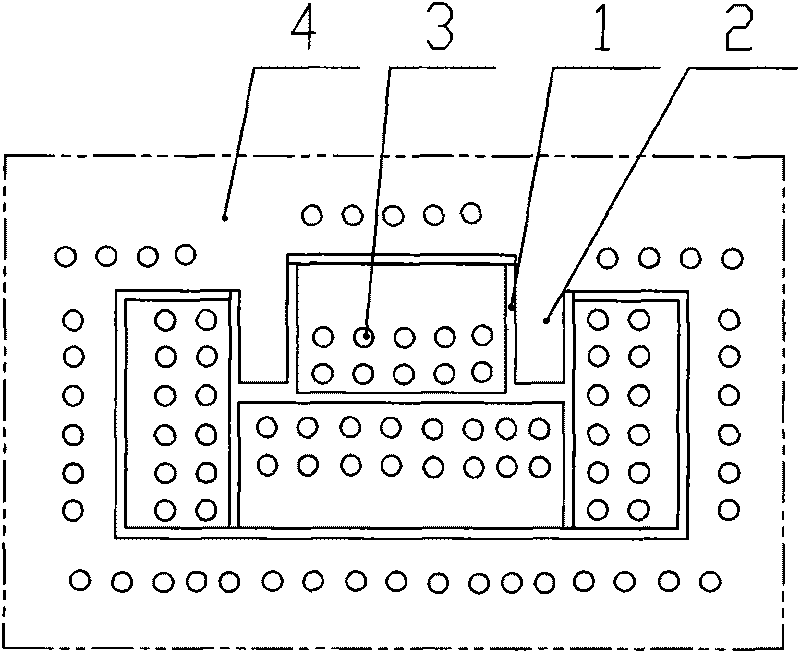

[0013] Such as figure 2 As shown, there are electronic components 3 that need to be shielded and welded on the PCBA board 4 on the periphery of the combined spout, and a tin overflow port 1 is provided at the junction of adjacent spouts and the edge of the overflow tin groove 2, which is very good Lead the tin liquid into the overflow tin tank 2 in a safe manner, so that the tin liquid overflowing from the pot mouth overflows from the tin overflow port 1 and then gathers in the overflow tin tank 2 and returns to the tin furnace without overflowing tin from the outside of the pot mouth And the electronic componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com