External baffle insertion type pot opening

A plug-in and spout technology, applied in the field of plug-in tin furnace spouts, can solve the problems of low work efficiency, easy to form false solder joints, unsuitable for large-scale batch processing, etc., and achieve the effect of ensuring sufficiency and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

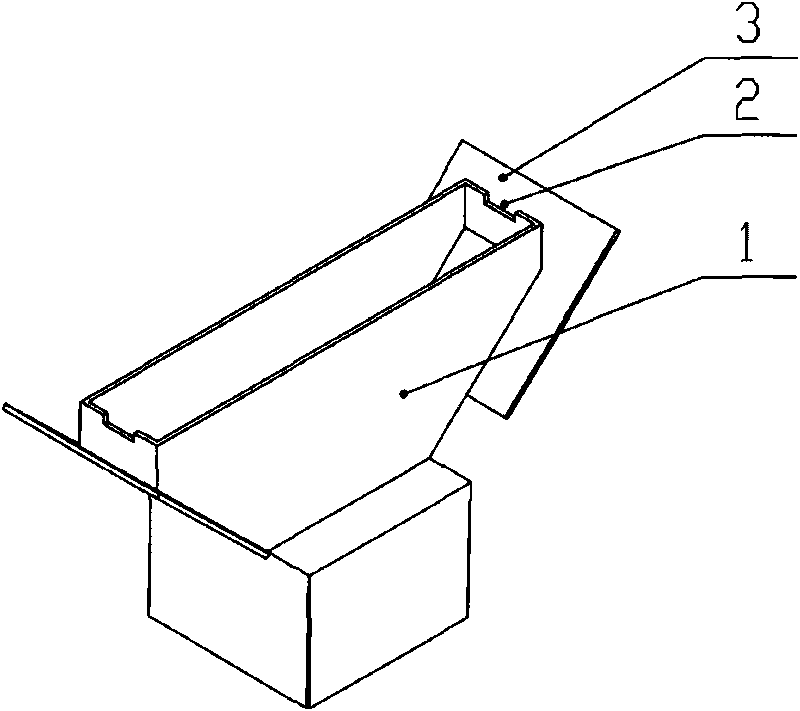

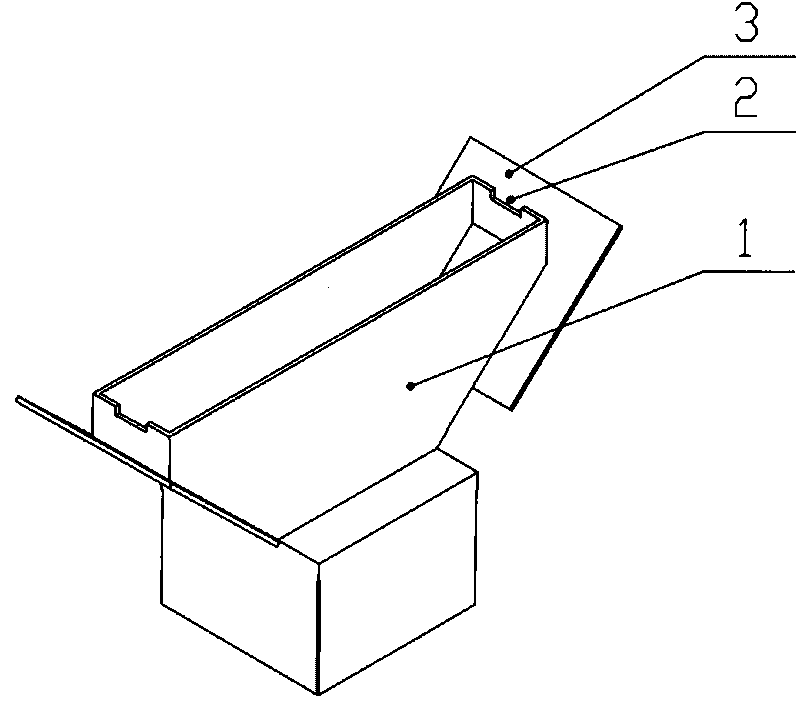

[0012] Such as figure 1 Shown is a plug-in spout with an outer stop, the mouth of the spout is provided with a tapered socket 1, at least one tin overflow port 2 is provided on the edge of the socket 1, and a tin overflow port 2 is provided on the outside of the spout 2 The blocking piece 3 is fixedly connected with the outer wall of the socket 1 . The tin overflow port 2 is a rectangular hole with a depth of 3-4mm.

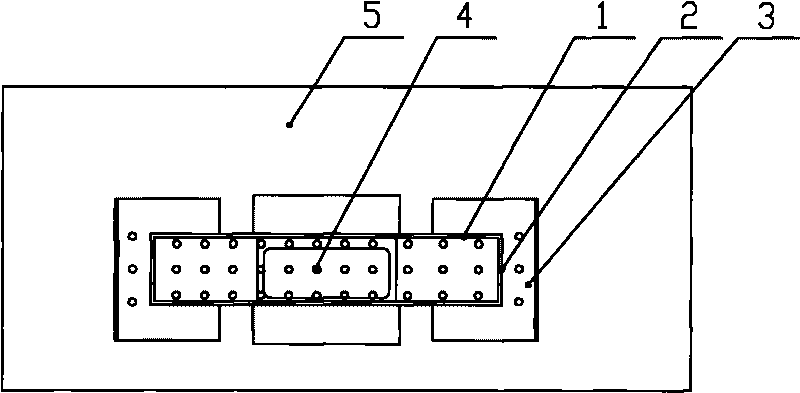

[0013] Such as figure 2 As shown, the spout of the present invention is mainly applied to the welding of electronic components 4 with short single-row leads. The baffle 3 well restricts the flow of liquid tin flowing from the overflow port 2 to the outside of the baffle, and protects the electronic components 4 outside the baffle 3 without soldering. On the PCBA board 5 , there are no other electronic components 4 outside the single row of leads or they are relatively far away, so that the tin liquid flowing out from the overflow tin opening 1 will not flow o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com