Spanner gripping coating structure

A technology of cladding structure and wrench, which is applied in the direction of wrench, hand-held tool, wrench, etc. It can solve the problems of heat conduction, unsafety, user's hand discomfort, etc., and achieve the effect of good force application and safety protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

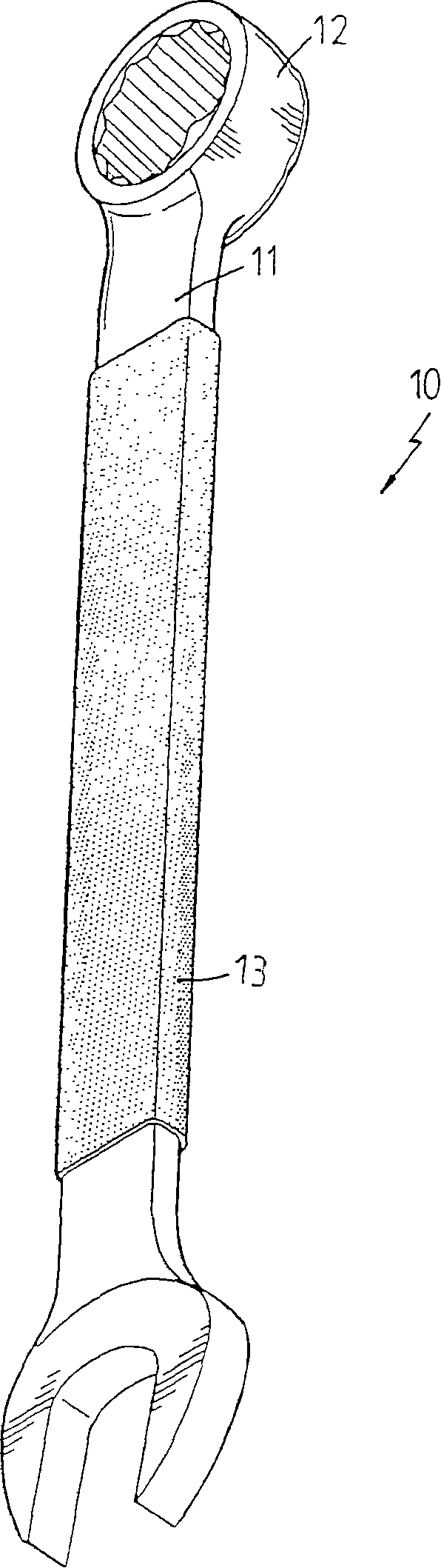

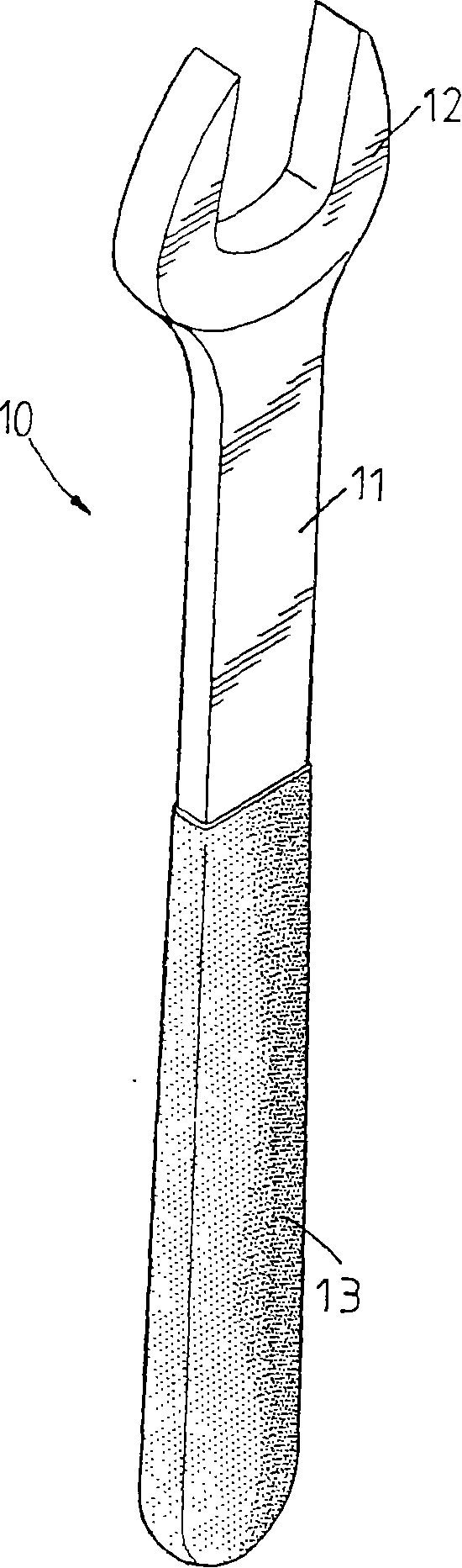

[0024] The present invention relates to a wrench holding covering structure, please refer to figure 1 As shown, the wrench gripping structure mainly includes a body 10;

[0025] The tool body 10 has a gripping portion 11, and the gripping portion 11 has at least one driving portion 12 at both ends. In this embodiment, the driving portion 12 is structured with an opening pulling portion and a closing pulling portion. Describe, use this driving part 12 to rotate screw member, and this tool body 10 utilizes the high-frequency method on this holding part 11, makes a leather material cover and fix and shape holding section 13, makes holding part 11 be covered with leather The material holding section 13 achieves the functions of convenient holding, high temperature resistance, low temperature resistance, impact resistance, non-abrasion resistance, insulation and electricity resistance.

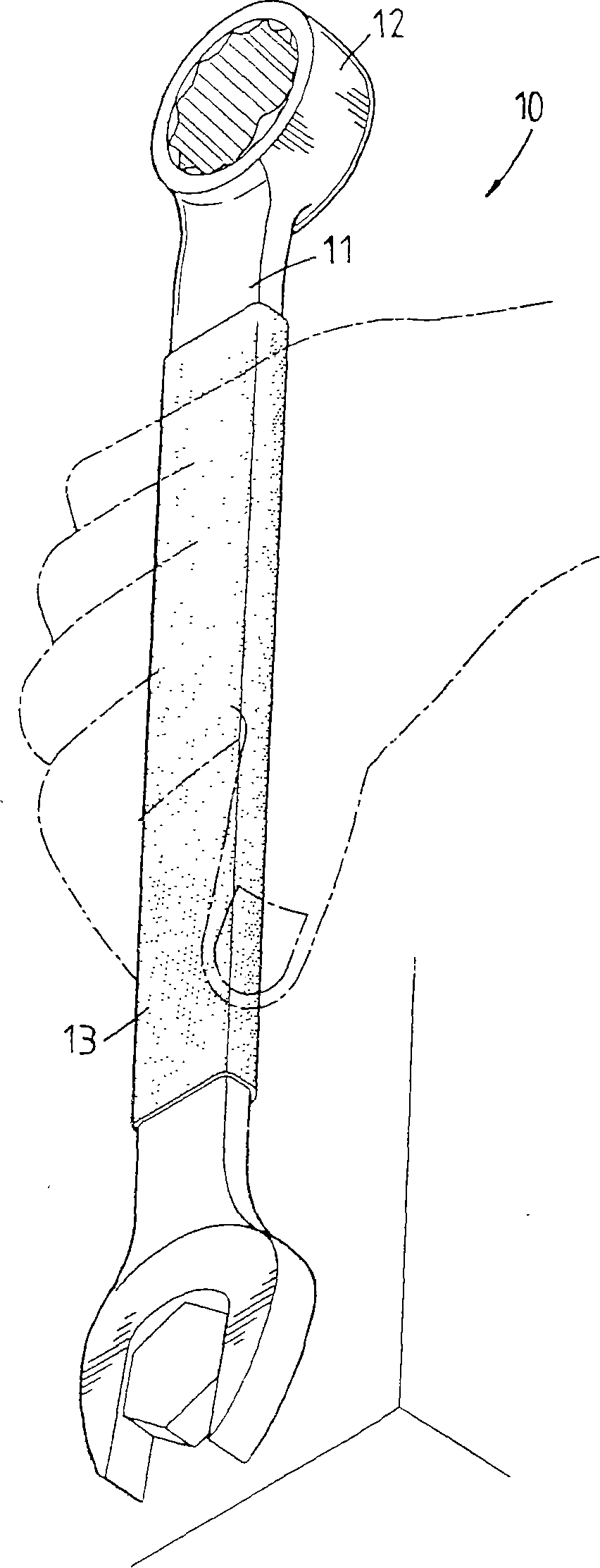

[0026] see again figure 2 As shown, when the present invention is in use, the user can opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com