Waterborne propeller for amphibious vehicle

An amphibious, propulsion technology, applied in amphibious vehicles, propulsion components, ship propulsion, etc., can solve the problems of easy damage, difficult maintenance, complex transmission structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

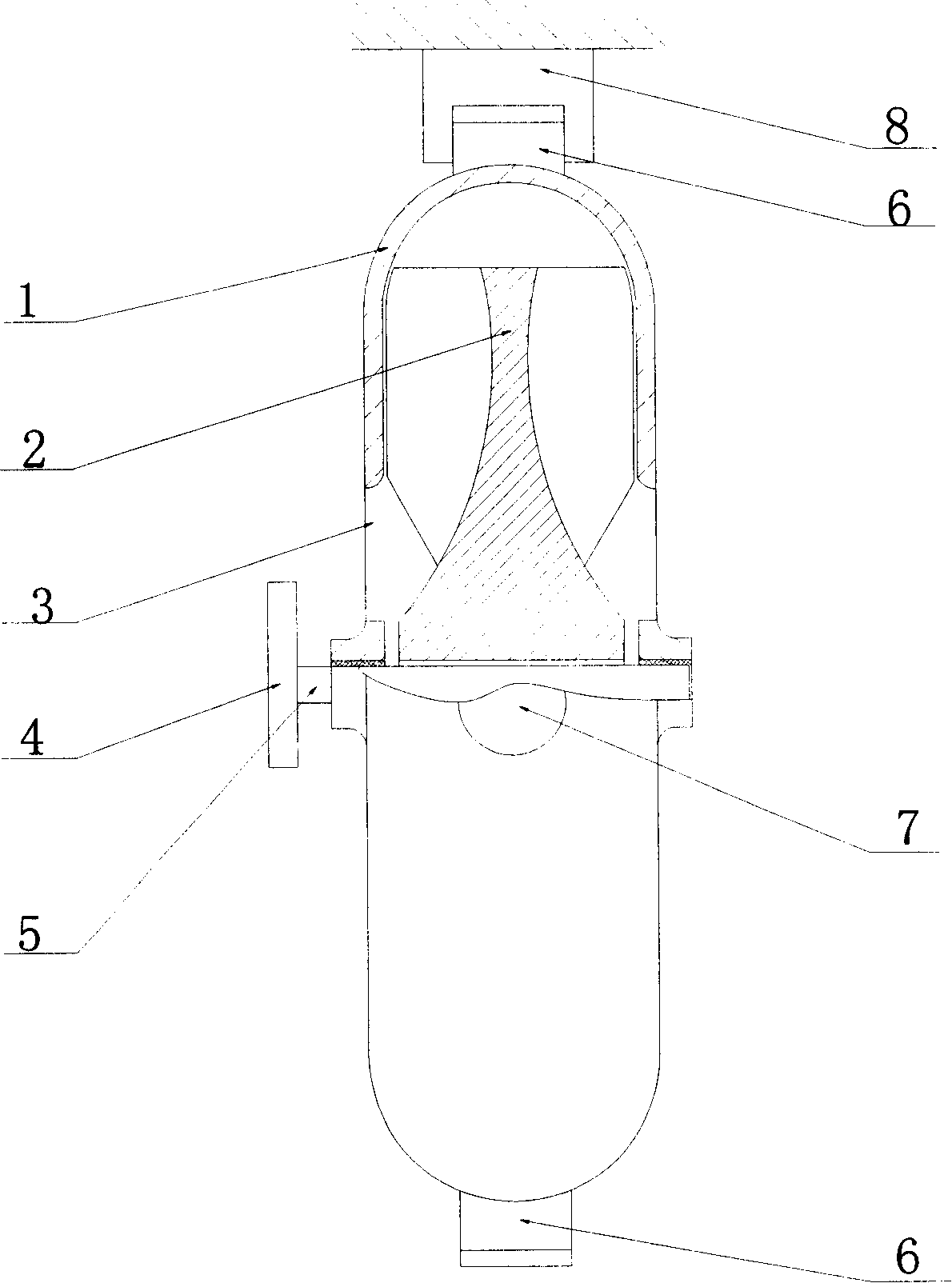

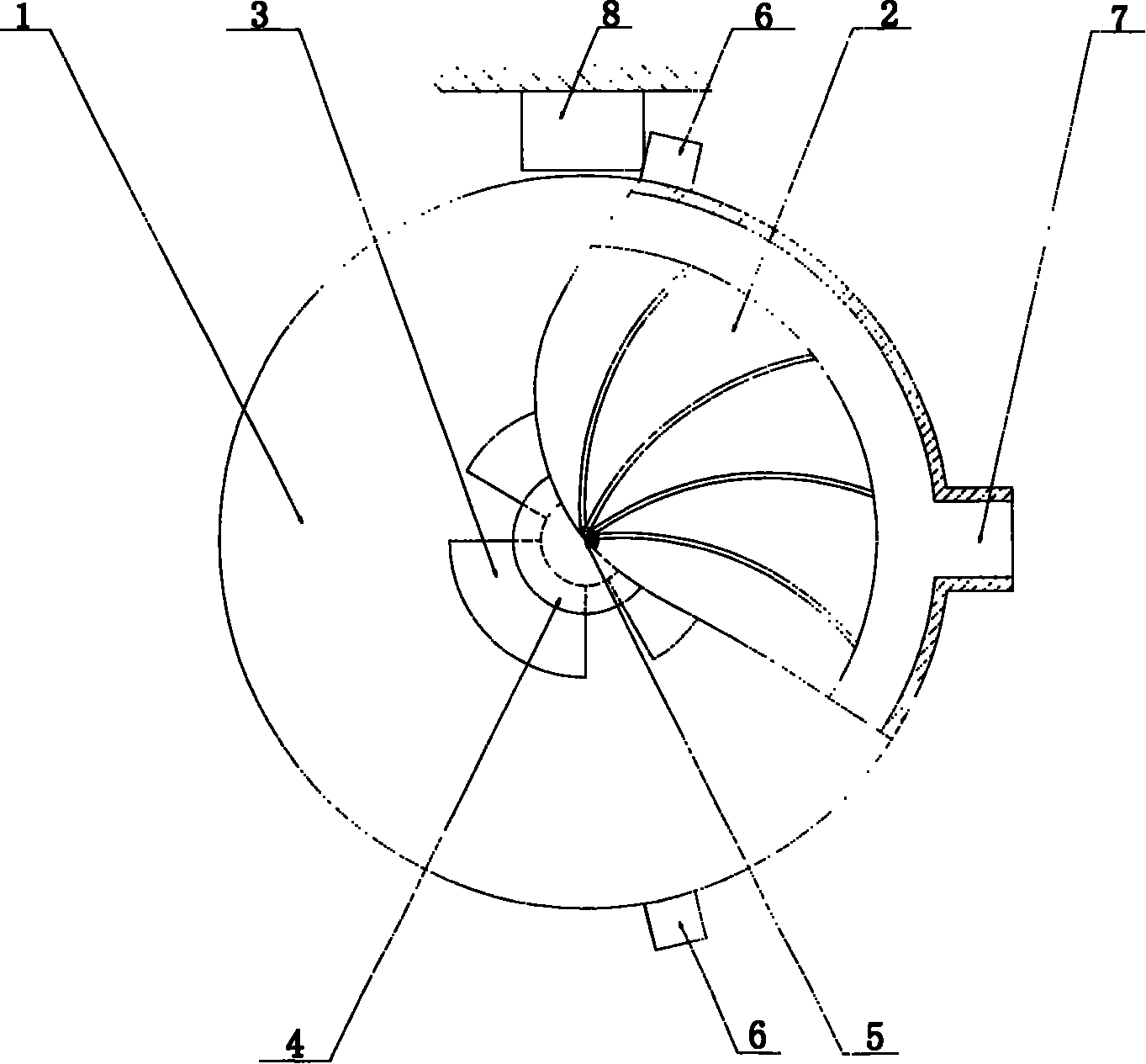

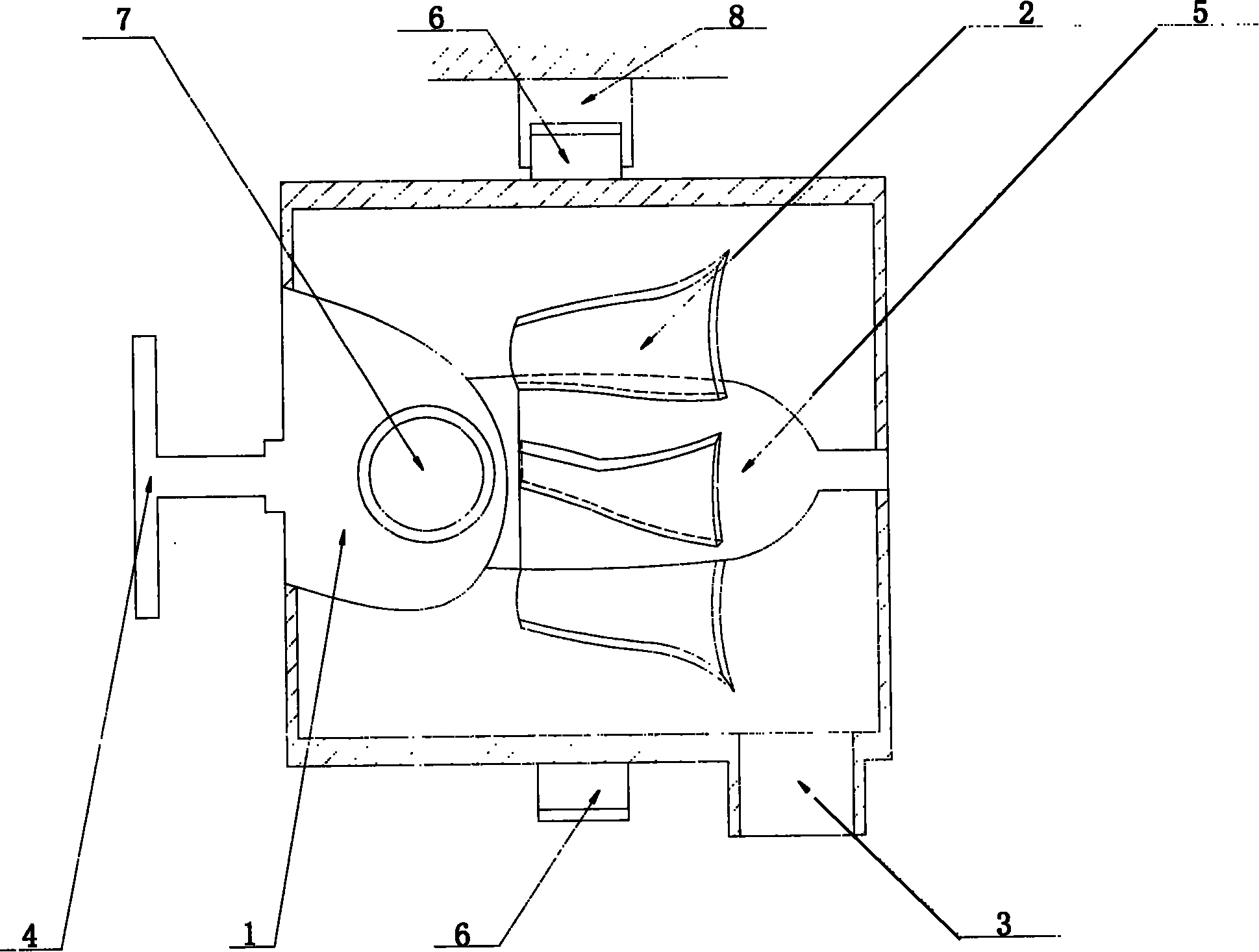

[0015] exist Figure 1-2 In the illustrated embodiment, the shaft (5), the impeller (2) coaxially mounted on the shaft (5) and the casing (1) with the water inlet (3) and the water outlet (7), wherein the shaft (5) It is installed on the casing (1), the impeller (2) is located in the casing (1), the casing (1) has a protrusion (6) on the outer circle, and the water outlet (7) is located in the radial direction of the outer circle of the casing (1). The water inlet (3) is located in the axial direction of the housing (1) and is concentric with the shaft (5). The end of the shaft (5) away from the impeller (2) is equipped with a flange (4). The impeller (2) is a centrifugal impeller.

[0016] During use, the fastening nuts of the driving wheel tires on the amphibious vehicle are unloaded, and the water propeller flange (4) of the amphibious vehicle is fixed on the axle close to the wheel hub by using nuts and bolts. A block (8) is installed on the car body, the block (8) is po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com