A multi-layer coiling column battery and its making technology

A cylindrical battery and process technology, applied in primary battery, secondary battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of large internal resistance, difficulty, and winding difficulty of batteries, so as to improve work efficiency and reduce internal resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

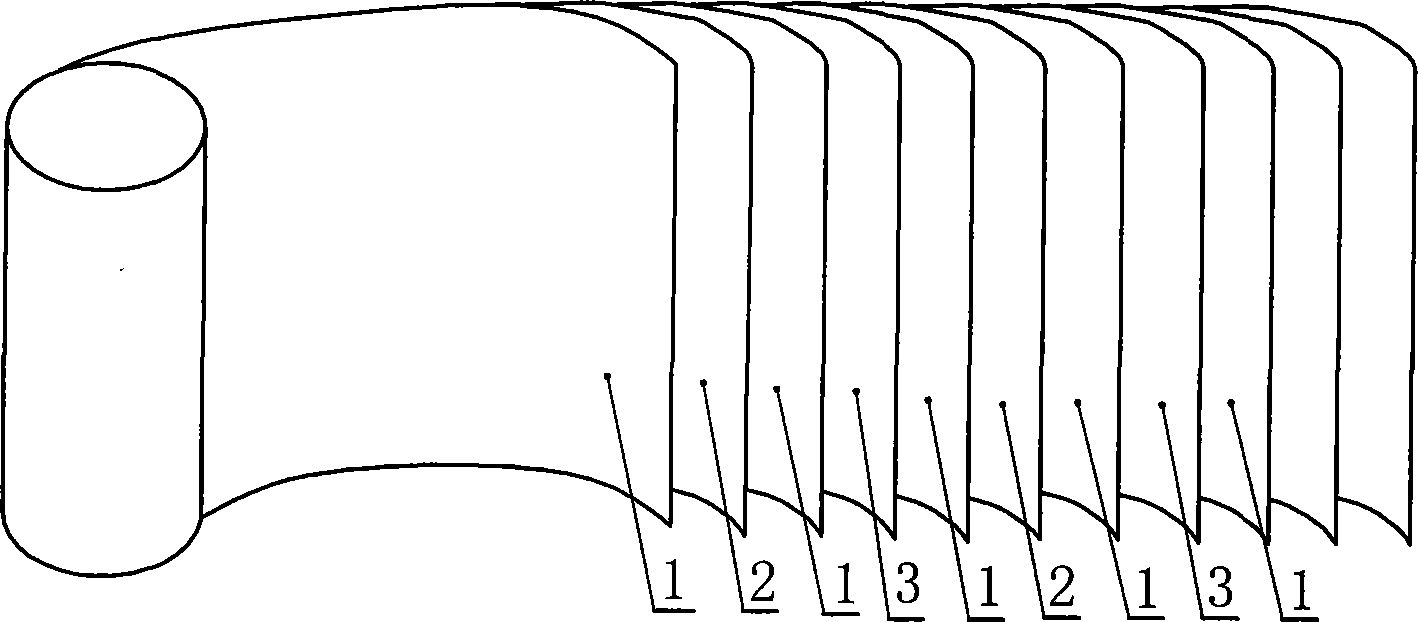

[0012] As shown in the figure, the present invention includes: a separator 1, a positive electrode sheet 2, and a negative electrode sheet 3. The separator 1, the positive electrode sheet 2, and the negative electrode sheet 3 are all multi-layered, and are stacked and then wound into a cylindrical core. in parallel.

[0013] The process of manufacturing multi-layer wound cylindrical batteries in the present invention: first cut the separator according to the length of the process design, then arrange the cut separator according to the number of layers and install it on the winding needle, first wind the separator one circle, and then gradually Put the negative electrode sheet flatly in the middle of the diaphragm, with the tab end in front, and the tab lead-out position upwards, close the stack, and start winding the negative electrode, so that the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com