Method for extracting and recognizing nondestructive detecting defect based on radial damping energy field

A technology of attenuating energy and non-destructive testing, which is applied in material analysis, image data processing, and instruments using radiation, and can solve the problems of seldom considering the gray distribution of internal regions of defects, waste of valuable information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

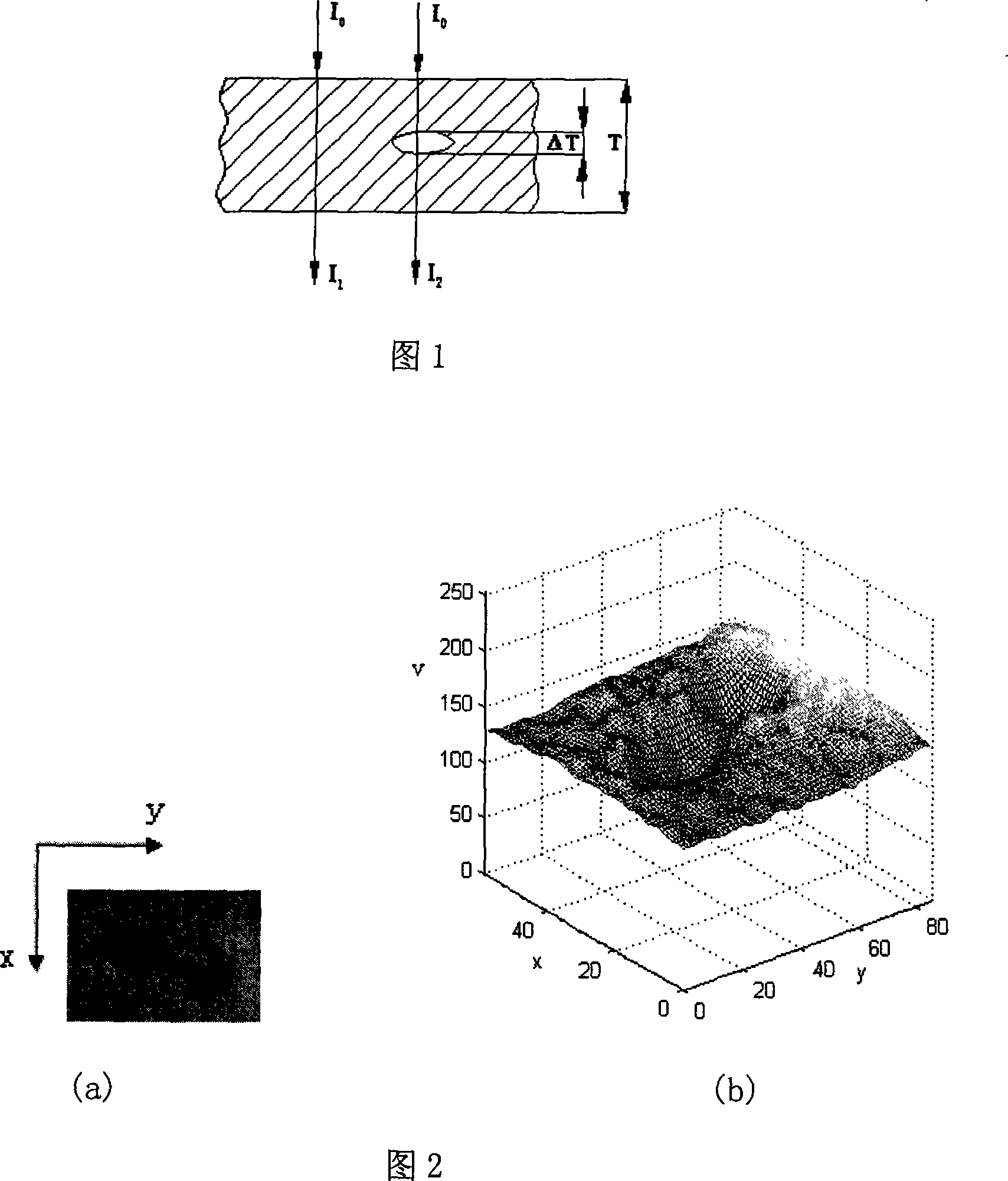

[0046] Figure 1 is a schematic diagram of the basic principle of ray detection, in which T and ΔT respectively represent the dimensions of the workpiece substrate and defects in the direction of ray transmission, and I 0 Indicates the incident ray intensity, I 1 , I 2 Respectively represent the intensity of rays penetrating the workpiece matrix and defect parts, and μ and μ′ represent the attenuation coefficients of the workpiece substrate and defects to rays, respectively. The attenuated energy field (ray attenuation energy field) distribution after the ray passes through the workpiece is as follows:

[0047]

[0048] Under normal exposure conditions, the blackness value of the film increases linearly with the logarithm of the ray exposure. After the film is digitally processed by CCD, the gray value of the digital image obtained is linearly related to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com