Positioning method for lead wire frame breadth direction in electroplating

A lead frame and positioning method technology, applied in the electrolytic process, electrolytic components and other directions, can solve the problems of dimensional changes, estimation and processing errors, and it takes 1 to 2 days, or even longer to adjust, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

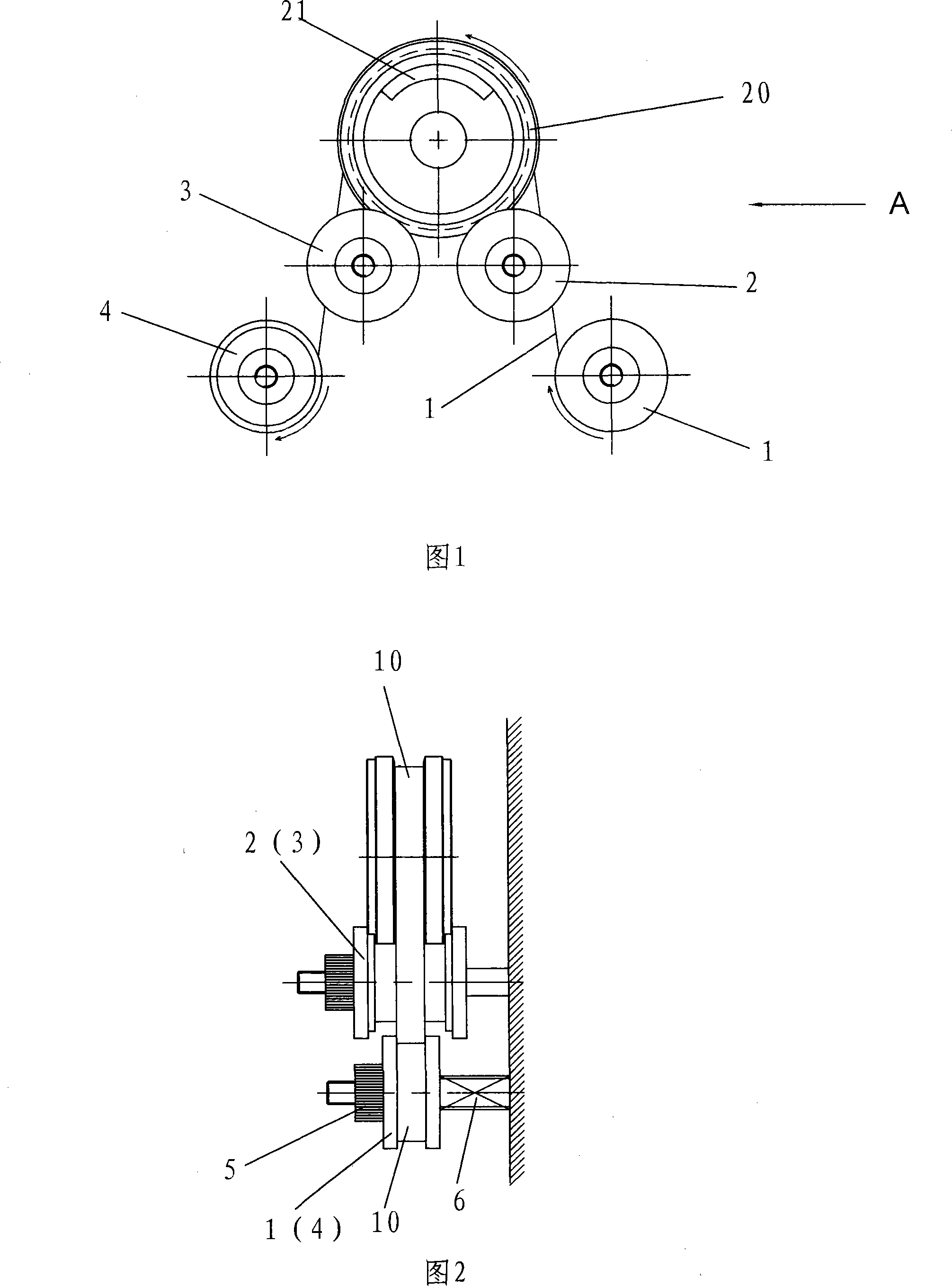

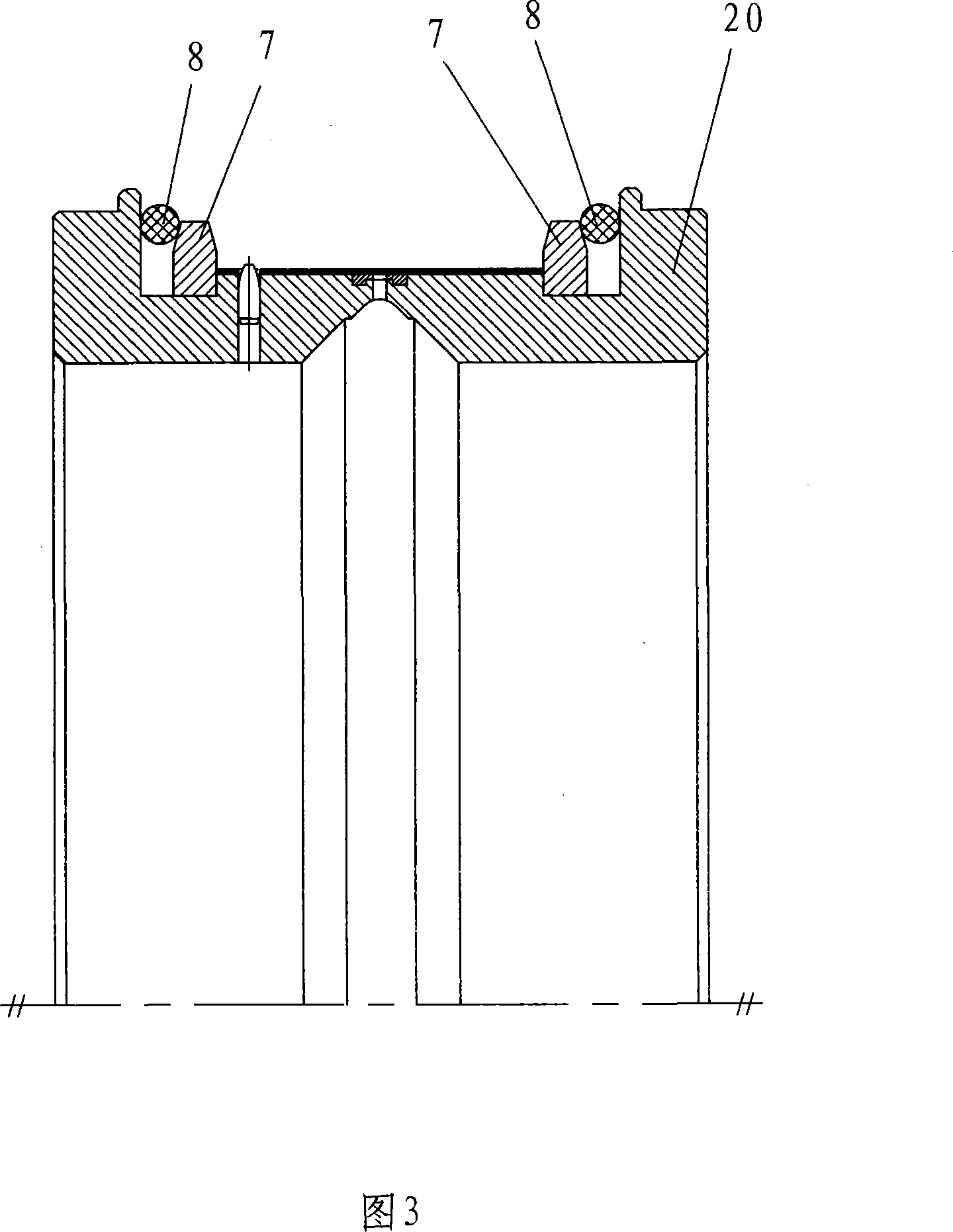

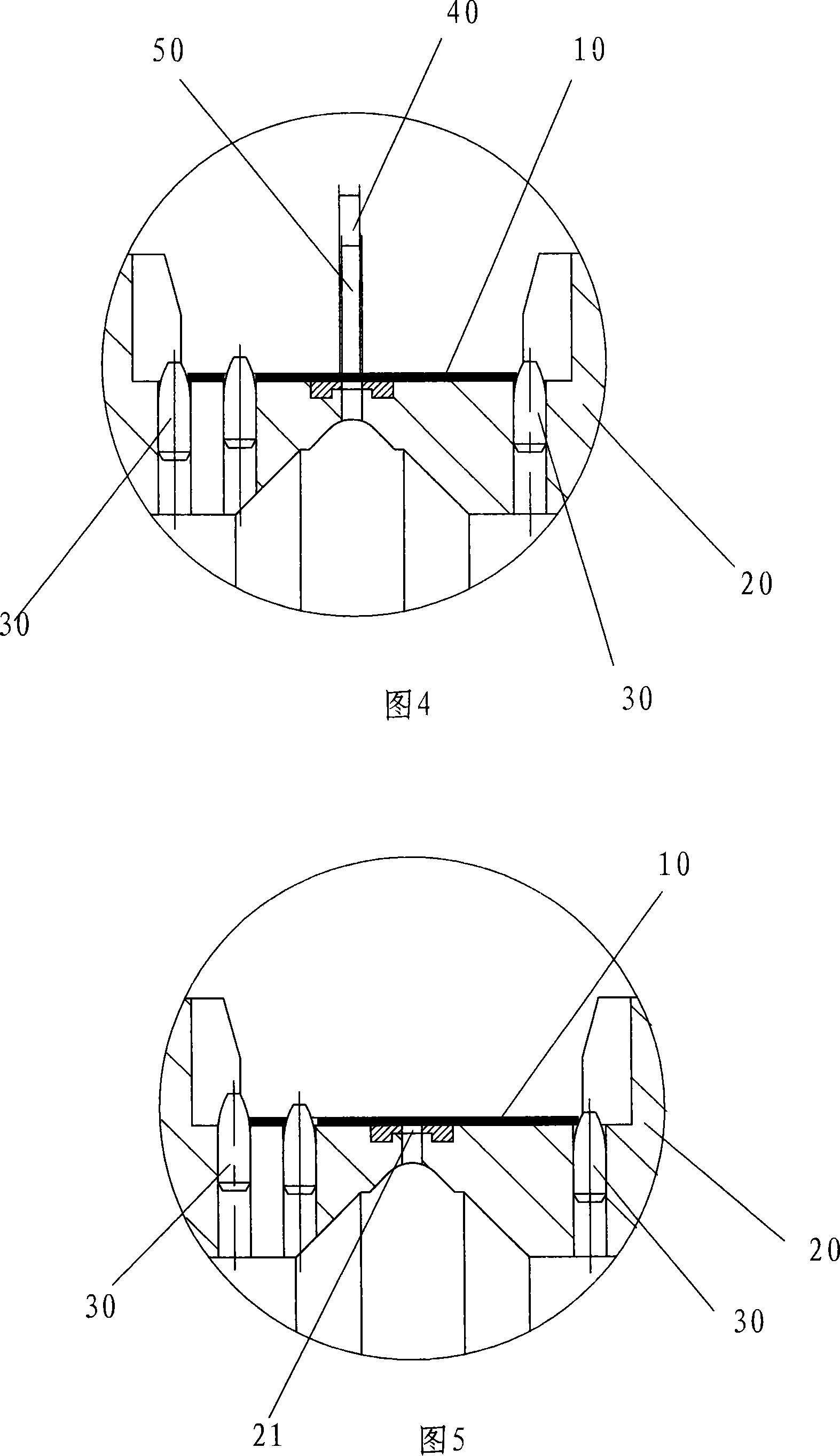

[0015] A method for positioning the width direction of the lead frame during electroplating provided by the present invention is to set a group of ceramic nails 30 on at least one side of the lead frame 10 in the width direction of the lead frame 10 on the electroplating mold 20 during electroplating. The other side of the lead frame 10 applies a pushing force to the lead frame 10 in the direction of the ceramic nail 30 , so that the lead frame 10 is close to the ceramic nail 30 .

[0016] Please refer to FIG. 4 and FIG. 5 . FIG. 4 is a schematic diagram of the principle of an implementation method of the present invention. FIG. 5 is a schematic structural diagram of FIG. 4 after adjustment. What Fig. 4 shows is that after the lead frame 10 is mounted on the electroplating mold 20, the width direction of the lead frame 10 has an error, and its ideal electroplating area 40 and the actual electroplating area 50 have deviations, and the lead frame 10 needs to be adjusted to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com