Ink-jetting head fluid supply device and ink-jetting head cleaning device

A technology of liquid feeding device and cleaning device, applied in printing devices, printing and other directions, can solve the problems of hindering liquid feeding, increasing pressure loss, and breaking the liquid feeding path, so as to reduce flow resistance, reduce pressure loss, and reduce contact area. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

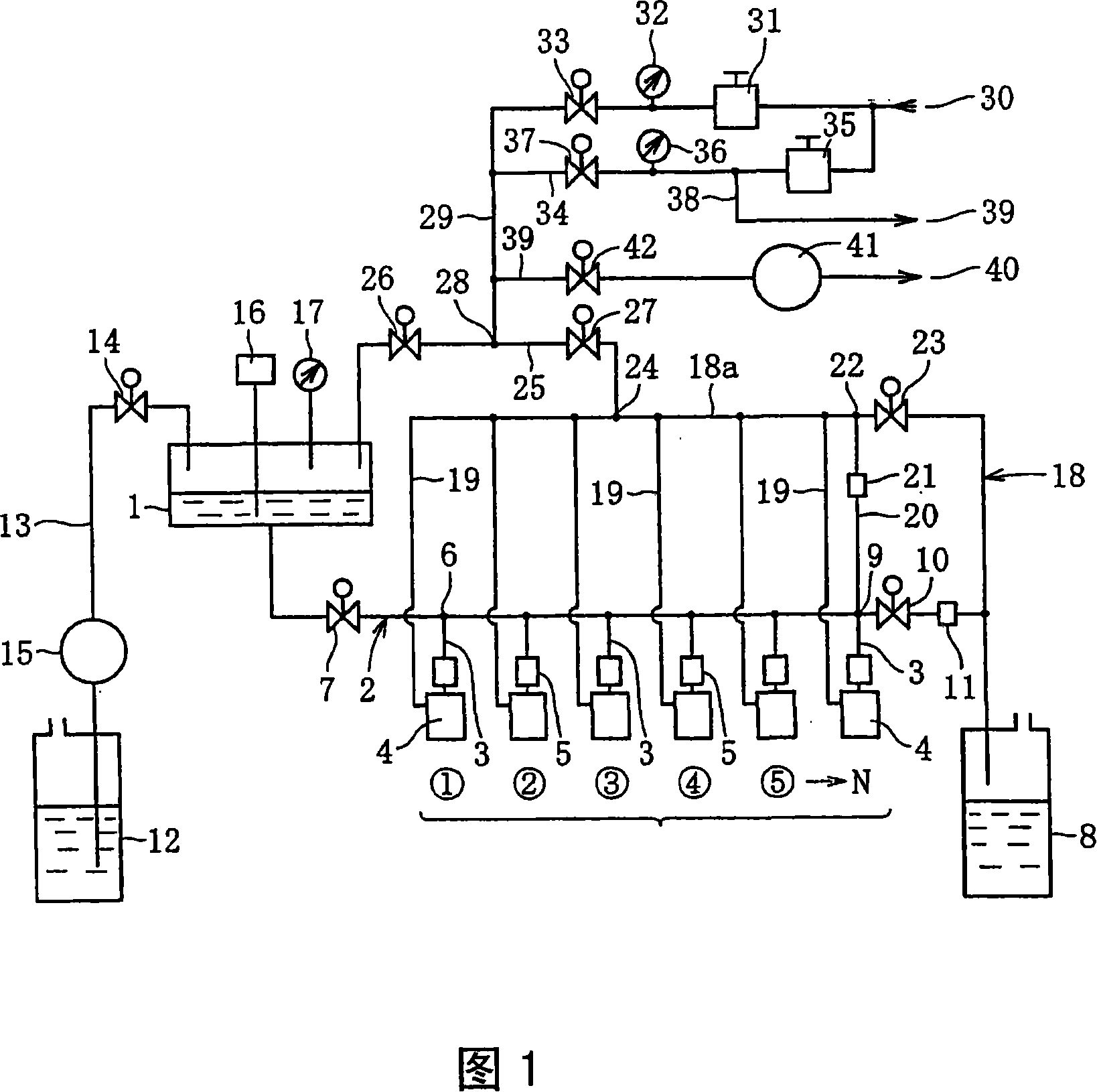

[0111] FIG. 1 illustrates an inkjet head liquid feeding device according to a first embodiment of the present invention. As shown in FIG. 1, in the inkjet head liquid delivery device of the first embodiment, the ink tank 1 storing the liquid material communicates with the common liquid delivery pipeline 2 extending horizontally below the ink tank 1, and, A plurality of independent liquid delivery pipelines 3 are connected at equal intervals to the common liquid delivery pipeline 2 . These independent liquid-feeding pipelines 3 extend downward from the common liquid-feeding pipeline 2, and the lower ends of each independent liquid-feeding pipeline 3 are respectively connected to the inkjet head 4 (the liquid storage part inside it), and in these vertical directions On the way, degassing units 5 for degassing bubbles such as air in the liquid material are respectively provided. In addition, in the illustration, six inkjet heads 4 are provided, but n number of six or more may be...

no. 2 approach

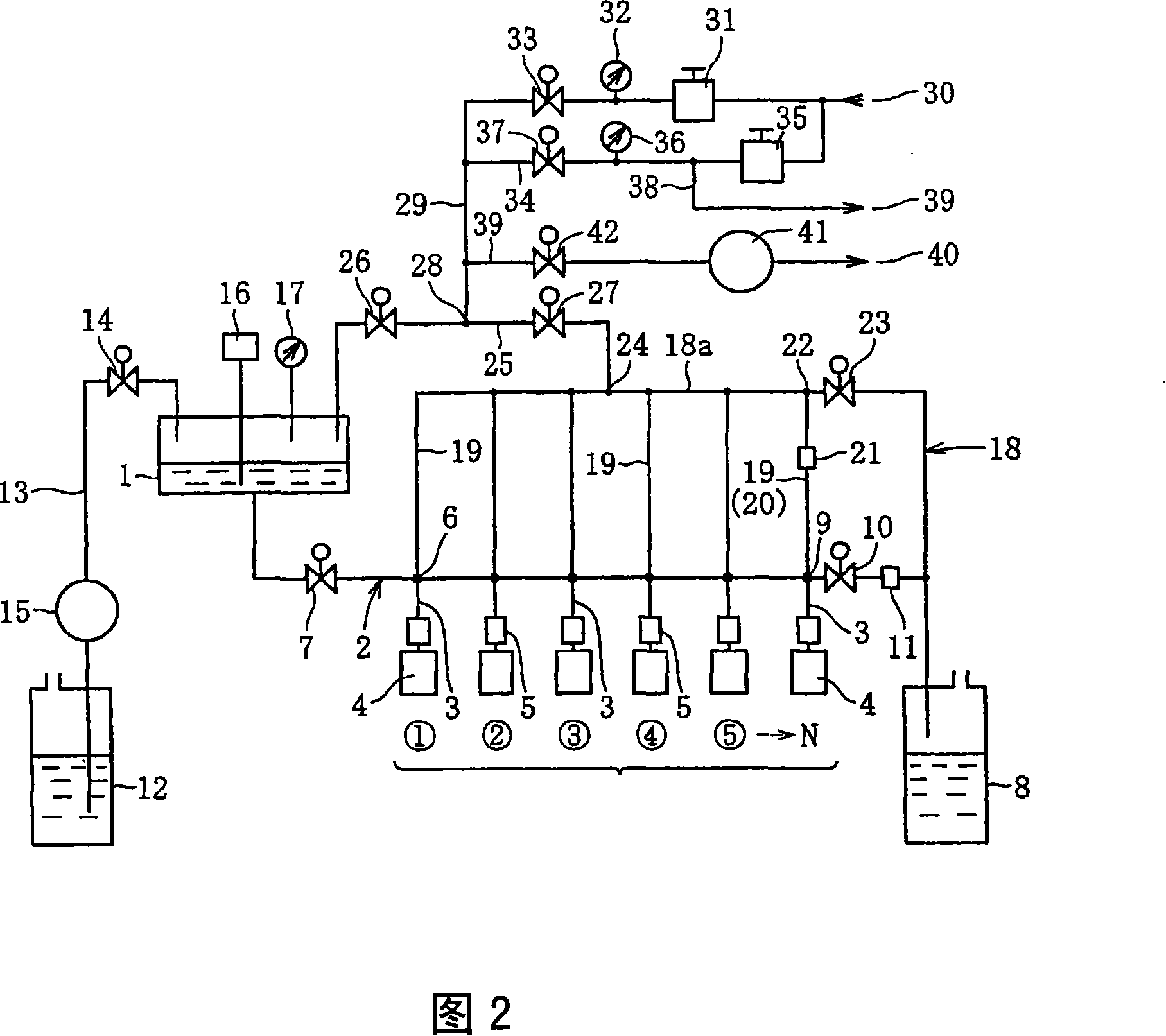

[0122] FIG. 2 illustrates an inkjet head liquid feeding device according to a second embodiment of the present invention. As shown in Figure 2, the inkjet head liquid delivery device of this second embodiment differs from the inkjet head liquid delivery device of the first embodiment above in two points: one is that the liquid is supplied from the side of the common diffuser pipeline 18 Each lower end of each independent air-dispersing pipeline 19 extending downwards from road pipeline 18a communicates with each joint of the common liquid-feeding pipeline 2 and each independent liquid-feeding pipe 3; Liquid and gas pipeline 20. The other components are the same as those of the inkjet head liquid feeding device of the above-mentioned first embodiment, and thus the same reference numerals are used for the components common to both, and redundant descriptions are omitted.

[0123] According to the inkjet head liquid delivery device of the second embodiment, the gas flowing in th...

no. 3 approach

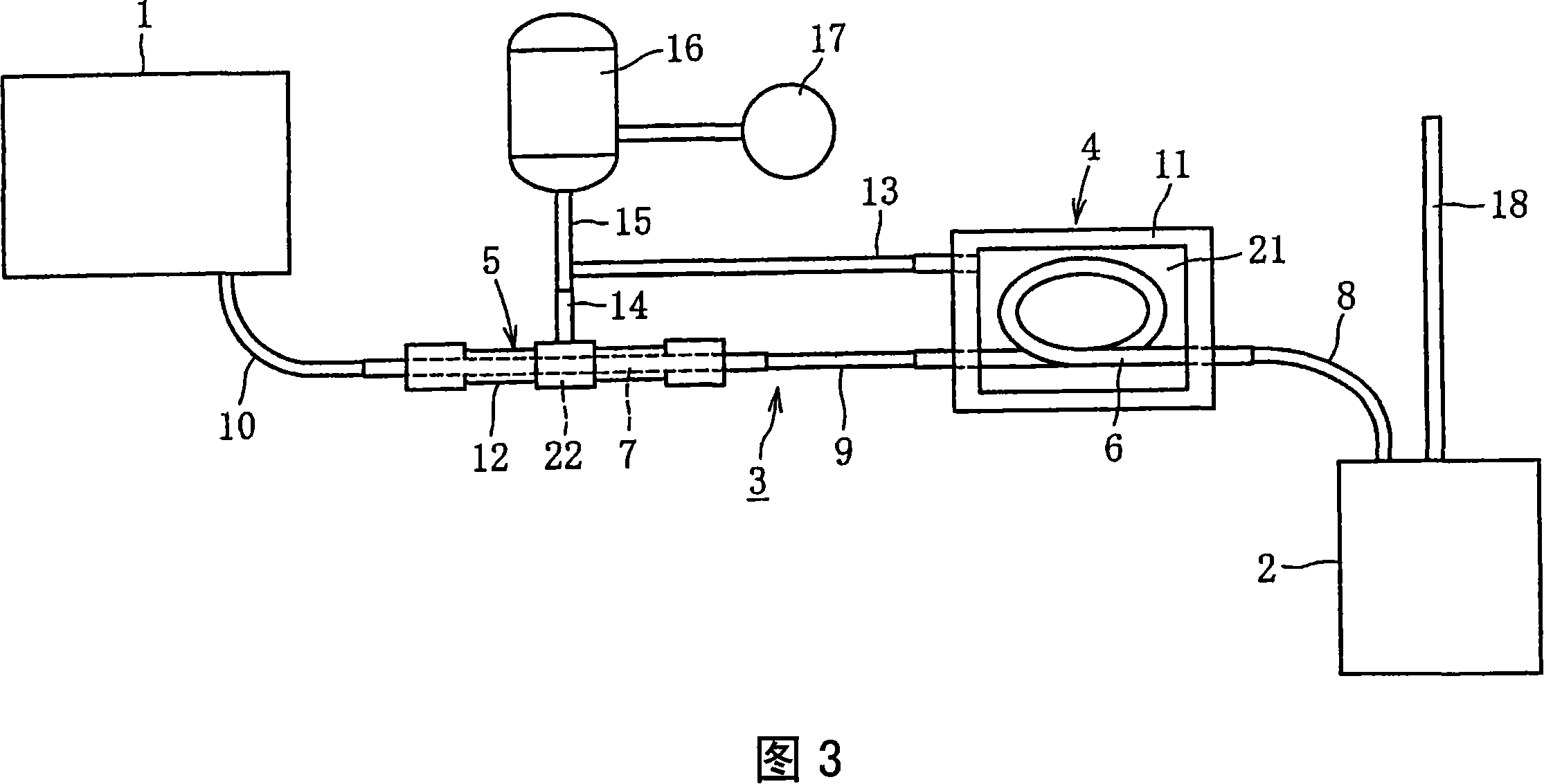

[0126] 3 to 5 illustrate an inkjet head liquid feeding device according to a third embodiment of the present invention. As shown in FIG. 3 , the inkjet head liquid supply device of the third embodiment has a liquid supply system for transporting the liquid material from the ink reservoir 1 storing the liquid material to the inkjet head 2 (internal liquid reservoir). The path 3 is provided with a first degassing unit 4 and a second degassing unit 5 at two places on the way of the liquid feeding path 3 . The liquid delivery path 3 is composed of two synthetic resin degassing tubes (hereinafter referred to as first and second degassing tubes 6 and 7 ) with air permeability and a single internal flow path, and an air-impermeable and single internal flow path. Three liquid-feeding pipes (hereinafter referred to as first to third liquid-feeding pipes 8, 9, 10) made of metal are connected. In this case, the first and second degassing pipes 6 and 7 are formed by cutting a pipe (trade...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com