Lower positioned camshaft type engine decompression device

A technology of decompression mechanism and camshaft, which is applied in the directions of engine components, machines/engines, valve devices, etc., can solve the problems of high production and processing costs, many normal work links, and many power transmission links, etc., to achieve decompression power transmission. Stable and reliable, low production cost, easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

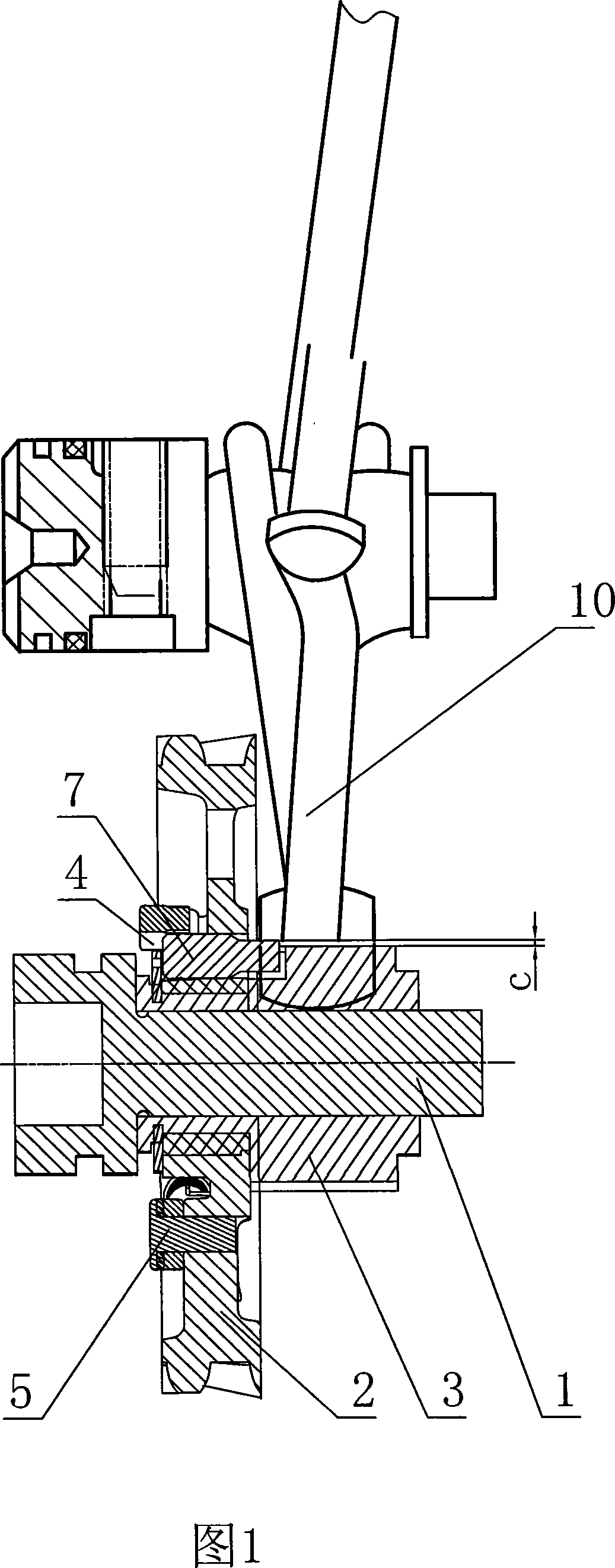

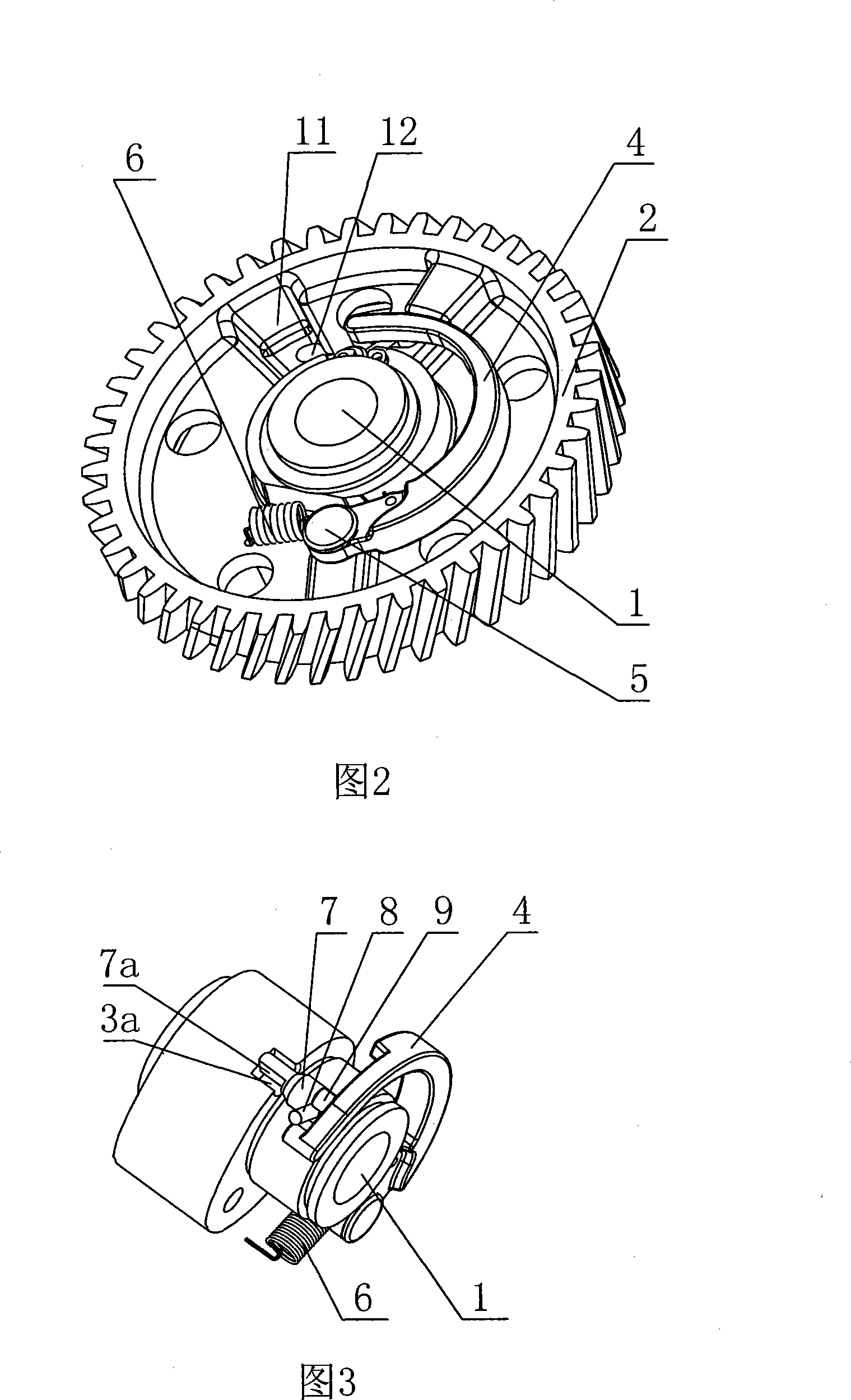

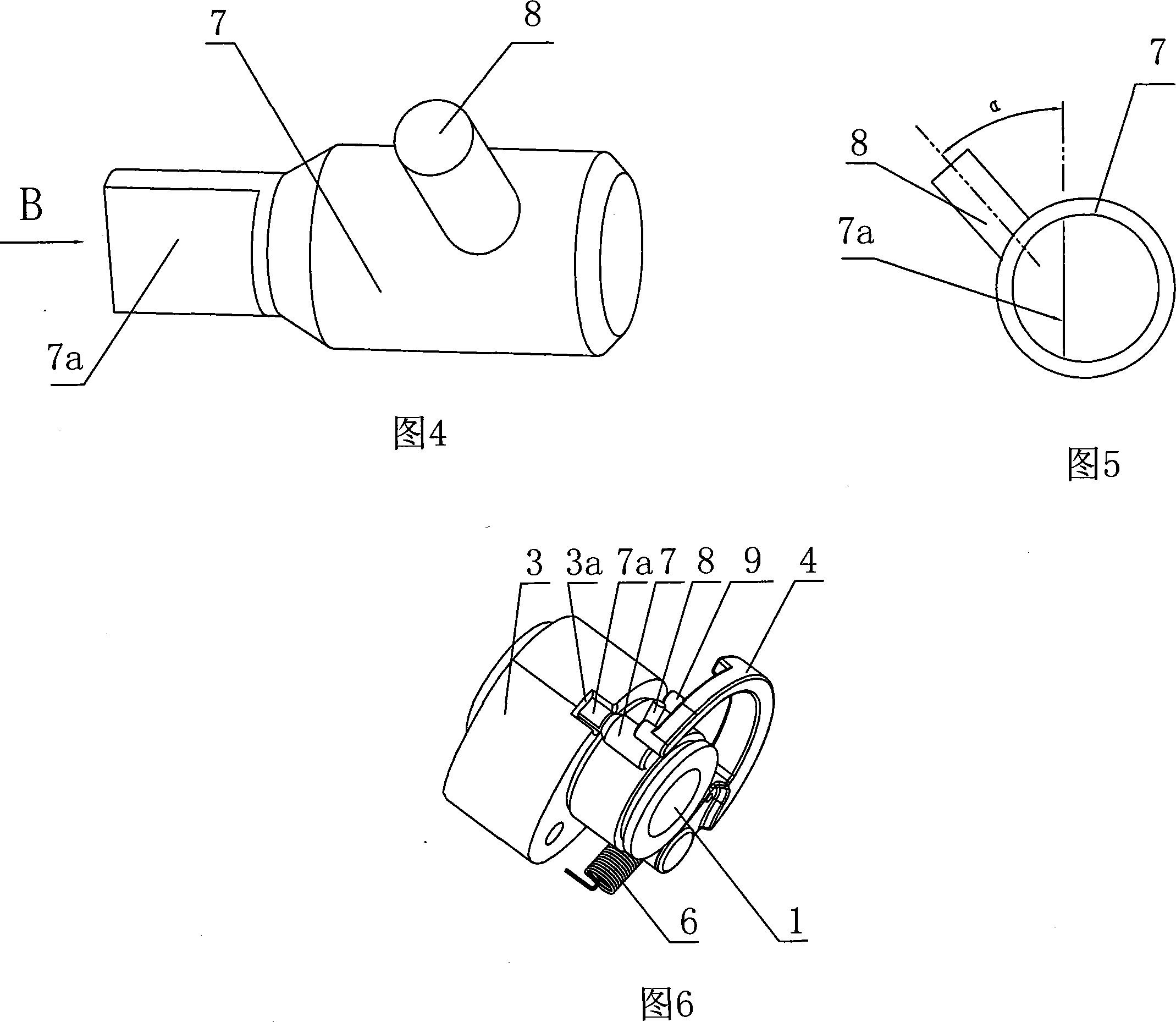

[0015] Referring to FIGS. 1 to 6 , the timing gear 2 of the lower camshaft engine is circumferentially fixed on the lower camshaft 1 and is adjacent to the exhaust cam 3 . An arc-shaped centrifugal block 4 is located on the axial end face of the timing gear 2, the fixed point end of the centrifugal block 4 is hinged with the timing gear 2, and the centrifugal block 4 is rotatably riveted and fixed on the timing gear 2 by a cylindrical pin 5 to form a hinge, and the centrifugal The free end of block 4 walks around the lower camshaft 1 and is opposite to the fixed point end. A return spring 6 is connected to the centrifugal block 4 and the timing gear 2. The return spring 6 is a tension spring, one end of which is connected to the crank arm of the centrifugal block 4 near the fixed point, and the other end is connected to the timing gear 2 at the Opposite direction of centrifugal motion. The axial end surface of the timing gear 2 is provided with a plurality of reinforcing ribs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com