Vacuum cleaner.

A technology of vacuum cleaners and cleaners, which is applied in the field of cleaners, and can solve problems such as the inability to accurately grasp the level of pollutants in the filter, inconvenient use of vacuum cleaners, and reduced service life of suction motors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, a vacuum cleaner according to an exemplary embodiment of the present invention will now be described in more detail with reference to the accompanying drawings.

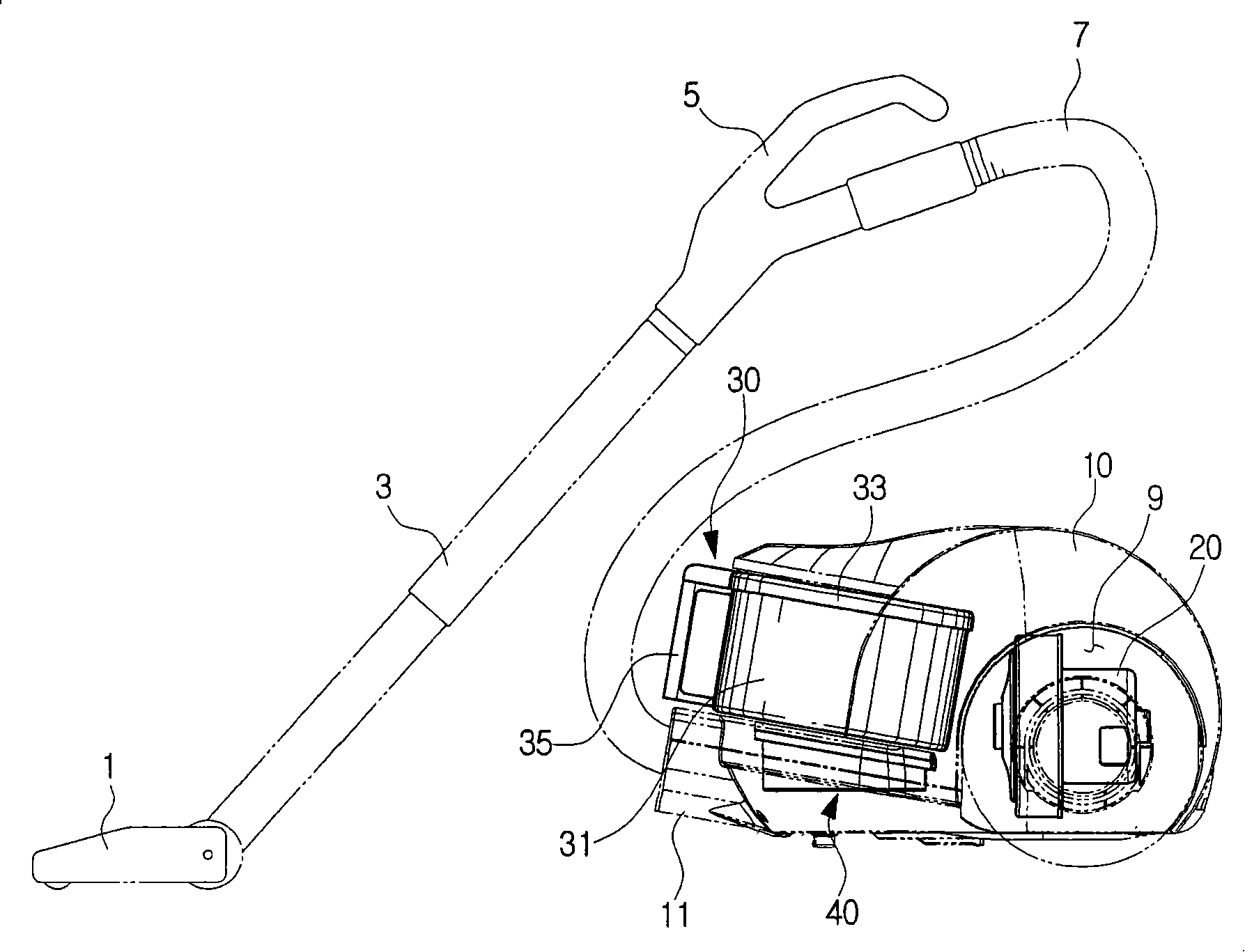

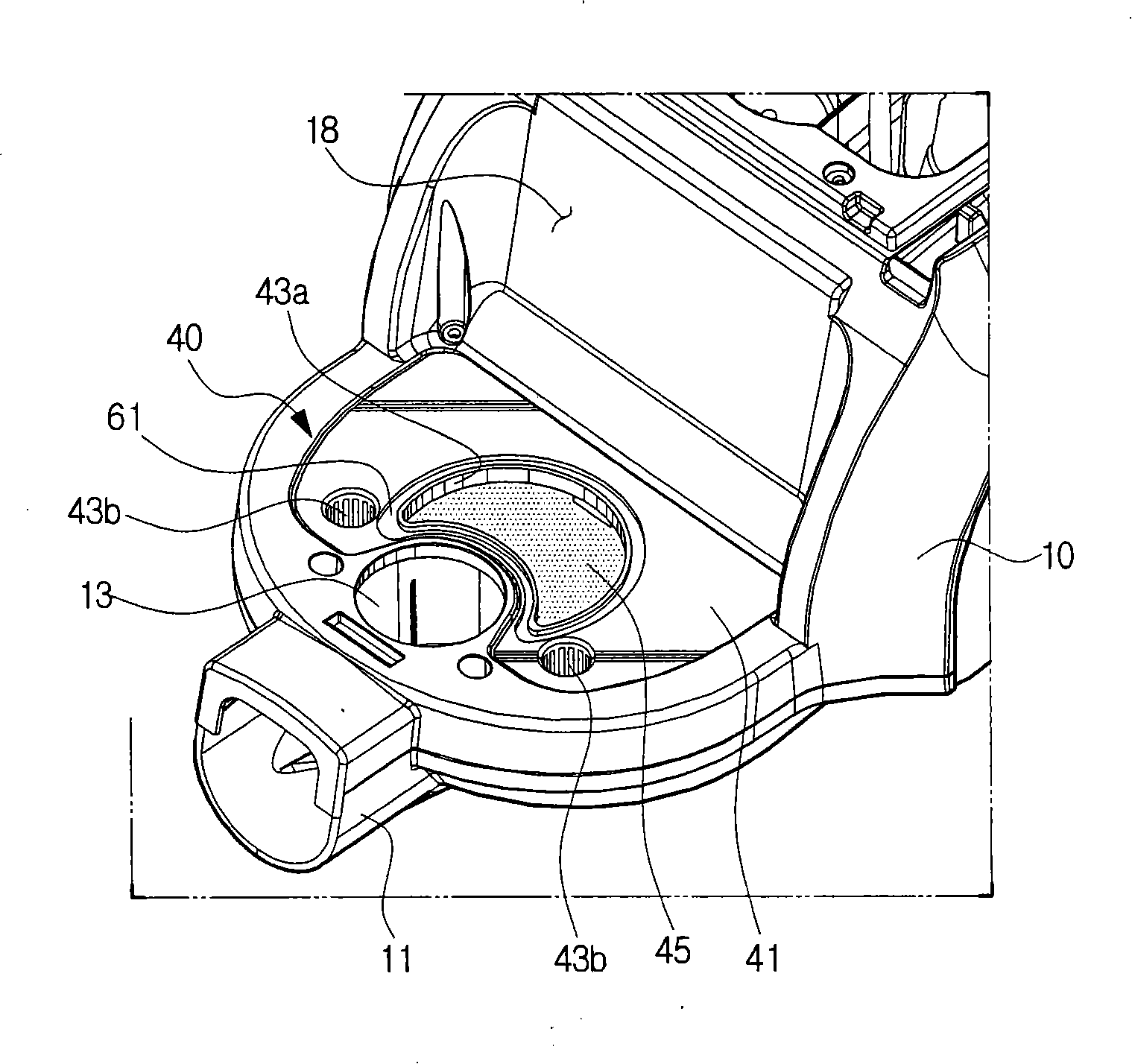

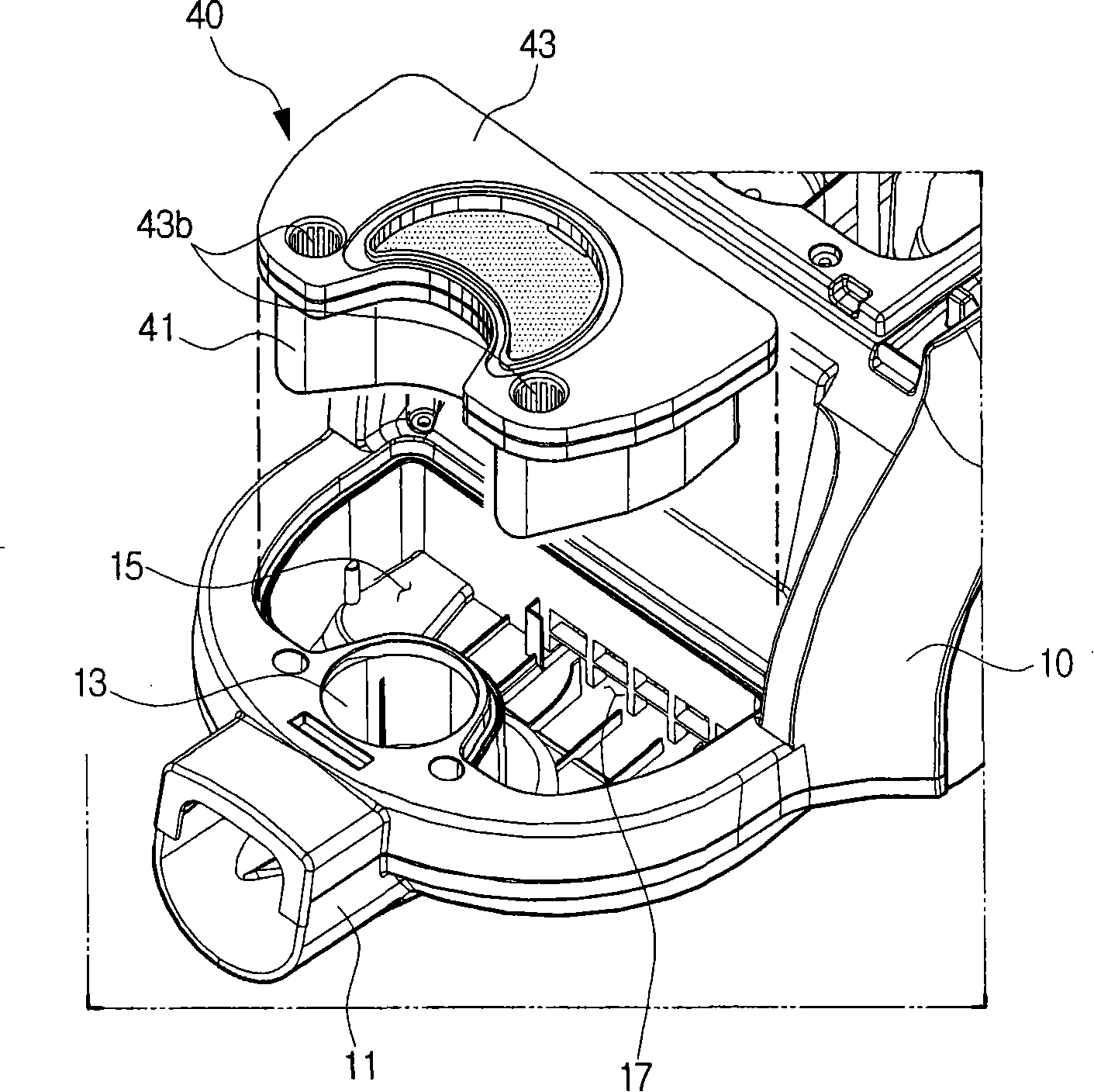

[0026] figure 1 is a schematic side view illustrating a vacuum cleaner according to an exemplary embodiment of the present invention, Figure 2A and Figure 2B is a schematic perspective view illustrating the installation and detachment state of the filter assembly installed in and detached from the cleaner body, image 3 is instantiated figure 1 Perspective view of the dust collection unit of the vacuum cleaner described in .

[0027] refer to figure 1 , a vacuum cleaner according to an exemplary embodiment of the present invention includes a suction nozzle 1 for sucking dust or dirt from a surface to be cleaned, an extension tube 3, a handle 5, a connecting hose 7, a cleaner body 10, A suction motor 20 , a dust collection unit 30 and a filter assembly 40 .

[0028] The suction motor 20 , t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap