Water-mixing device for waterhead heat pump units

A water source heat pump unit and water mixing technology, which is applied in heat pumps, refrigerators, refrigeration components, etc., can solve the problems affecting the use effect of water mixing devices, the difficulty of mixing water into the host water system, and affecting the technical promotion of water source heat pump systems, etc., to achieve Achieve water-saving operation, improve water mixing effect, and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

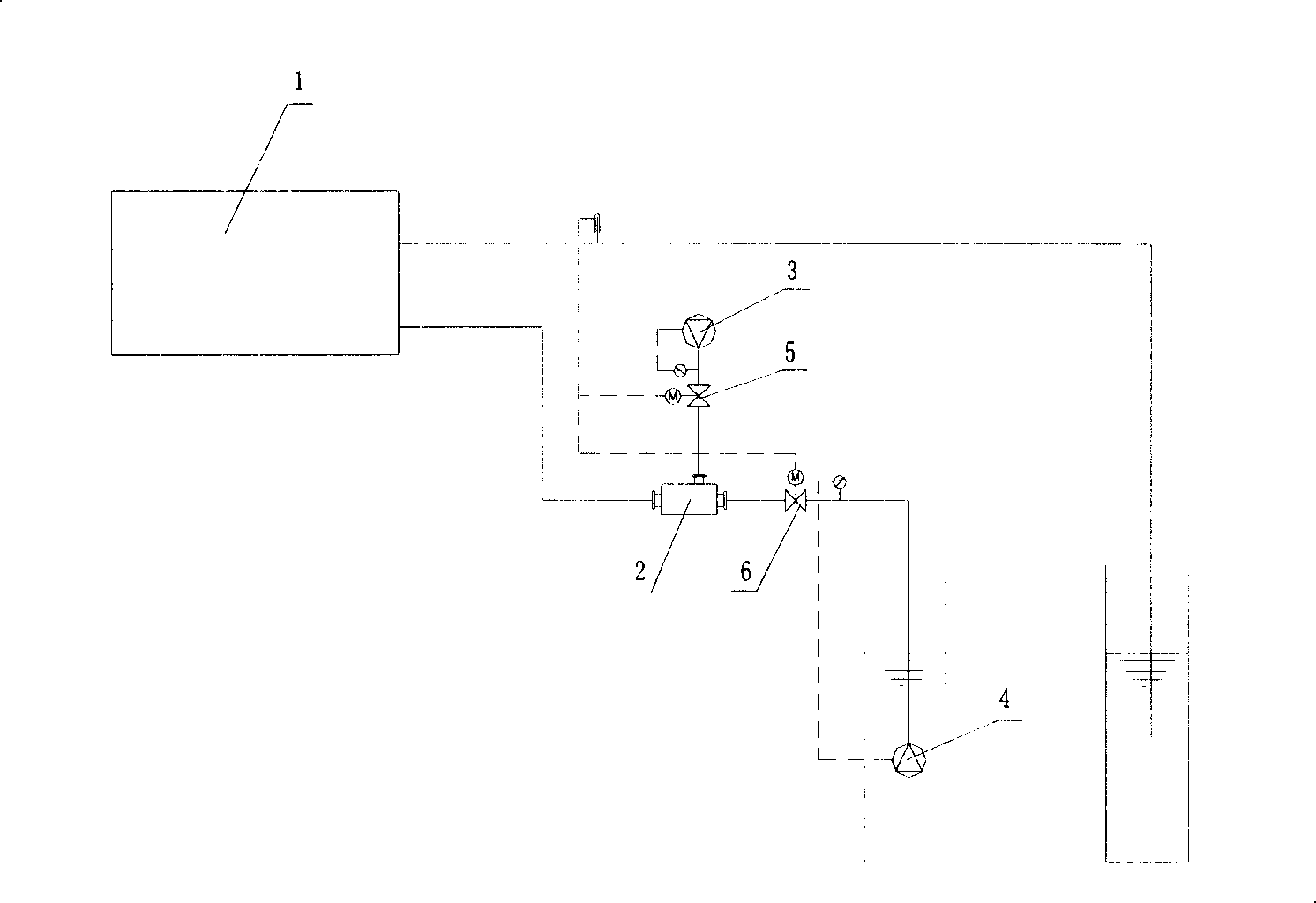

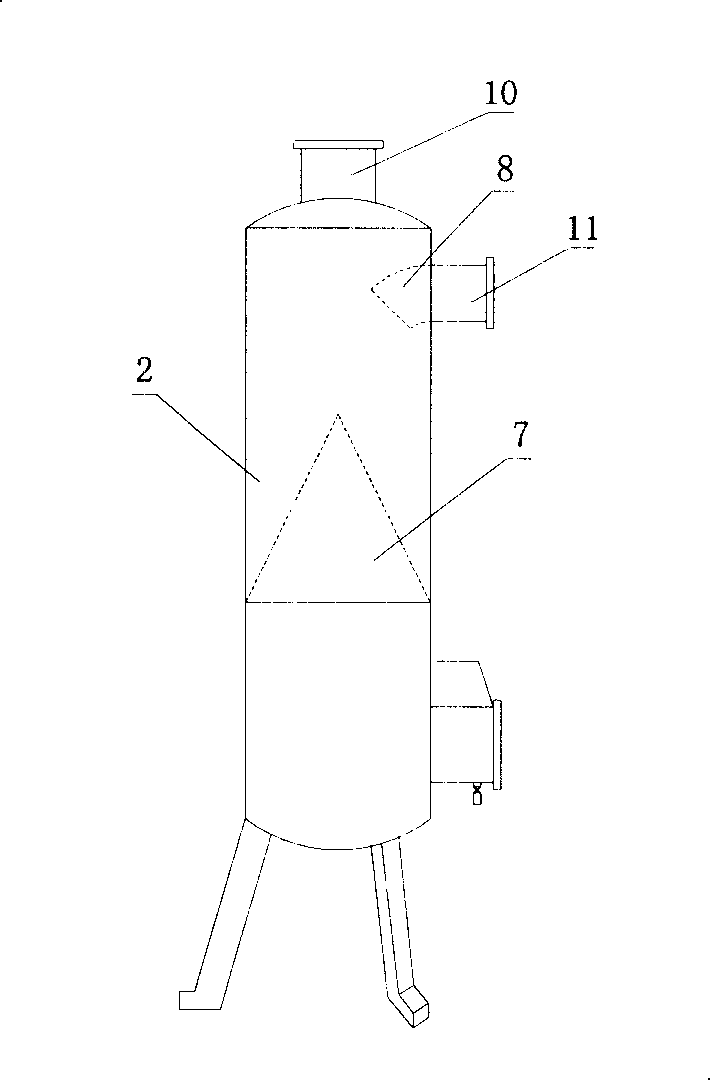

[0014] see figure 1 and figure 2 The present invention includes a water source heat pump unit 1 and a water mixer 2 connected to the inlet of its water system, a submersible pump 4 placed in the water source and pumping the water source, and a pump connected to the outlet of the water system of the water source heat pump unit 1 and drained from the water source heat pump unit 1 Mixing pump 3. The cross-sectional area of the tank body of the water mixer 2 is larger than the main pipe area of the water system. The top of the water mixer 2 is provided with a water inlet 10 vertically, and the side of the water mixer 2 is provided with a water inlet 2 11 horizontally. In the inner cavity of the water mixer 2, a section of bent pipe 8 inclined downward is arranged to communicate with the water inlet 2 11. . The first water inlet 10 and the second water inlet 11 are connected to the mixing water pump 3 and the submersible pump 4 respectively. Electric two-way valve 1 5 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com