Winding machine with wet-type friction slice clutch having hollow hook lowering function

A friction plate and clutch technology, applied in the field of hoists, can solve the problems of brake slippage, slippage, unreliable clutching and braking, etc., and achieves the effects of beautiful appearance, compact structure and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

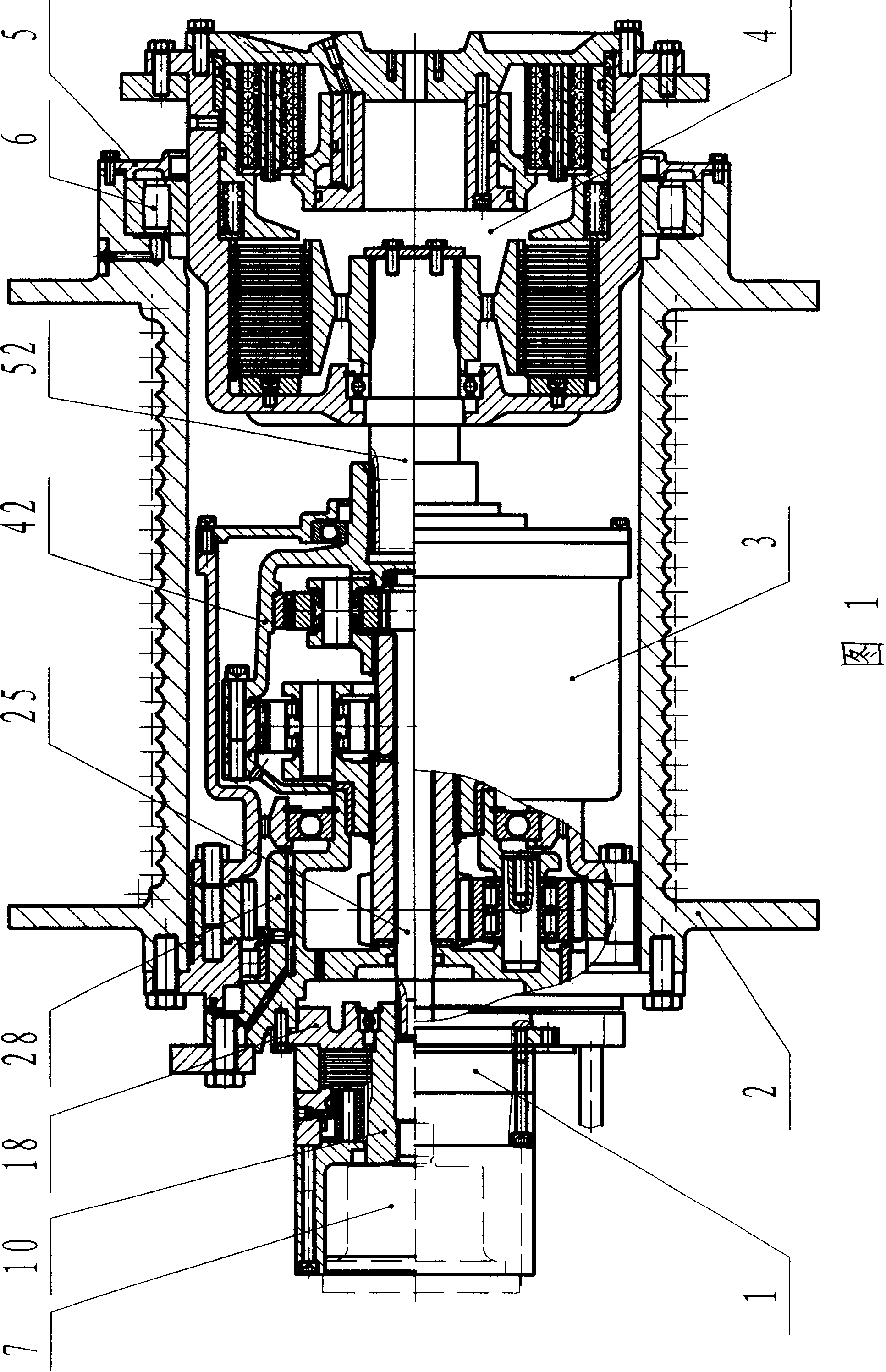

[0016] As shown in FIG. 1 , the present invention consists of a brake 1 , a reel 2 , a planetary reducer 3 , and a wet friction plate clutch 4 . Both the planetary speed reducer 3 and the wet friction plate clutch 4 are placed in the reel 2 . Reel 2 adopts fence type reel. The brake 1 is fixed on the three-stage planet carrier 28 of the planetary reducer 3 with bolts through the flange 18; there is a spline sleeve 10 on the brake 1 for the connection between the output shaft of the hydraulic motor 7 and the input shaft 25 of the planetary reducer 3, The connecting shaft 52 of the clutch 4 is connected with the spline sleeve of the first-stage and second-stage ring gear casing 42 of the planetary reducer 3 that can rotate, and the clutch casing 60 is carried on the end of the reel 2 through the self-aligning bearing 6, and is reversed with the end cover 5 The core bearing 6 is axially positioned, and the end cover 5 and the reel 2 are fixed with bolts.

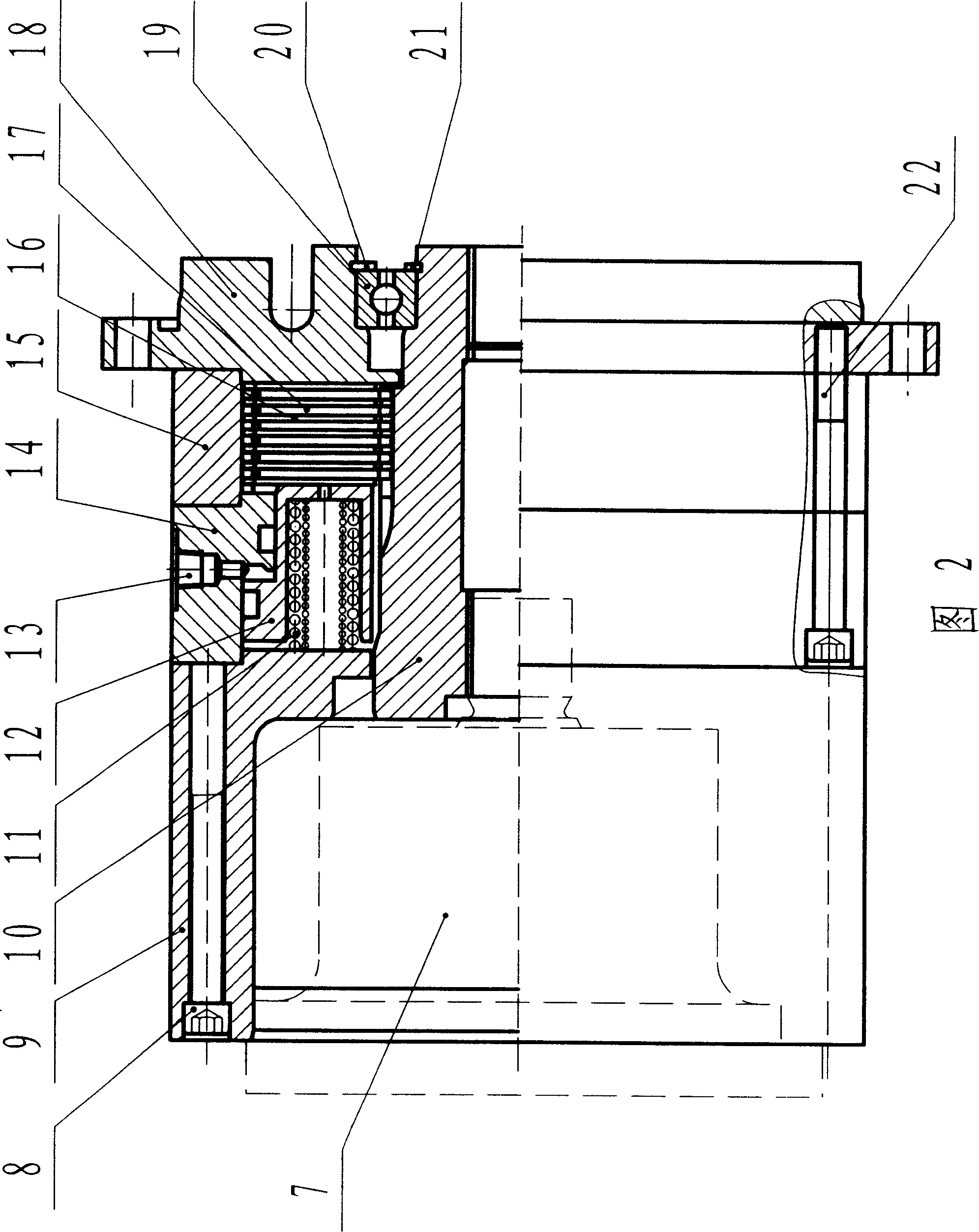

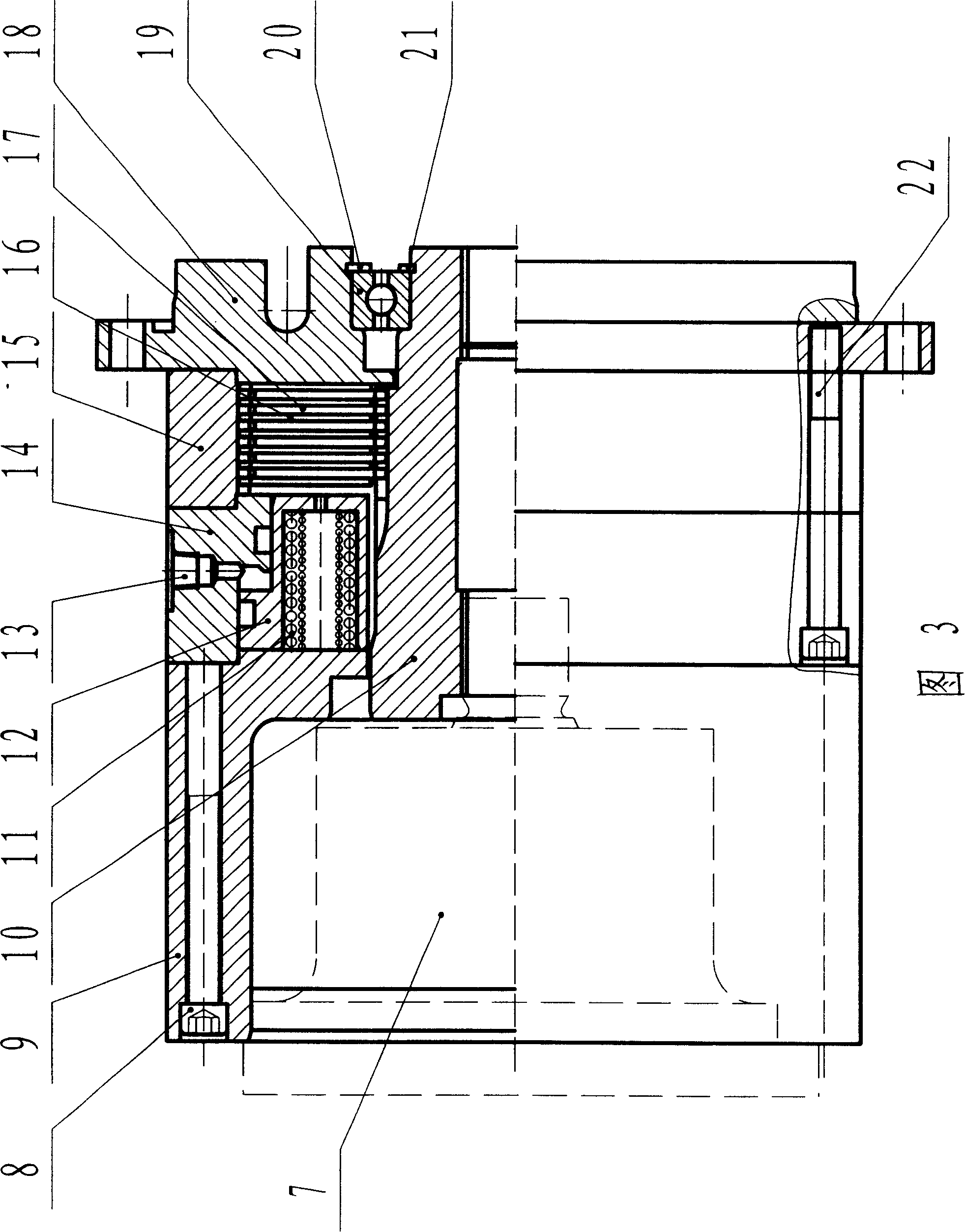

[0017] Figure 2 and F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com