Multi-light tube backlight module

A technology of backlight module and lamp tube, applied in optics, nonlinear optics, instruments, etc., can solve problems such as high cost and inability to automate production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

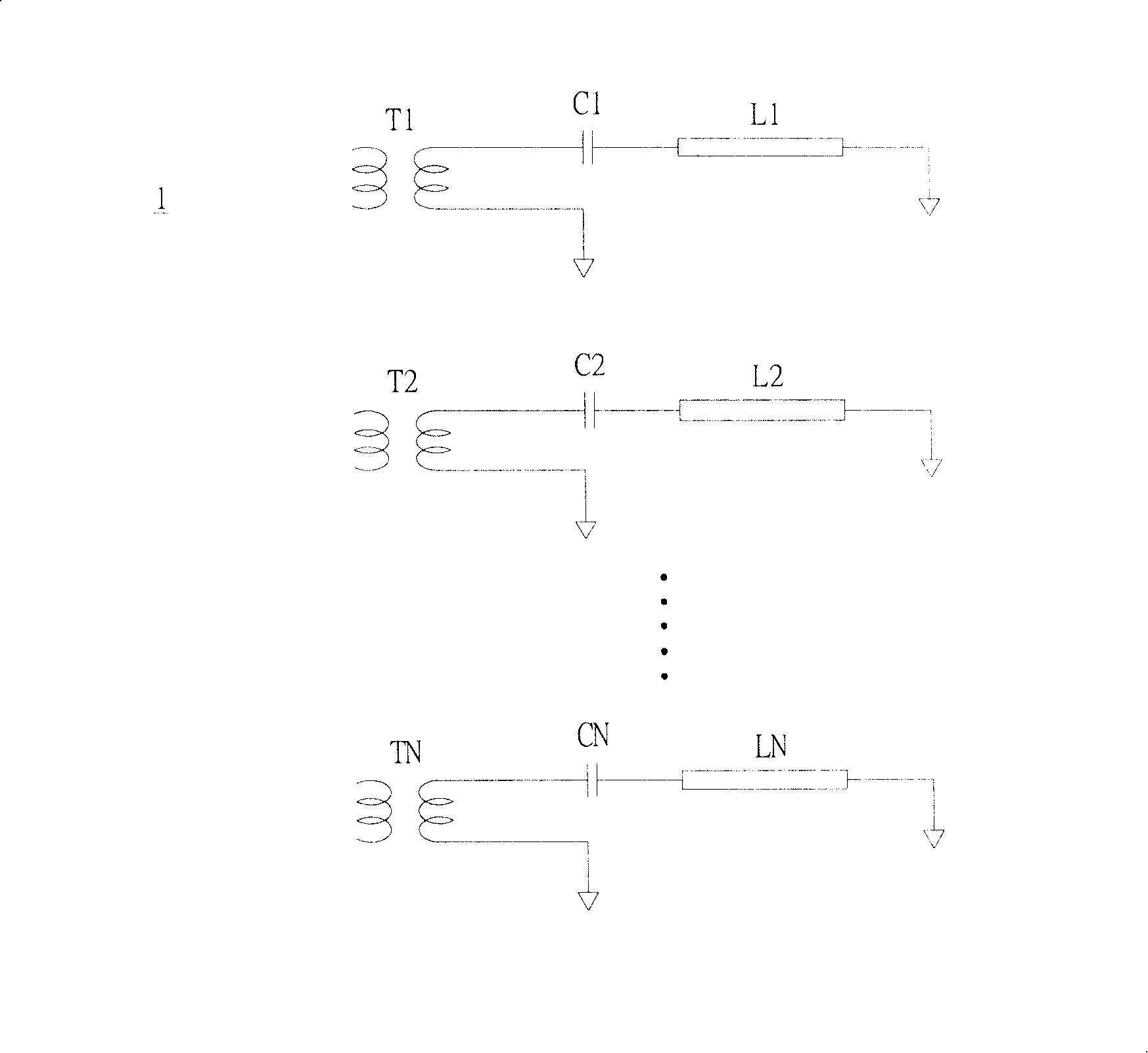

[0044] Please refer to Figure 5 , which is a schematic circuit diagram of the backlight module according to the first embodiment of the present invention. The backlight module 3 of the present invention uses a driving transformer T to provide high-voltage driving signals to the cold-cathode lamps L1-LN through the high-voltage capacitors C1-CN in a one-to-many manner, and then drives the cold-cathode lamps L1-LN. Suitable for a liquid crystal display panel (not marked).

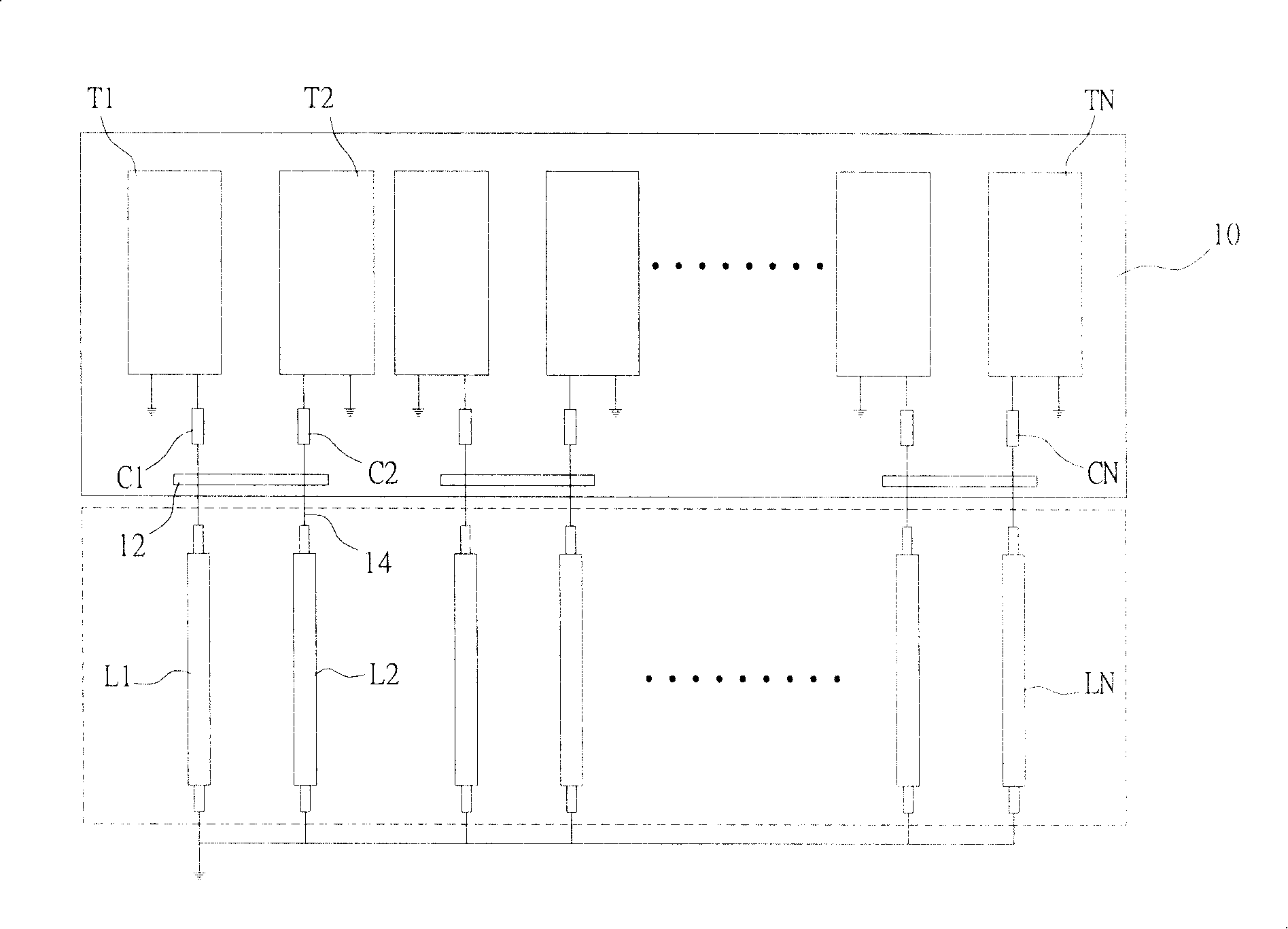

[0045] Cooperate Figure 5 ,refer to Image 6 ,it's for Figure 5 Schematic diagram of the circuit setup. exist Image 6 Among them, the backlight module 3 of the present invention includes a drive unit 30 and a backlight unit 32, the drive unit 30 includes a control circuit board 300 and a drive transformer T, and the backlight unit 32 includes a circuit board 320 and at least one cold cathode lamp L1- LN. The drive transformer T is disposed on the control circuit board 300 , and the secondary side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com