Fixed insertion type pot mouth

A plug-in and spout technology, applied in the field of fixed plug-in spout, can solve the problems of low work efficiency, unsuitable for large-scale batch processing, and easy formation of virtual welding of joints, and achieves the effect of ensuring adequacy and firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

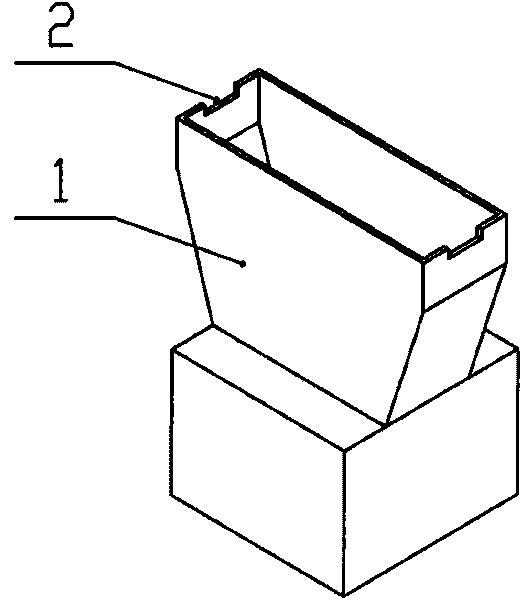

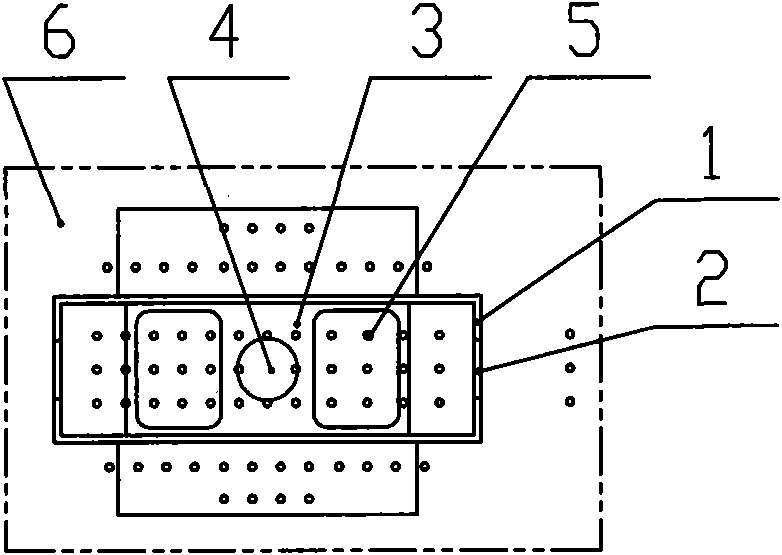

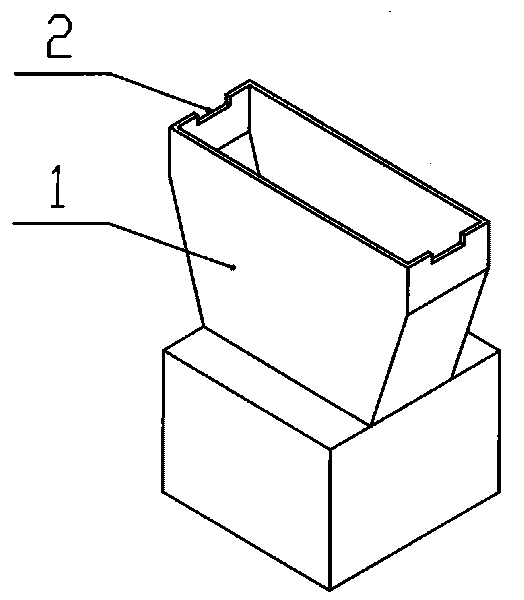

[0013] Such as figure 1 A fixed plug-in spout is shown, the mouth of the spout is provided with a tapered socket 1, and at least one overflow tin port 2 is provided on the edge of the tapered socket 1, and the overflow tin port 2 is a rectangular Gap, the depth of which is 3-6mm. A fixing plate 3 is arranged on the inner wall of the spout, and a fixing hole 4 is provided on the fixing plate 3 .

[0014] Such as figure 2 As shown, before welding, the spout and the PCBA board 6 are firmly connected through the fixing holes 4 on the fixing plate 3 through the fixing bolts. Depending on the distribution, usually there is no electronic component 5 on the PCBA board outside the tin overflow port 2 or it is relatively far away, so that the tin liquid flowing from the tin overflow port will not spread and other electronic components around the tin overflow port 5 on.

[0015] When in use, place the PCBA board at a predetermined position above the spout, and keep a certain distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com