Spray gun for powder electrostatic coating

An electrostatic spraying and powder technology, which is applied in the direction of electrostatic spraying device, liquid spraying device, spraying device, etc., can solve the problems such as inability to correspond to shapes, difficulty in adjusting the width of graphics, etc., achieve less spraying operations, easy and fast correspondence, and improve spraying efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

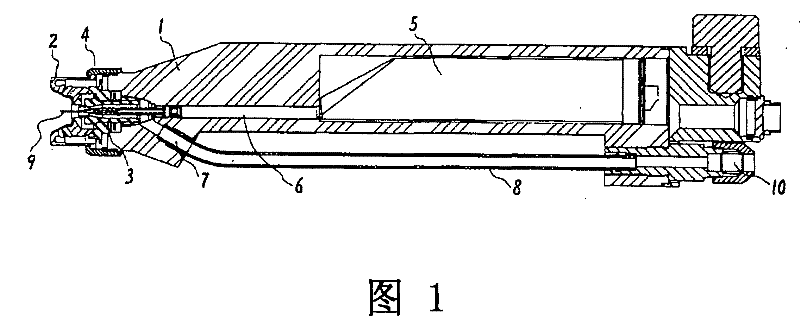

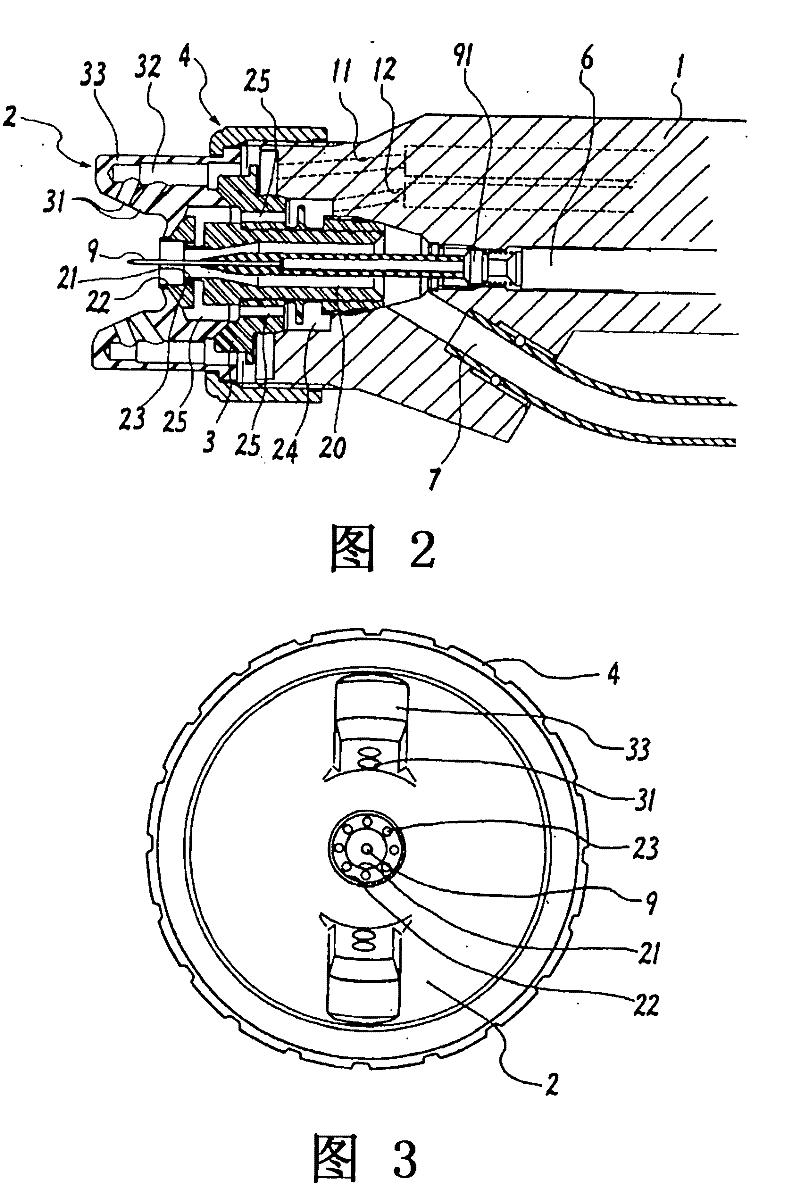

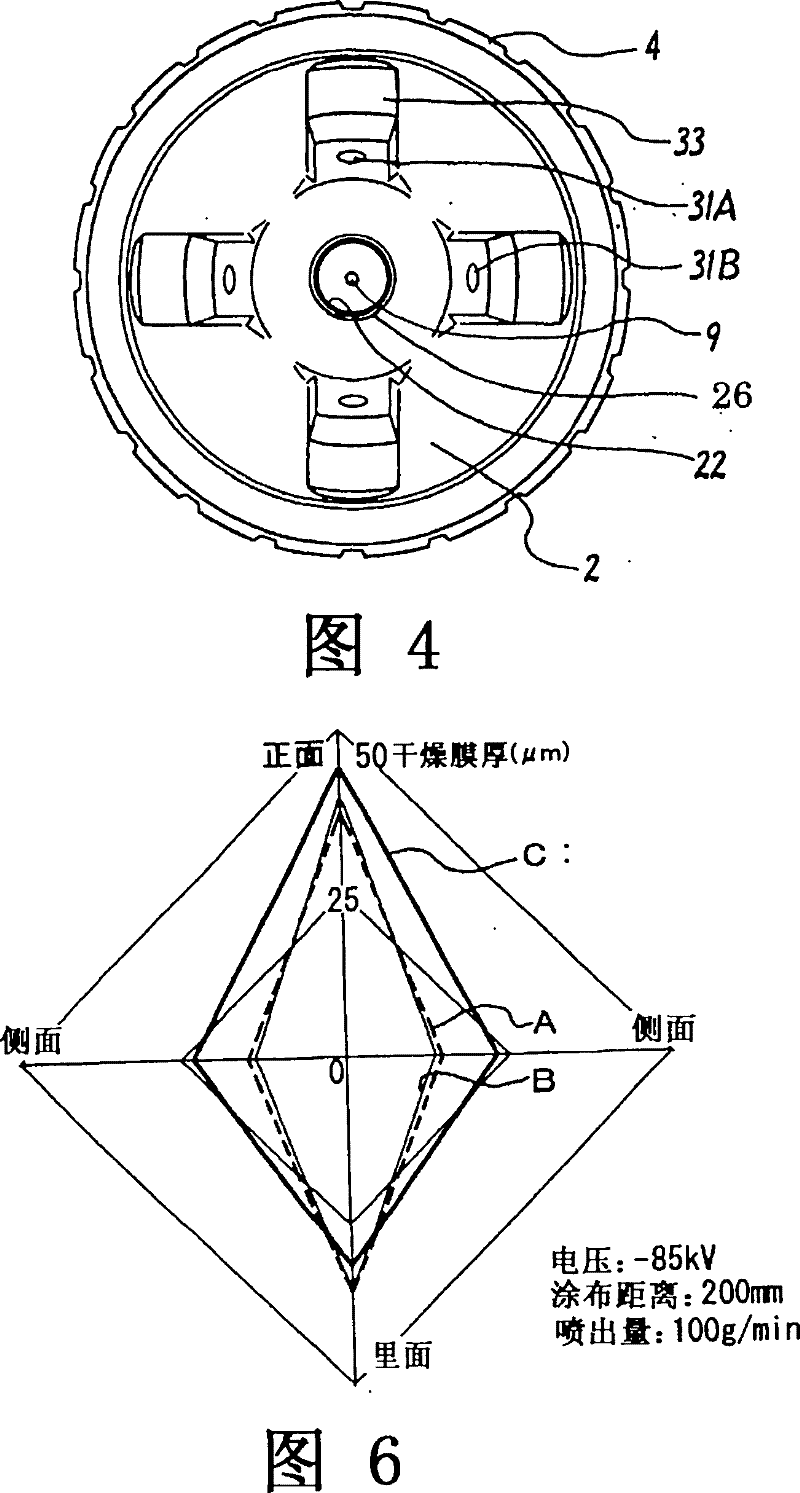

[0036] figure 1 It is a view showing the overall cross-section of the spray gun for powder electrostatic spraying according to the embodiment of the present invention. A powder nozzle 3 constituting a spraying device is attached to the front end of the gun body 1 , and an air cover 2 mounted concentrically with the powder nozzle 3 is detachably attached by a cover 4 . The powder inlet 10 provided at the rear of the gun body 1 is connected to the powder nozzle 3 through a supply hose 8 and a powder passage connected to the carrier inlet 7 near the front end. The air passages for adjusting the spray are not shown in detail in the figure. Such as figure 2 As shown, the adjustment air supply path 11 is opened at the front end of the gun body 1 and is connected to the adjustment air hole 32 of the air cover 2 from between the powder nozzle 3 and the cover 4 . Another auxiliary air supply path 12 opens in an auxiliary air chamber 24 formed by installing the powder nozzle 3 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com