Cleaning device and method for cleaning workpieces

A technology for cleaning devices and workpieces, which is applied to chemical instruments and methods, cleaning methods and appliances, and solid separation, and can solve problems such as time-consuming, difficulty in correct calibration of tuyere nozzles, and incorrect detection of workpiece positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

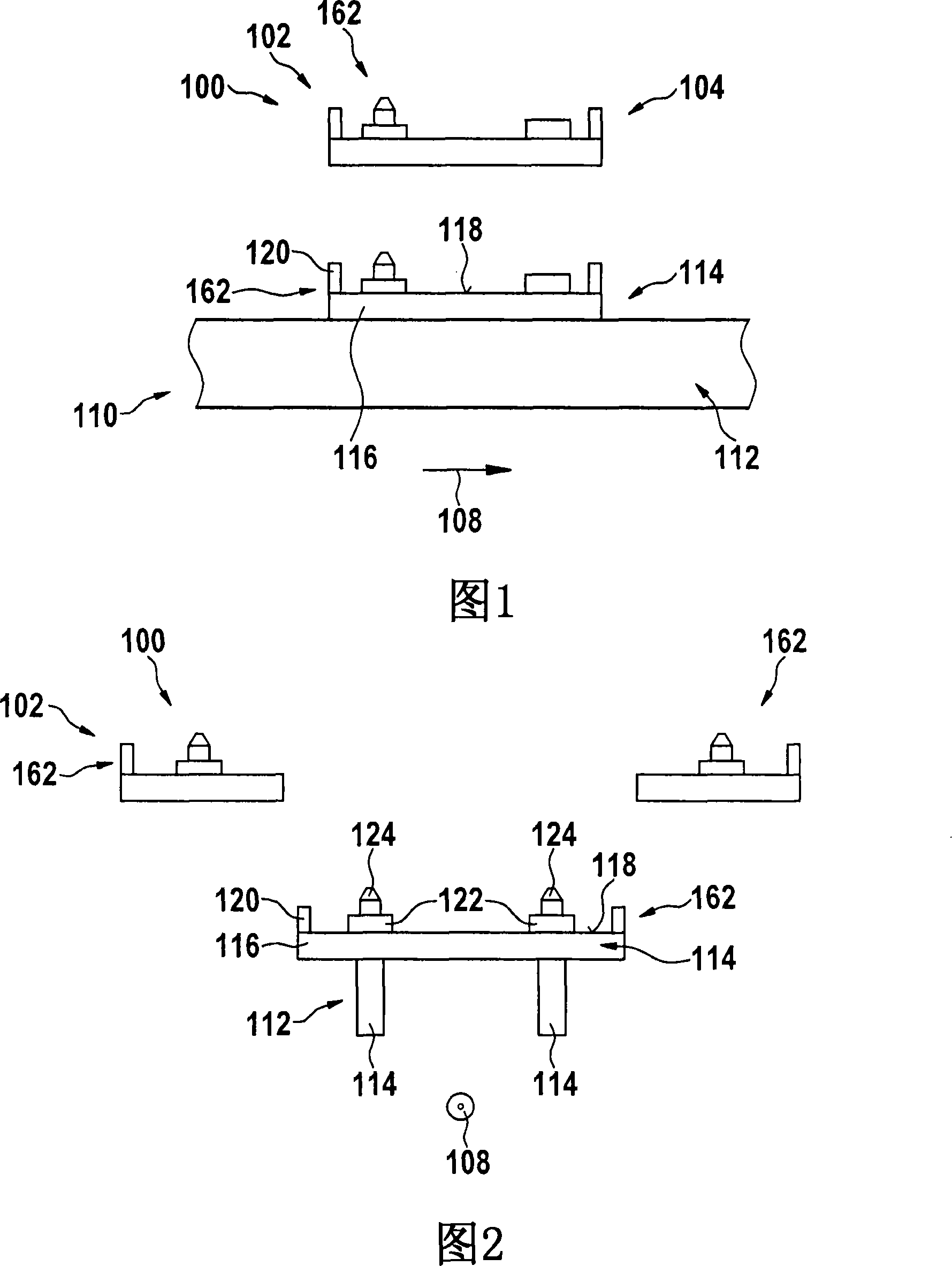

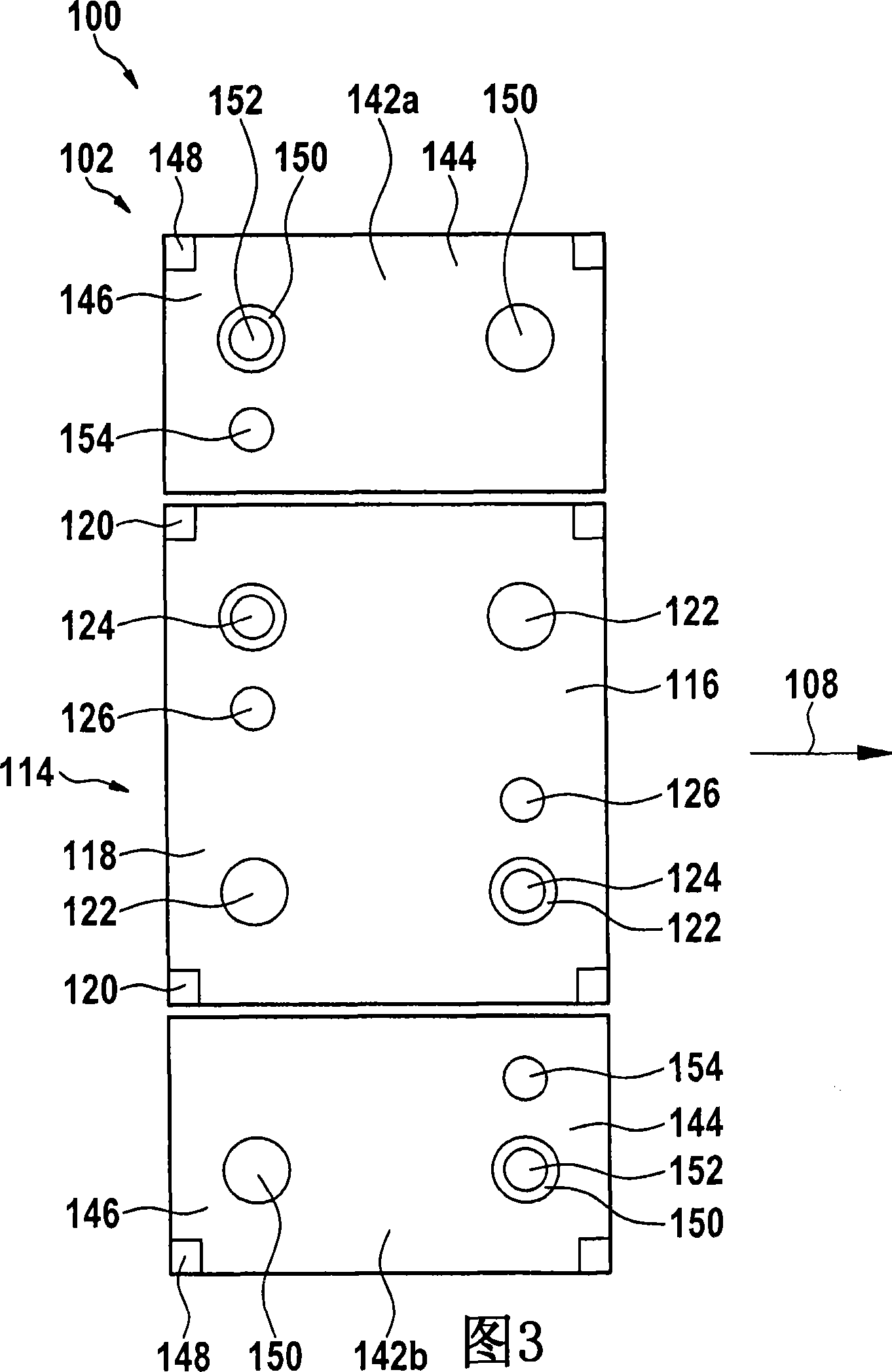

[0057] The cleaning apparatus shown generally at 100 in FIGS. 1-7 includes a plurality of processing stations 102, each of which performs a processing step for workpiece cleaning, one of which is shown in FIGS. 1-3.

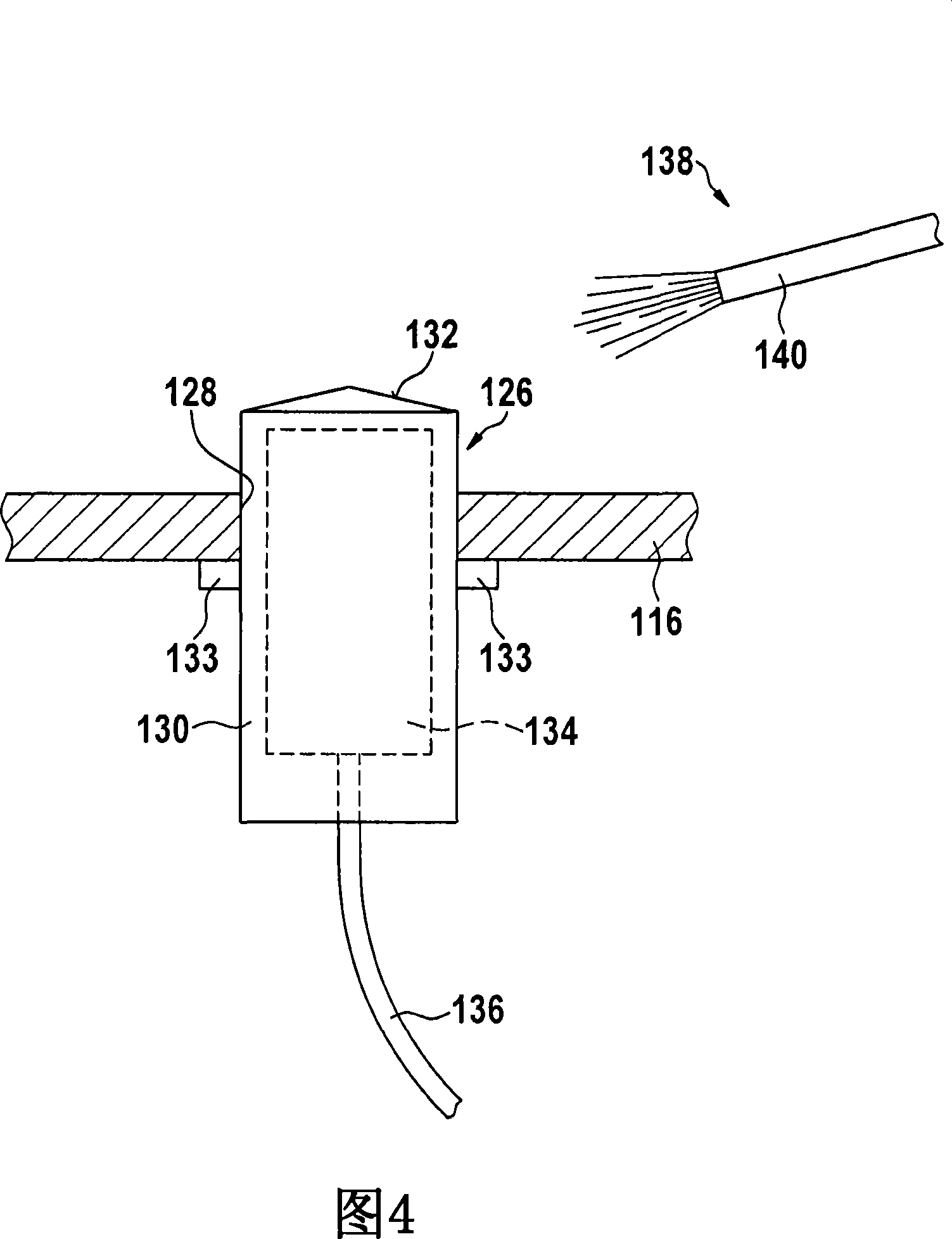

[0058] Each processing station 102 includes a fixed workpiece holder 104 as shown in FIGS. 1-3 and processing tools for performing workpiece cleaning (not shown), such as tuyeres, nozzles, movable spray guns or the like.

[0059] In order to be able to move the workpiece 106 (see FIGS. 5-7 ) to be cleaned from the fixed workpiece holder 104 of the first processing station 102 in the transport direction 108 (see FIGS. 1-3 ) to the first processing station in the transport direction 108 On the fixed workpiece holder 104 of the second processing station 102 in the back, the cleaning device 100 includes a conveying device 110 in the form of a slide-type multi-station automatic feeding device 112, which includes two slats 114 extending along the conveying direction 108...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com