Method for automatic measurement of shaking amplitude of straddle-seat type single traffic rail beam

A straddle-type monorail, automatic measurement technology, applied in the direction of measurement device, measurement of ultrasonic/sonic/infrasonic, image analysis, etc., can solve the problem of unguaranteed measurement accuracy, high labor intensity, affecting the service life of vehicles and track components and operating safety And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

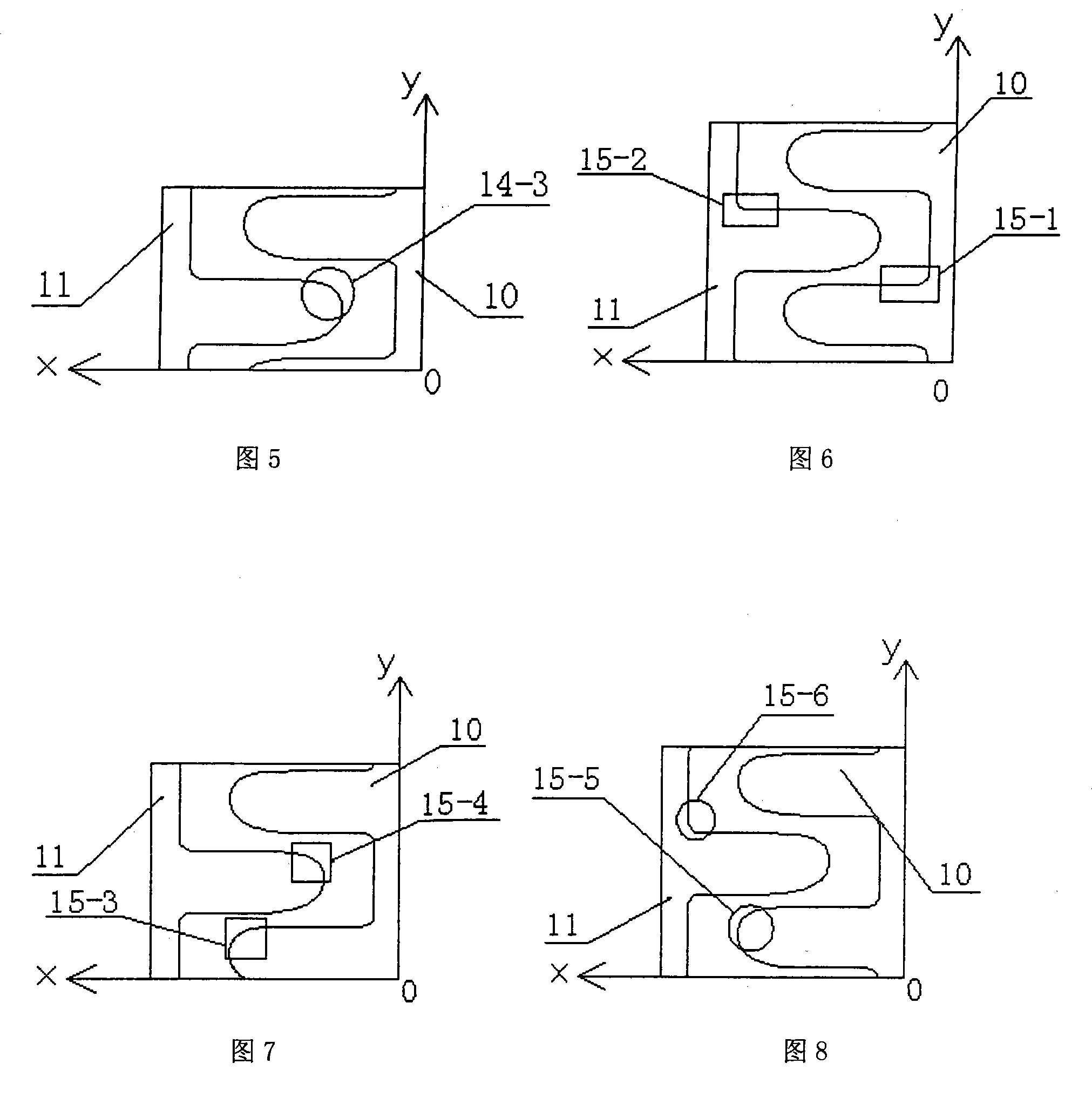

[0051] In this embodiment, the measurement accuracy is 0.2mm, a single template is used, and the template is a rectangle. When a single template is selected, the factor of camera shaking is ignored. In this case, only the displacement difference of the single template in the image relative to the coordinate origin is required to obtain the shake amplitude value of the measured track beam. The image resolution is 640×512, the frame rate is 100 frames per second, and the edge detection algorithm is used to make the feature template.

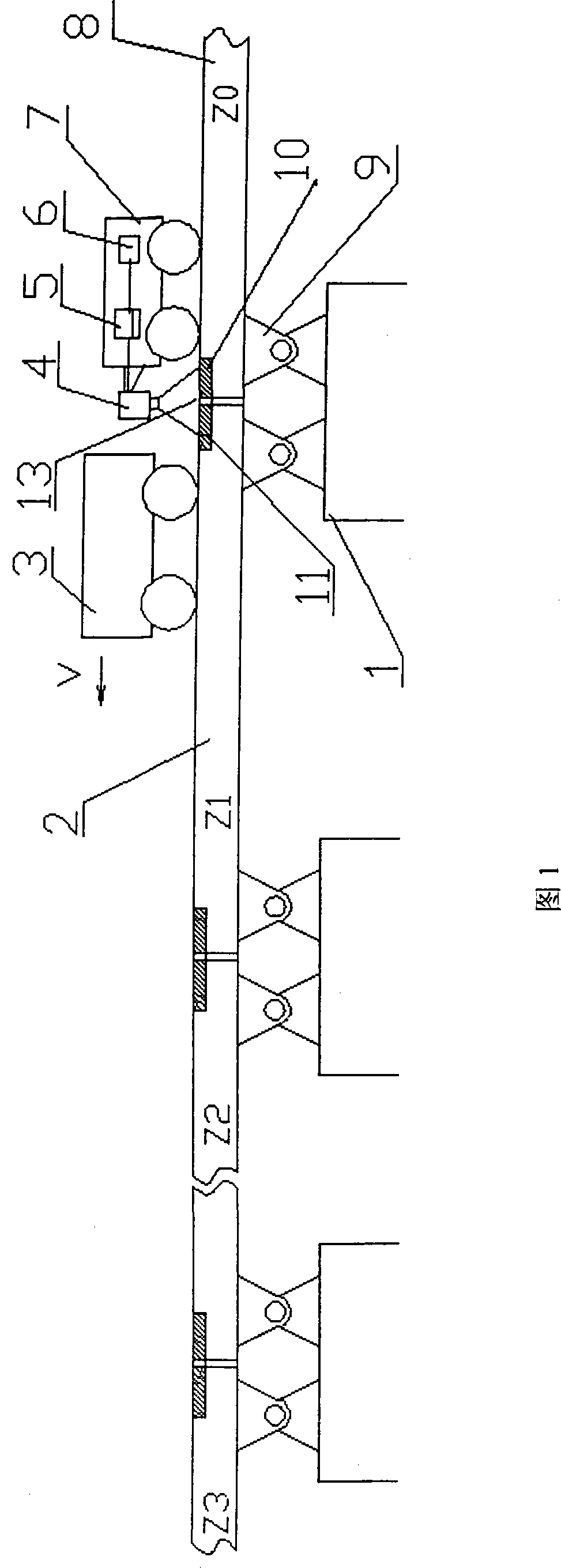

[0052] In Fig. 1, the equipment for measuring the swaying amplitude of the track beam includes an excitation vehicle 3 and an image data acquisition vehicle composed of a straddle monorail vehicle 7, a digital camera 4, a computer 5 and an AC power supply 6. Both the incentive car 3 and the straddle-type monorail traffic car 7 are Q2DGZ-1 cars produced by Xiangtan Motor Company. Camera 4 adopts DH-HV1302 digital camera produced by China Daheng (G...

Embodiment 2

[0094] In Fig. 1, the equipment used is exactly the same as in Example 1. In this embodiment, the measurement accuracy is 0.2mm, a single template is used, the template is rectangular, the image resolution is 640×512, the frame rate is 100 frames per second, and the edge detection algorithm is used to make the feature template.

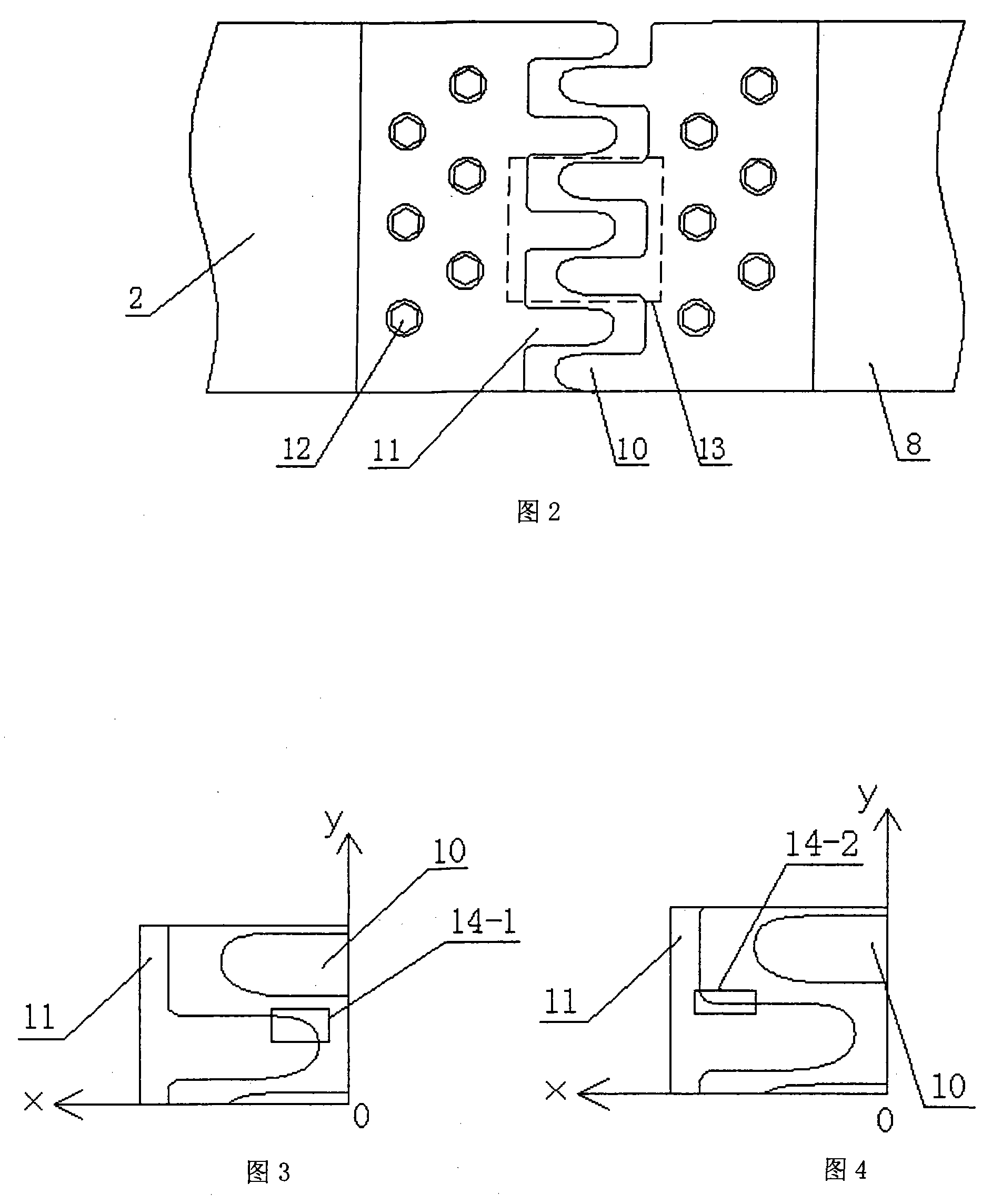

[0095] In Figure 1, Figure 2, Figure 4, Figure 9, and Figure 10: the specific steps and technical requirements for measuring the track beam are as follows:

[0096] In the step (1-2), the camera is a digital camera, the measurement accuracy A is 0.2 mm, the calibration template is a 38-type high-precision calibration template, and the digital camera lens is fixed on the front of the image data acquisition vehicle Above, the distance between the two points is 100mm, so that the pixel coordinate difference between the two points on the corresponding bitmap image in the computer is (1 / 0.2)×100=500 pixels, and the vertical distance is 230mm;

[0097] In...

Embodiment 3

[0122] In Fig. 1, the equipment used is exactly the same as in Example 1. In this embodiment, the measurement accuracy is 0.2mm, a single template is used, the template is circular, the image resolution is 640×512, the frame rate is 100 frames per second, and the differential method is used to extract the edge of the image to make the feature template.

[0123] In Fig. 1, Fig. 2, Fig. 5, Fig. 9, and Fig. 10, the specific implementation steps and technical requirements are compared with the technical solutions, and the same steps and technical requirements are not repeated here. The different technical requirements are as follows:

[0124] In the step (1-2), the camera is a digital camera, the measurement accuracy A is 0.2 mm, the calibration template is a 38-type high-precision calibration template, and the digital camera lens is fixed on the front of the image data acquisition vehicle Above, the distance between the two points is 100mm, so that the pixel coordinate difference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com