A method for preparing titanium nitride bulk with controllable composition

A titanium nitride and system technology, which is applied in the field of preparation of titanium nitride blocks with controllable composition, can solve the problems affecting the airworthiness certification of civil aircraft engines, lack of airworthiness certification, etc., and solve the problem of uncontrollable titanium nitride composition, Abundant preparation methods, uniform effect of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

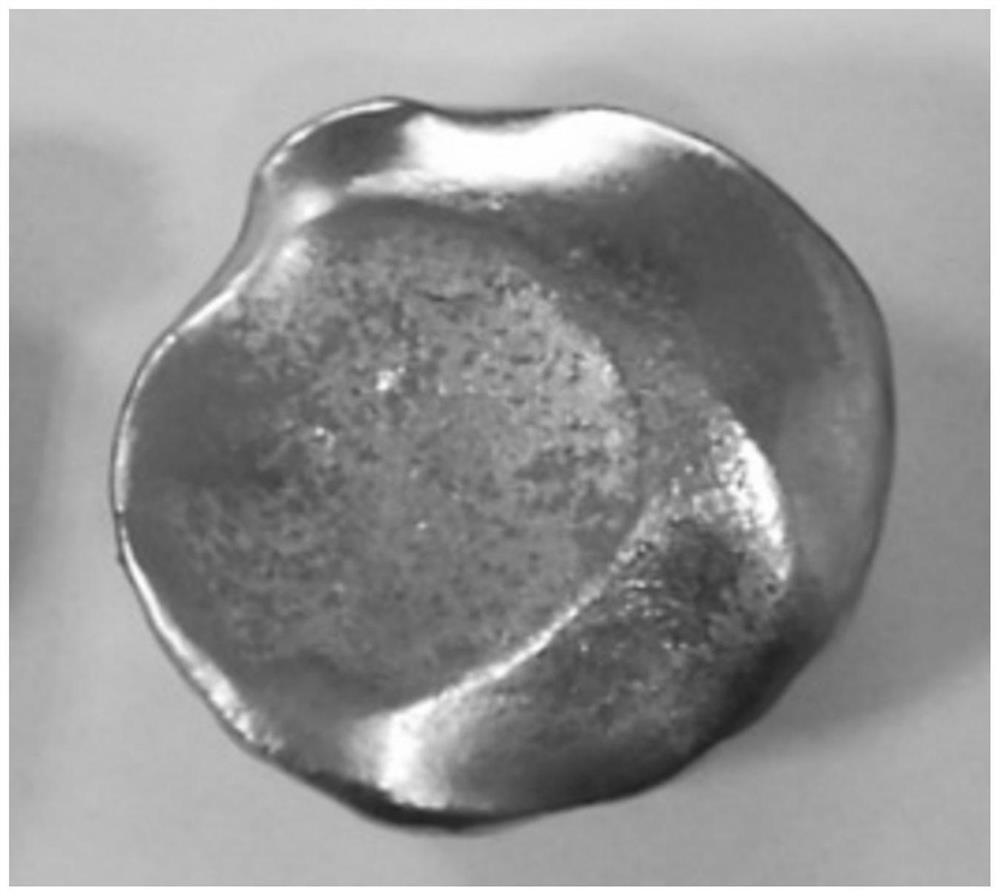

[0029] In this embodiment, the preparation method of a titanium nitride block with a nitrogen content of 2wt% comprises the following steps:

[0030] (1) select titanium alloy (brand is Ti-6Al-4V) powder and nitrogen content to be the industrial titanium nitride powder of 20% (wt), the granularity of two kinds of powders is 30 microns;

[0031] (2) According to titanium nitride with a nitrogen content of 2wt%, the weight ratio of titanium alloy powder to industrial titanium nitride powder is 9:1, and the two powders in the above ratio are weighed and mixed evenly, and then mixed evenly by cold pressing process The powder is compressed into blocks;

[0032] (3) placing the compressed block mixture in a high-vacuum Ar atmosphere protection non-consumable electric arc furnace;

[0033] (4) Before smelting, vacuumize the furnace to 3×10 -4 Pa, after flushing the furnace with argon for 3 times, vacuumize to 3×10 -4 Pa, refill with argon to -0.03MPa (the reading of the vacuum gau...

Embodiment 2

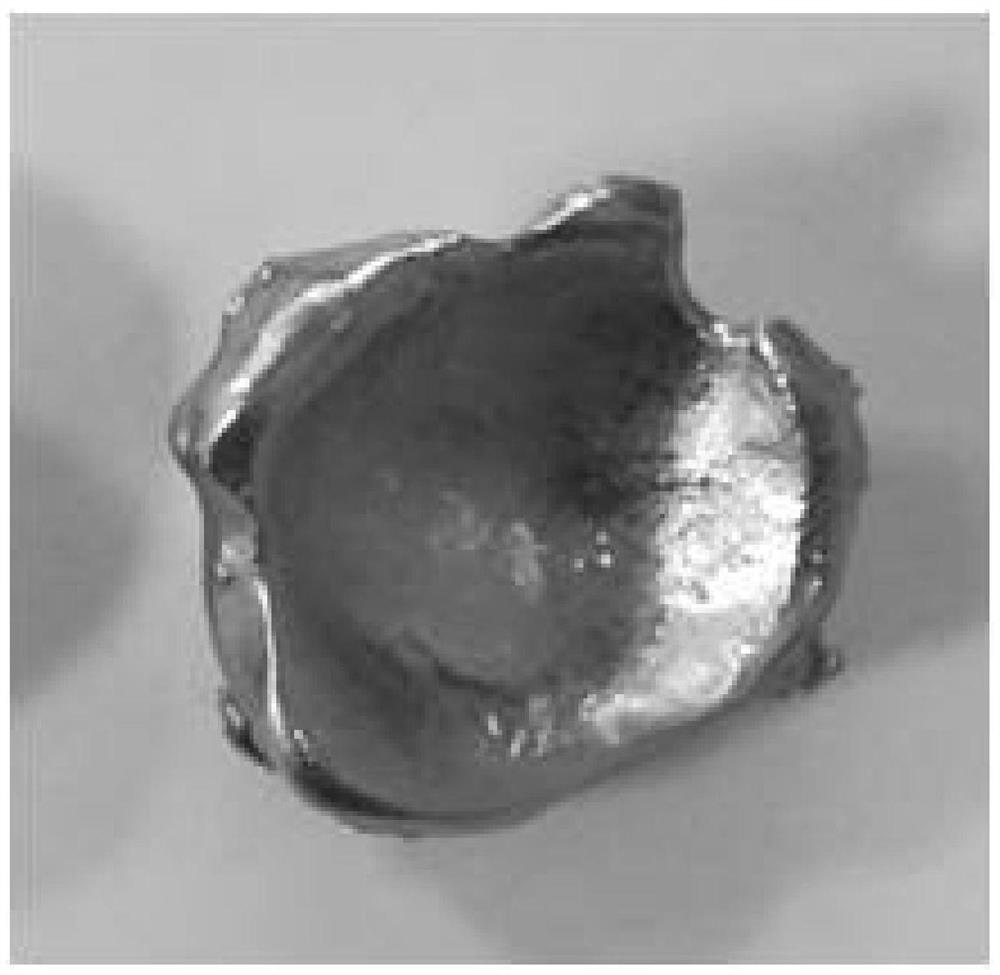

[0037] In this embodiment, the method for preparing a titanium nitride block with a nitrogen content of 4wt% comprises the following steps:

[0038] (1) select titanium alloy (brand is Ti-6Al-4V) powder and nitrogen content to be the industrial titanium nitride powder of 20% (wt), the particle size of two kinds of powders is 20 microns;

[0039] (2) According to titanium nitride with a nitrogen content of 4wt%, the weight ratio of titanium alloy powder to industrial titanium nitride powder is 4:1, and the two powders in the above ratio are weighed and mixed evenly, and then mixed evenly by cold pressing process The powder is compressed into blocks;

[0040] (3) placing the compressed block mixture in a high-vacuum Ar atmosphere protection non-consumable electric arc furnace;

[0041] (4) Before smelting, vacuumize the furnace to 1×10 -4 Pa, after flushing the furnace with argon for 2 times, vacuumize to 1×10 -4 Pa, refill with argon to -0.025MPa (the reading of the vacuum g...

Embodiment 3

[0045] In this embodiment, the method for preparing a titanium nitride block with a nitrogen content of 8 wt% includes the following steps:

[0046] (1) select titanium alloy (brand is Ti-6Al-4V) powder and nitrogen content to be the industrial titanium nitride powder of 20% (wt), the granularity of two kinds of powders is 10 microns;

[0047] (2) According to titanium nitride with a nitrogen content of 8wt%, the weight ratio of titanium alloy powder to industrial titanium nitride powder is 3:2. Weigh the two powders in the above ratio and mix them evenly, and then use cold pressing process to mix them evenly The powder is compressed into blocks;

[0048] (3) placing the compressed block mixture in a high-vacuum Ar atmosphere protection non-consumable electric arc furnace;

[0049] (4) Before smelting, vacuumize the furnace to 5×10 -4 Pa, after flushing the furnace with argon for 4 times, vacuumize to 5×10 -4 Pa, refill with argon to -0.02MPa (the reading of the vacuum gaug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com