Lug boss top opening type tin overflowing pot opening

A technology of overflowing tin and pot opening, which is applied in the direction of assembling printed circuits with electrical components, etc., can solve the problems of low work efficiency, easy formation of virtual welding of contacts, unsuitable for large-scale batch processing, etc., to ensure adequacy and firmness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

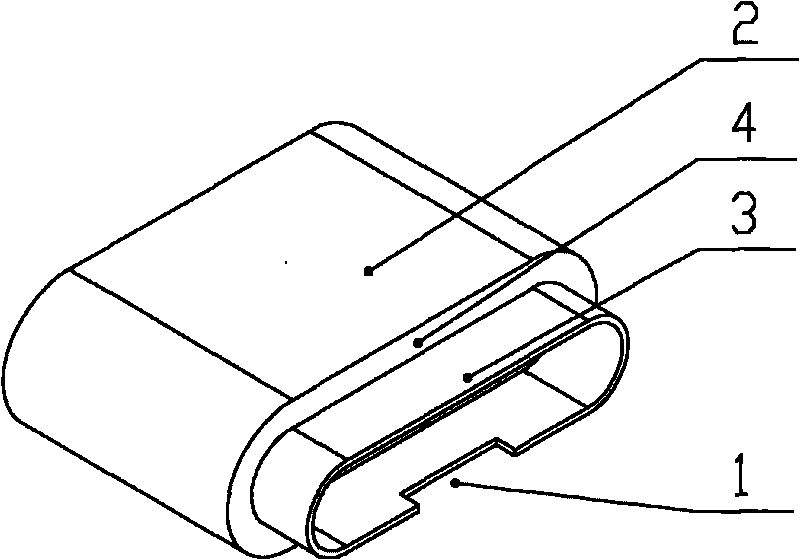

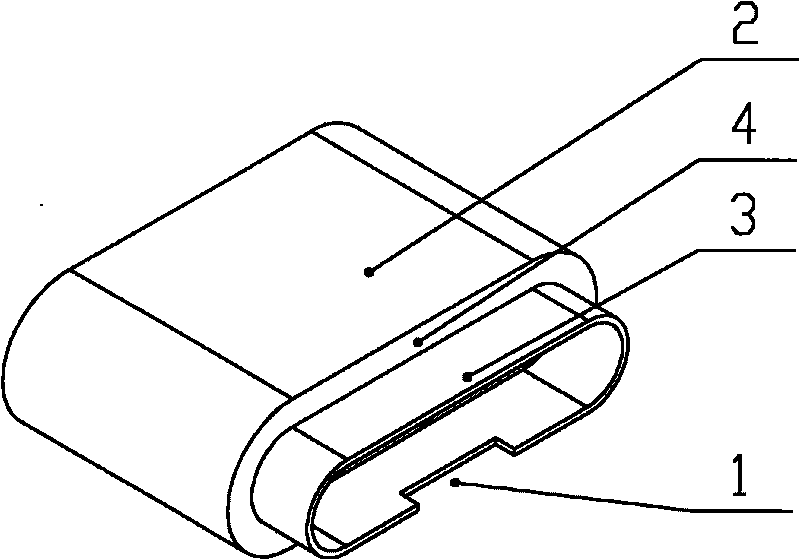

[0012] Such as figure 1 Shown is a kind of overflowing tin spout with an upward opening on the boss, the spout is composed of a base body 2 and an insertion port 3, a step 4 is formed between the base body 2 and the insertion port 3, and a The tin overflow opening 1 is a rectangular opening with a depth of 3-6 mm.

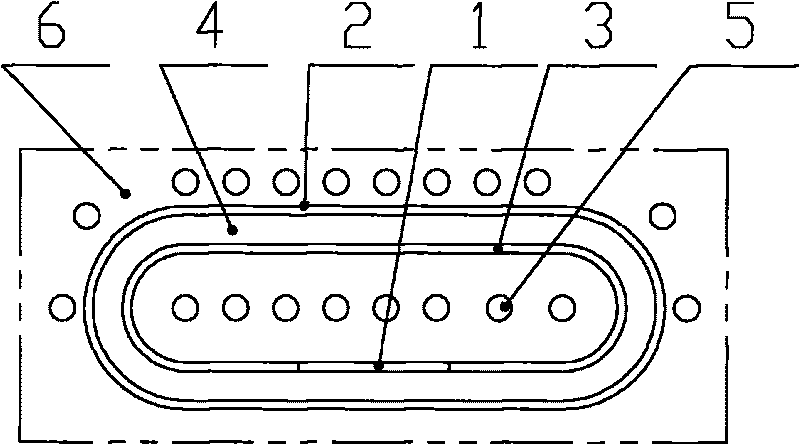

[0013] Such as figure 2 As shown, the insertion port 3 is provided on the base body 2, which is more convenient for the insertion port 3 to go deep into the electronic components 5 on the PCBA board 6 . The tin overflow port 1 arranged on the insertion port 3 is designed in a triangular shape. When the tin liquid flows out from the tin overflow port 1, the triangular shape of the tin outlet hole 1 also plays a good role in diversion.

[0014] When in use, place the PCBA board at a predetermined position above the spout, and keep a certain distance between the plane of the board and the tin outlet of the spout, generally controlled at 2-4mm. The shape of the spo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com