Shell with flat visual window lens and its making method

A technology for window lenses and manufacturing methods, which is applied to camera bodies, electrical equipment casings/cabinets/drawers, optics, etc., can solve the problems of multiple assembly processes, increased thickness, and unstable performance, so as to reduce manufacturing processes, The thickness of the shell is thin and the effect of material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

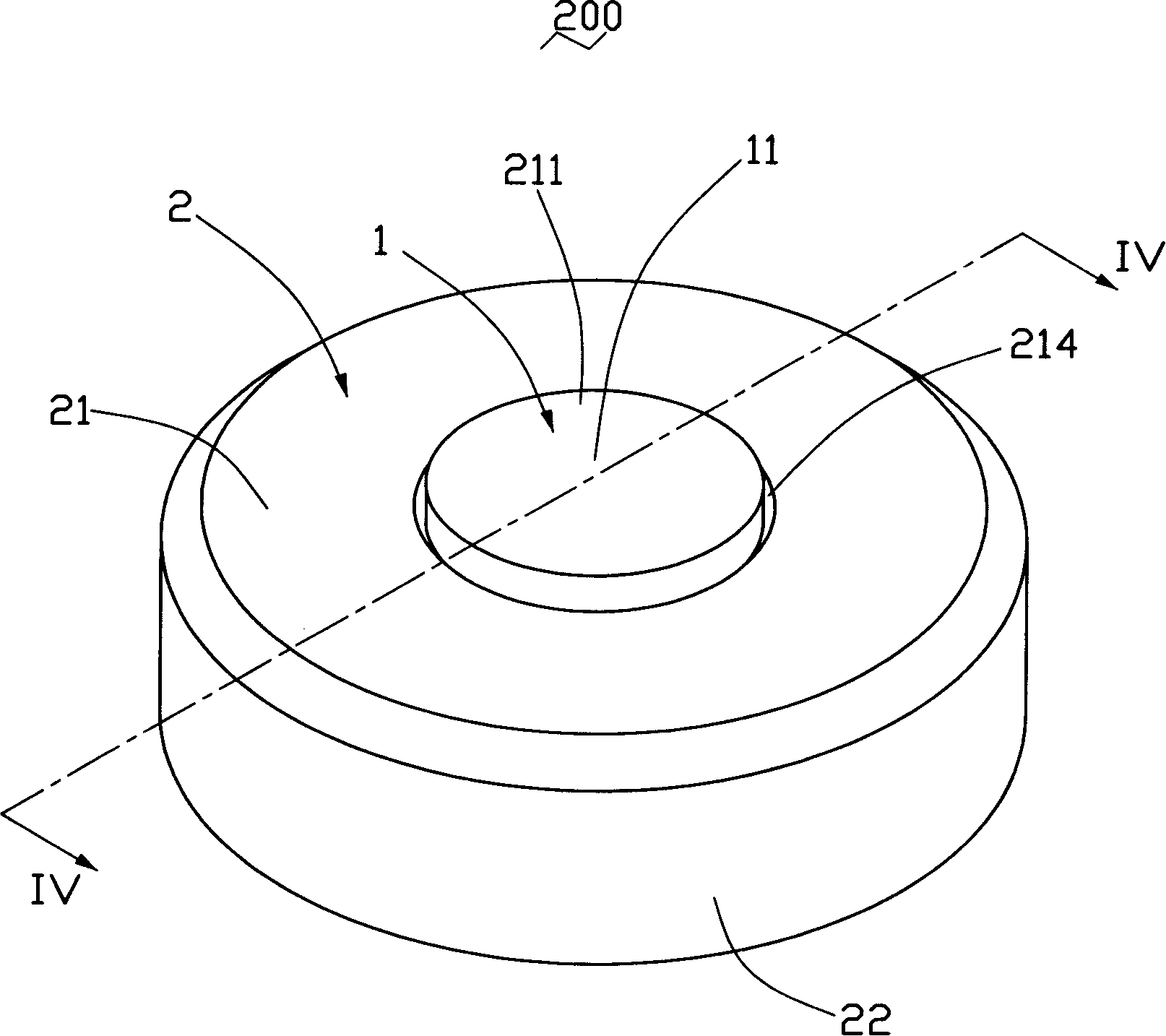

[0024] see image 3 and Figure 4 , the housing 200 with a flat window lens in a preferred embodiment of the present invention includes a flat window lens 1 and a peripheral housing 2 .

[0025] The flat window lens 1 is made of a PMMA lens with an AR (anti-reflection coating) coating, and the PMMA lens with an AR coating has a surface hardness of up to 5H and a light transmittance of up to 99%. The flat window lens 1 is a disc, which includes a window portion 11 and a joint portion 12 integrally formed with the window portion 11 . The joint portion 12 extends from the outer periphery of the window portion 11 and has a thickness smaller than that of the window portion 11 . The joint portion 12 extends an engagement portion 122 . The window portion 11 serves as a main window for receiving and transmitting light from the outside, and the joint portion 12 serves as a joint portion between the flat window lens 1 and the peripheral housing 2 . The peripheral casing 2 is made of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com