Light-emitting panel for illuminating or displaying images provided with a composite transparent upper electrode

A technology for image display panel and electroluminescent layer, which is applied in the direction of installation/support/configuration/insulation of electroluminescent light source, electrode assembly, electric light source, etc., and can solve problems such as unfavorable luminous efficiency and loss of transparency of the upper electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

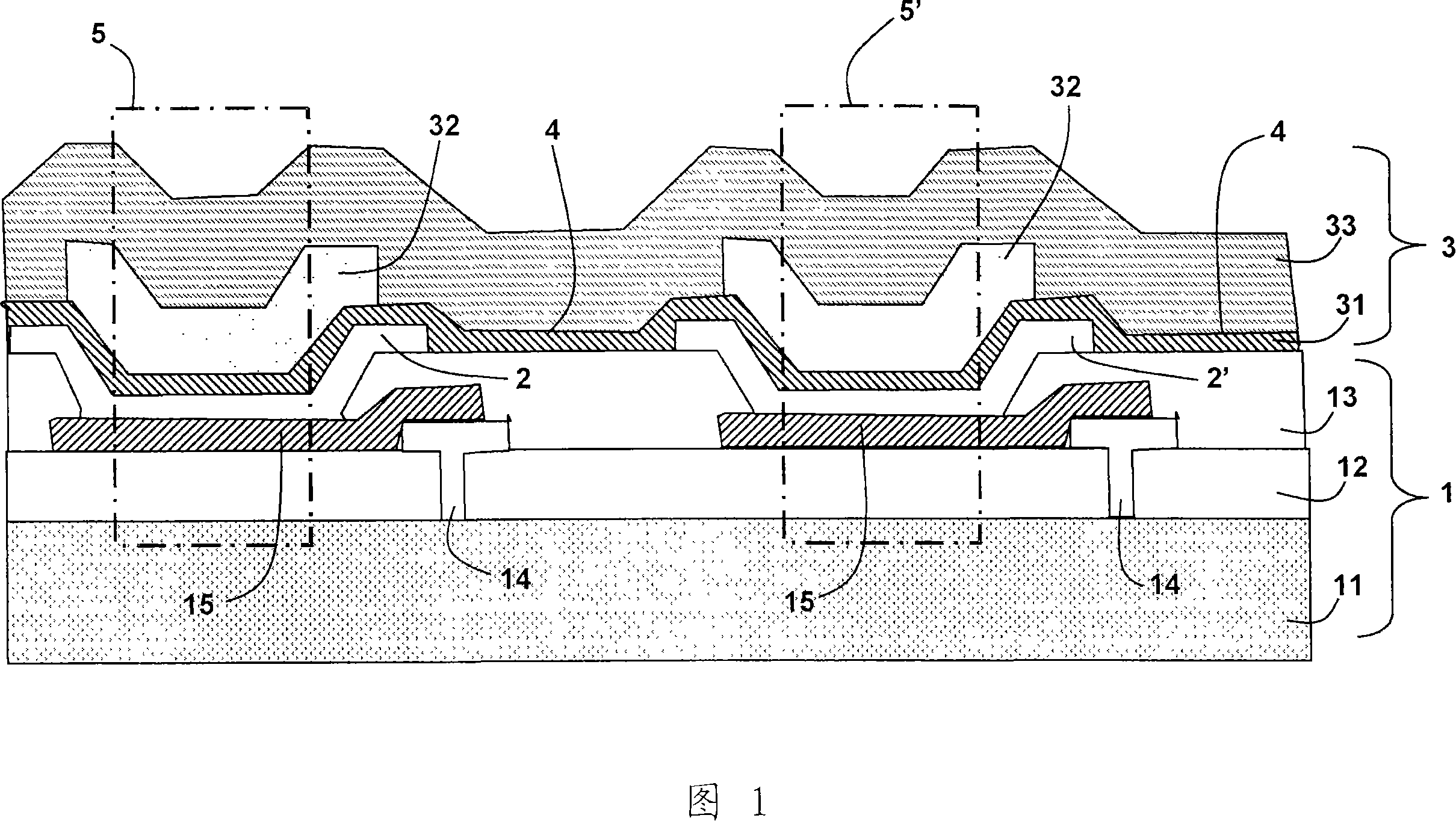

[0030]The structure starts with a substrate 1 incorporating here the known active matrix, the manufacture of which will not be described in detail here: a rigid plate 11 made of insulating material supports the so-called "pixel circuit" for the diodes. A network of control / supply circuits, each having an output 14 connected to a lower electrode 15, which is preferably metallic and reflective. This rigid plate generally supports several electrically insulating layers, including a first insulating layer 12 for isolating the components of the pixel circuit from each other in particular and a second insulating layer 12 for separating the diodes and isolating the lower electrode from the upper electrode outside the emitting area of the diode. Two insulating layers 13 . At the position of the diode, this second insulating layer 13 is penetrated by a window, exposing the surface of the lower electrode 15 . Finally, the substrate integrates a further array (not shown) of electrodes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com