Bass transmission mechanism for accordions

A technology of transmission mechanism and bass machine, which is applied to accordions, wind instruments, instruments, etc. It can solve the problems of difficult size guarantee, short service life, and difficult processing, and achieve the effects of improving precision, improving transmission sensitivity, and reducing motion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

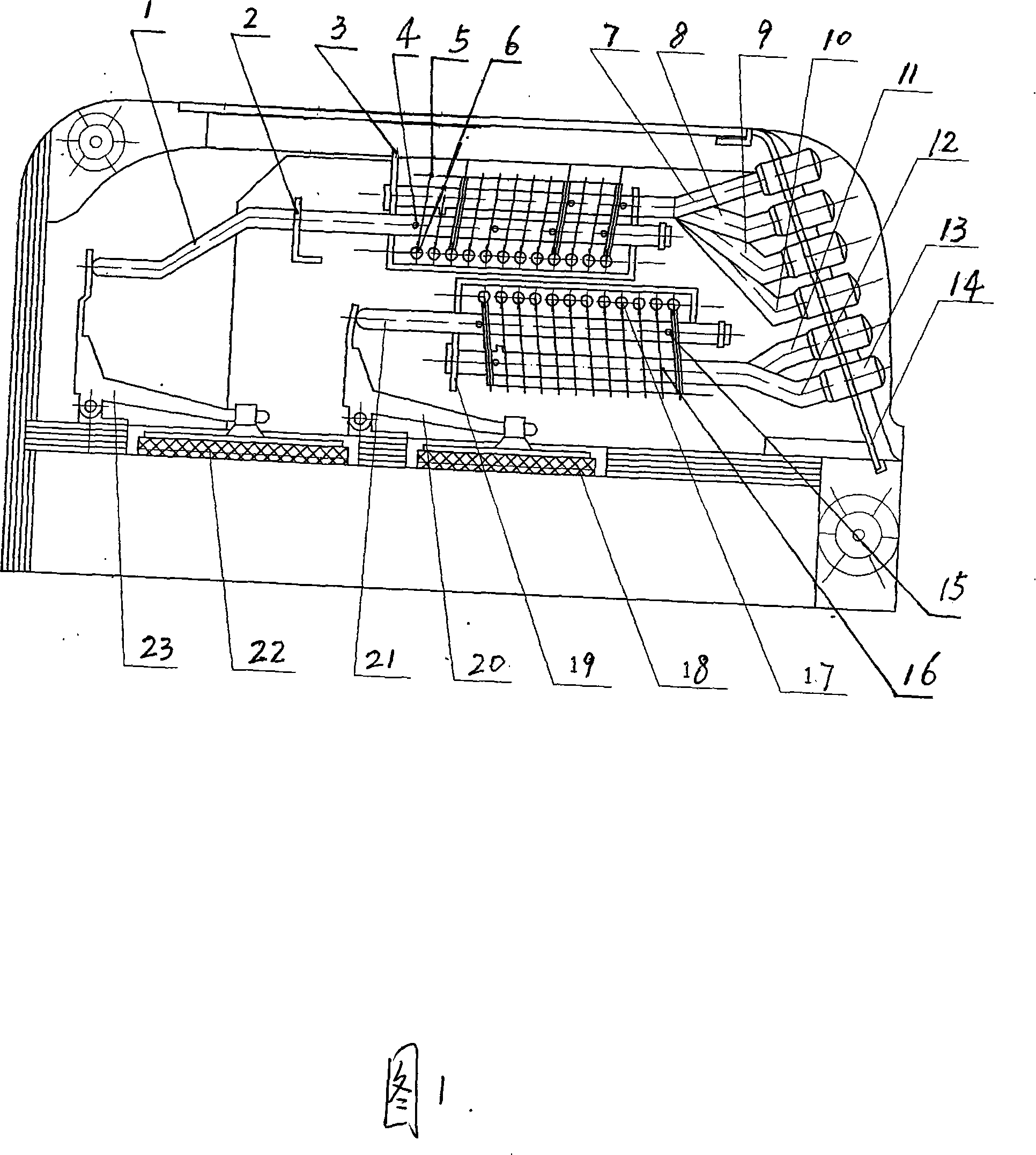

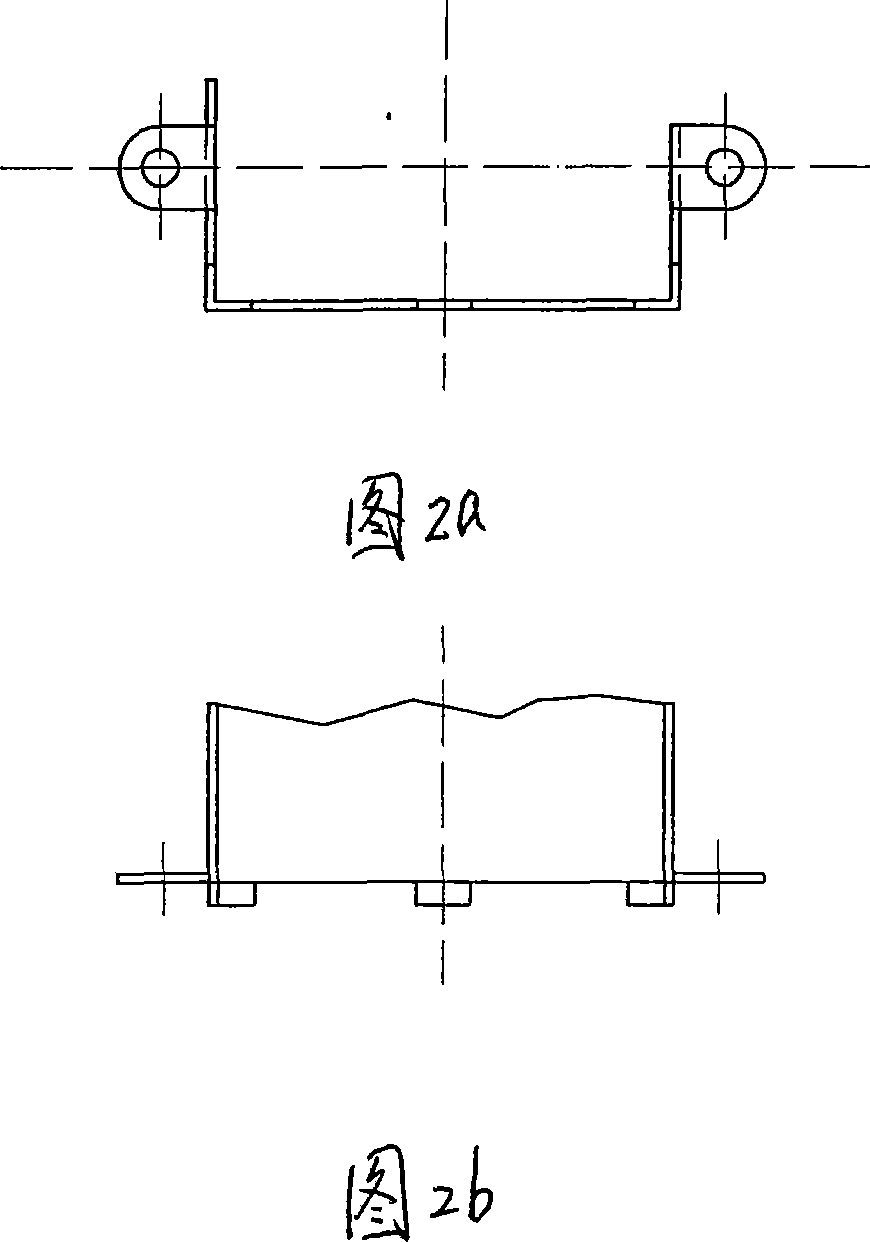

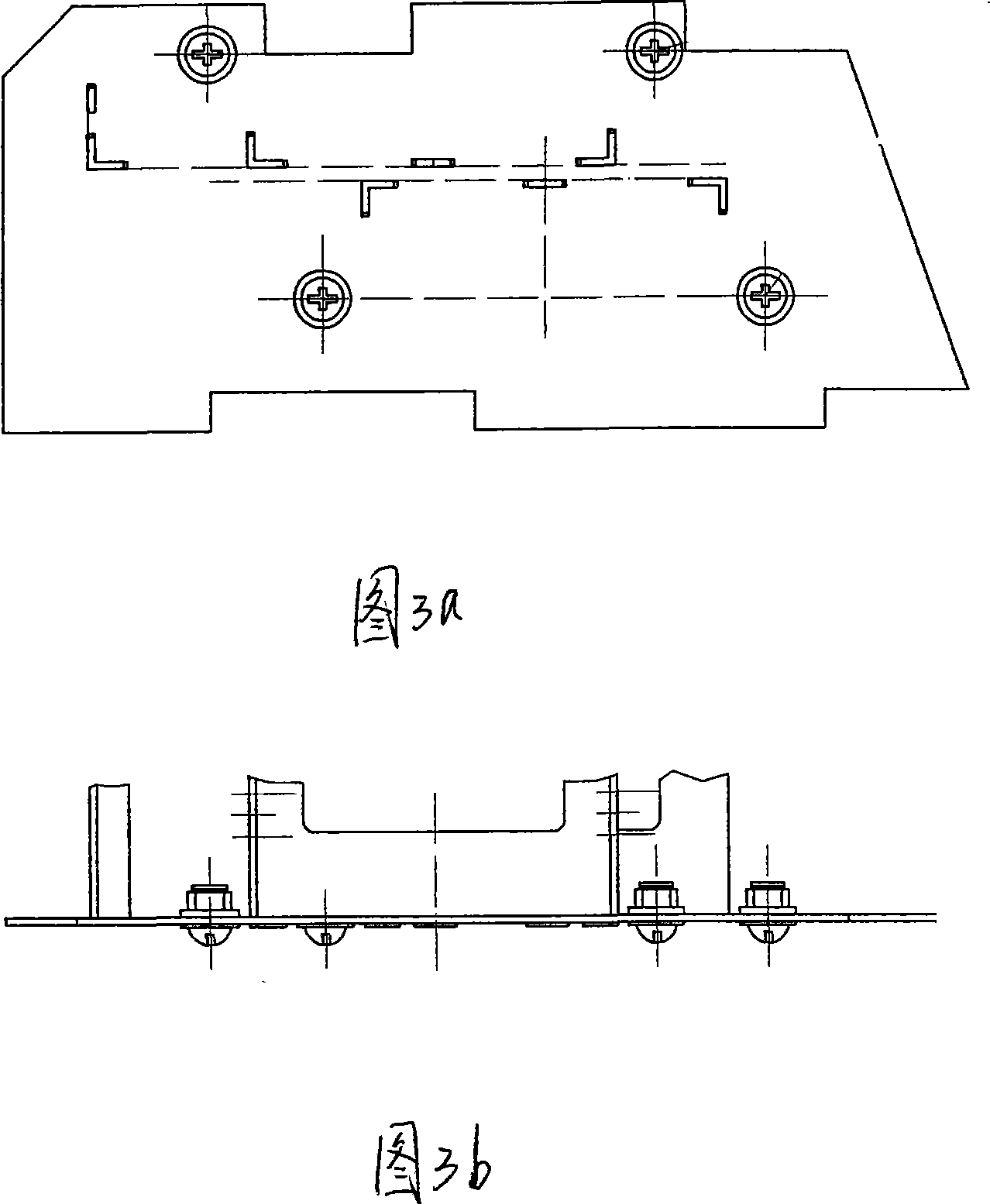

[0016] As shown in Figures 1, 2a, and 2b, the object of the present invention is achieved in that the harmony thread rolling groove 3 and the bass thread rolling groove 19 are made of hard aluminum alloy material, and are formed by one-time hot extrusion. Top sheet 7,8,9,10,11,12 and pushing teeth 4,15 are made of stainless steel. Integral top piece 7,8,9,10,11,12 welds push tooth 4,15. The welding between top pieces 7, 8, 9, 10, 11, 12 and push teeth 4, 15 adopts T-type welding, which is completed by automatic welding equipment. The shape of push teeth 4,15 welded by top sheet 7,8,9,10,11,12 is a cylinder. As shown in Fig. 1, 3a, 3b, the assembly of the accordion bass machine frame 24 adopts the flexible connection mode of bolts 25.

[0017] The bass transmission mechanism of the accordion bass machine is the internal transmission mechanism of the accordion bass keyboard, and the pronunciation of the bass and harmony required by the performance is realized by the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com