Method for making water-proof vamp

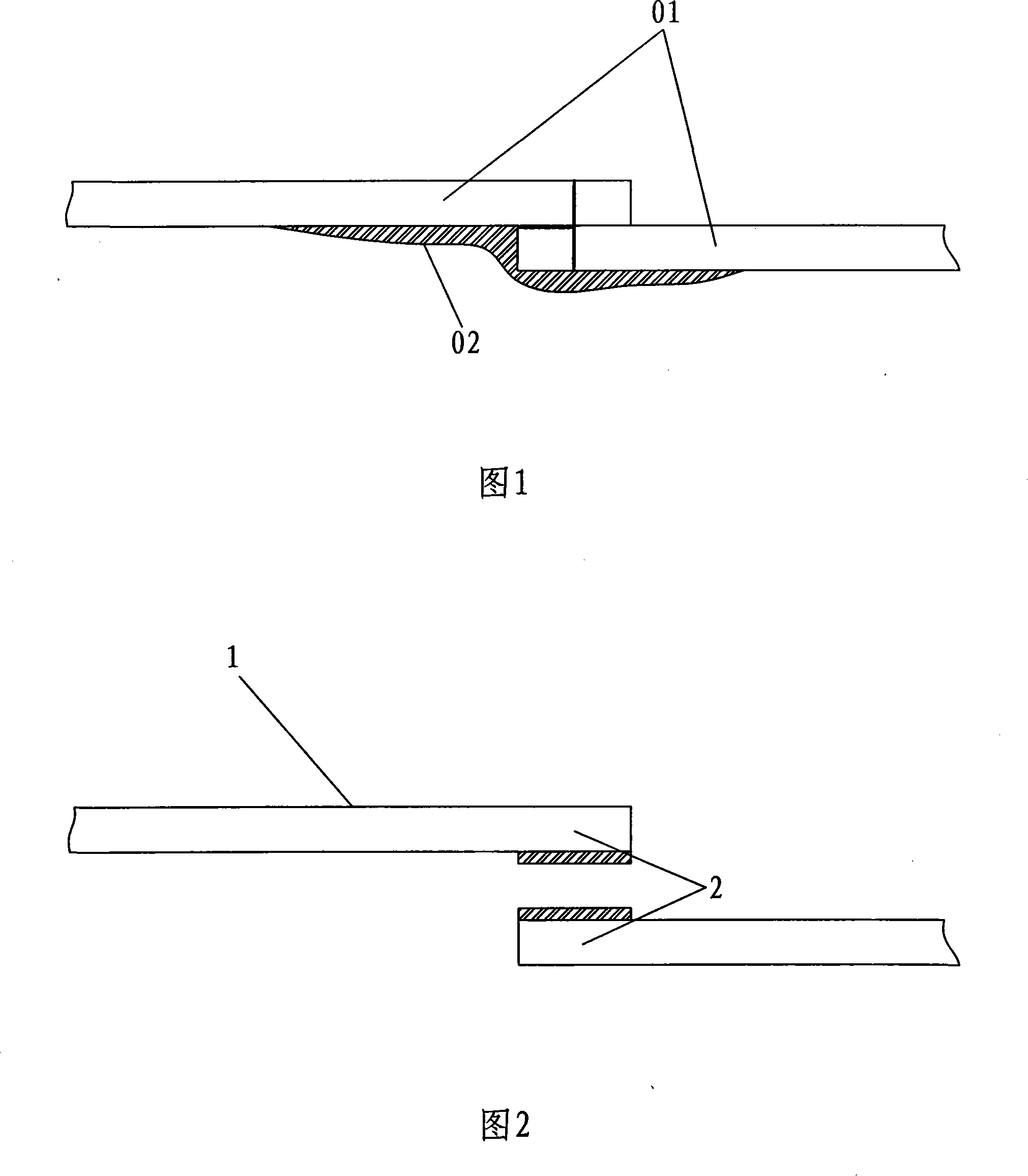

A production method and technology of waterproof shoes, which are applied to shoe uppers, footwear, boot legs, etc., can solve the problems of large usage of waterproof glue 02, low production efficiency, cumbersome production process, etc., so as to save consumption, improve production efficiency, The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

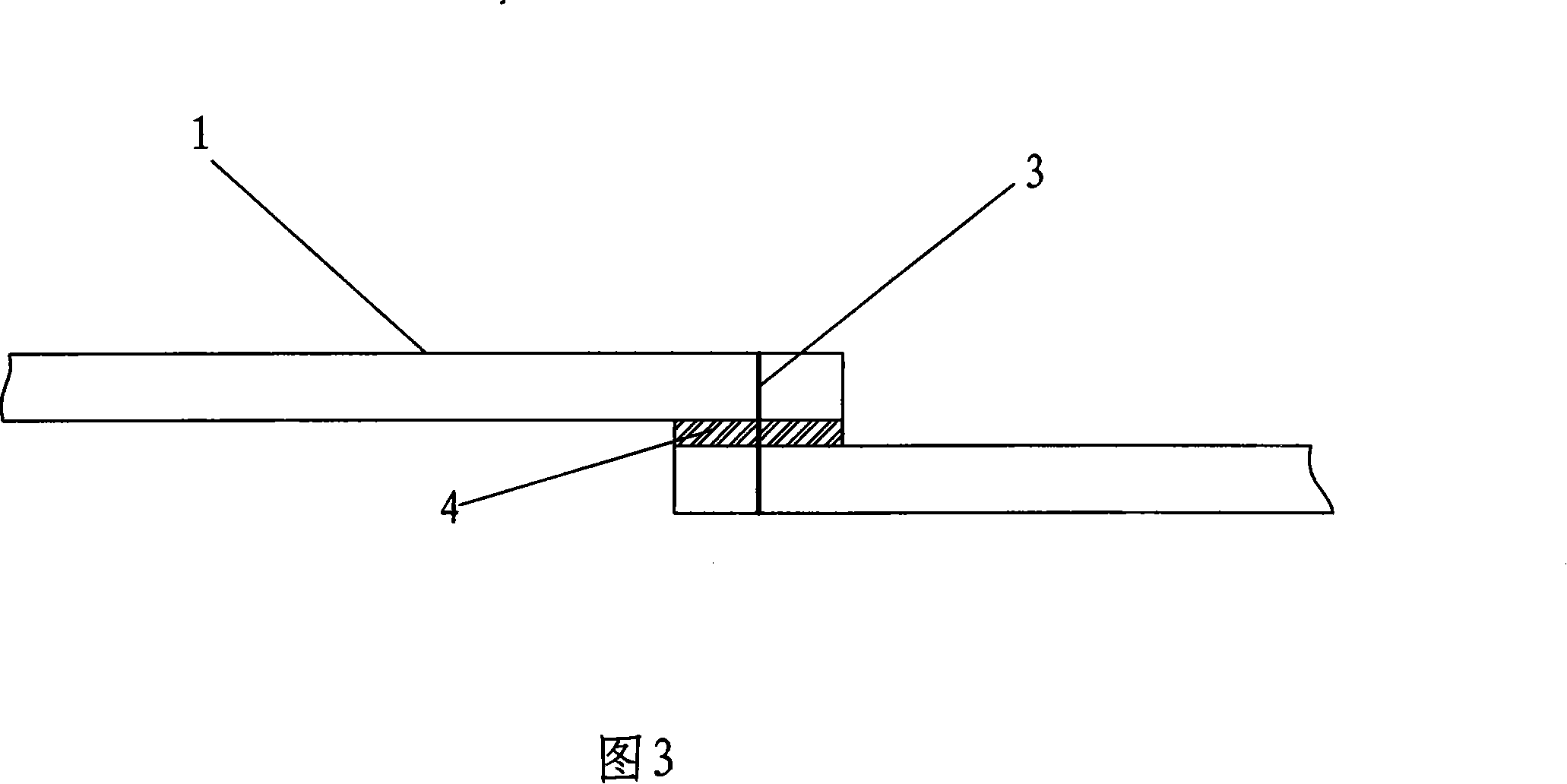

[0024] Embodiment one, see accompanying drawing 2, shown in 3, this method is to adopt the manufacturing method of sewing after first coating waterproof glue 4, at first take out two pieces of waterproof shoe upper cut pieces 1 that will be sewn together, will be positioned at above The joint part 2 at the lower end of a piece of waterproof shoe upper piece 1 and the joint part 2 at the upper end of the lower waterproof shoe upper piece 1 are evenly coated with waterproof glue 4 with a thickness of 0.3 mm and hot-melt glue. Wait for 8 seconds for waterproof glue Dry and form an adhesive film of 0.15 mm, tightly attach the joints 2 of the two waterproof shoe upper pieces 1, the pressure of the joint is 0.8 kg / square centimeter, and then use the waterproof line 3 in the joint Sew the middle of the joint part 2 together, and sew the two waterproof vamp pieces 1 together, the number of sewing stitches is 4 stitches / cm, and the stitches are distributed in the joint part 2, and final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com