Pressure-stock-type two-stage double-agent desulfurization device and application method thereof

A desulfurization device and dual preparation technology, applied in the field of backlog type two-stage dual preparation desulfurization device, can solve the problems of harm of conveying equipment, accumulation of hydrogen sulfide gas, corrosion and damage of oil storage square tanks, etc., so as to improve personal safety and reduce desulfurization. cost, ensuring sufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

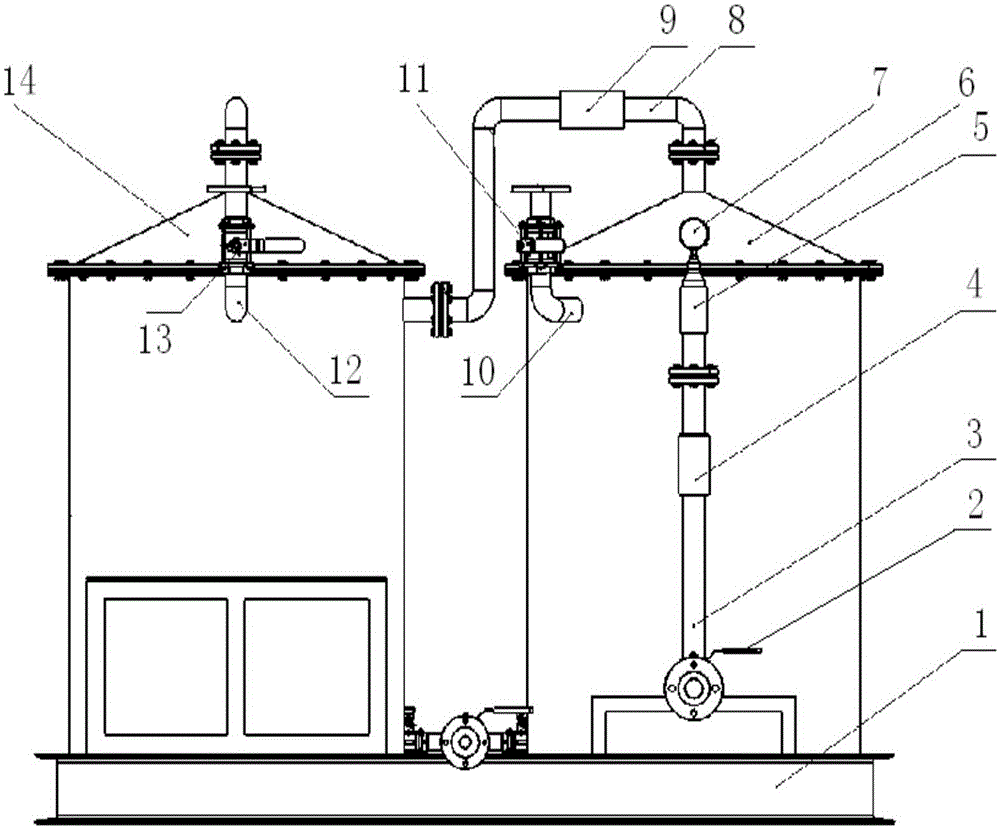

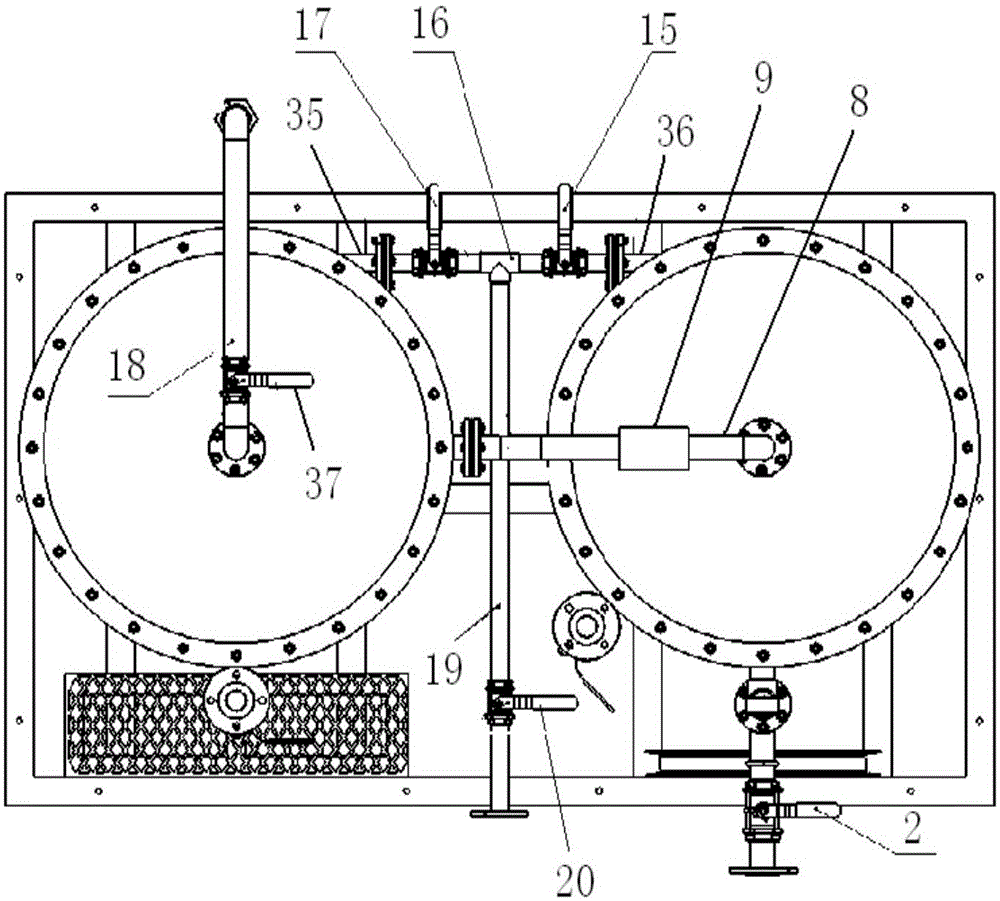

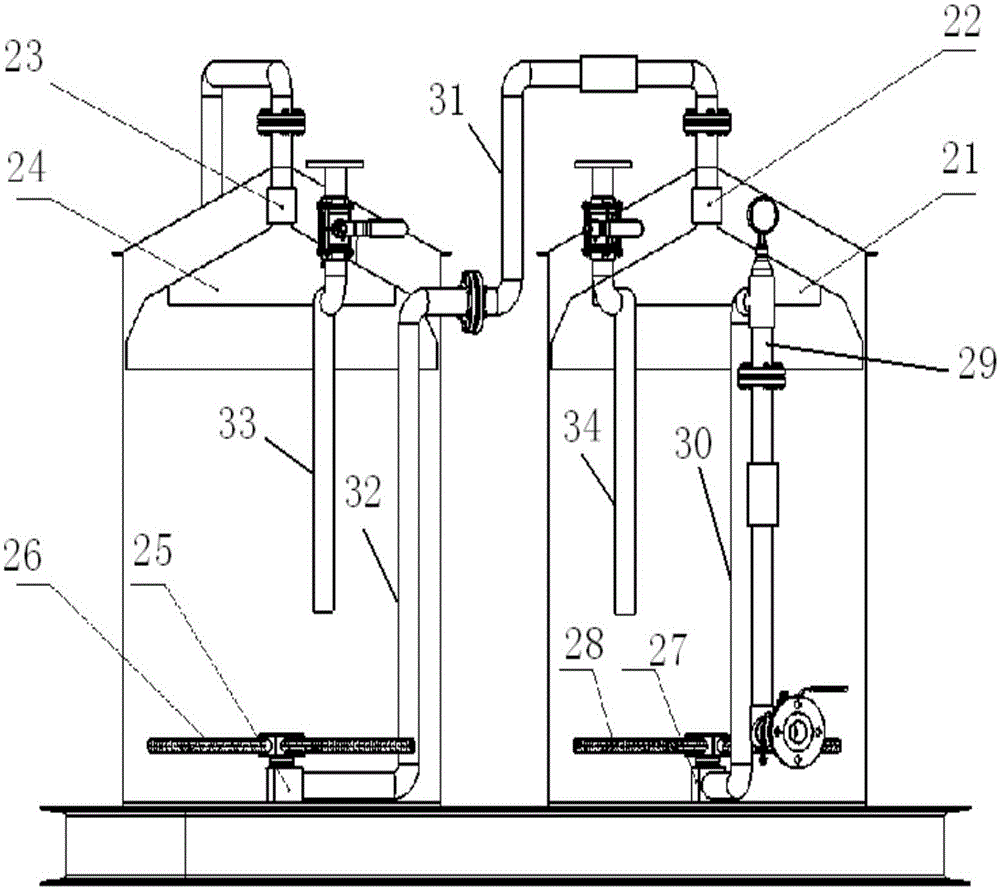

[0027] Such as figure 1 and image 3 As shown, a backlog type two-stage dual-preparation desulfurization device of the present invention includes a base 1 on which a primary desulfurization tank 6 and a secondary desulfurization tank 14 are fixed, and the tops of the primary desulfurization tank 6 and the secondary desulfurization tank 14 are The shape is conical; the upper part of the outer wall of the primary desulfurization tank 6 is provided with a first three-way joint 5 connected to the inner cavity of the first-level desulfurization tank 6, and the upper end of the first three-way joint 5 is connected with a pressure gauge 7, and the first three-way joint The lower end of 5 is connected with partial pressure control valve 4, and the other end of partial pressure control valve 4 is connected with inlet pipe 3, and the first high pressure gate 2 is arranged on the inlet pipe 3; The first pipeline 29 in the inner chamber of the first-stage desulfurization tank, one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com