Alkaline drug enteric preparation and preparation method thereof

An enteric-coated preparation and alkaline technology, which is applied in the field of enteric-coated preparations of alkaline drugs and their preparation, can solve problems such as being uneconomical and inconvenient, affecting the curative effect and application, affecting the gastric digestion and absorption function, etc., and achieving good compliance , stable and long-lasting effect in the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

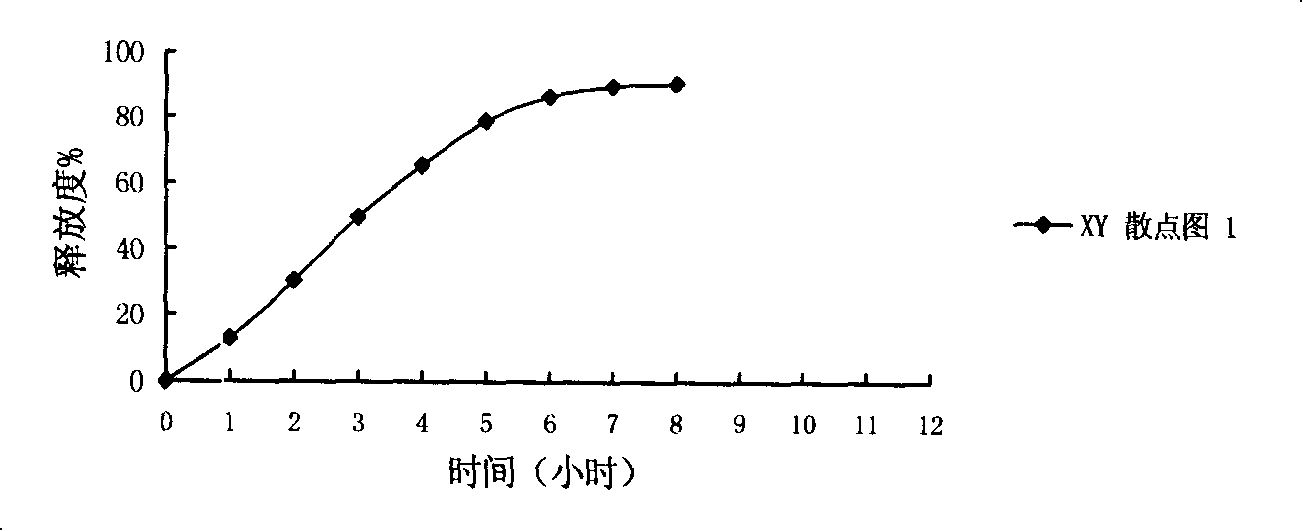

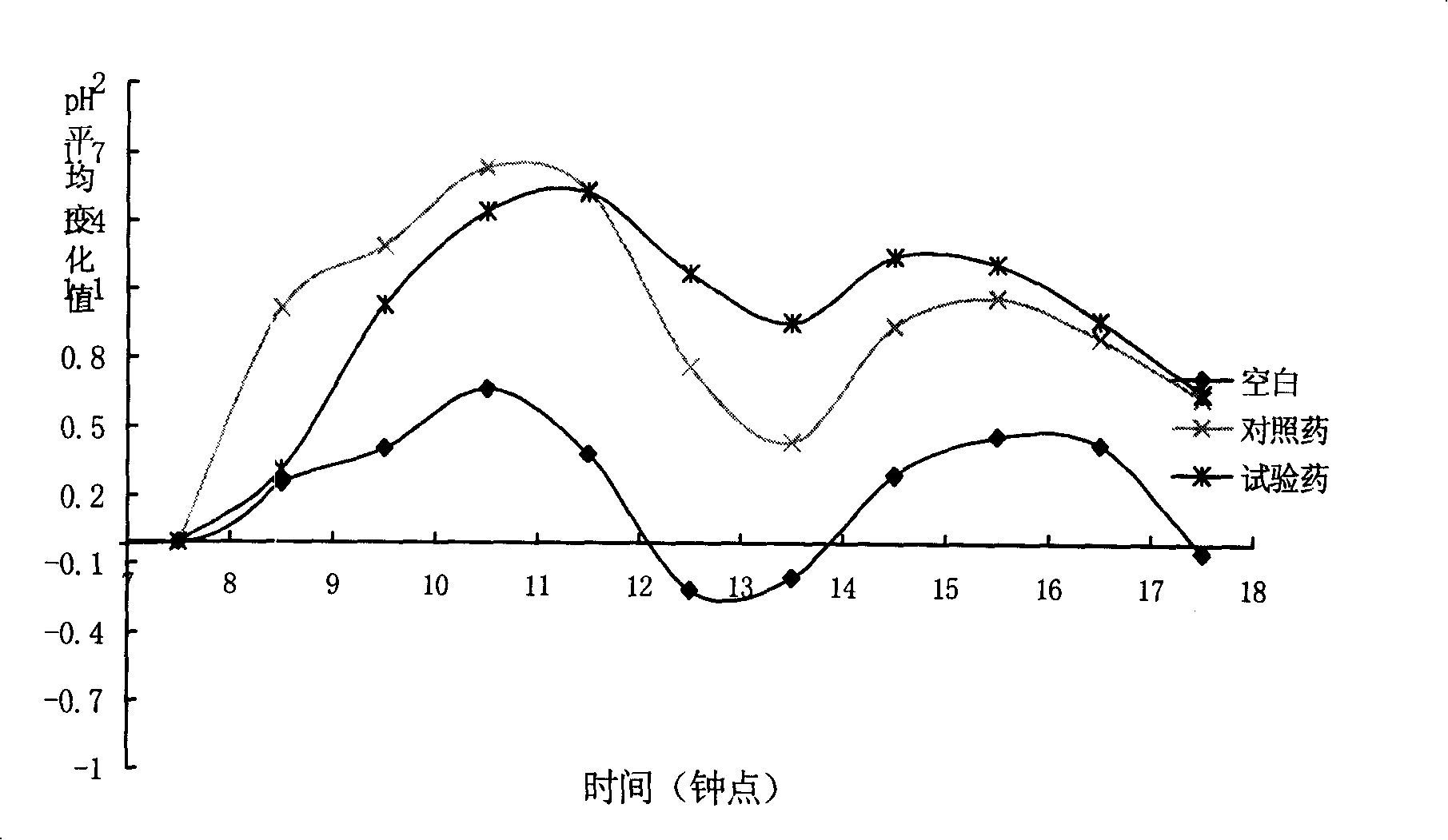

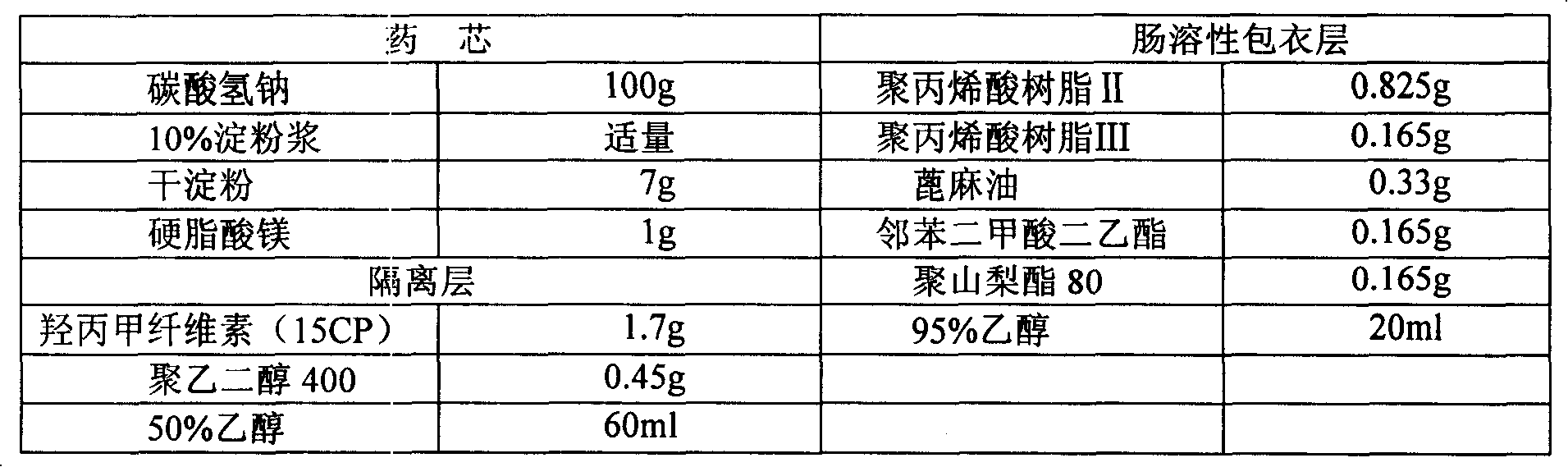

[0035] Embodiment 1: sodium bicarbonate enteric-coated tablet

[0036] Prescription: 1000 tablets

[0037]

[0038] Preparation process: crush sodium bicarbonate through a 80-mesh sieve, add 10% starch slurry (that is, mix starch and water and heat it) to make a soft material by rapid stirring, granulate with a 14-mesh sieve, and dry in an oven. Set the temperature at 40°C, raise the temperature to 50°C after 1 hour, and dry; the dry granules are sieved through a 12-mesh sieve, added with dry starch and magnesium stearate, and mixed well. Detect the intermediate, and convert the tablet weight into the pharmaceutical core according to the content. According to the prescription, add the hypromellose and polyethylene glycol of the isolation layer into ethanol for soaking and dissolving; After mixing sesame oil, diethyl phthalate and polysorbate 80, the coating operation is carried out. Put the tablets in the coating pot, turn the coating pot and blow hot air to make the tem...

Embodiment 2

[0040] Embodiment 2: sodium bicarbonate enteric-coated tablet

[0041] Prescription: 1000 tablets

[0042]

[0043] Preparation process: crush sodium bicarbonate through an 80-mesh sieve, add 10% starch slurry to make a soft material by rapid stirring, granulate with a 14-mesh sieve, and dry in an oven. The initial temperature of the oven is 40 ° C, and the temperature is raised to Dry at 50°C; sieve the dry granules through a 12-mesh sieve, add dry starch and magnesium stearate and mix well. Detect the intermediate, and convert the tablet weight into the pharmaceutical core according to the content. According to the prescription, add the hypromellose and polyethylene glycol of the isolation layer into ethanol for soaking and dissolving; After mixing sesame oil, diethyl phthalate and polysorbate 80, the coating operation is carried out. Put the tablets in the coating pot, turn the coating pot and blow hot air to make the temperature in the pot reach about 40°C, first spr...

Embodiment 3

[0045] Embodiment 3: sodium bicarbonate enteric-coated tablet

[0046] Prescription: 1000 tablets

[0047]

[0048]

[0049] Preparation process: crush sodium bicarbonate through an 80-mesh sieve, add 10% starch slurry to make a soft material by rapid stirring, granulate with a 14-mesh sieve, and dry in an oven. The initial temperature of the oven is 40 ° C, and the temperature is raised to Dry at 50°C; sieve the dry granules through a 12-mesh sieve, add dry starch and magnesium stearate and mix well. Detect the intermediate, and convert the tablet weight into the pharmaceutical core according to the content. According to the prescription, add the hypromellose and polyethylene glycol of the isolation layer into ethanol for soaking and dissolving; After mixing sesame oil, diethyl phthalate and polysorbate 80, the coating operation is carried out. Put the tablets in the coating pot, turn the coating pot and blow hot air to make the temperature in the pot reach about 40°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com