Protective dismantle and assembly method for large-scale towering steel structures

An installation method and steel structure technology, applied in building structure, building maintenance, construction, etc., can solve the problems of difficult demolition and construction, achieve the effects of reducing high-altitude operations, safe and reliable construction, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

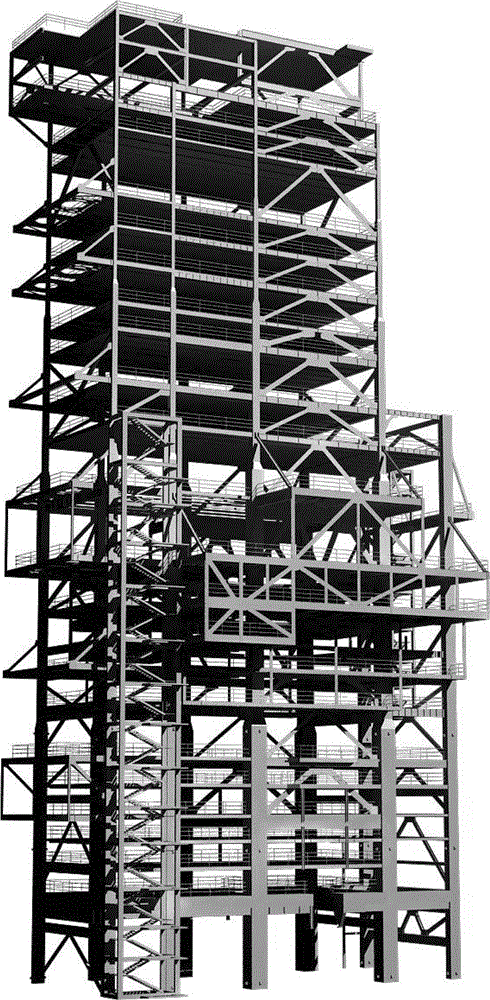

[0074] A method of protective removal and installation for large towering steel structures such as image 3 and Figure 4 As shown, including: the lower frame, the middle frame, the upper frame and the platform system of each layer, wherein the lower frame is located at -1.6m~+30m, the middle frame is located at +30m~+62m, and the upper frame is located at +62m~+118m , the platform system of each floor is located at +3.8m~+118m;

[0075] The hoisting of a large crane with a 750-ton crawler crane is carried out in sequence according to its station position and lifting capacity, combined with the structural characteristics of the tower, as follows:

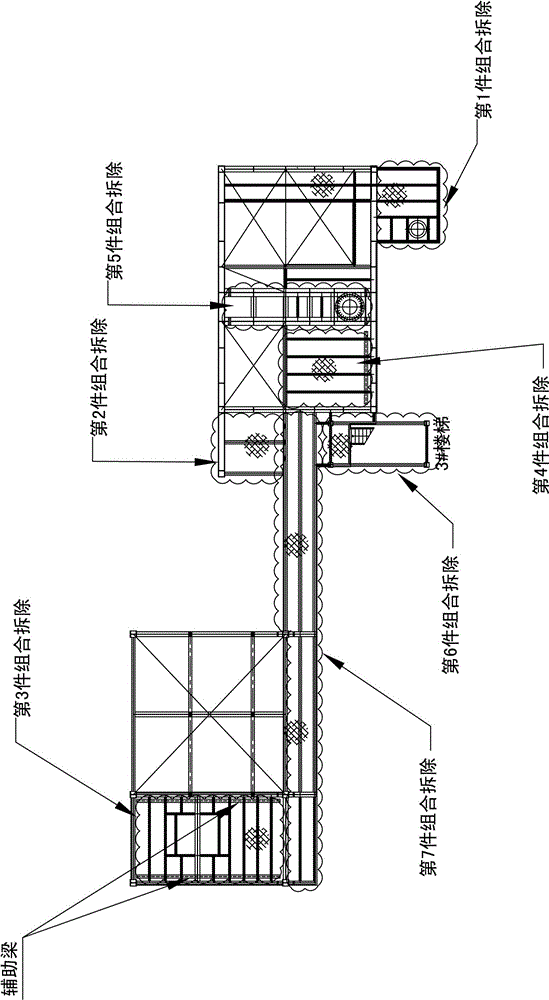

[0076] A. Remove the tower in sections from top to bottom, as attached Figure 6 and Figure 7 As shown, the main frame of C1~C4 is divided into 9 sections, the frame of C5~C6 is divided into 5 sections, and the frame of C7~C10 is divided into 7 sections; the division of C1~C10 is as follows figure 2 shown;

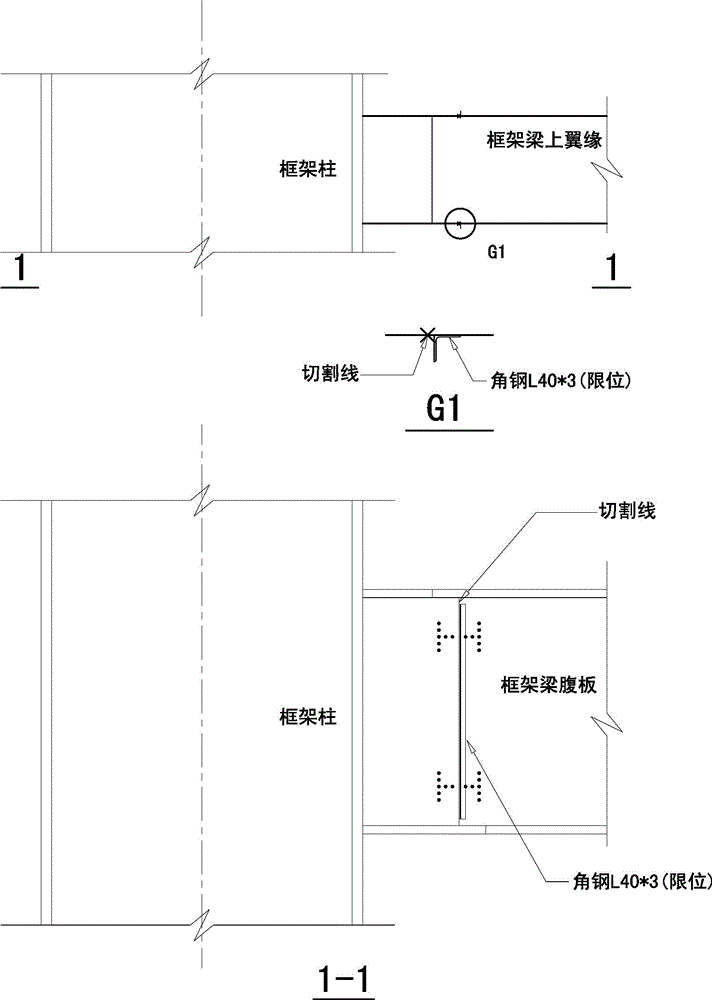

[0077] B. If Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com