Rapid vacuum dispersion reaction kettle

A vacuum fast, reactor technology, applied to the pressure vessel used in the chemical process, etc., can solve the problems affecting the metallographic uniformity of the alloy, uneven distribution of the alloy phase, poor dispersion of alloy elements, etc., to achieve enhanced sealing isolation, Strong process adaptability and the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

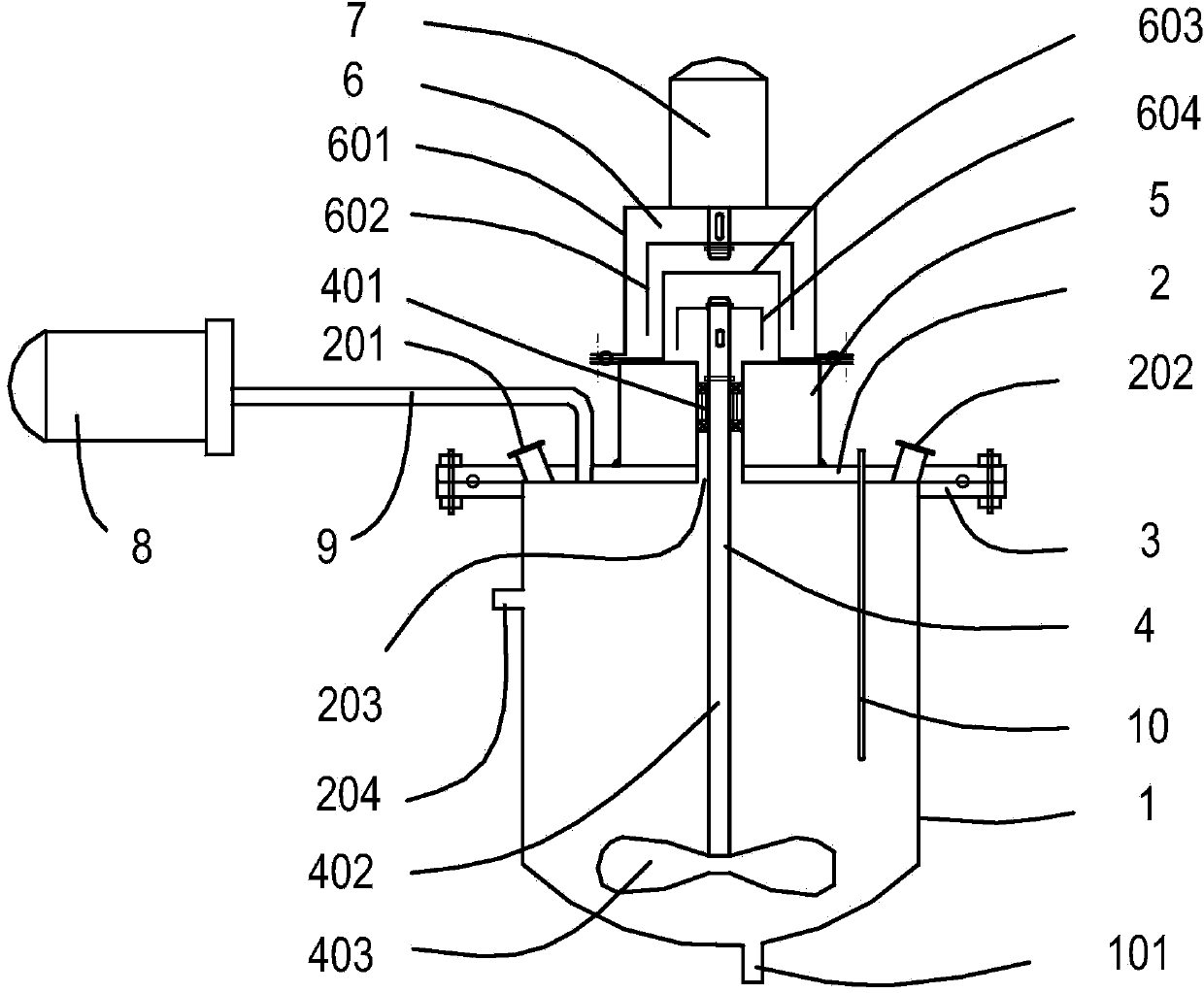

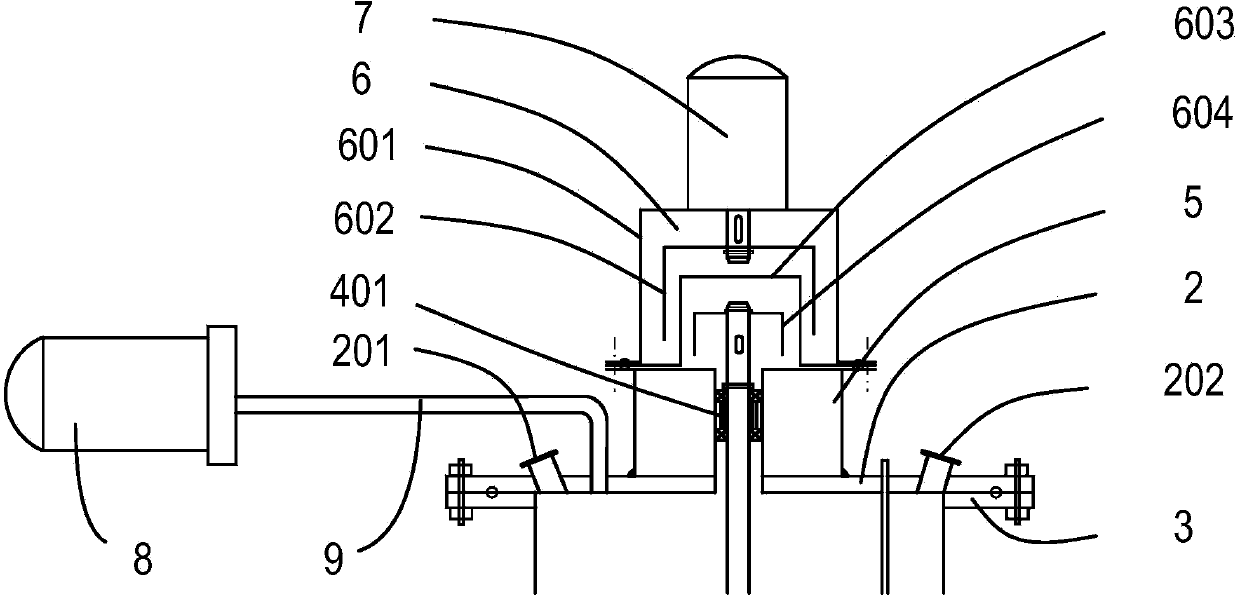

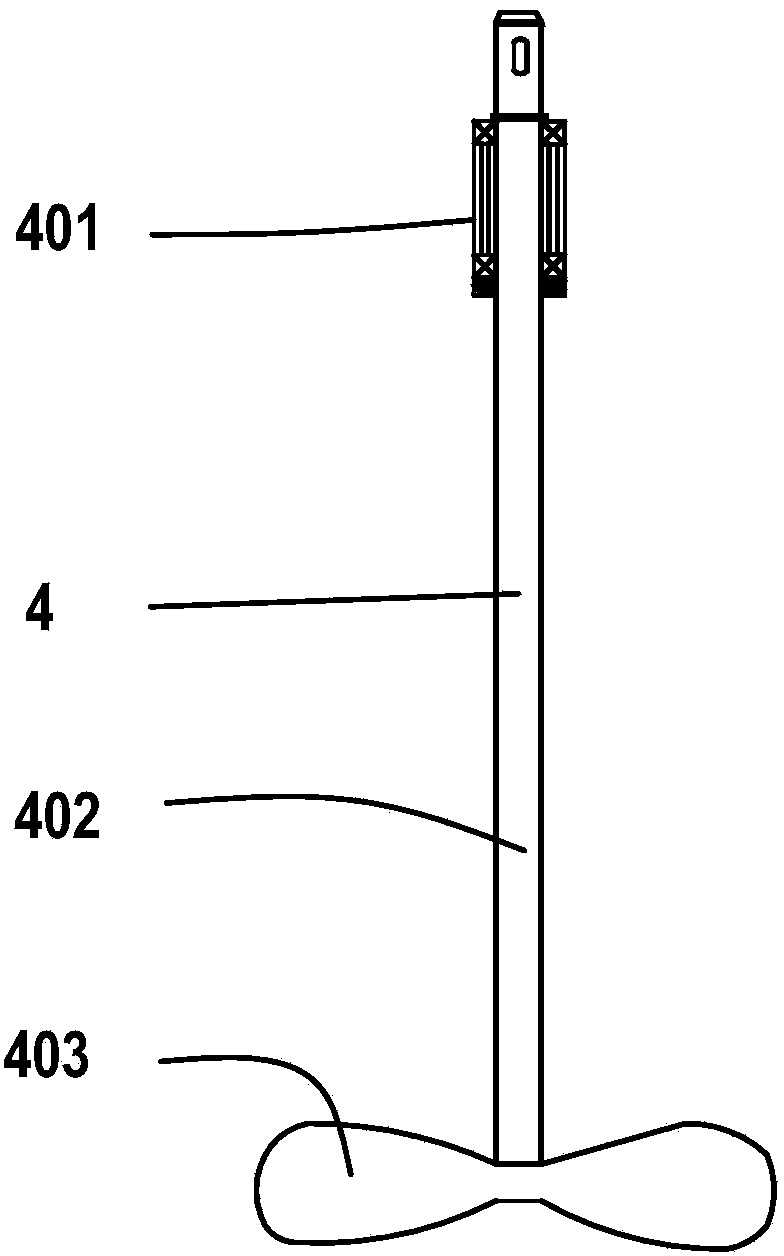

[0027] Such as Figure 1 to Figure 6 As shown, the vacuum rapid dispersion reactor of the present invention comprises a cooling jacket 5, an agitator 4, a kettle body flange 3, a kettle cover 2, and a kettle body 1, and the kettle body 1 is connected with the kettle body 2 through the kettle body flange 3 Constitute the reaction kettle body, the connection between the kettle body flange 3 and the kettle cover 2 is provided with a first seal, the kettle cover 2 is provided with an agitator installation port 203, and the kettle cover 2 on the periphery of the agitator installation port 203 is provided with a cooling jacket 5. The core of the cooling jacket 5 is provided with an agitator bearing seat 401; it also includes a magnetic transmission device 6, which includes a machine base 601, an outer magnetic drum 602, an isolation sleeve 603, an inner magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com