Device for on-line detecting airtightness of bottle seal

A tone and tightness technology, which is applied in the direction of measuring the acceleration and deceleration rate of fluids and using liquid/vacuum for liquid tightness measurement. It can solve the problems of complex operation process and low efficiency, and achieve the effect of improving detection sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The patent of the present invention provides a device that can detect and judge the airtightness of packaging bottles after sealing on the automatic packaging linkage line, and can automatically remove the packaging bottles that are judged to be unqualified from the linkage line. It is an indispensable device to ensure the quality of packaging sealing.

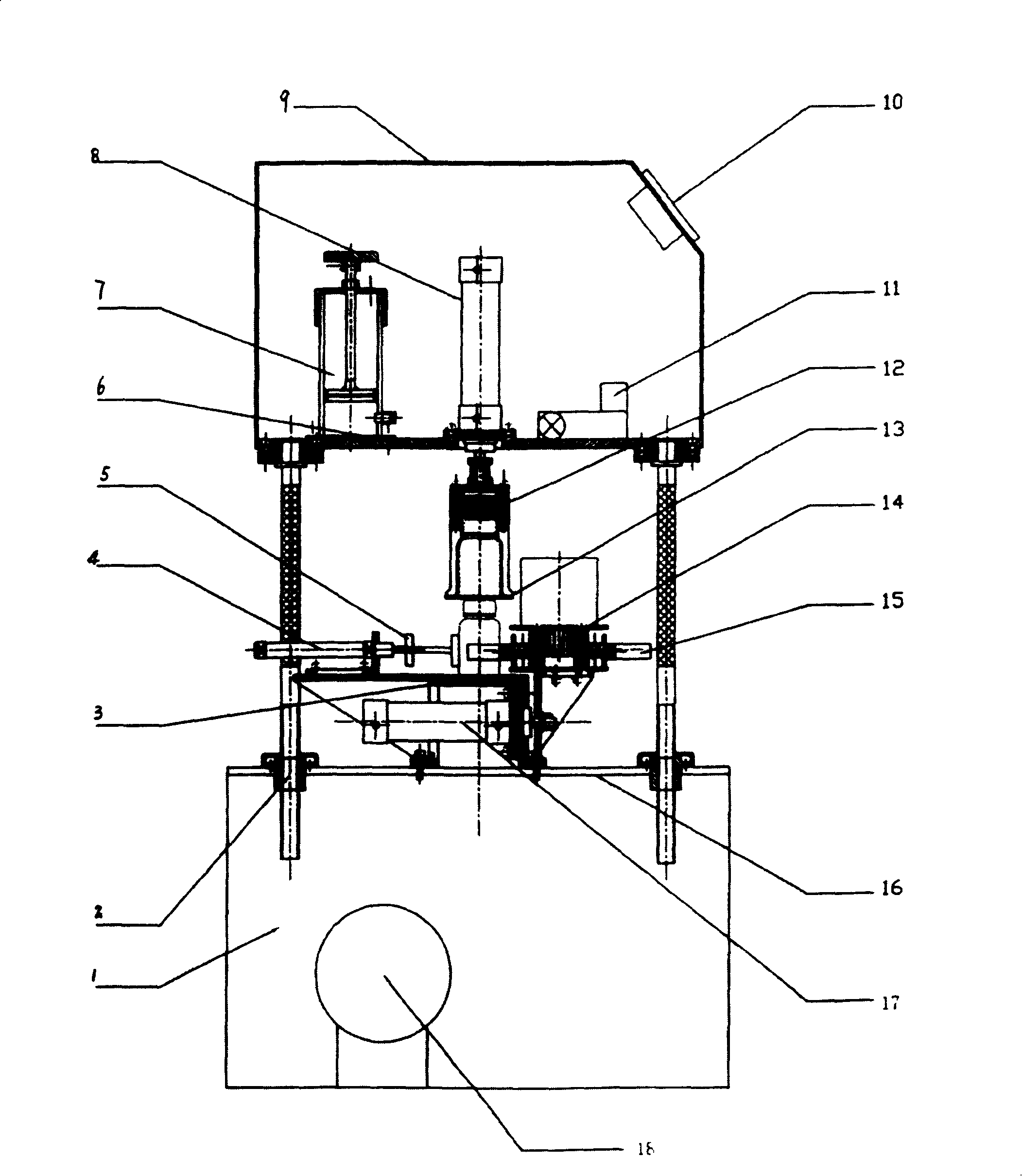

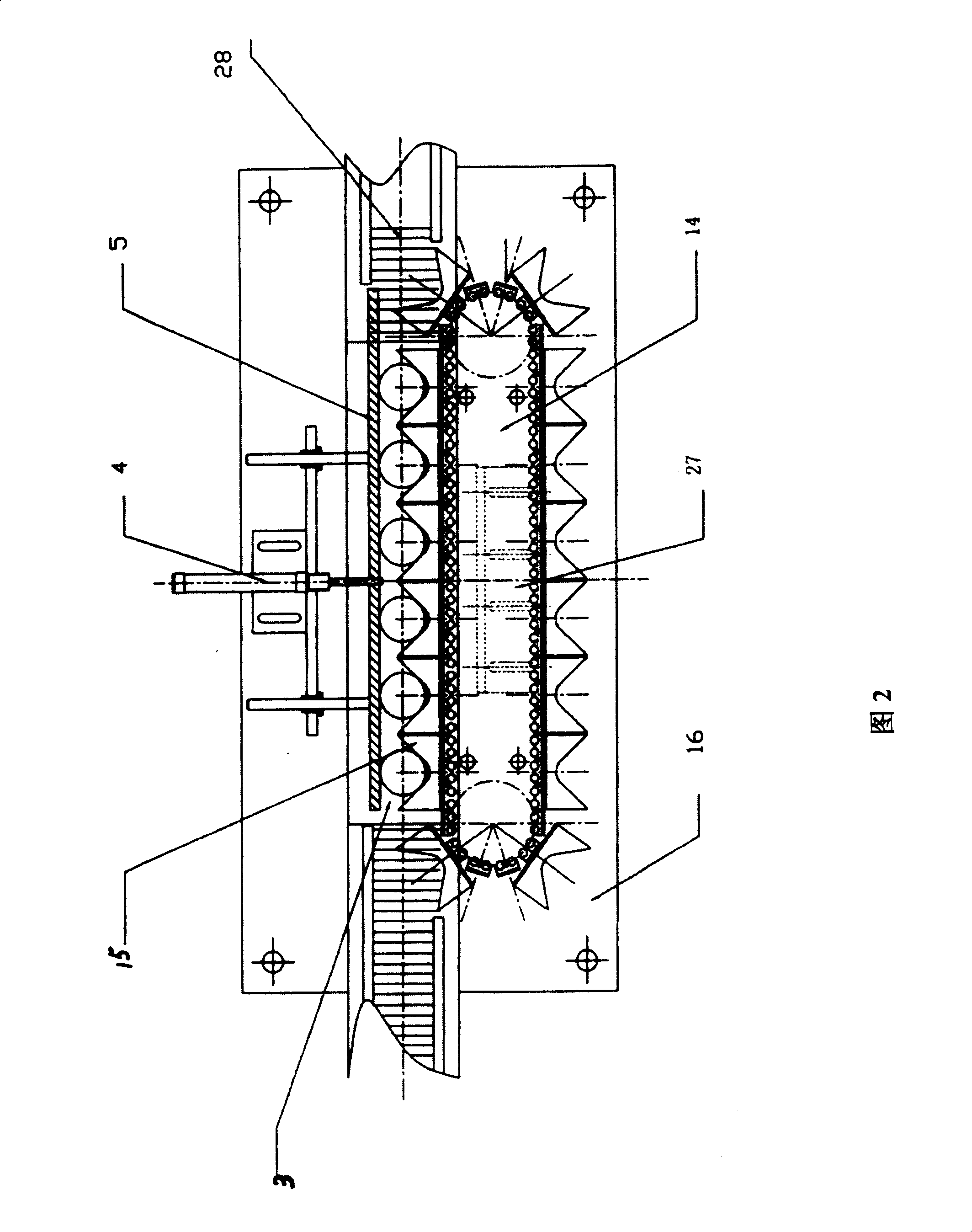

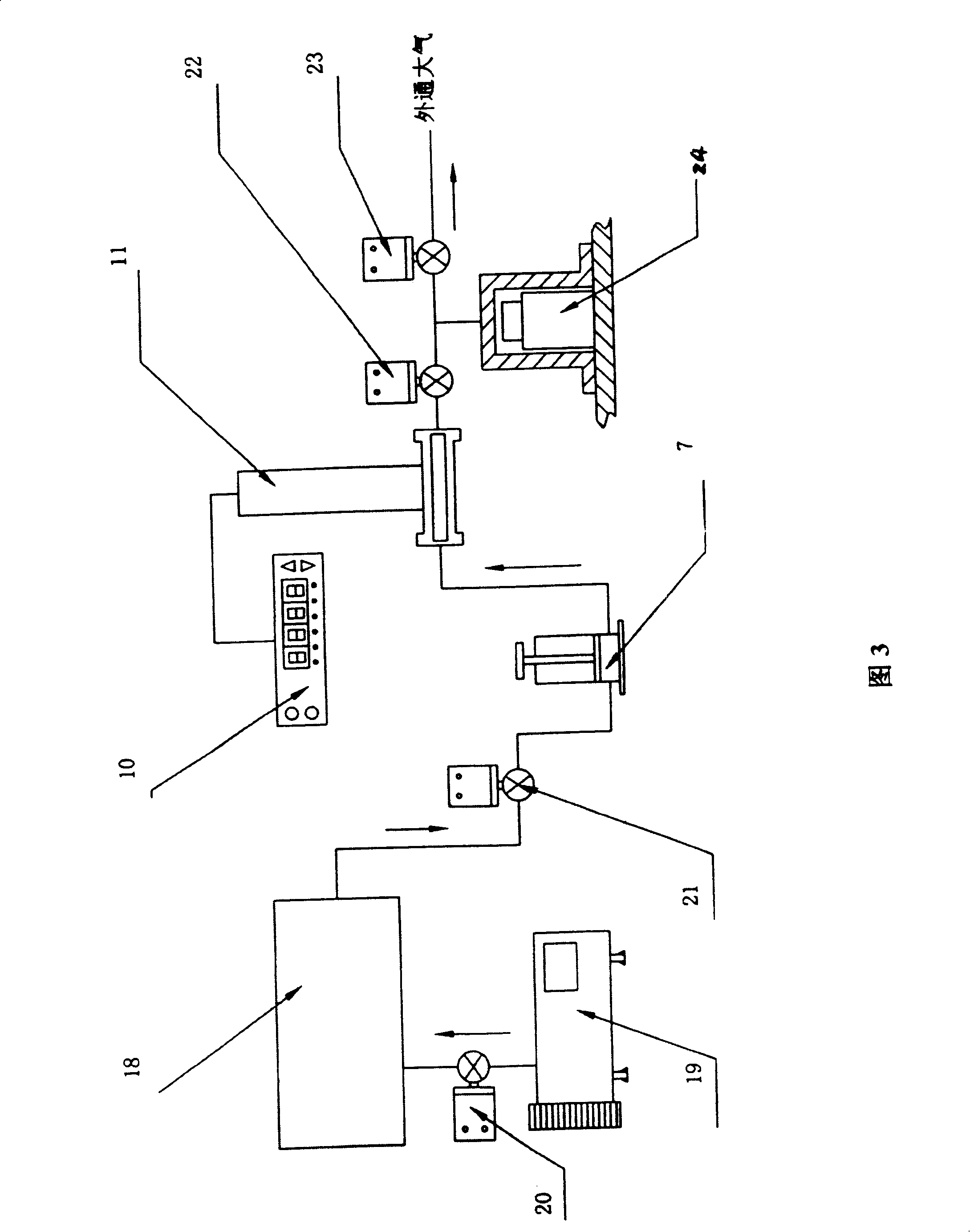

[0035] Device structure of the present invention sees figure 1 -3, as shown in the figure: it includes a positioning conveying mechanism 14 installed on the lower table 16 of the cabinet 1, a number of negative pressure detection mechanisms 12 installed on the positioning conveying mechanism 14 and a lifting mechanism 2 of the negative pressure detecting mechanism, See figure 1 . The positioning conveying mechanism 14 includes a conveyer belt 28 that is placed horizontally on the slideway and can move forward and backward under the action of the pusher 17. The chain plate of the conveyer belt 28 is equipped with a rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com