Temperature control base for measuring semiconductor light-emitting device

A technology of light-emitting devices and semiconductors, which is applied in the direction of single semiconductor device testing, temperature control, and measuring devices. It can solve problems that affect injection, cannot be constant, and affect test accuracy, and achieve accurate test results, good sealing effects, and water vapor reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

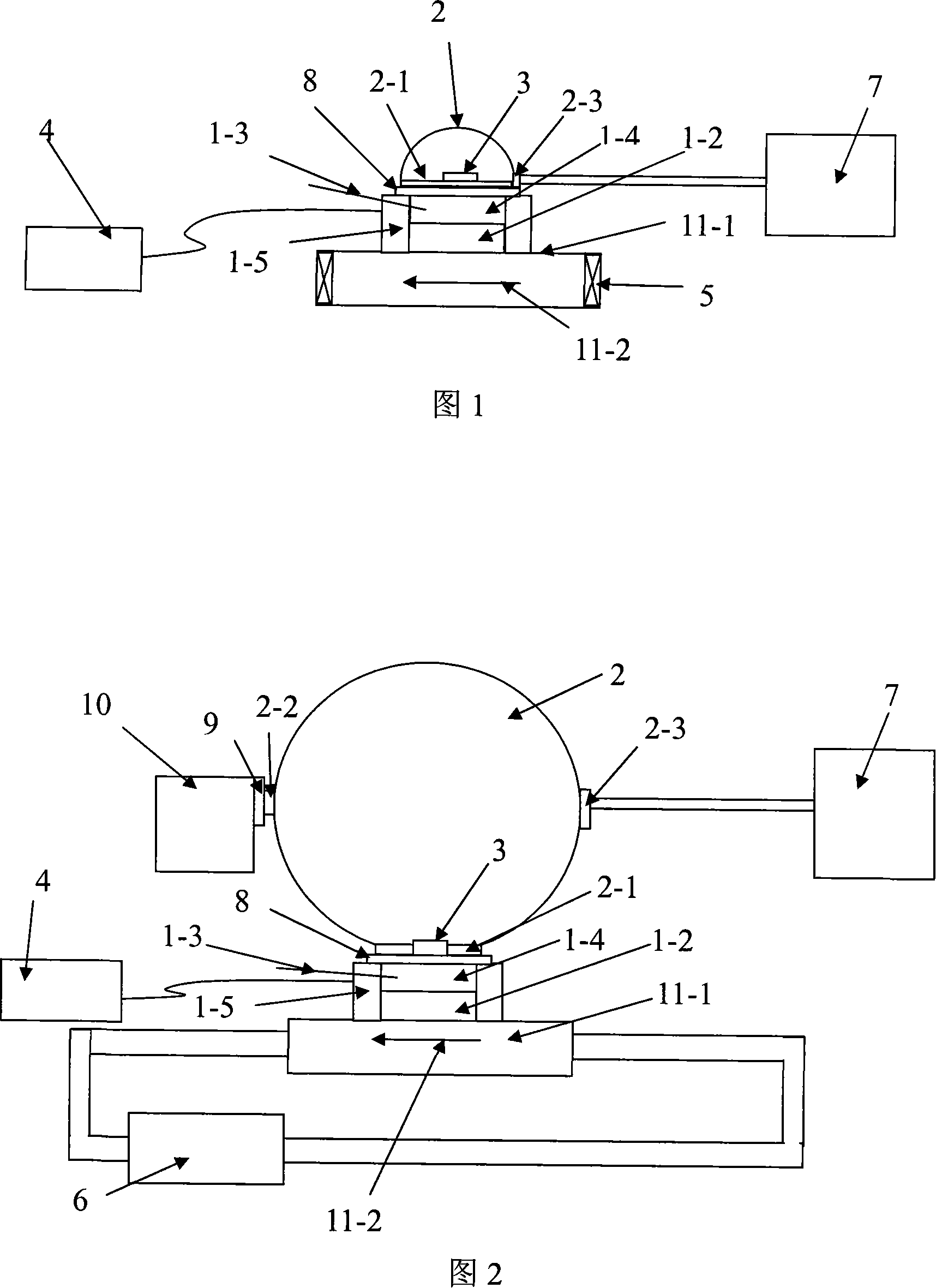

[0020] Embodiment 1: The temperature control seat for measuring semiconductor light-emitting devices, as shown in Figure 1, it can be matched with the tested part 3 and the light measuring device 10. It includes a temperature control device and a sealing cover matched with the temperature control device 2. The test piece 3 can be placed in the sealing cover 2 to cooperate with the temperature control device.

[0021] The temperature control device includes a heat dissipation device, temperature measurement elements 1-3, a temperature control element 1-2 matched with the heat dissipation device, a thermostatic seat 1-4 matched with the temperature control element 1-2, a thermostatic seat 1-4 and a temperature control element The exposed part of 1-2 is covered with a heat-insulating layer 1-5, the heat-insulating layer 1-5 is provided with a placement opening for the tested piece 3, and the tested piece 3 can be installed on the thermostatic seat 1-4 through the placement opening. T...

Embodiment 2

[0025] Embodiment 2: The temperature control seat for measuring semiconductor light-emitting devices, as shown in Figure 2. On the temperature control seat, the sealing cover 2 is a photometric integrating sphere, and the opening 2-1 matched with the thermostat seat 1-4 It is located on the wall below the sphere and on the cut surface of the sphere, and the tested object 3 is located in the center of the opening 2-1. There is a test port 2-2 on the side wall of the sphere. A light transmission channel 9 is installed on the test port 2-2. The outer end of the light transmission channel 9 is connected to a light measuring device. The light measuring device can be with a detector or with light. Transmitter's photometric instrument 10.

[0026] The heat dissipation device includes a heat dissipation base 11-1, a convection cavity 11-2 arranged on the heat dissipation base 11-1, a power pump 6 matched with the convection cavity 11-2, and the convection cavity 11-2 can pass gas or liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com