Modified acrylic acid waterproof paint and preparation method thereof

A waterproof coating, acrylic technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of easy bubbles, affect waterproof performance, high glass transition temperature, and achieve the effects of simple construction, reliable quality and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

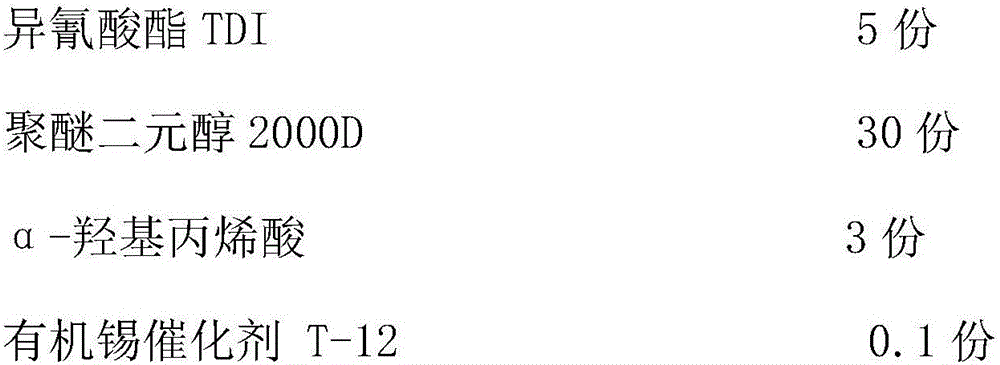

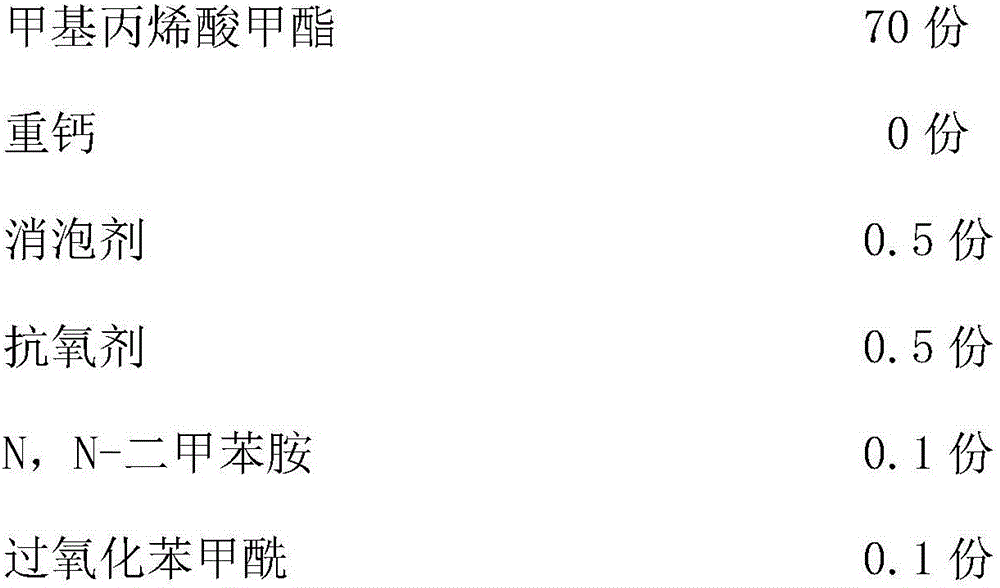

[0022] 1. Raw material ratio

[0023]

[0024]

[0025] 2. Process

[0026] (1) Add 30 parts by weight of polyether diol 2000D to the reaction vessel, stir and heat up to 100-120°C, and dehydrate for 2-3 hours under the condition of -0.01MPa vacuum;

[0027] (2) Lower the temperature to 50-100°C, add 5 parts by weight of isocyanate under high-speed stirring, and after 3-5 hours of reaction, add 3 parts by weight of hydroxyacrylic acid and 0.1 part by weight of organotin catalyst T-12, and continue the reaction for 2 After ~3 hours, the polyurethane prepolymer can be obtained by discharging;

[0028] (3) Add 70 parts by weight of acrylic acid monomer (methyl methacrylate) in the cylinder, the polyurethane prepolymer made by 1 part by weight, 0.5 parts by weight of defoamer, 0.5 parts by weight of antioxidant, 0.1 parts by weight of Accelerator (N, N-xylidine) in parts by weight, after being stirred evenly at a high speed, the modified acrylic waterproof coating can be o...

Embodiment 2

[0031] 1. Raw material ratio

[0032]

[0033]

[0034] 2. Process

[0035] (1) Add 50 parts by weight of polyether trihydric alcohol 330N into the reaction vessel, stir and heat up to 100-120°C, and dehydrate for 2-3 hours under the condition of -0.01MPa vacuum;

[0036] (2) Lower the temperature below 50-100°C, add 10 parts by weight of isocyanate under high-speed stirring, and after 3-5 hours of reaction, add 10 parts by weight of 2-hydroxyethyl methacrylate and 0.2 parts by weight of catalyst, After continuing to react for 2-3 hours, the polyurethane prepolymer can be obtained by discharging;

[0037] (3) Add 80 parts by weight of acrylic acid monomers, 26 parts by weight of the prepared polyurethane prepolymer, 60 parts by weight of pigments and fillers, and 1 part by weight of accelerators in the cylinder, and stir evenly at high speed to obtain modified acrylic acid waterproof coating;

[0038] (4) Add 2 parts by weight of initiator to the modified acrylic wate...

Embodiment 3

[0040] 1. Raw material ratio

[0041]

[0042] 2. Process:

[0043] (1) Add 70 parts by weight of polyether polyol to the reaction vessel, stir and heat up to 100-120°C, and dehydrate for 2-3 hours under the condition that the vacuum is -0.01MPa;

[0044] (2) Lower the temperature to 50-100°C, add 10 parts by weight of isocyanate under high-speed stirring, and after 3-5 hours of reaction, add 10 parts by weight of 2-hydroxyethyl methacrylate and 0.2 parts by weight of organotin catalyst T-12, continue to react for 2 to 3 hours and then discharge to obtain polyurethane prepolymer;

[0045] (3) Add 35 parts by weight of acrylic acid monomer (methyl methacrylate), 30 parts by weight of polyurethane prepolymer, 30 parts by weight of pigment and filler, 2 parts by weight of defoamer, and 2 parts by weight of accelerator in the cylinder , After stirring at a high speed, the modified acrylic waterproof coating can be obtained.

[0046] (4) Add 3 parts by weight of initiator (az...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com